Mechatronics Robots

Unknown

During my final graduate semester at JHU, I participated in Mechatronics (EN.530.421) where I built several small scale robots from scratch.

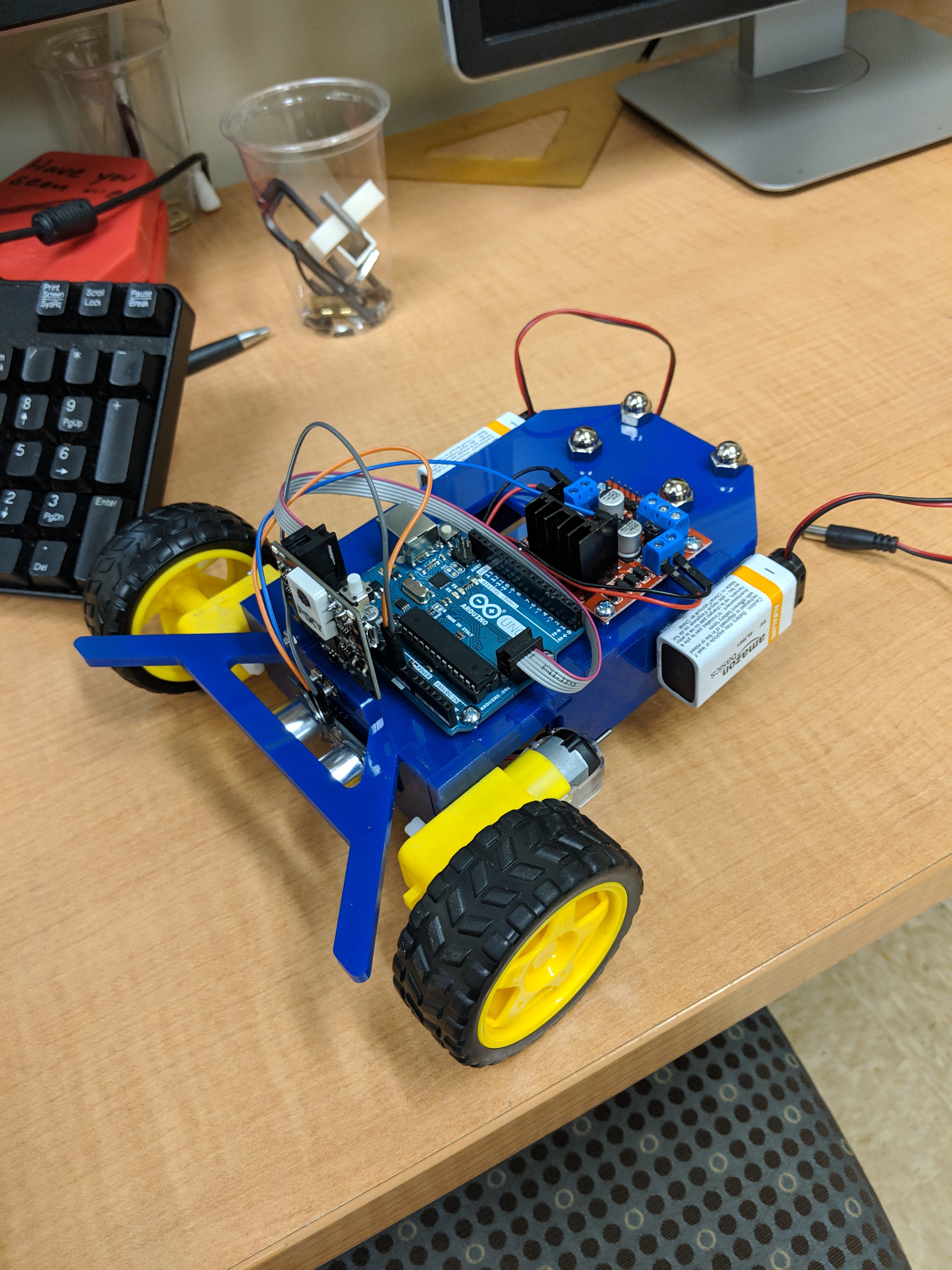

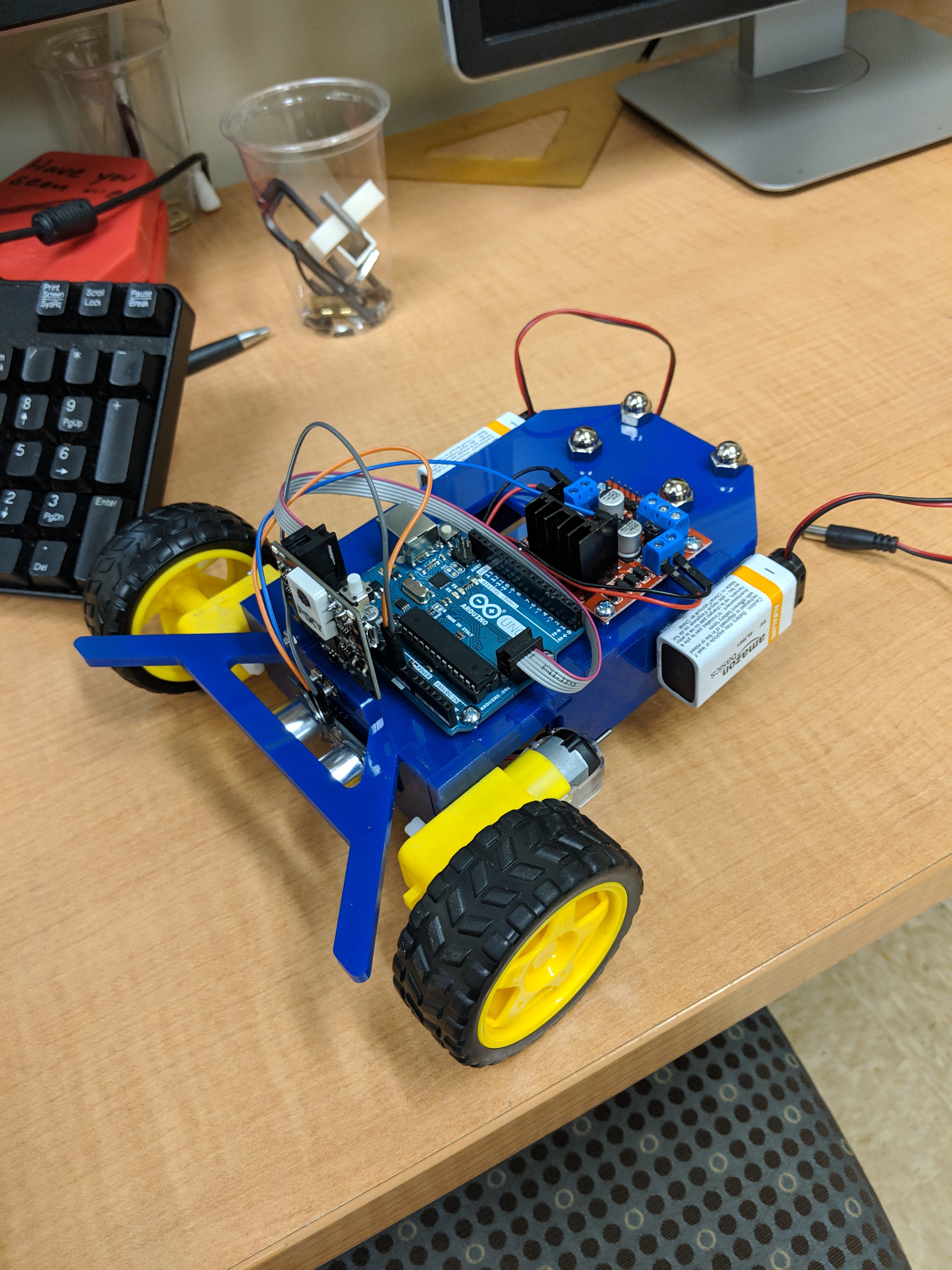

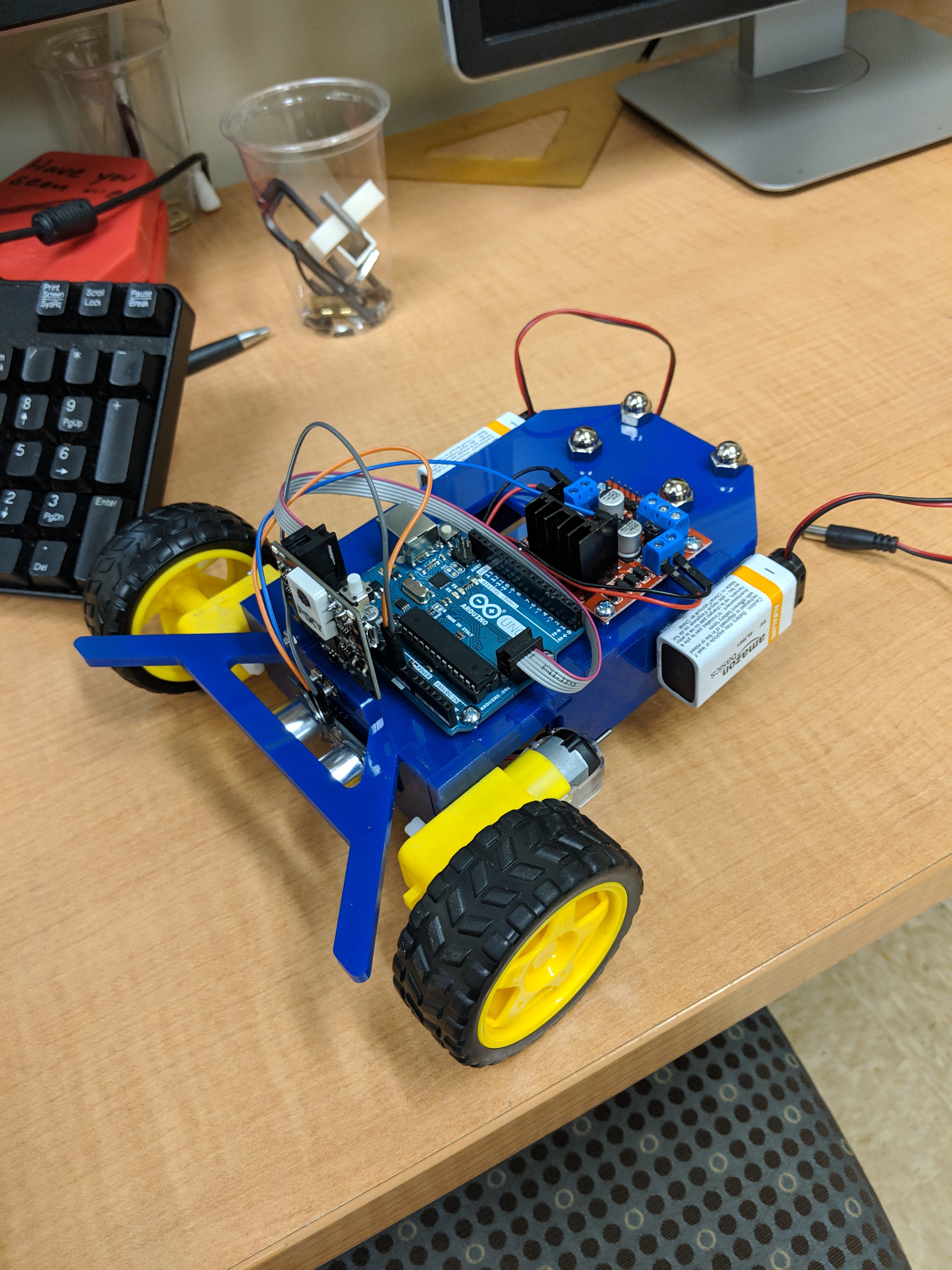

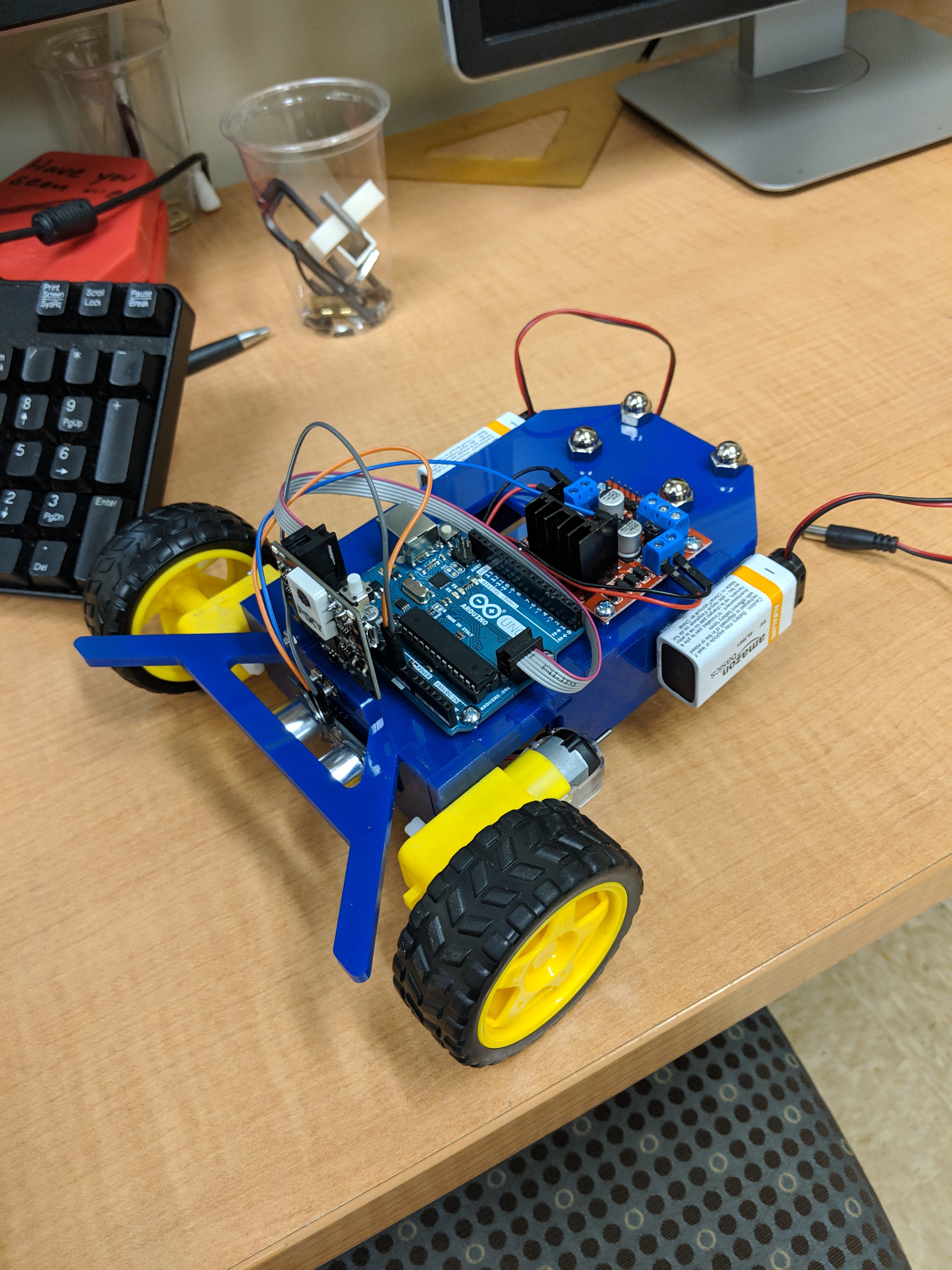

Maze Solving Robot

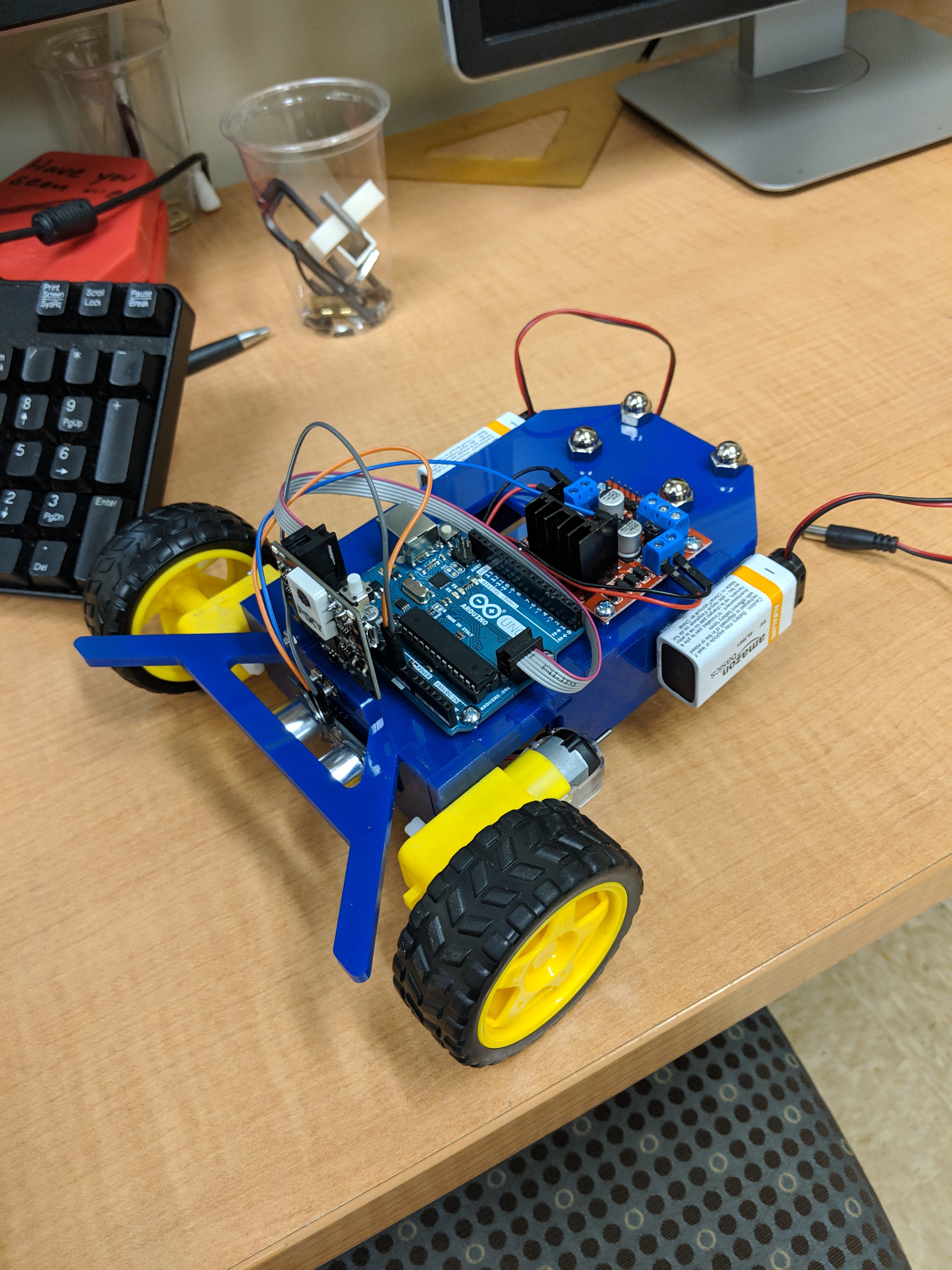

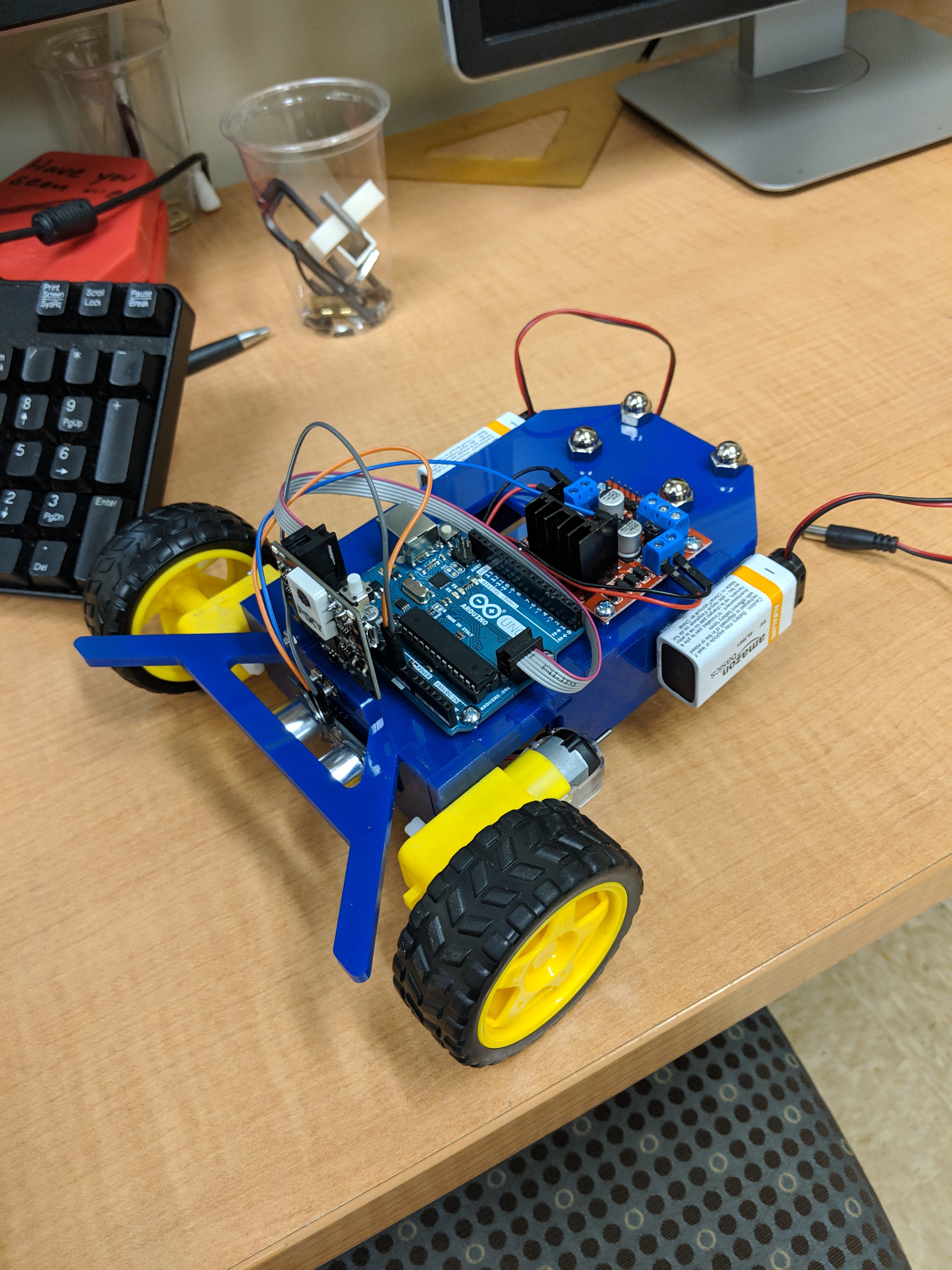

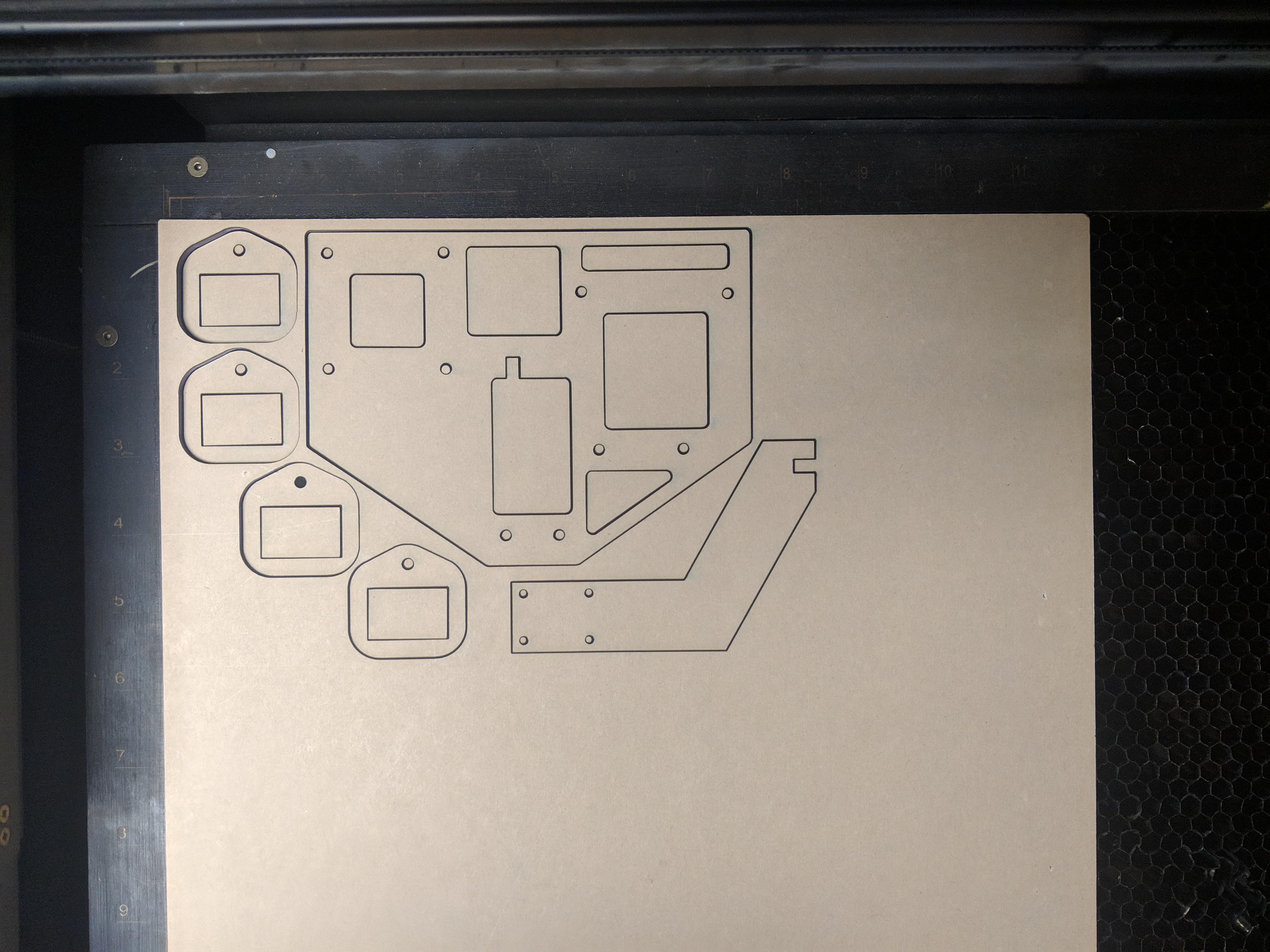

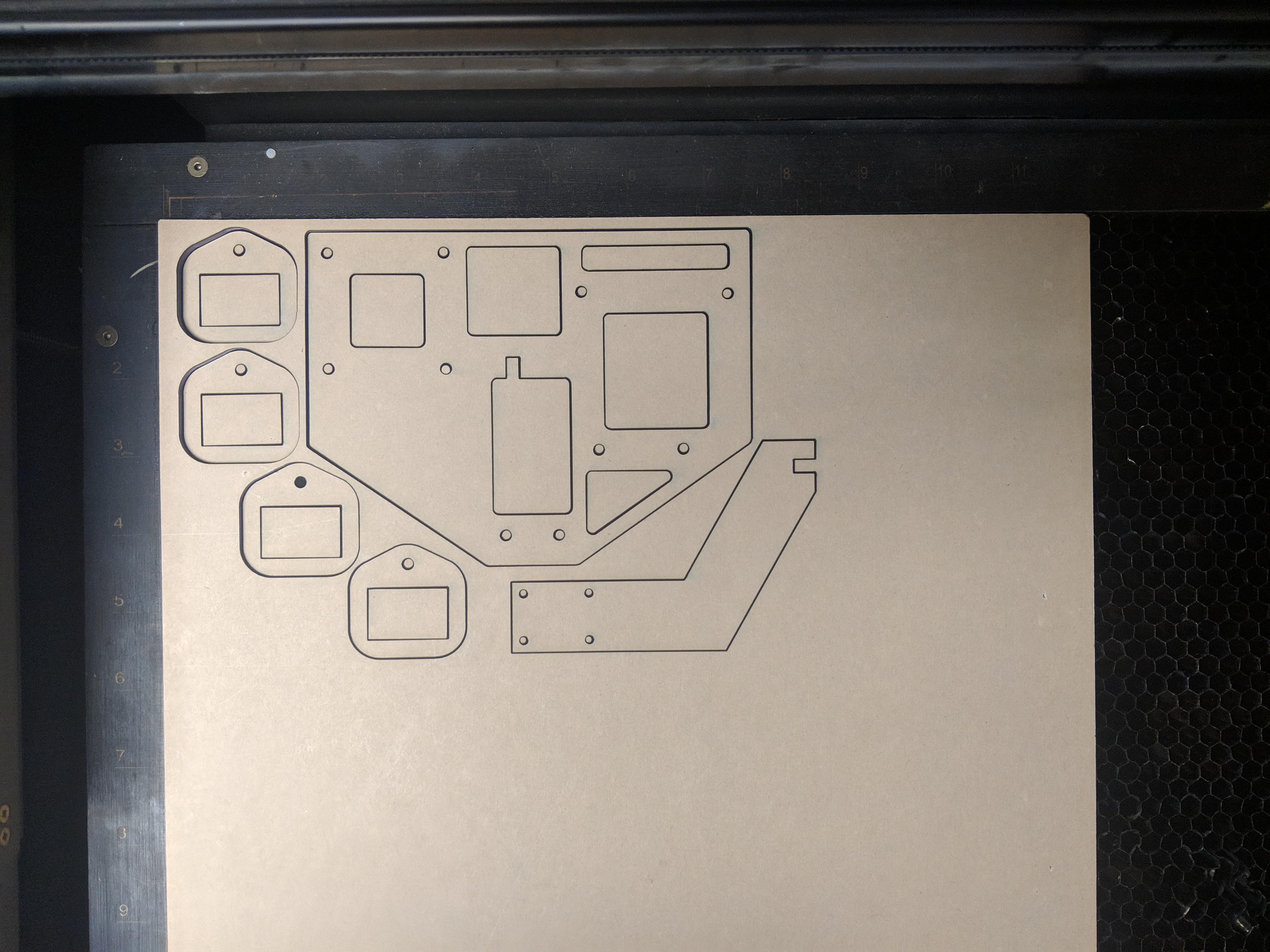

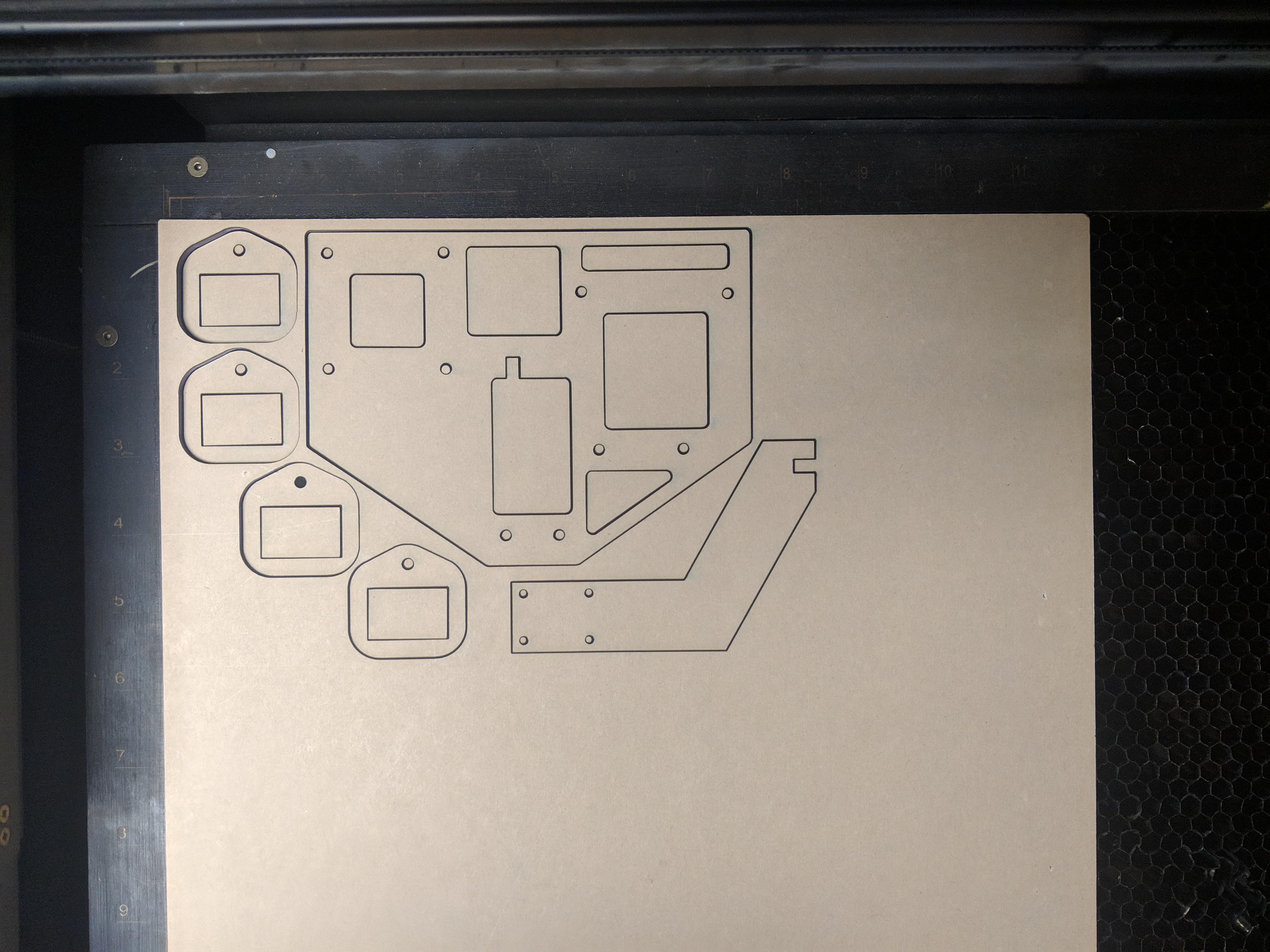

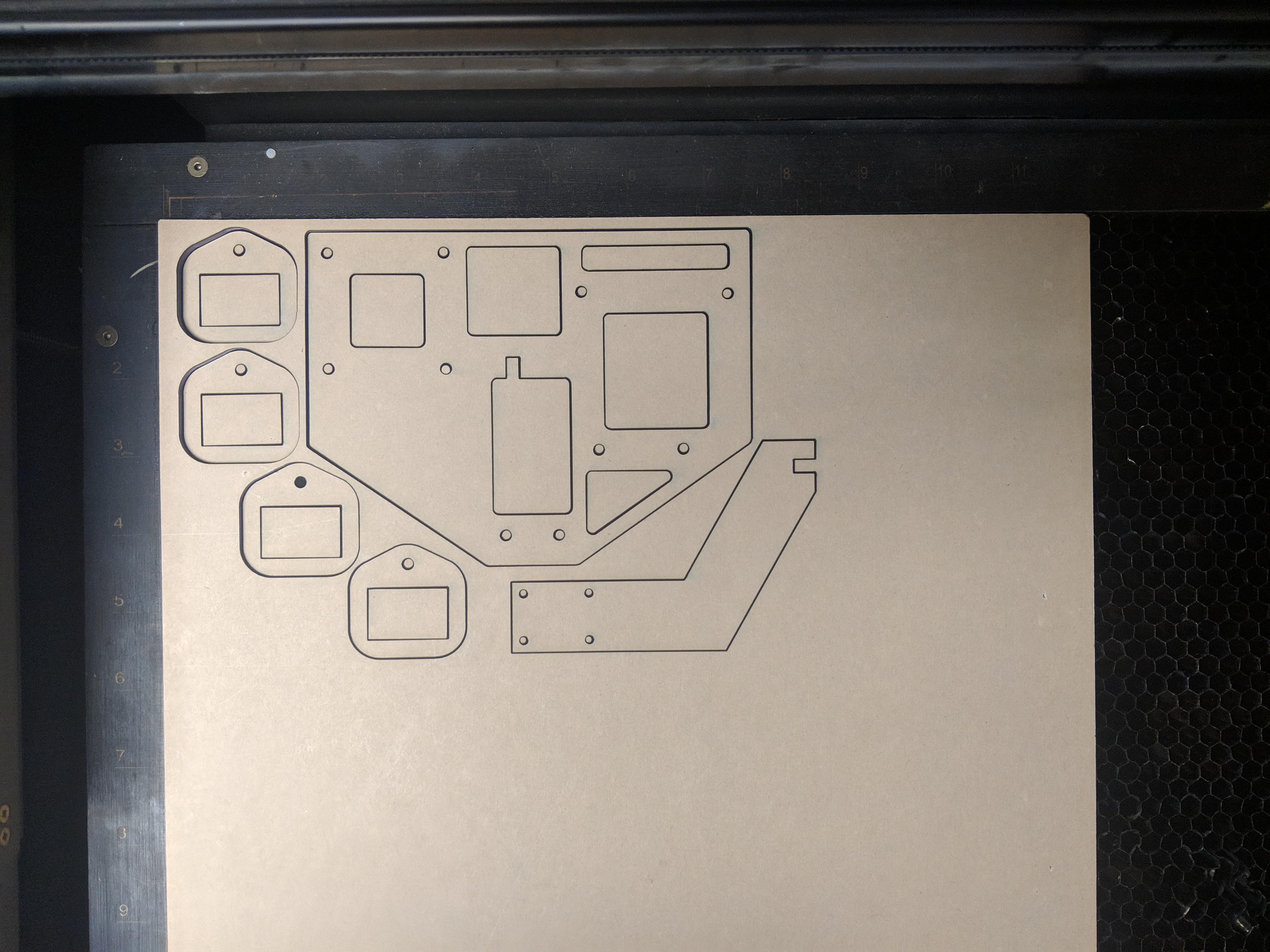

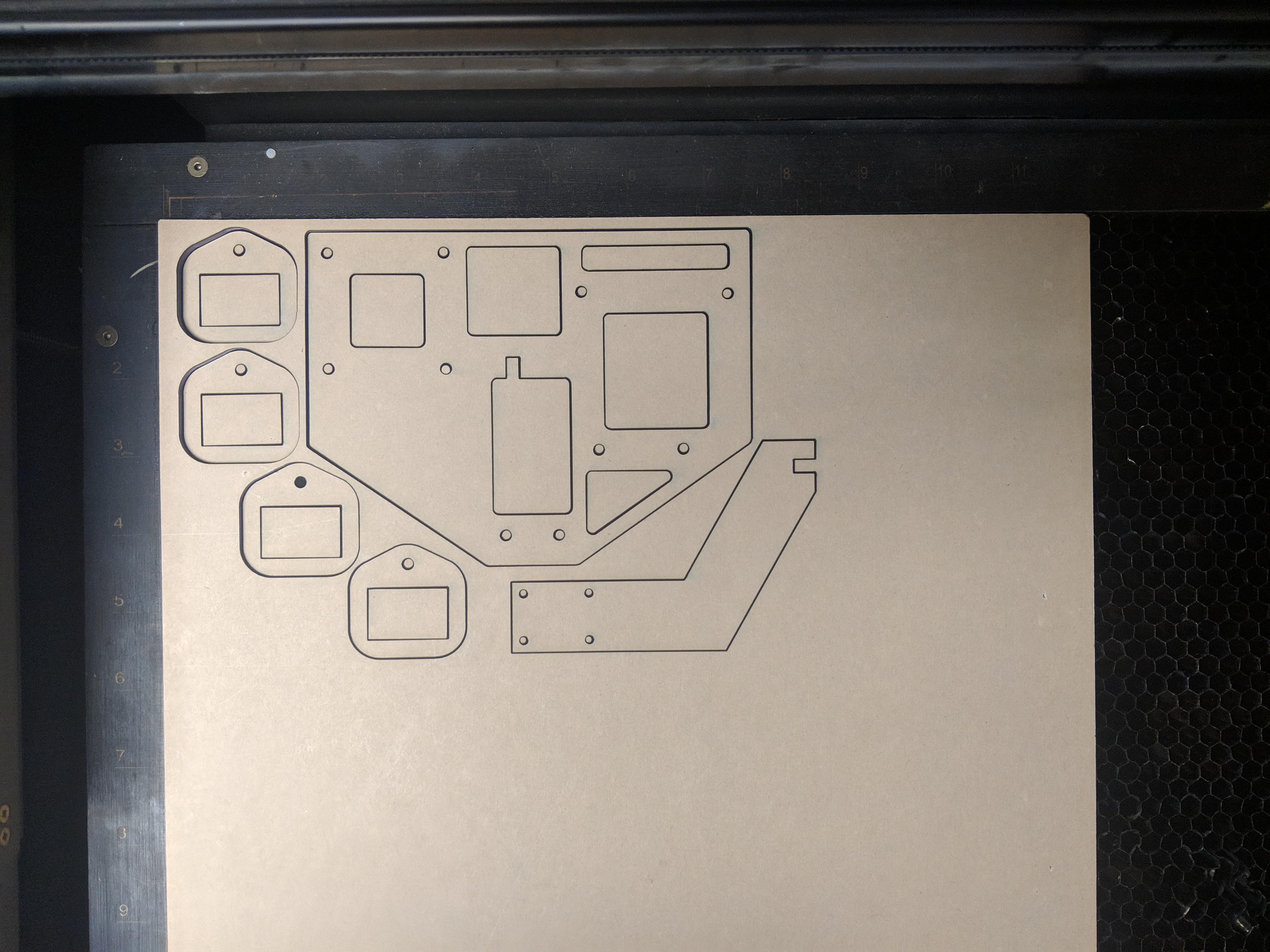

The first robot we built was a maze solving robot. For sensors, we were allowed a single PixyCam, an ultrasonic depth sensor, and a pair of flexible deformation sensors. For this robot, I was on a team with two other people. My responsibilities consisted of designing and fabricating the chassis, while they focused on programming the robot. To solve the maze, the robot may use any algorithm, as well as use the colored square hints placed throughout the maze.

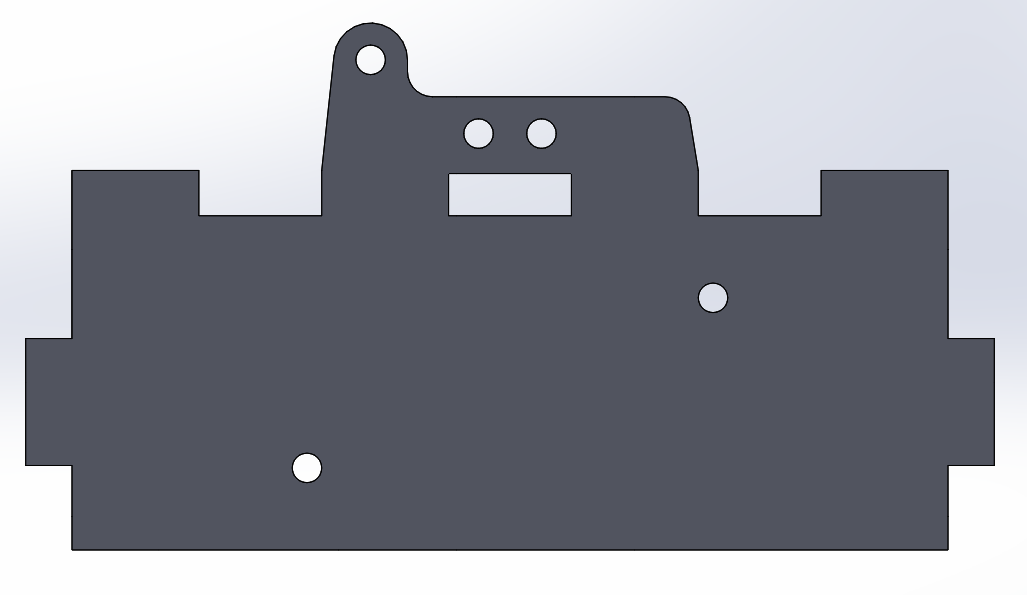

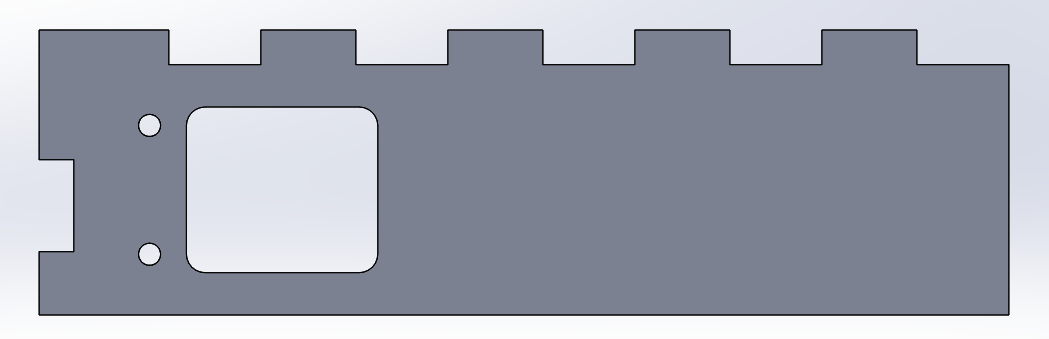

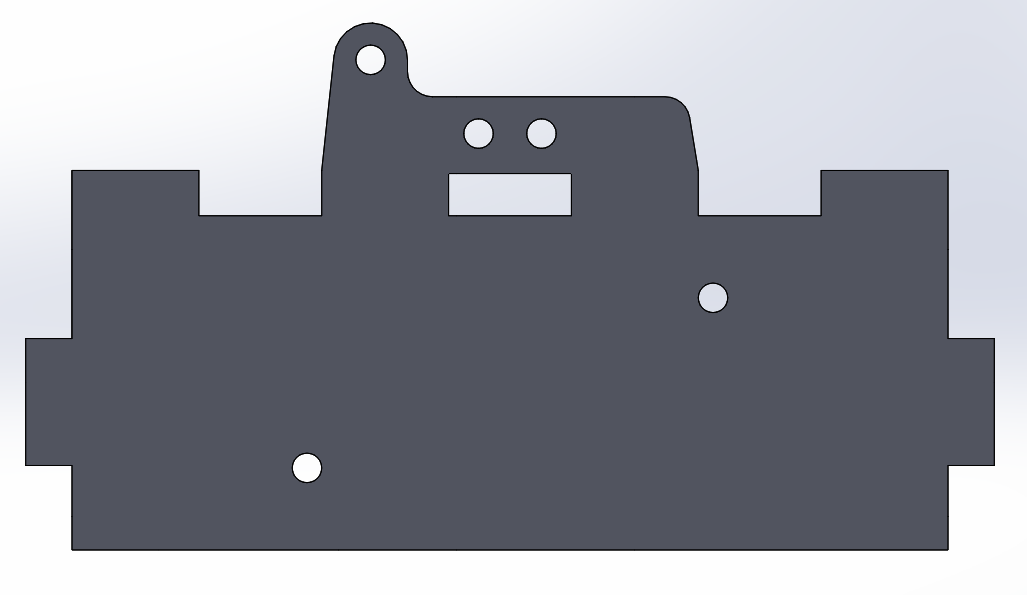

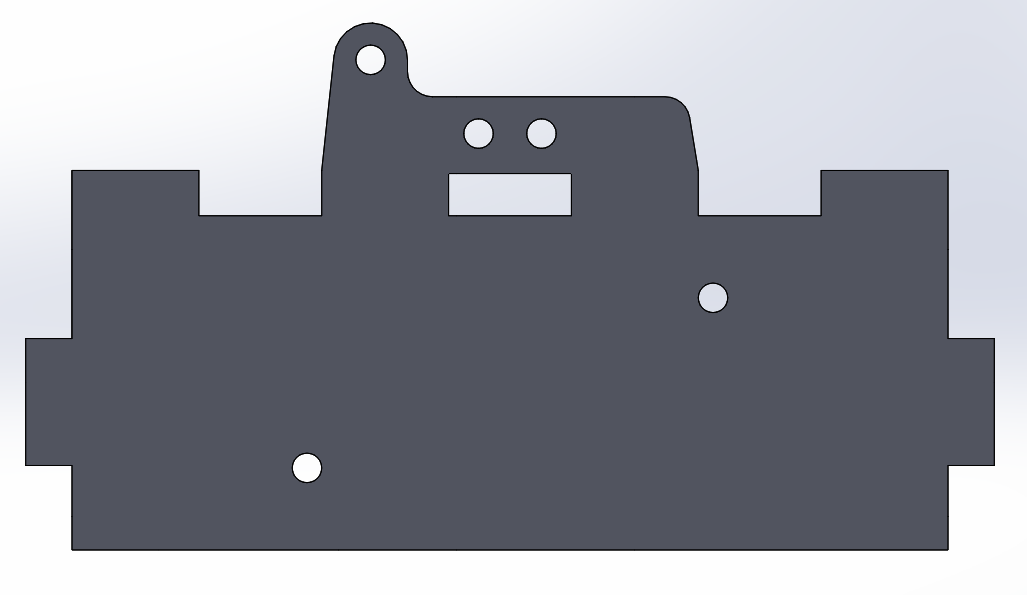

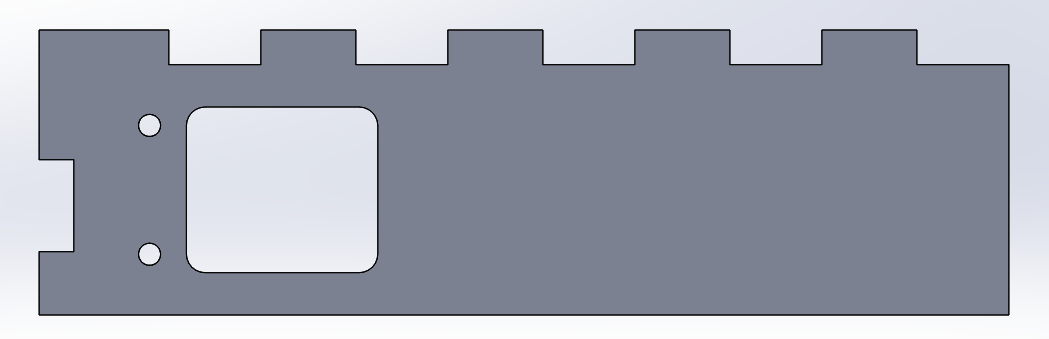

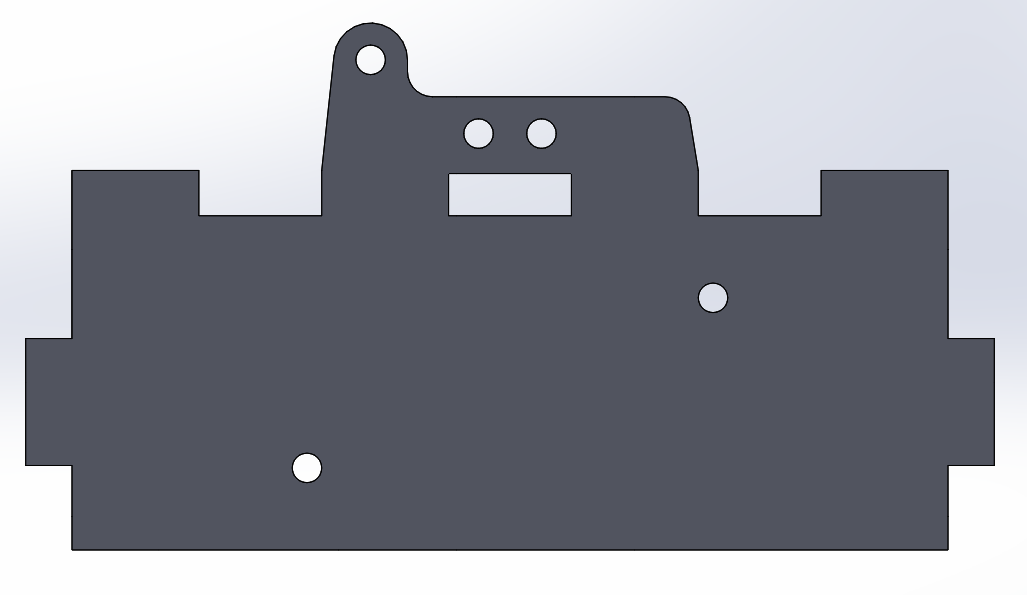

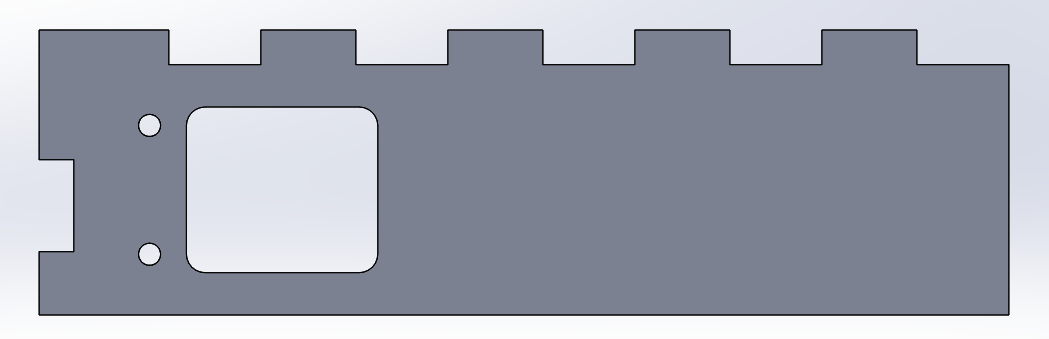

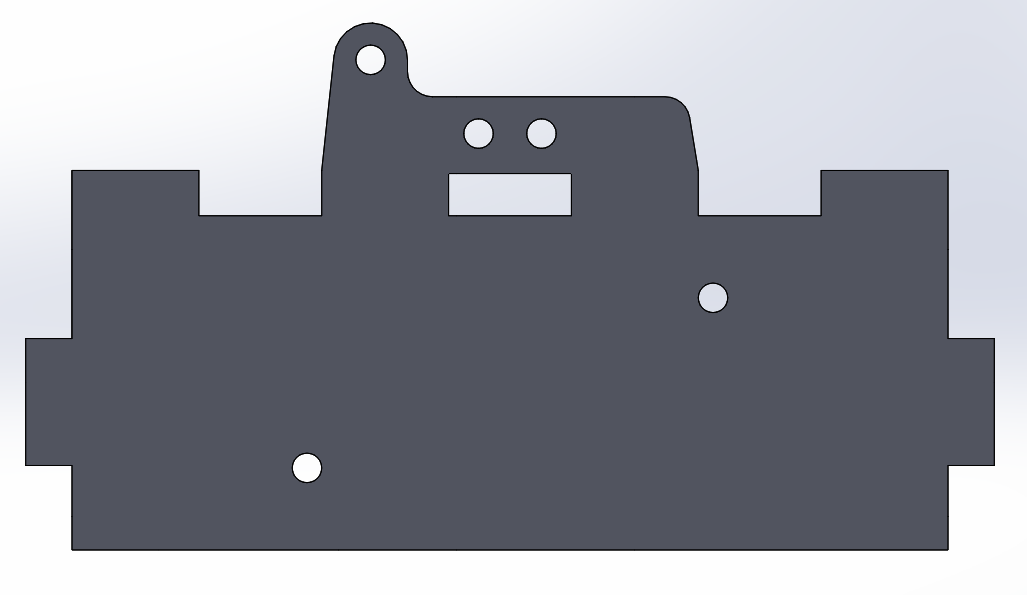

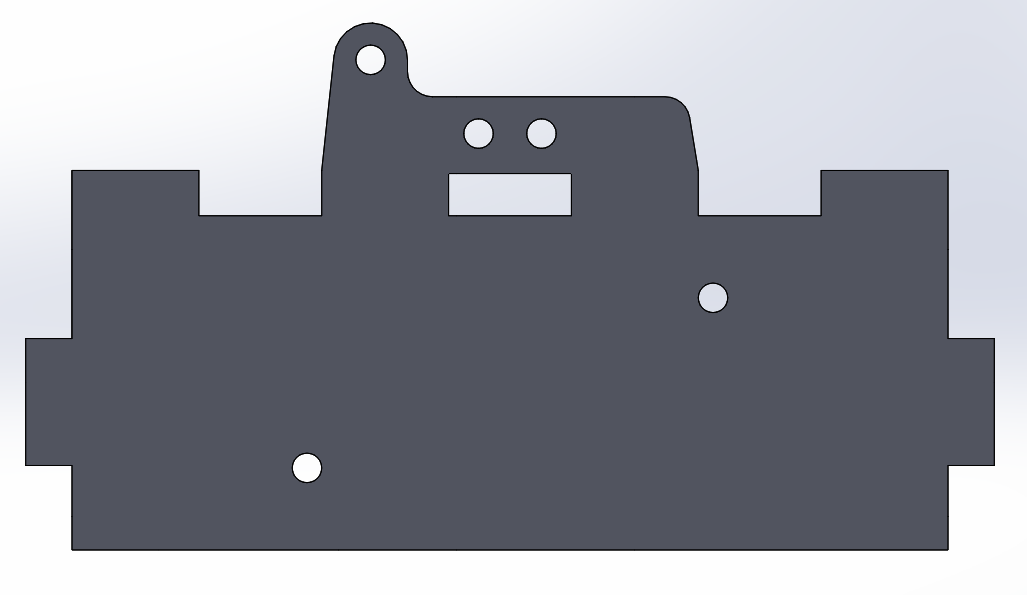

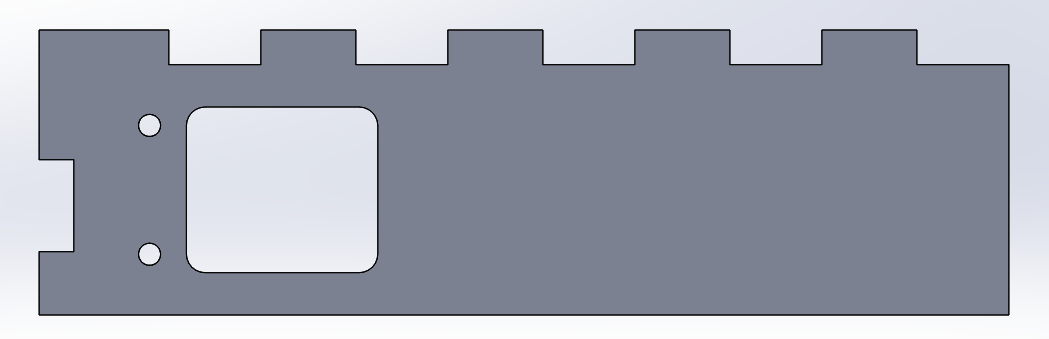

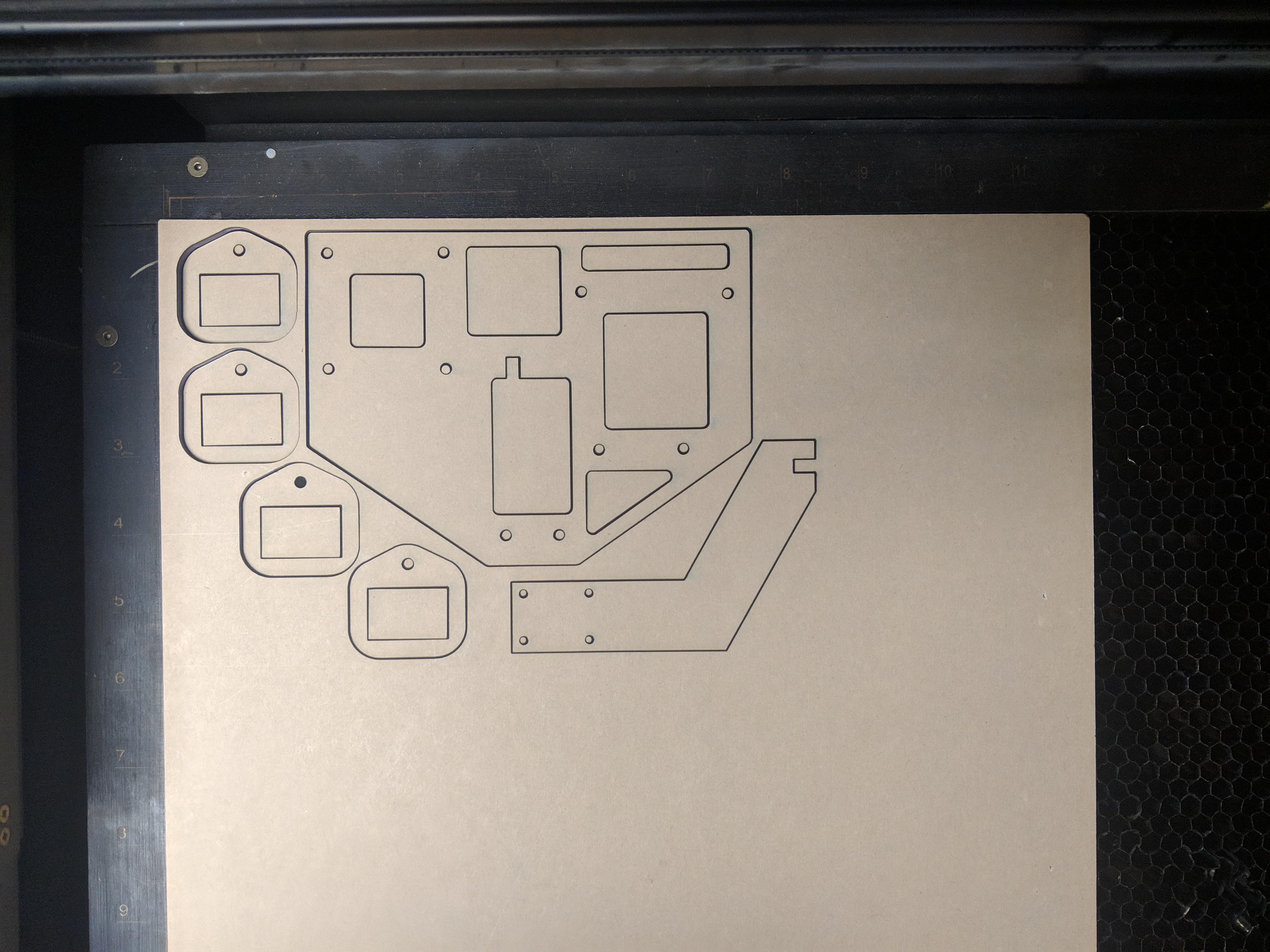

An interesting feature of the chassis design is that it was design to fit together using nothing but friction joints. This means that each joint is slightly larger than where it is supposed to fit, and the interference between both sides holds the parts together—no glue was needed, and the only fasteners were to hold components to the body. Normally, laser cut acrylic isn't cut with such tight tolerances, but with a little bit of experimentation, I was able to get it to work quite nicely.

Balancing Robot

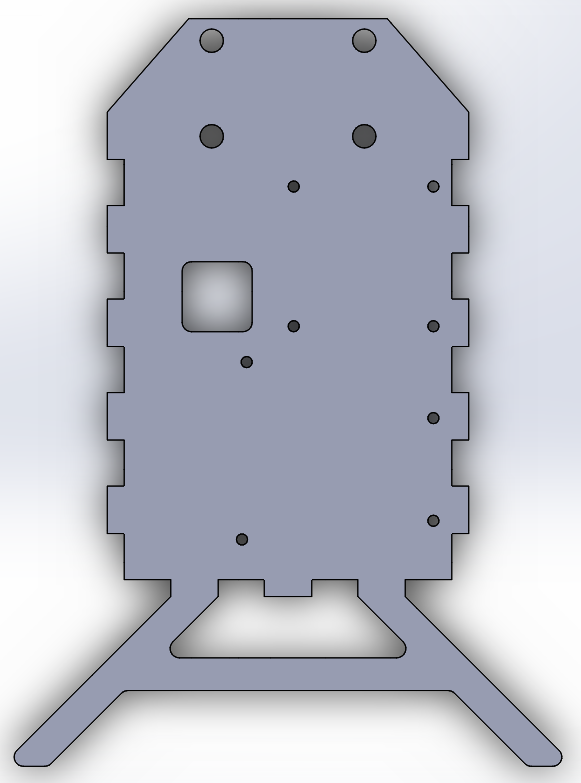

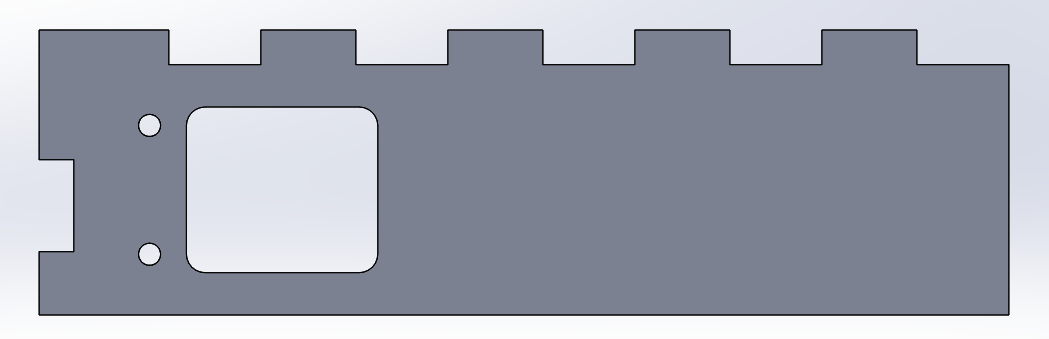

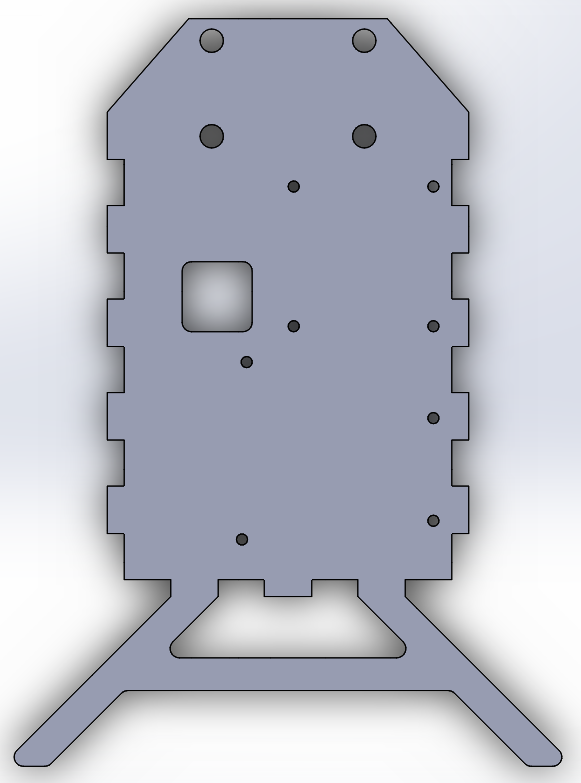

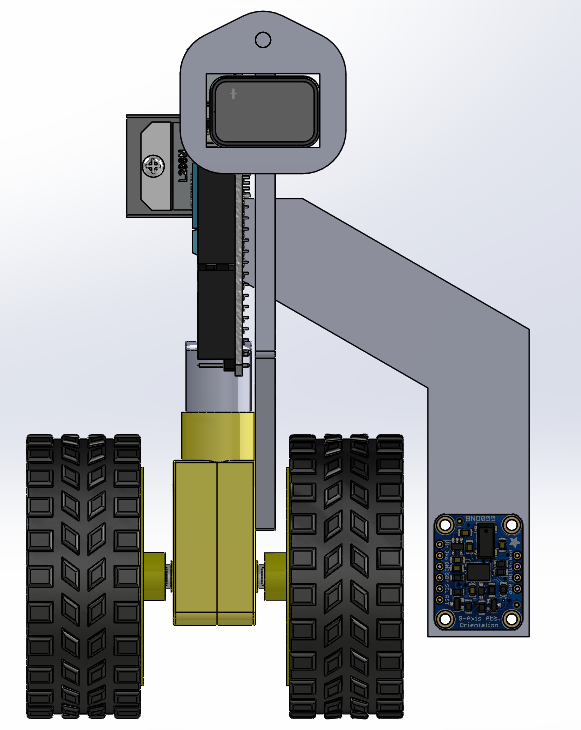

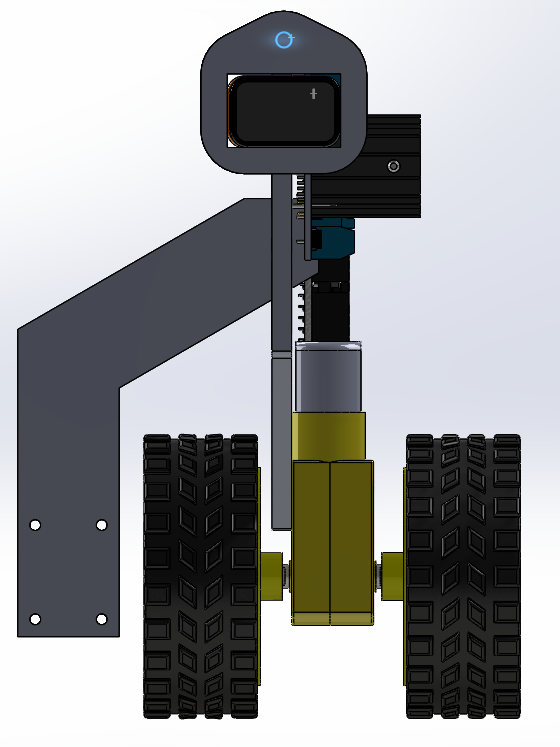

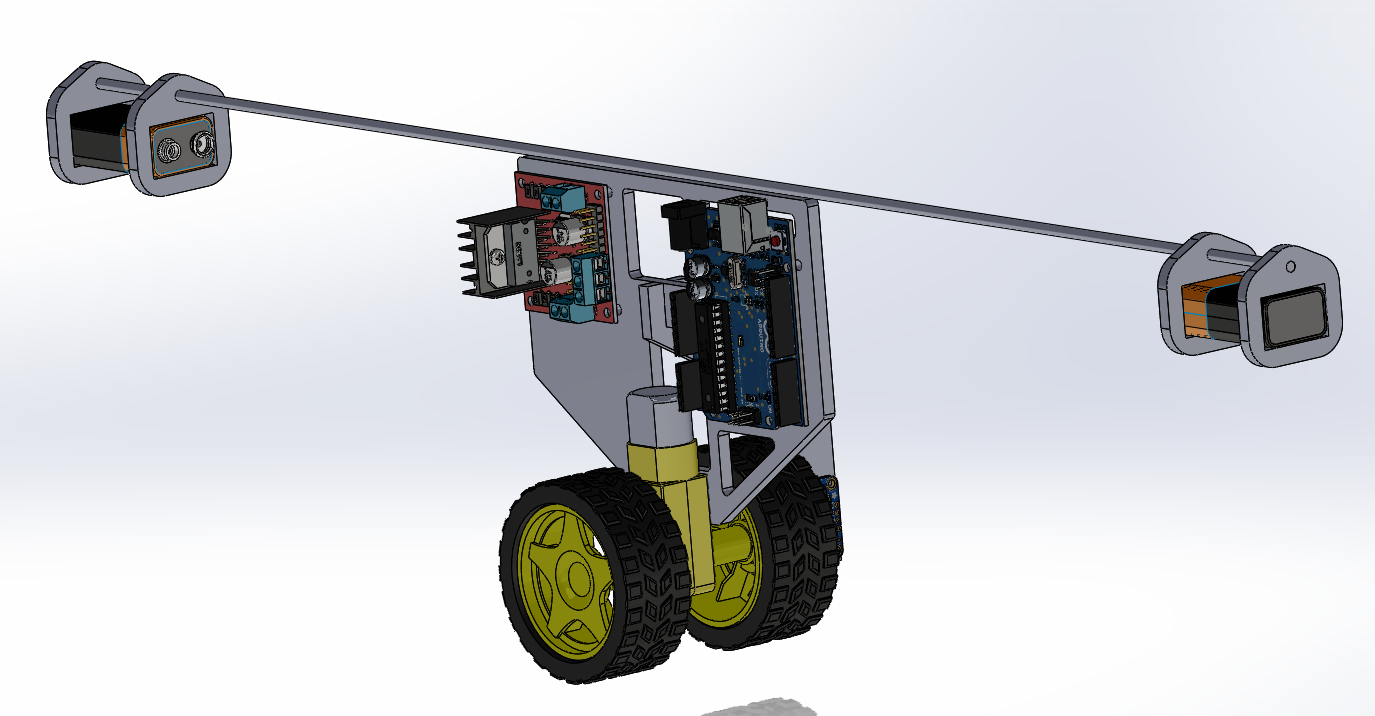

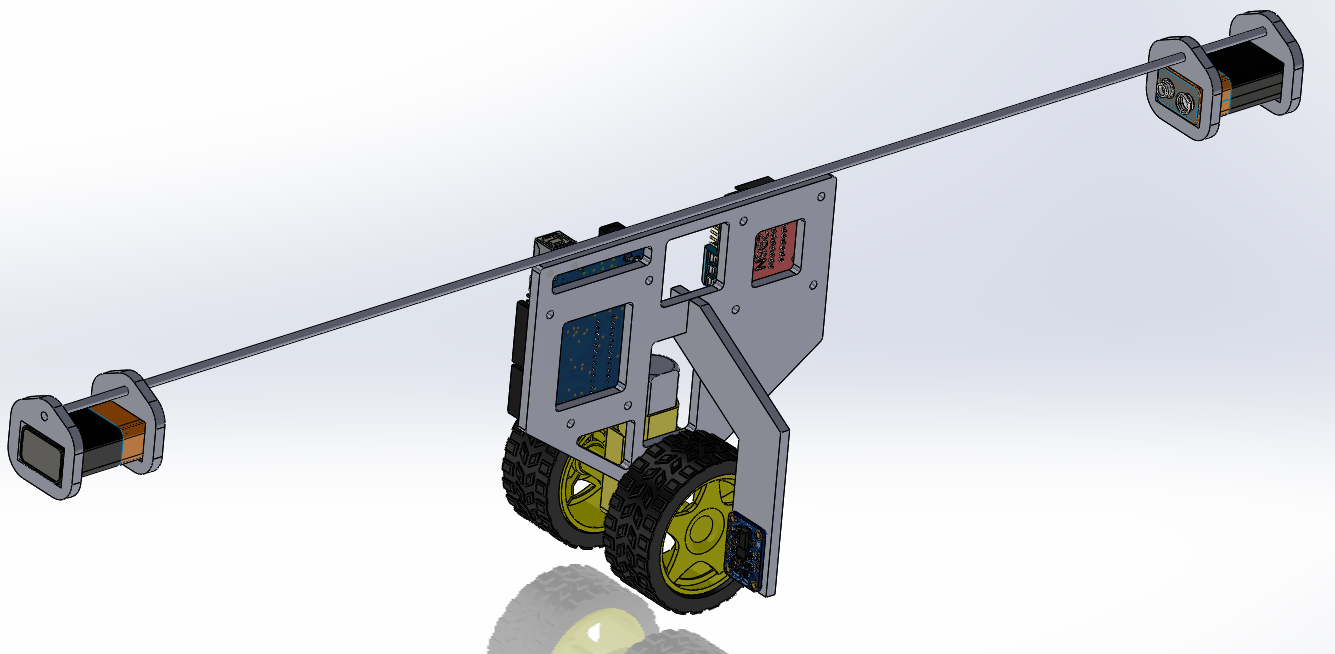

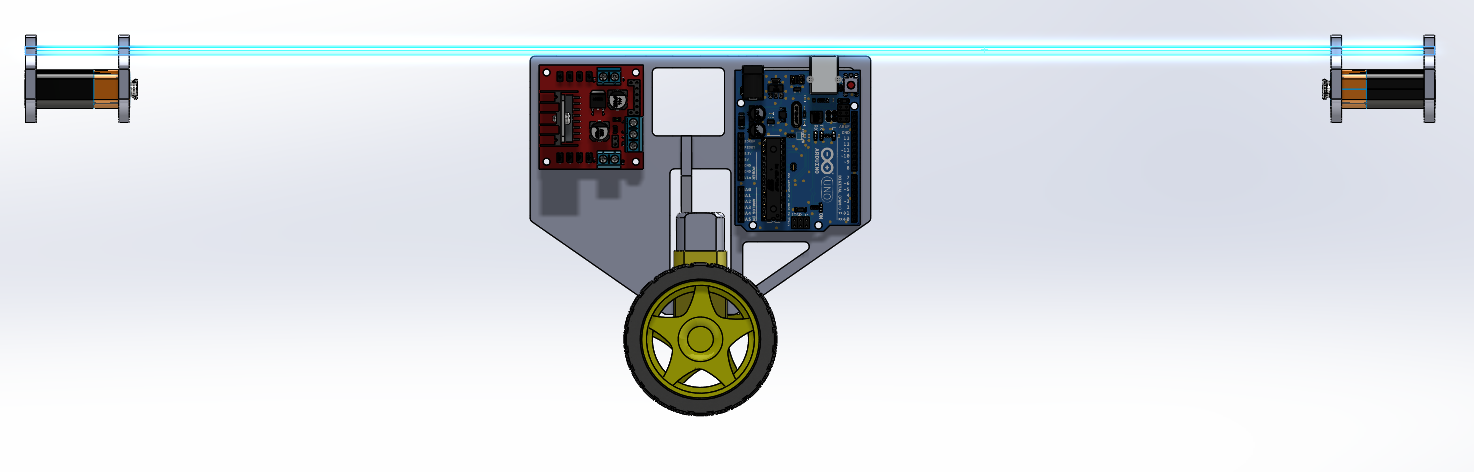

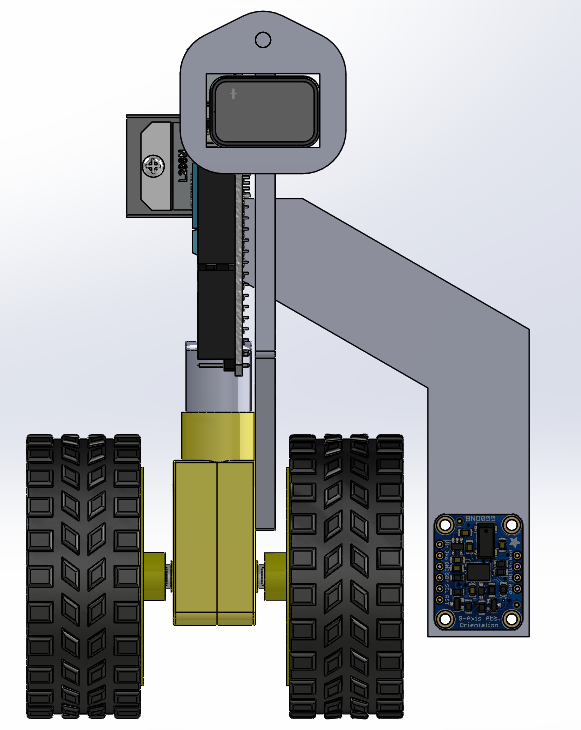

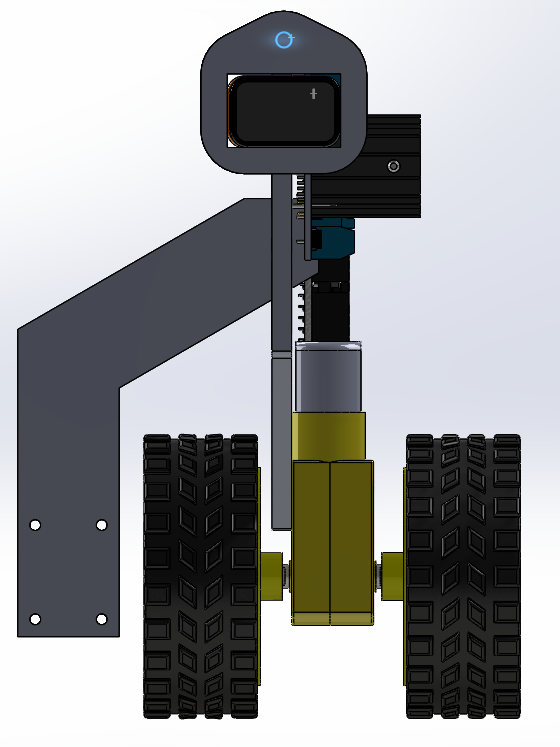

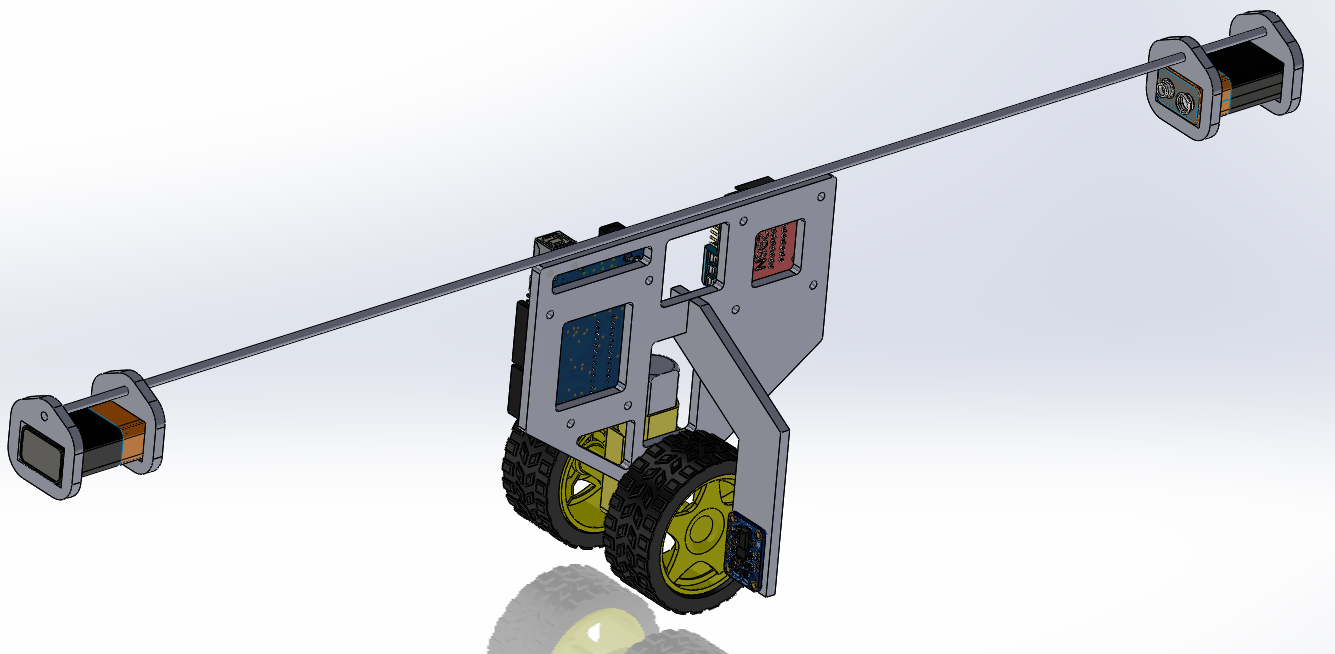

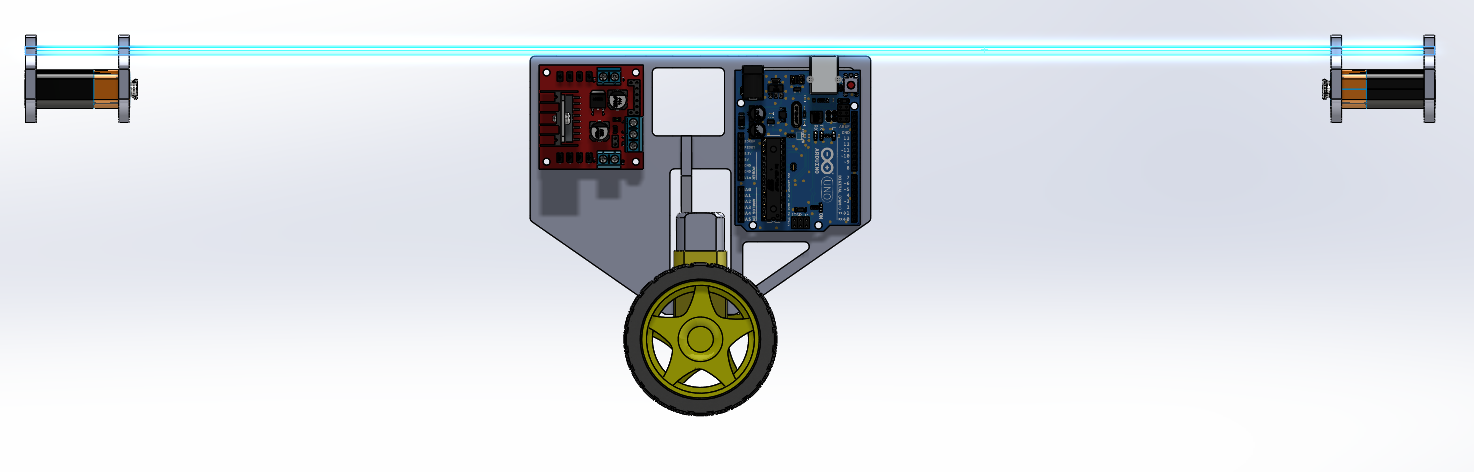

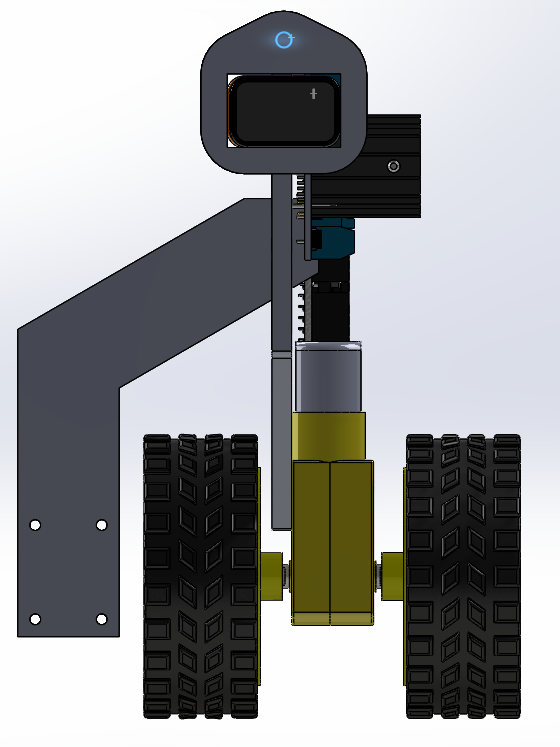

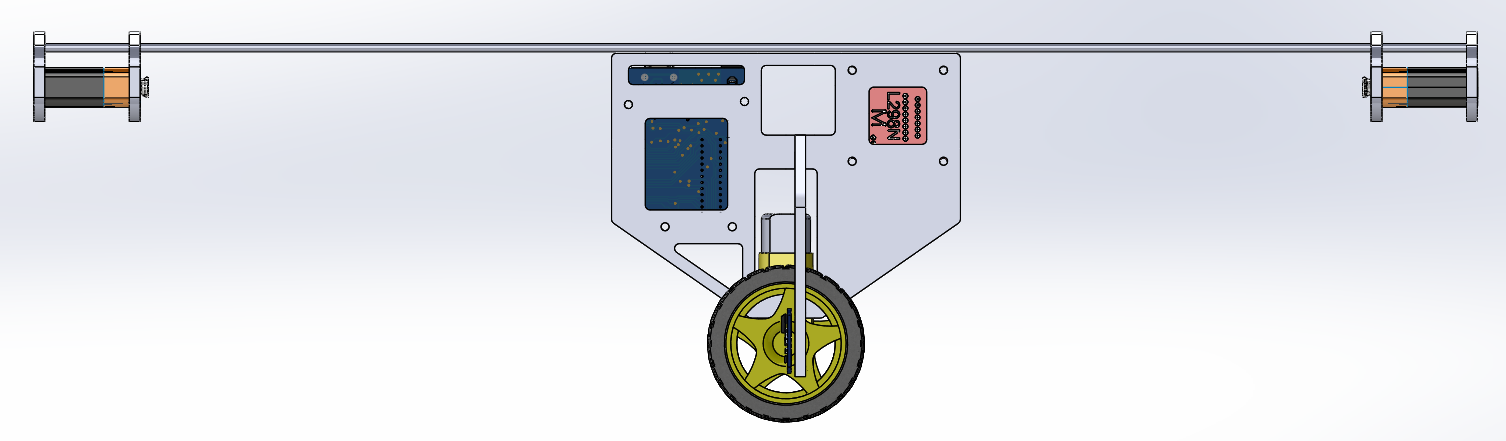

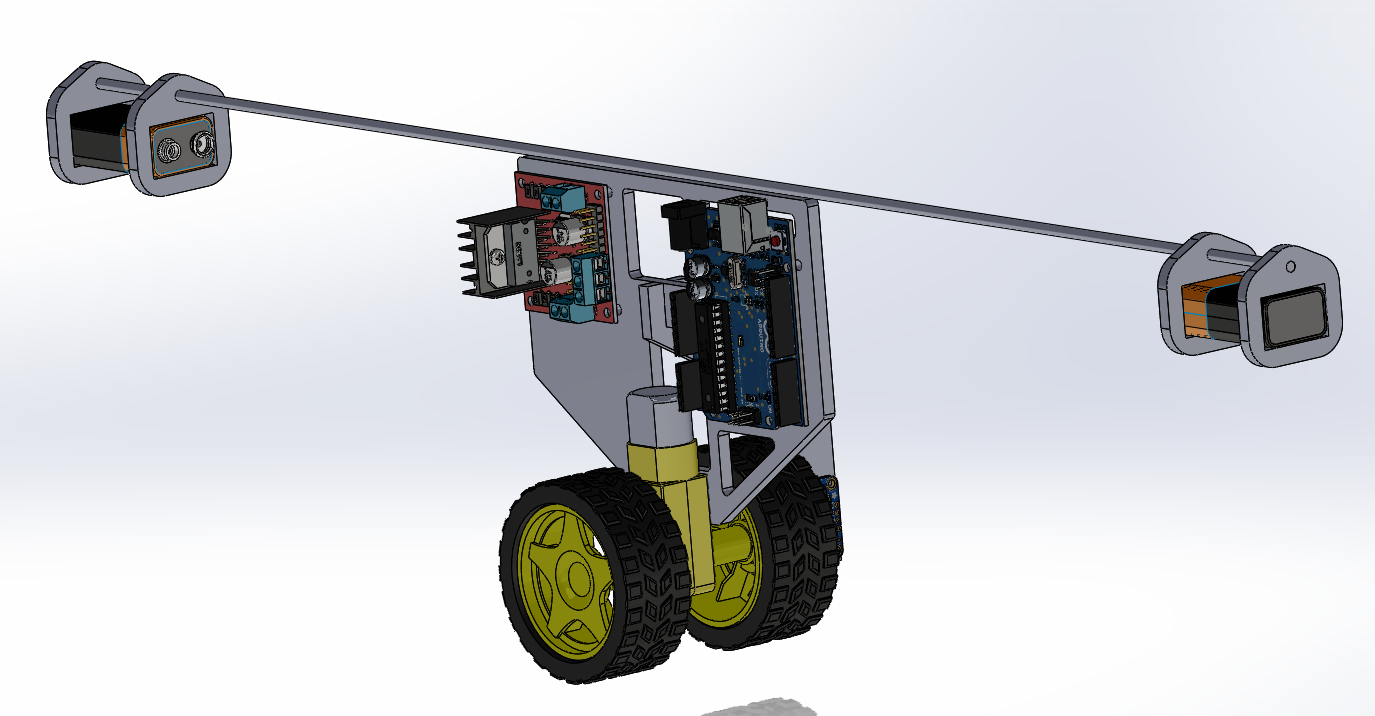

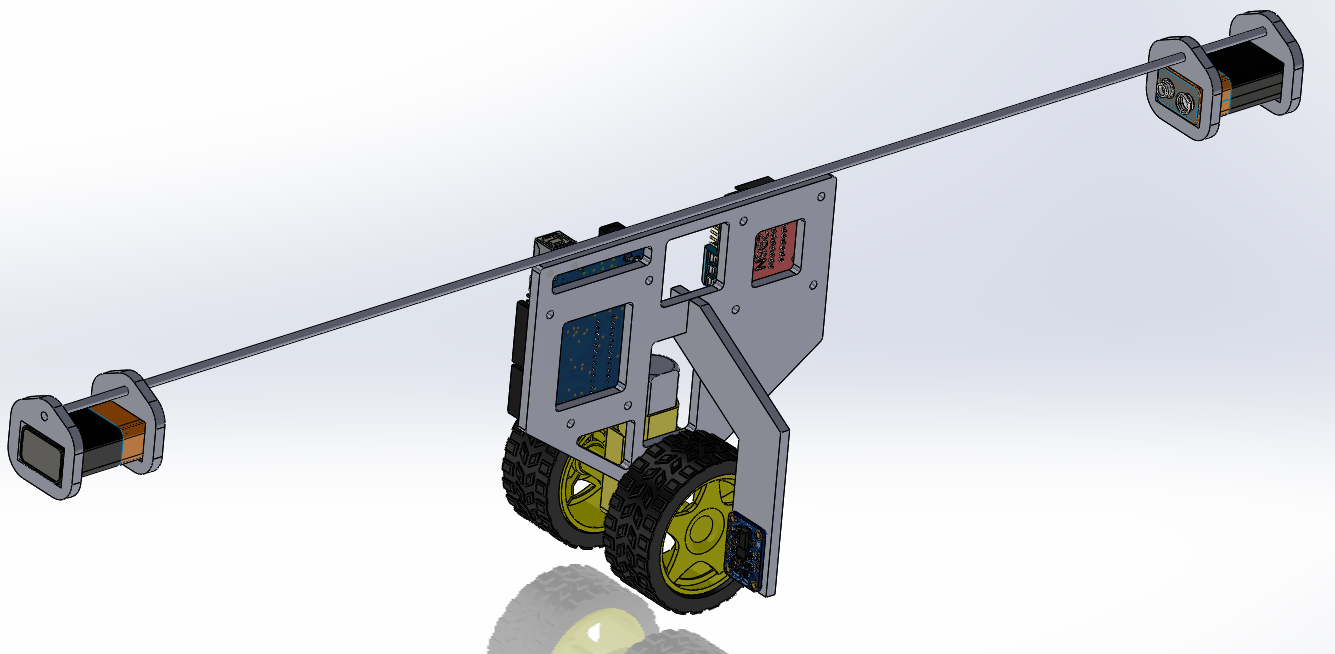

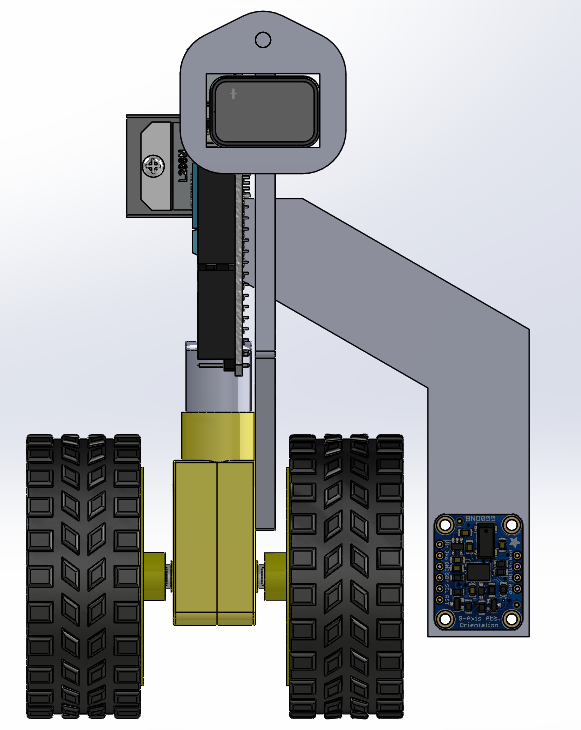

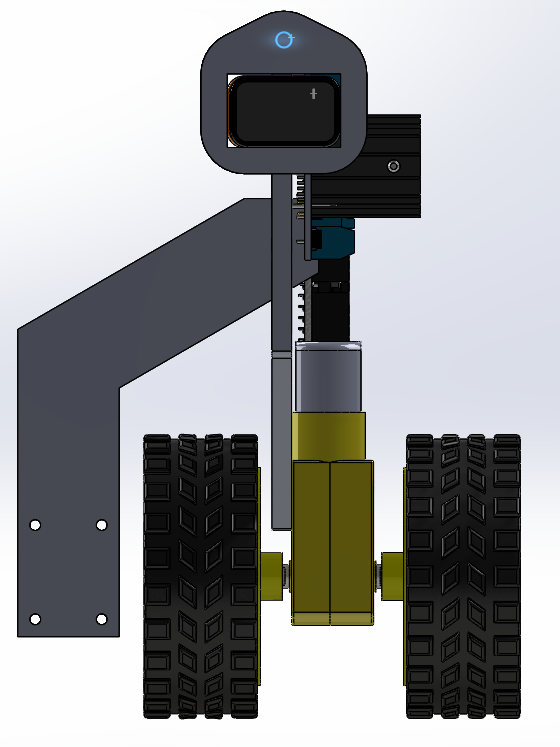

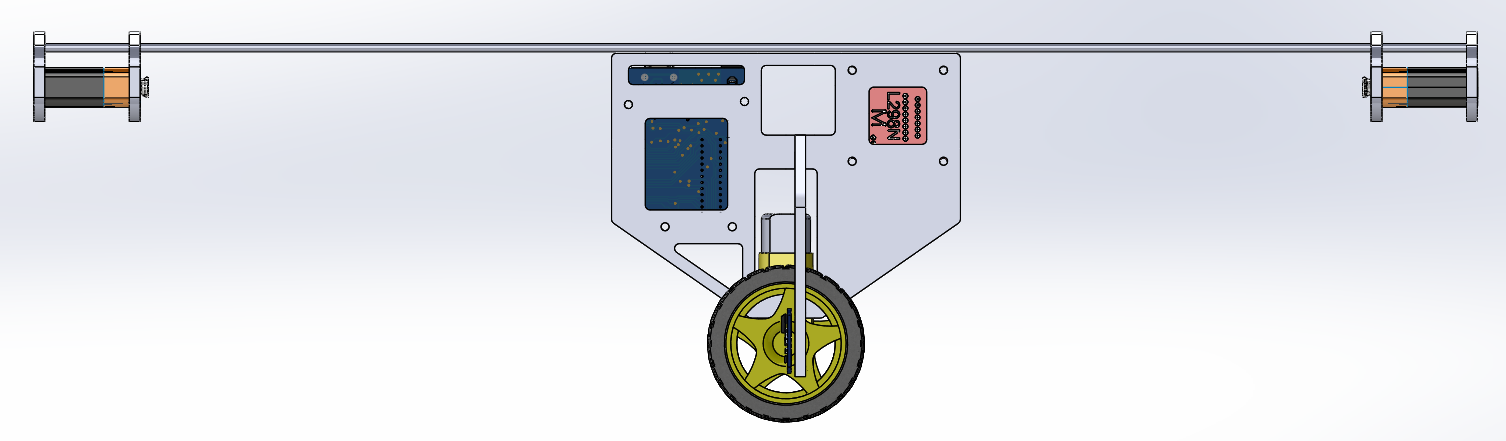

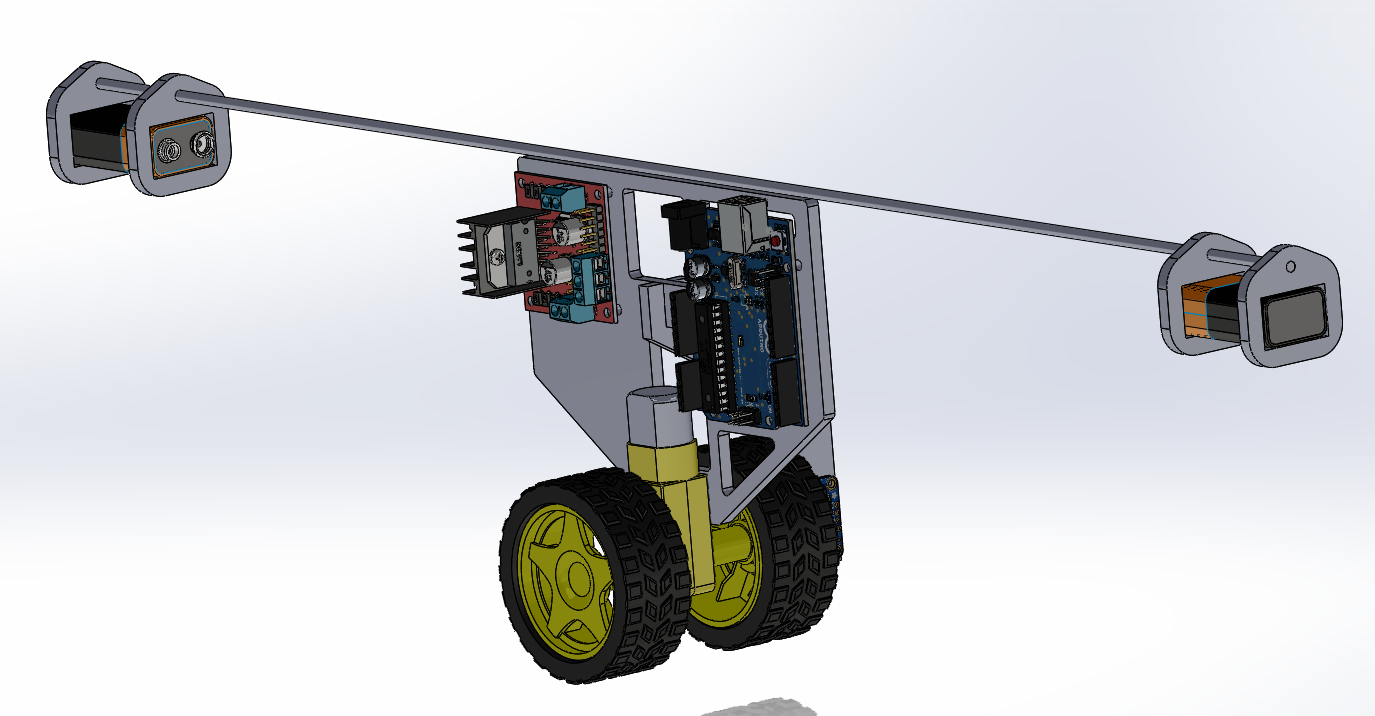

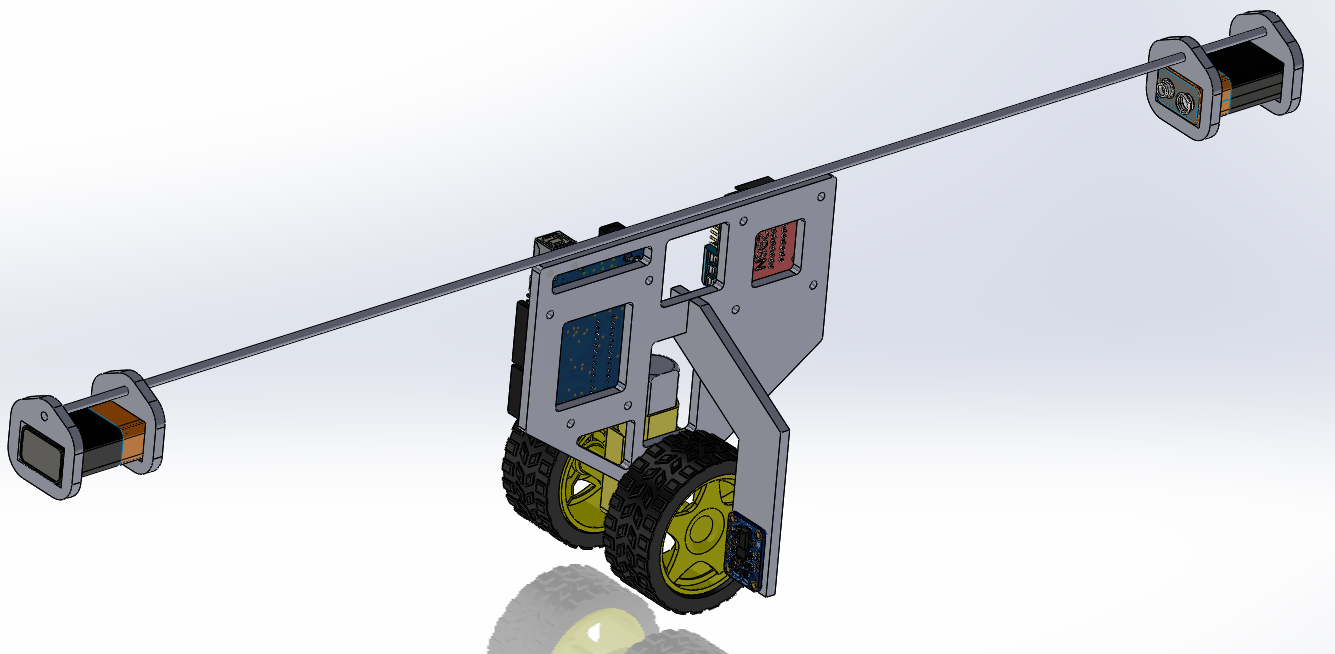

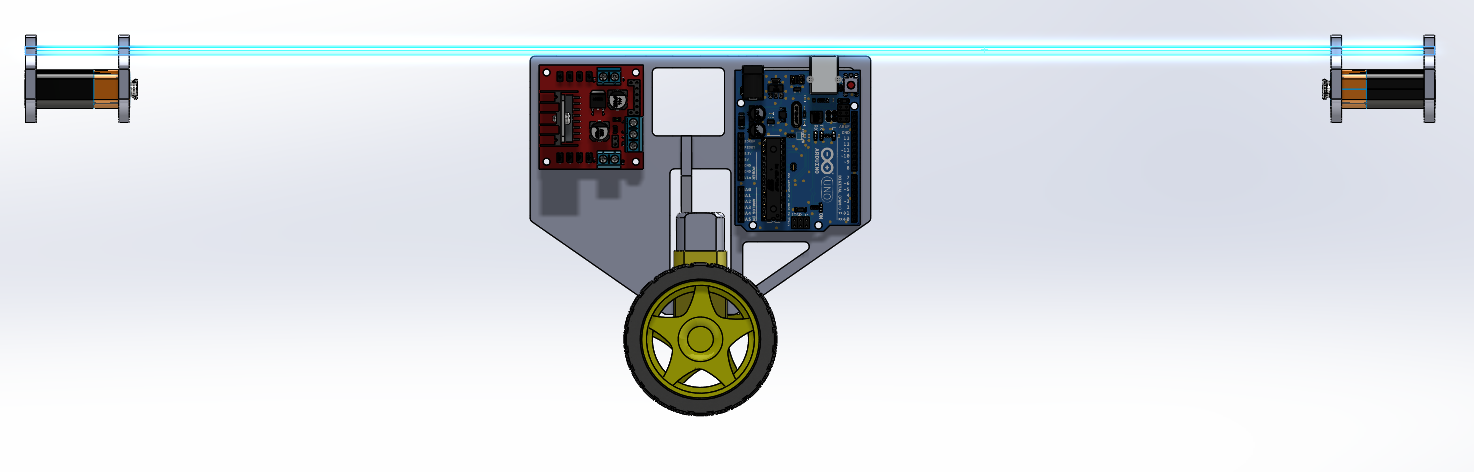

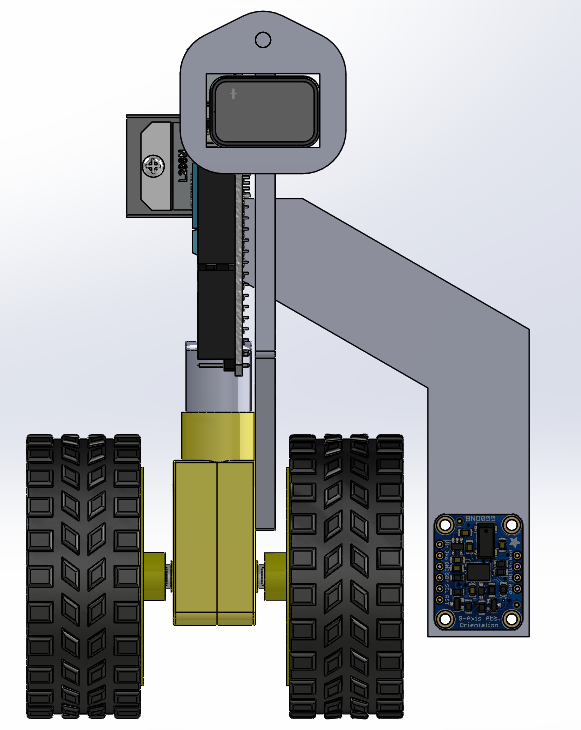

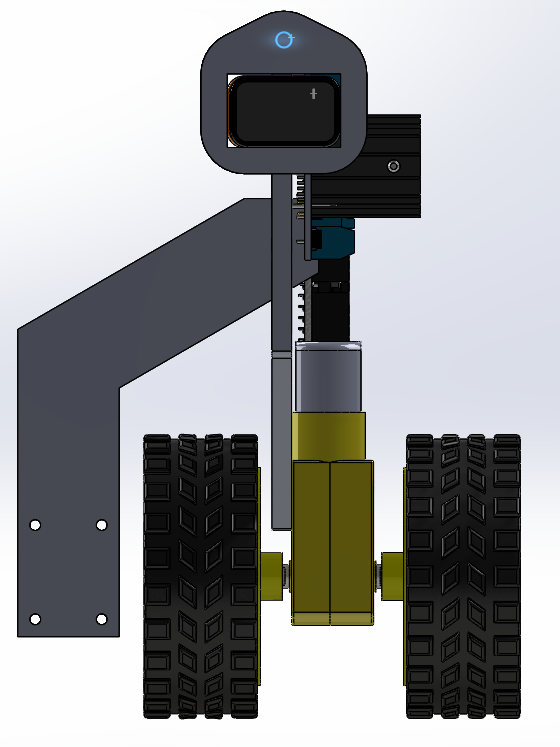

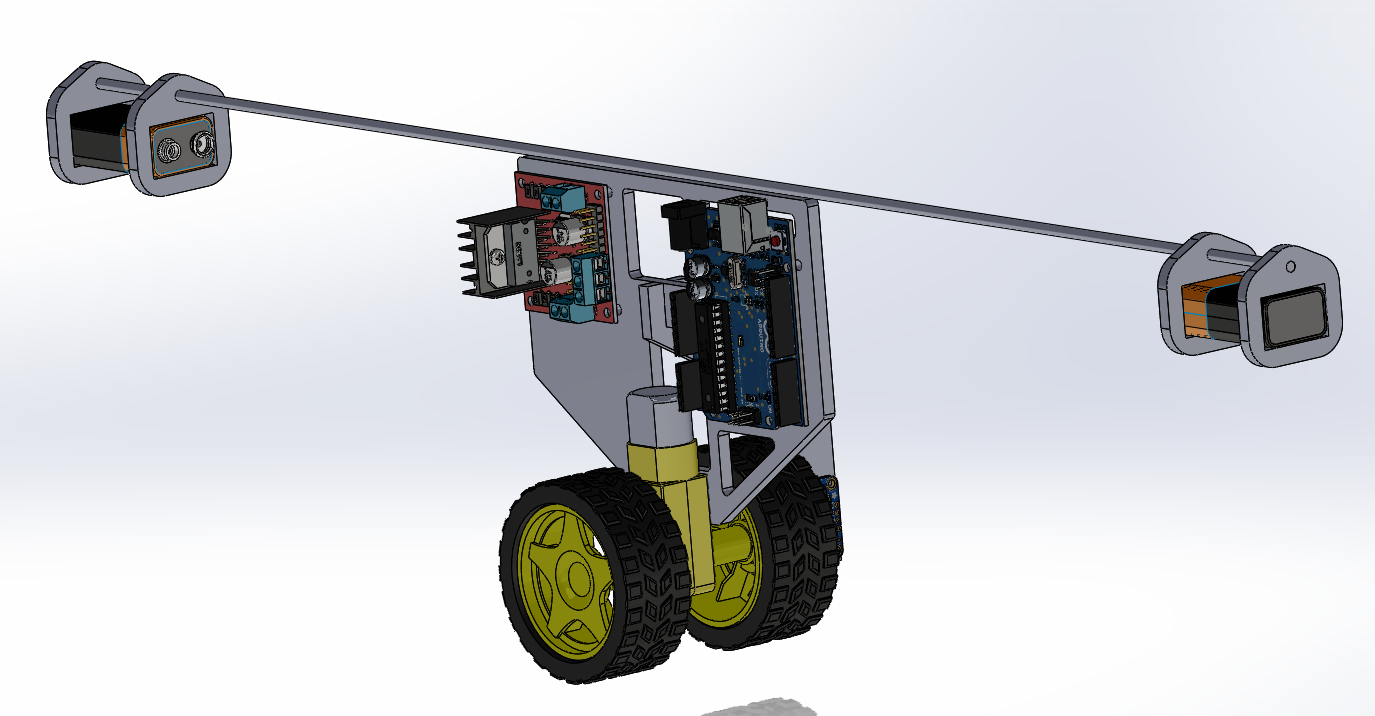

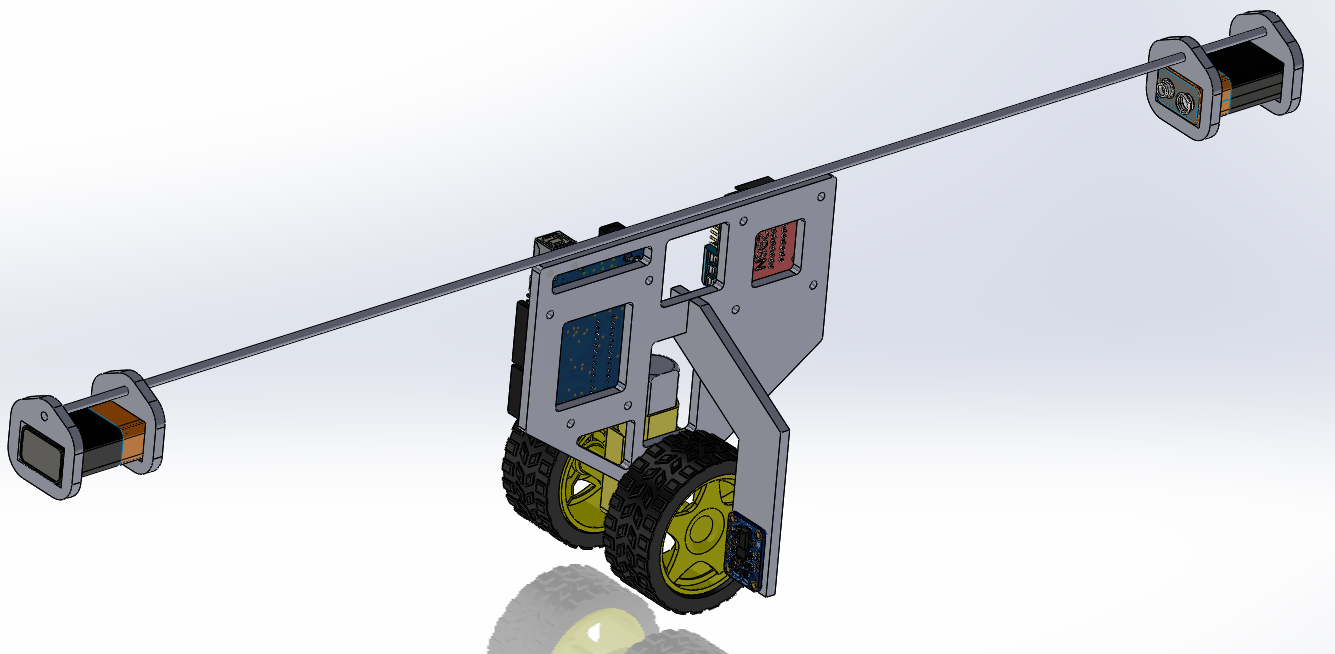

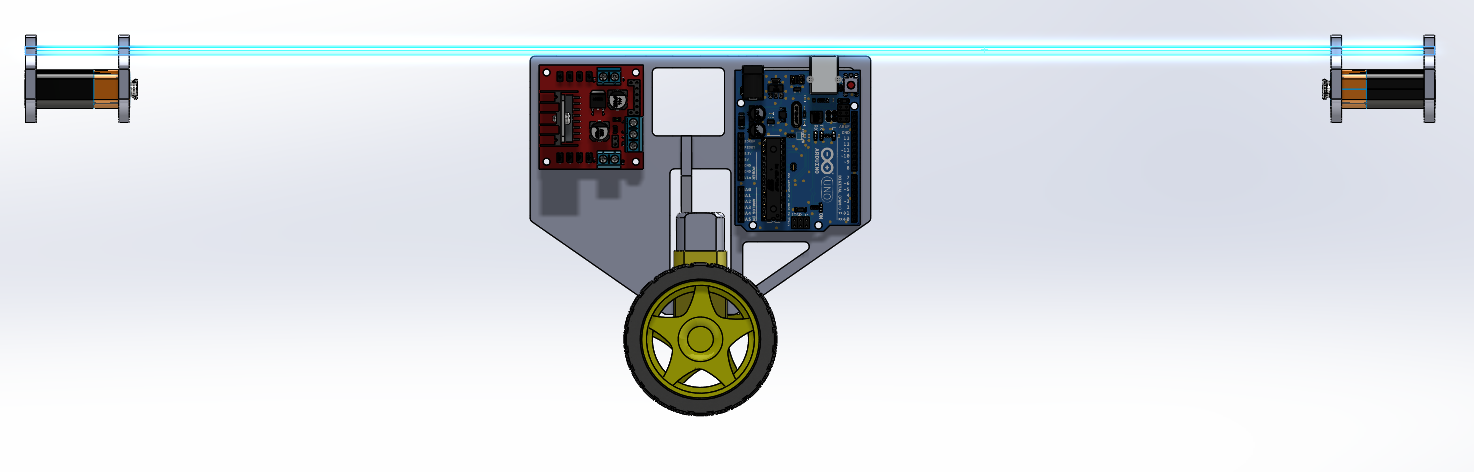

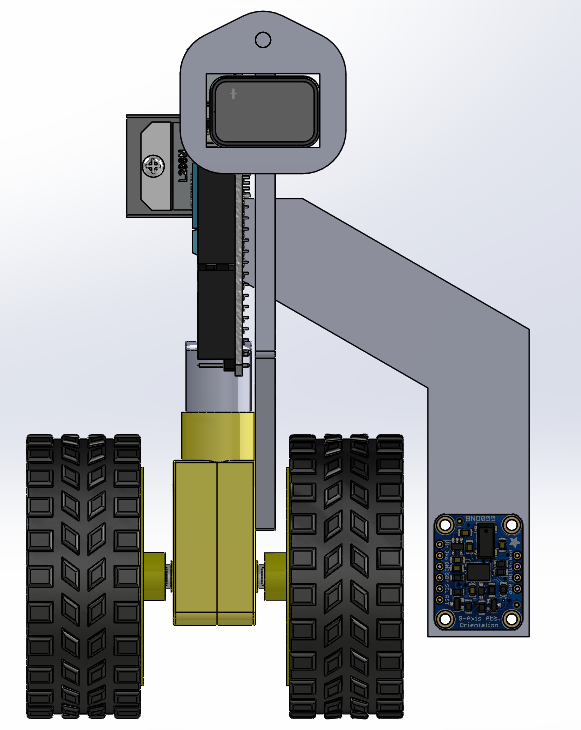

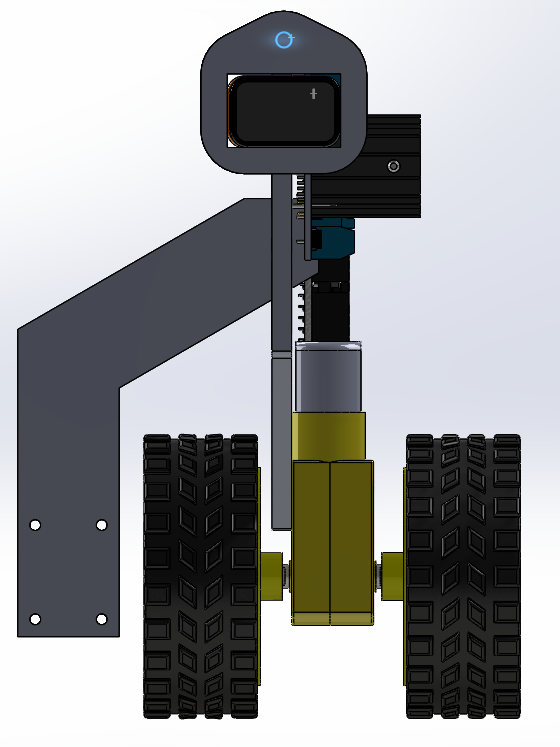

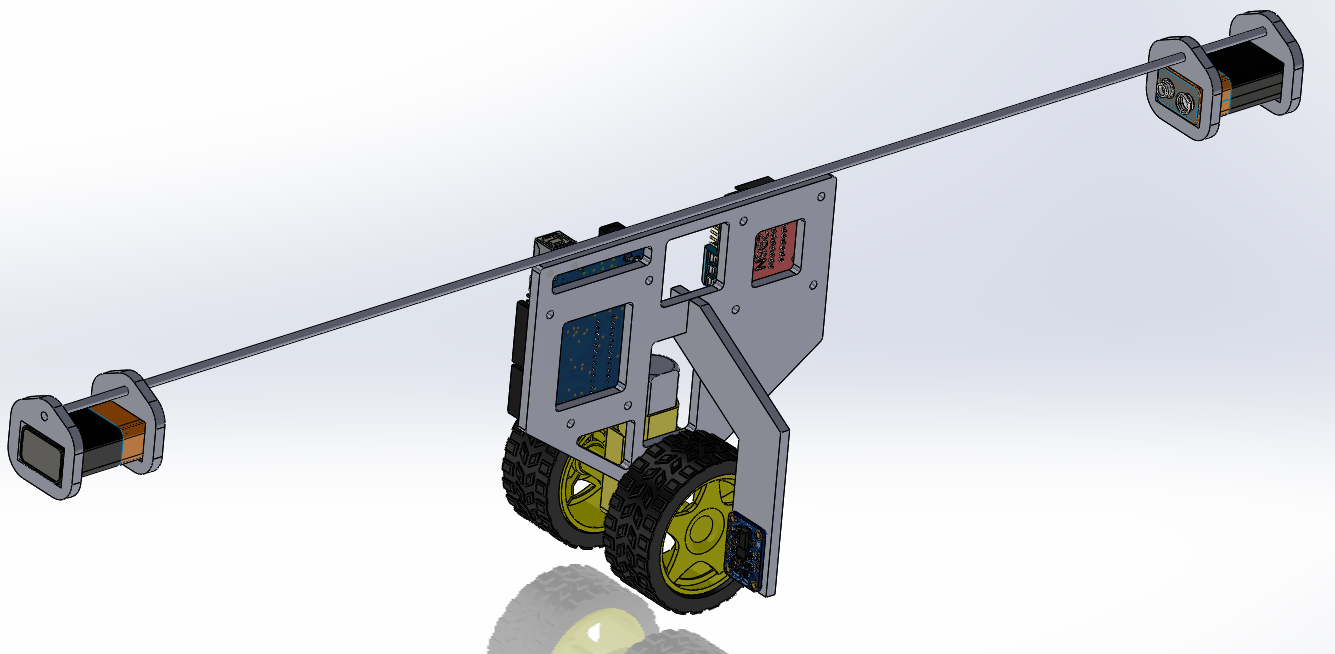

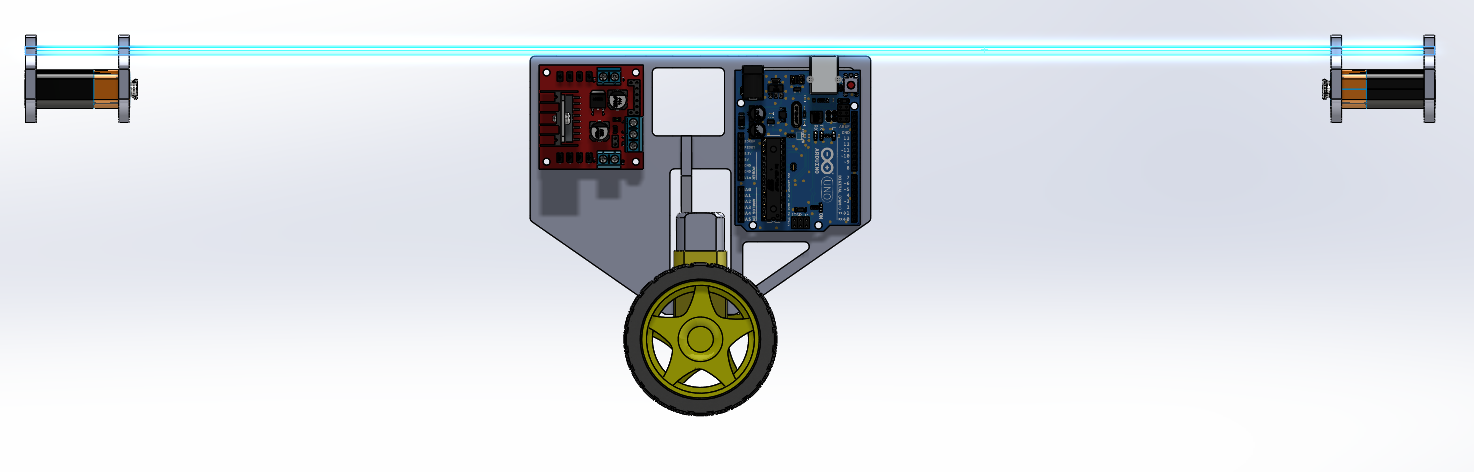

The second robot we built was a robot designed to balance along a single axis. For sensors, we were only allowed a single accelerometer/gyro. We worked in teams of three, and I was again tasked with designing and fabricating the robot body. Additionally we all ended up writing separate balancing algorithms since the problem turned out to be rather intractable.

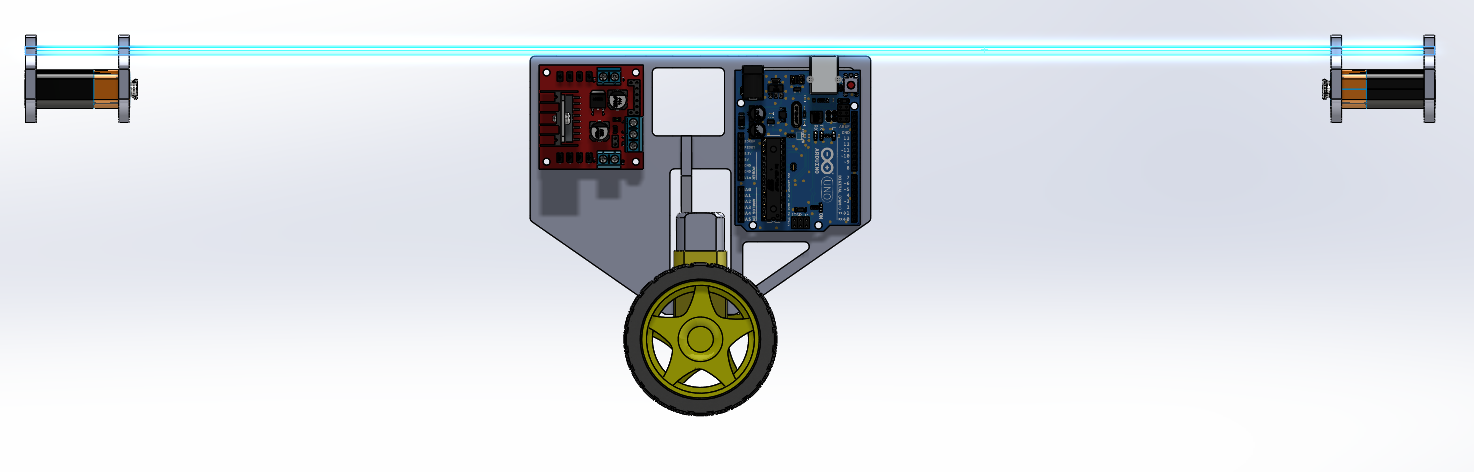

As it turned out, the motor we were provided for the robot was actually not quite strong enough for the task—it lacked sufficient torque to drive the system away from perturbations back to equilibrium—so no one in the class was successful in getting their robot to balance for arbitrarily long. To combat this on our robot, I added a balance beam to the robot which allowed us to maximize the robot's moment of inertia along the balance axis. Ultimately, the longest we managed to get it to balance for was the 20 seconds shown in the video below.

Hockey Robots

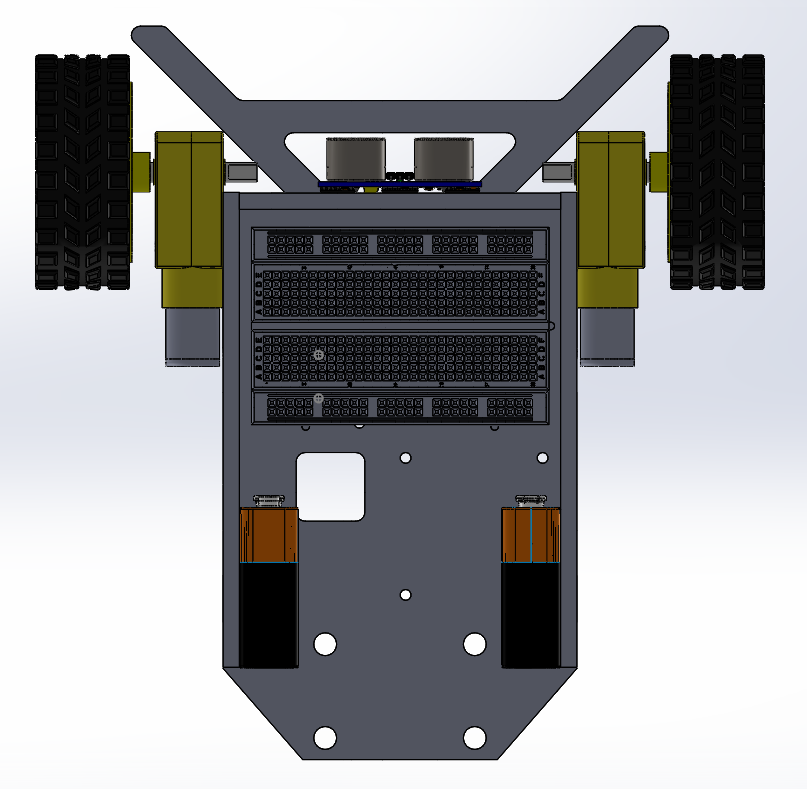

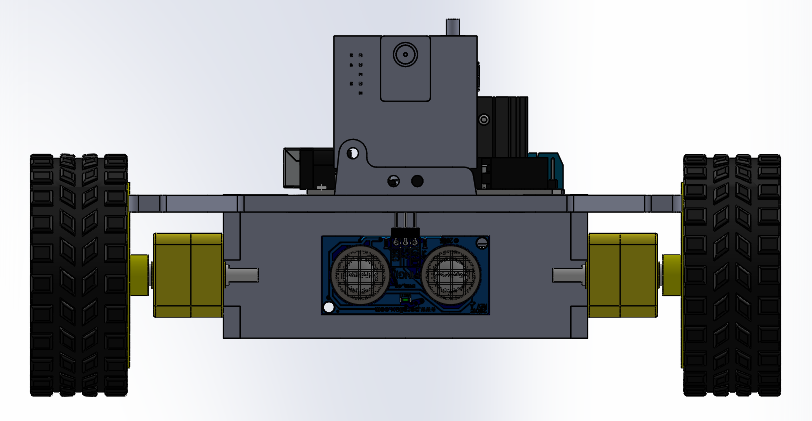

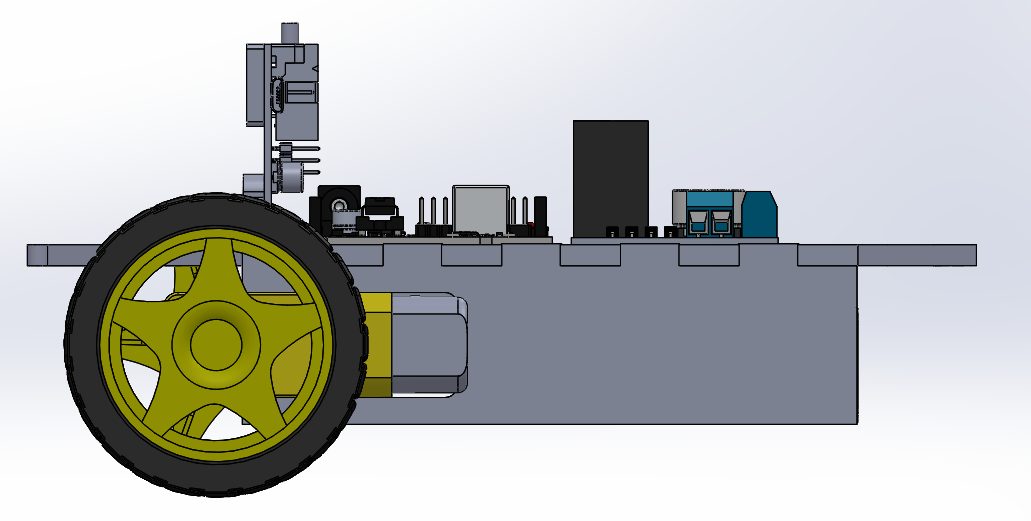

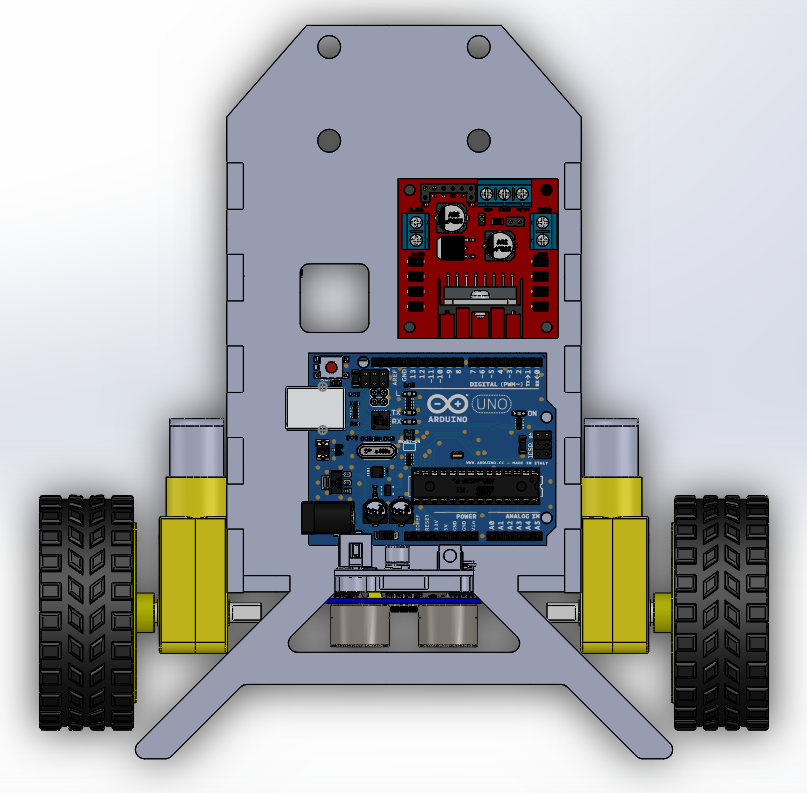

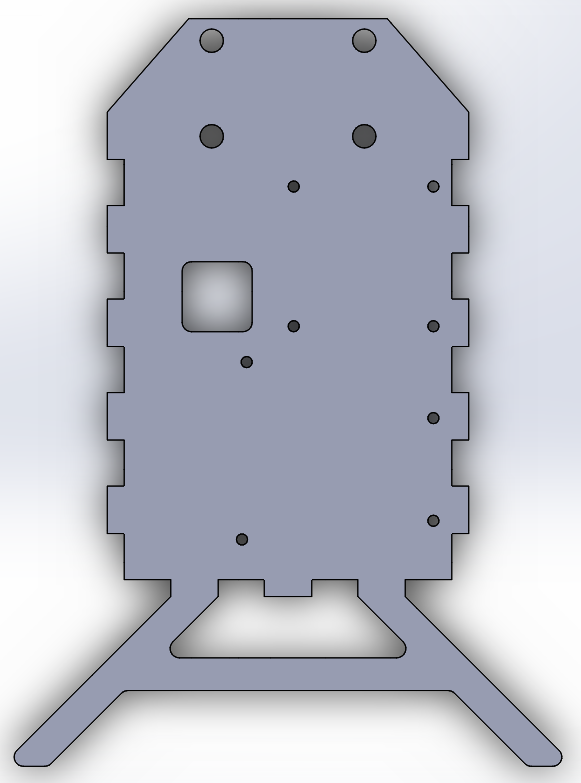

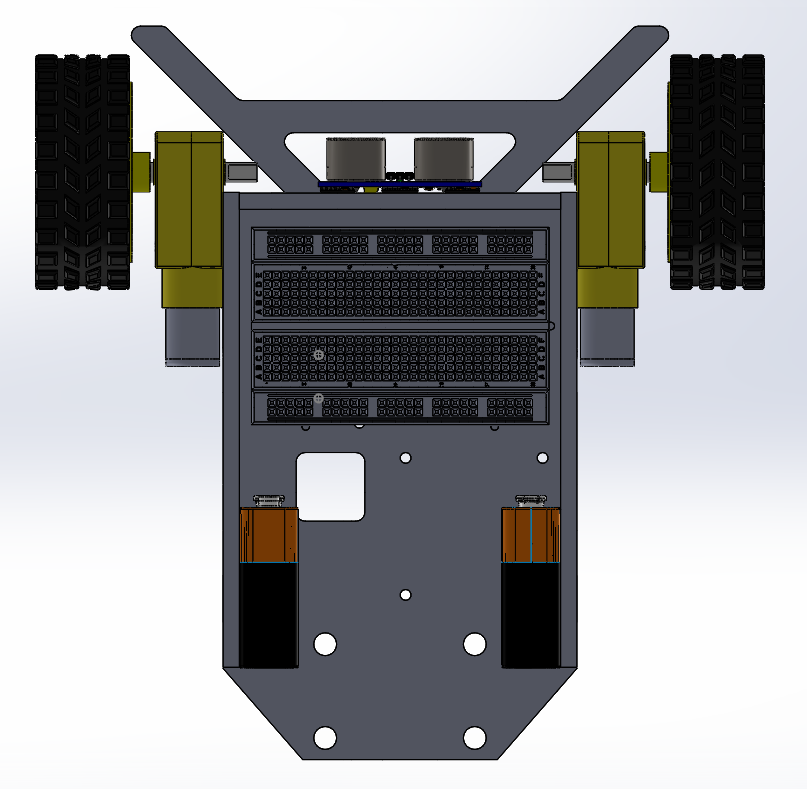

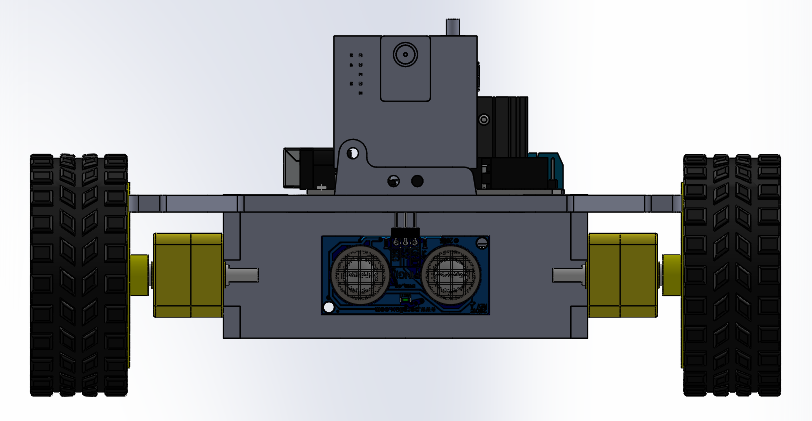

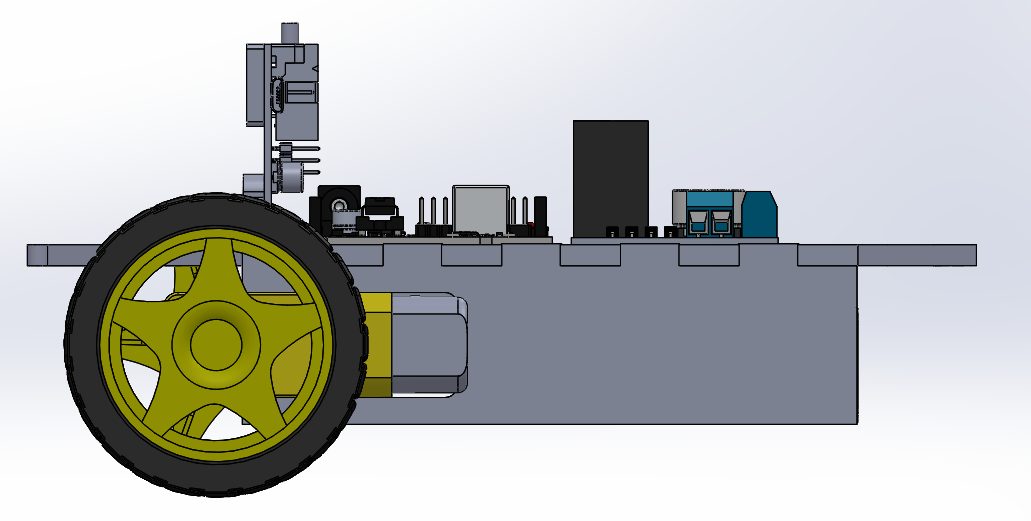

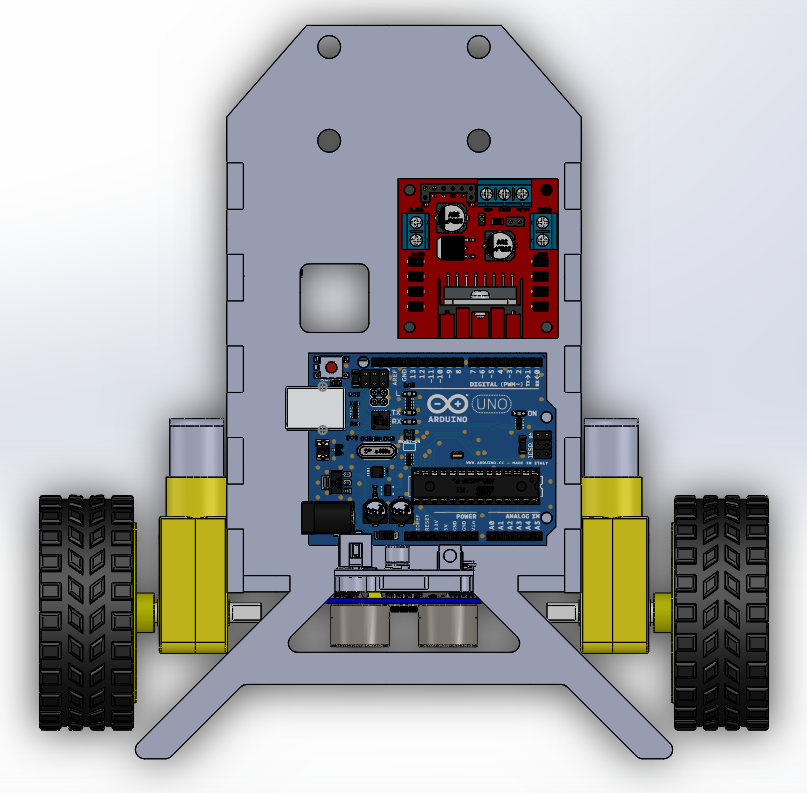

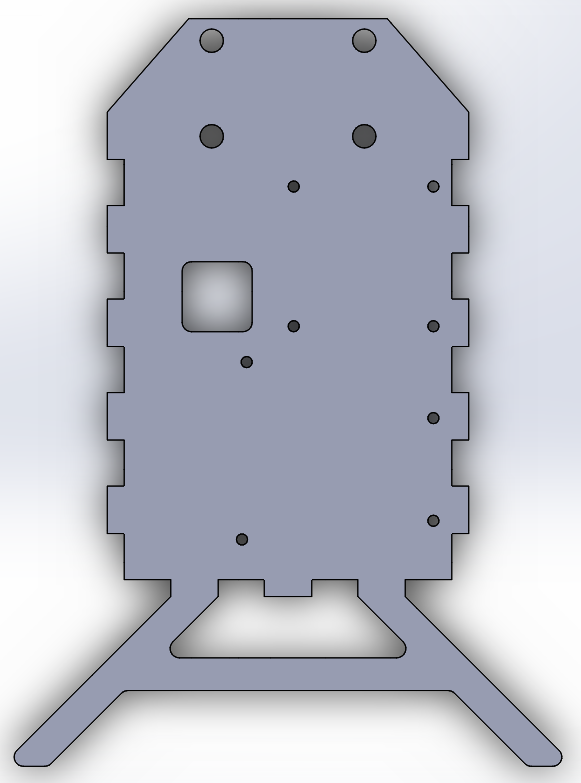

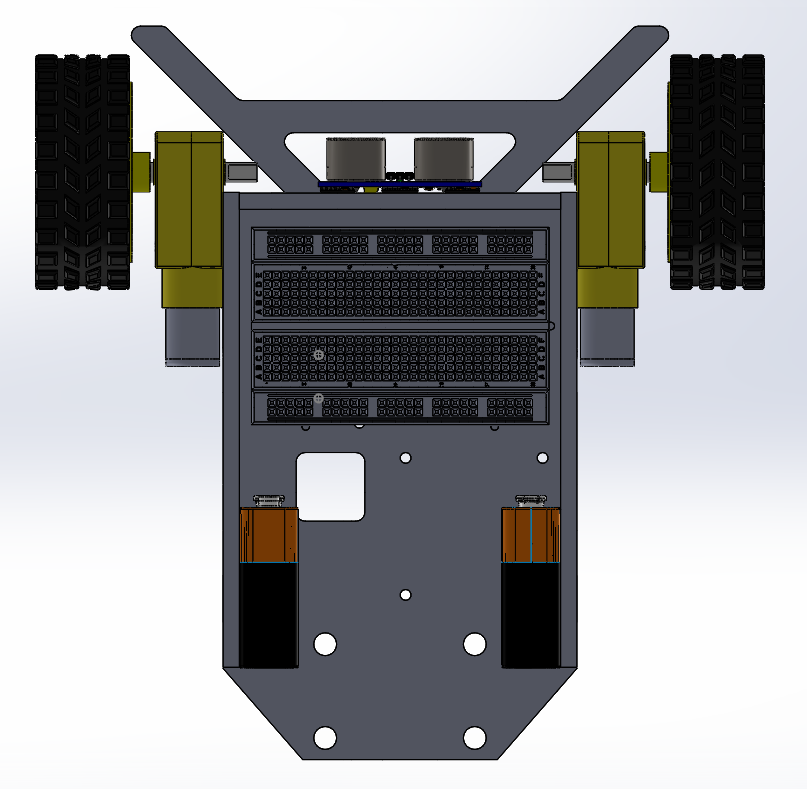

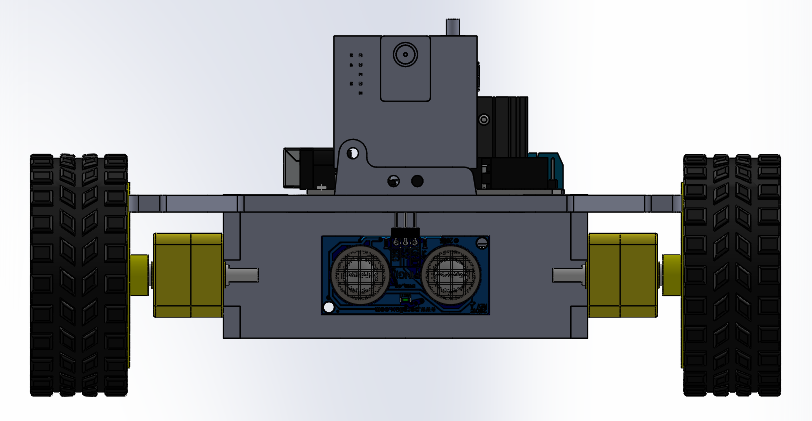

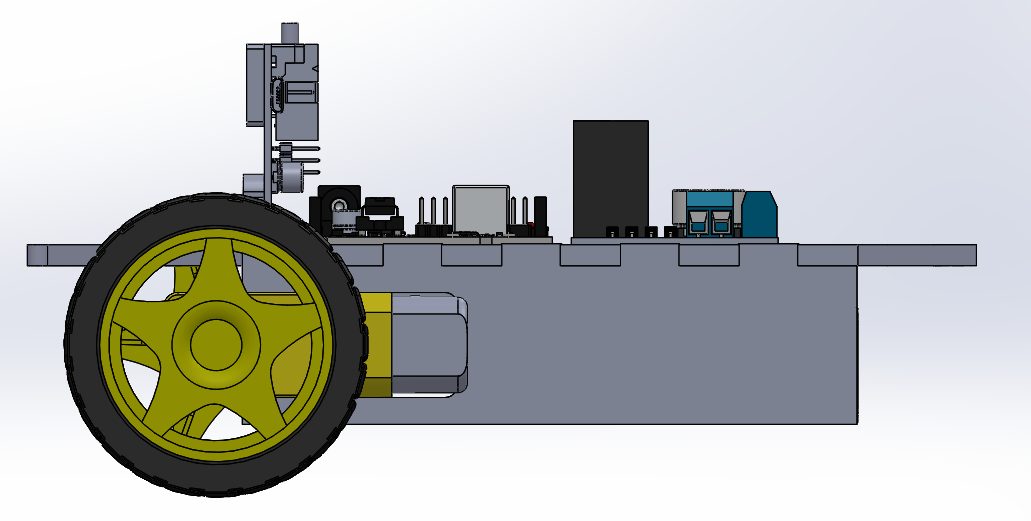

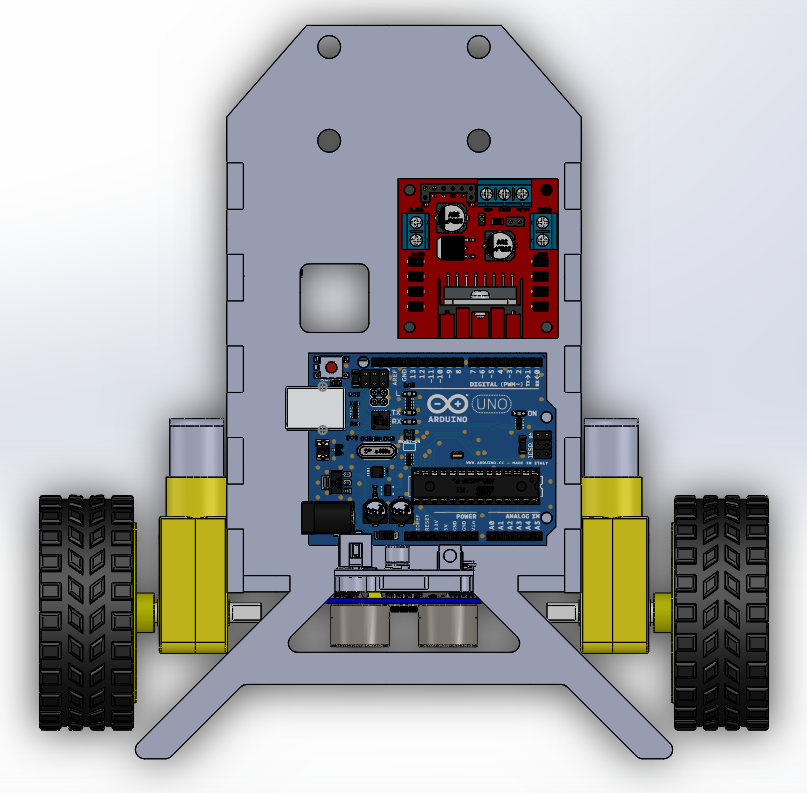

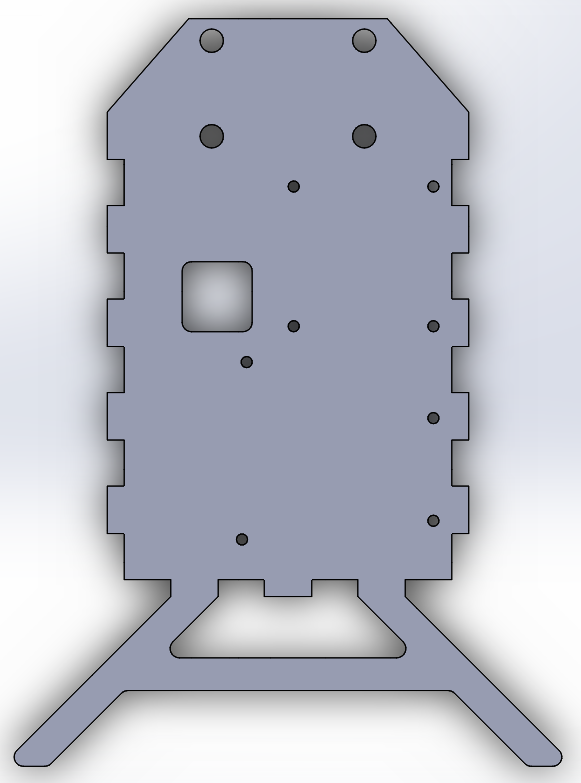

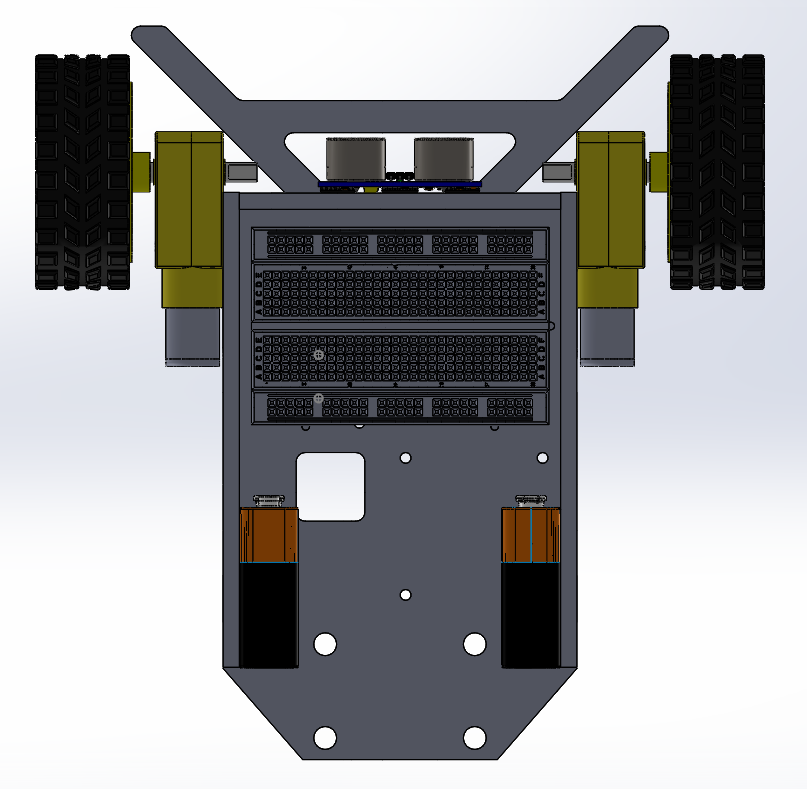

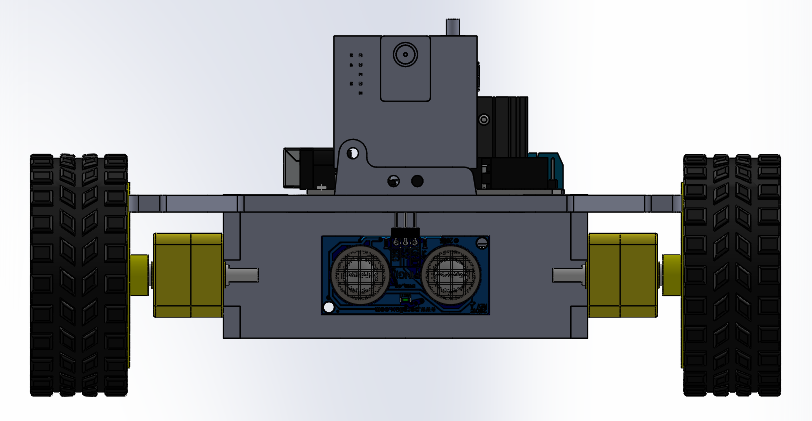

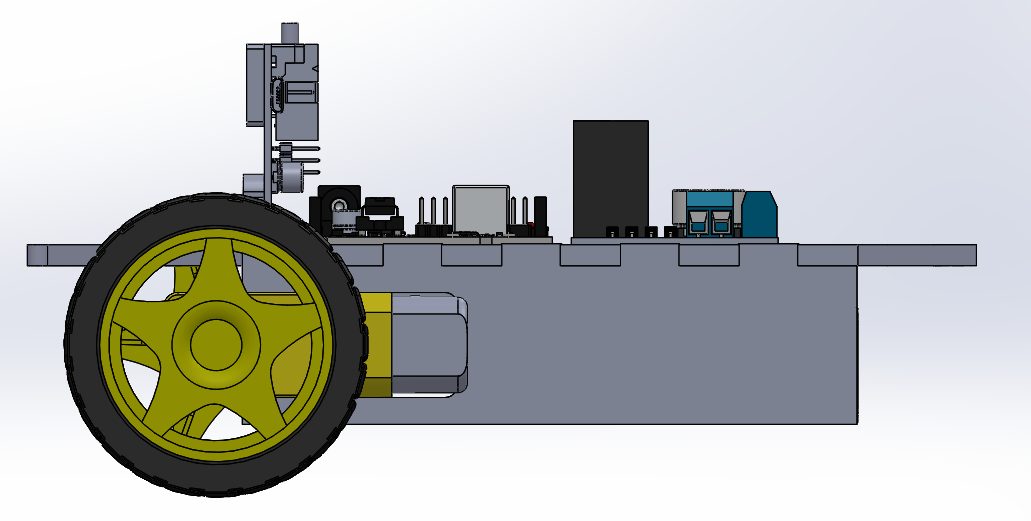

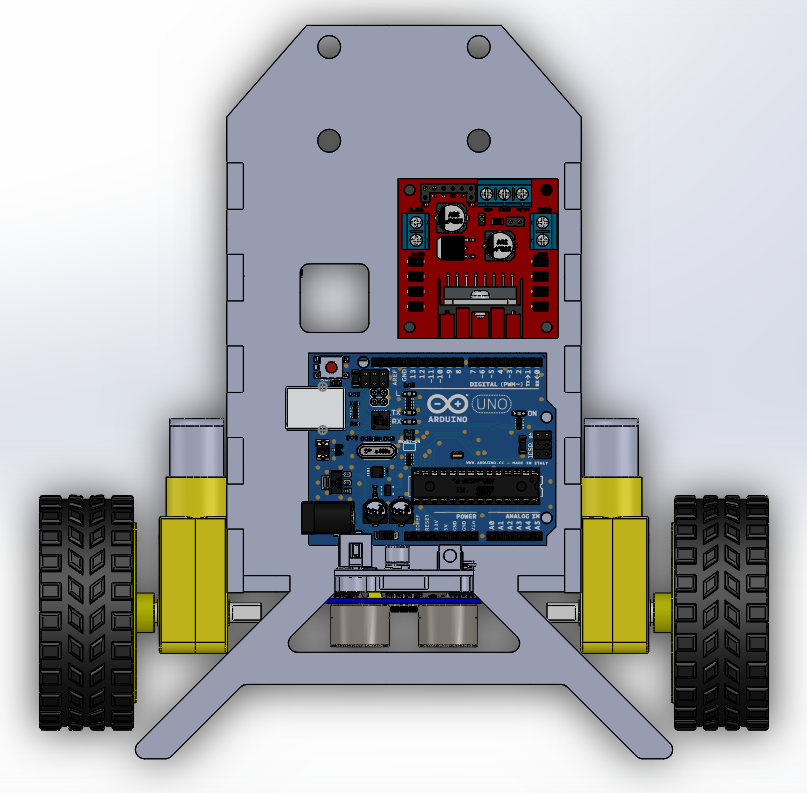

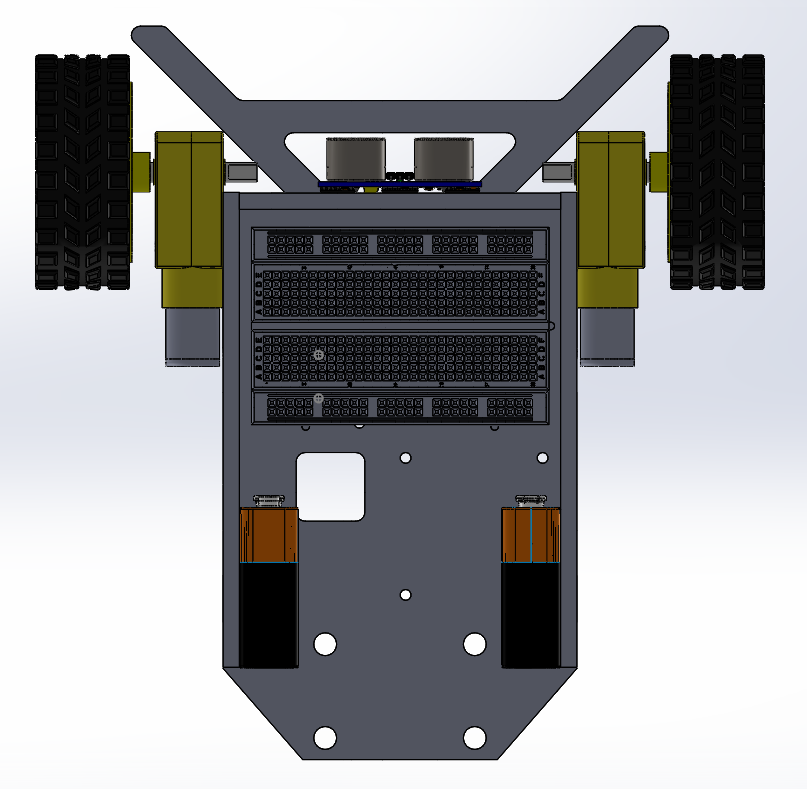

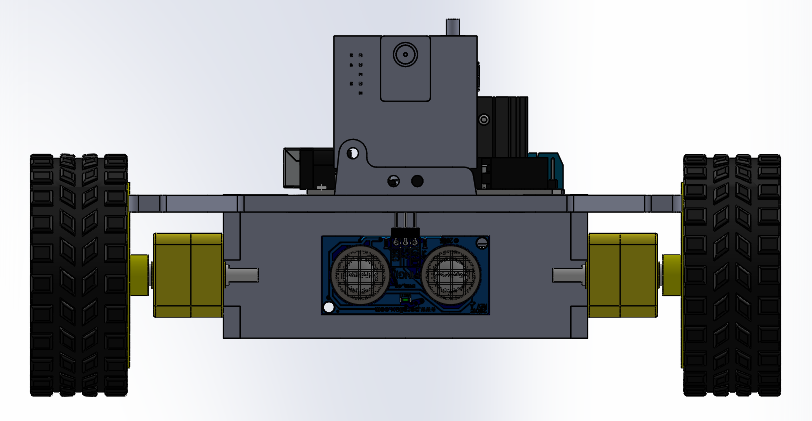

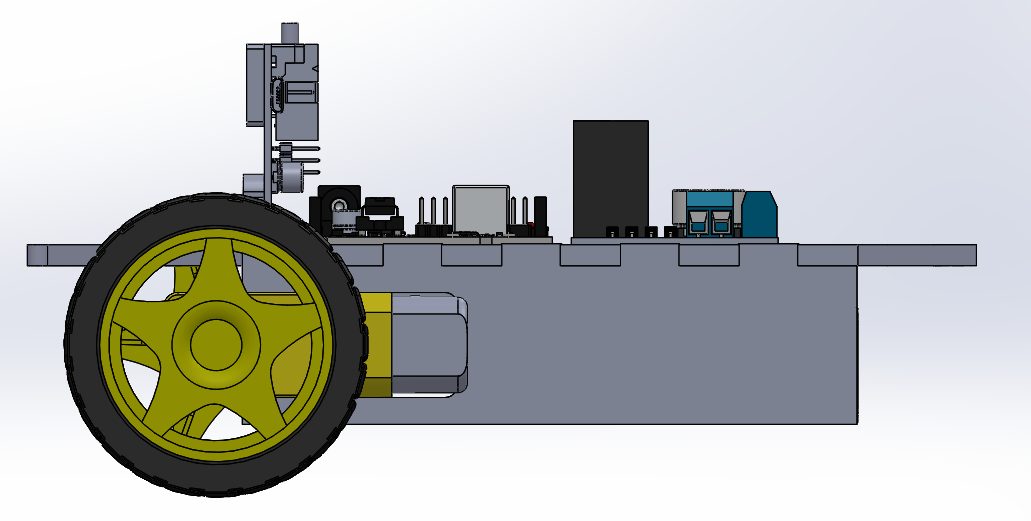

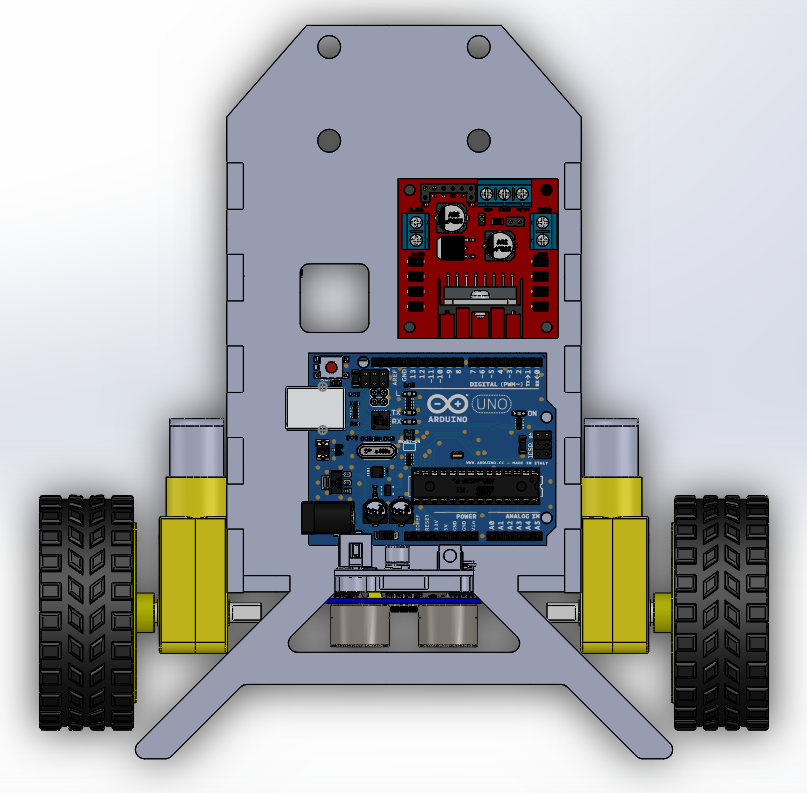

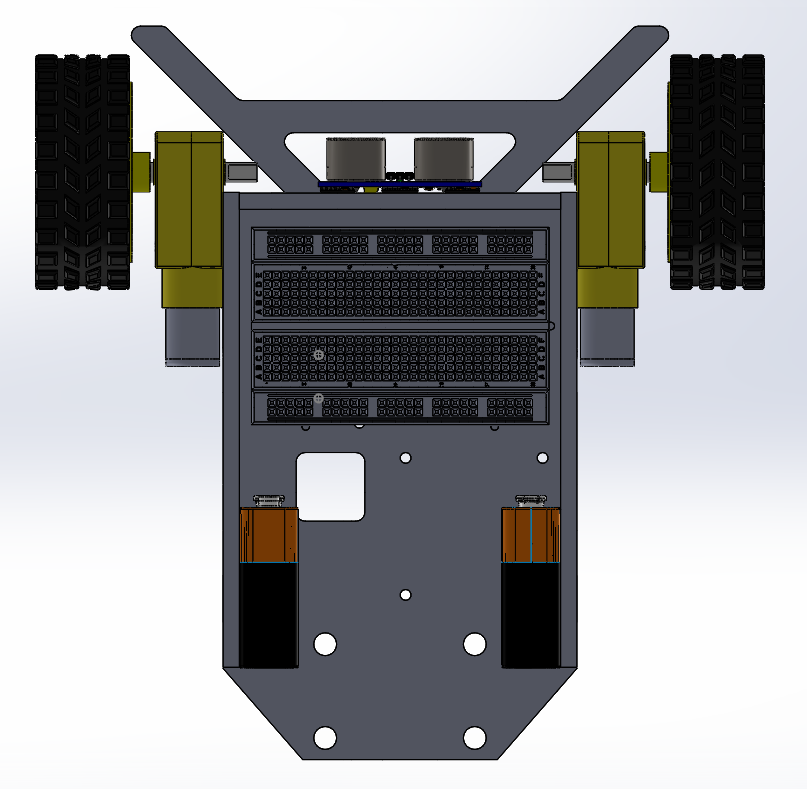

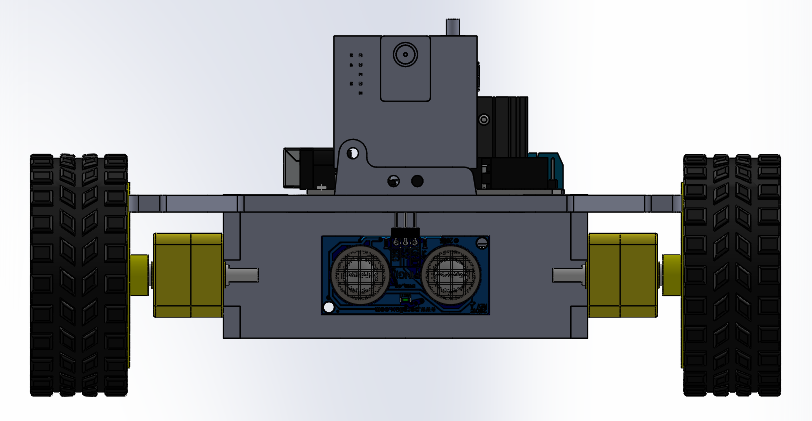

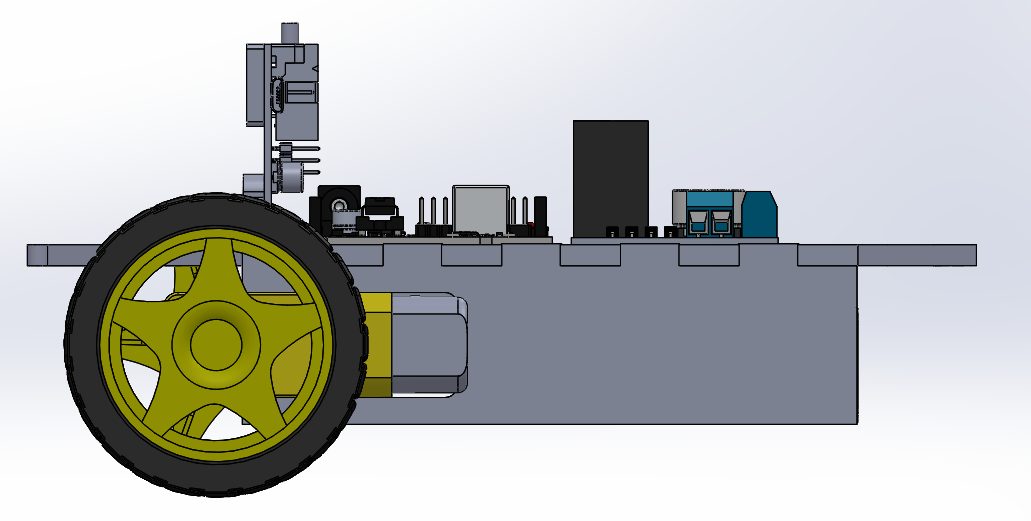

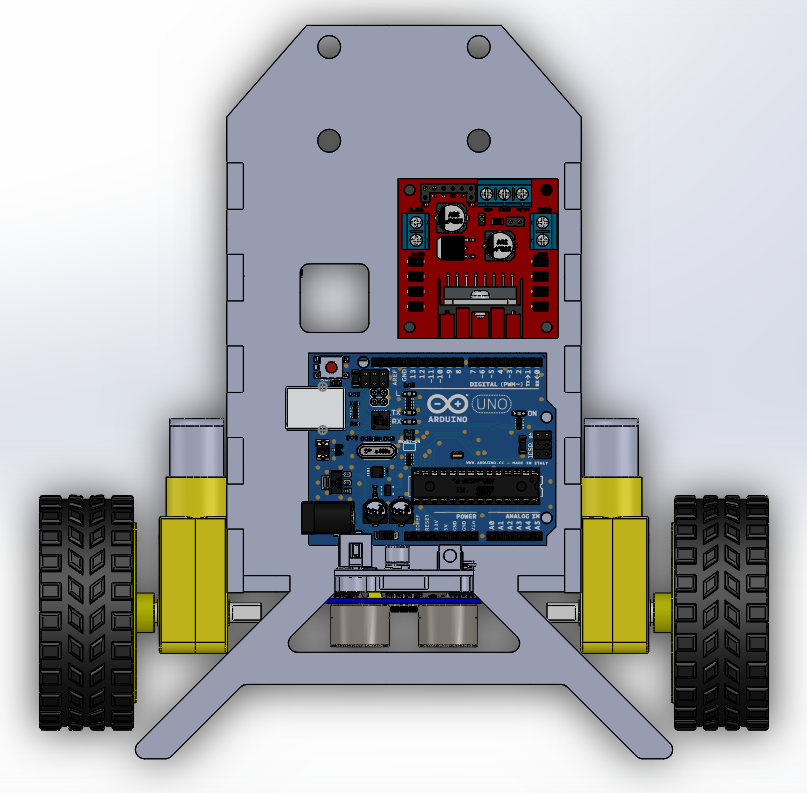

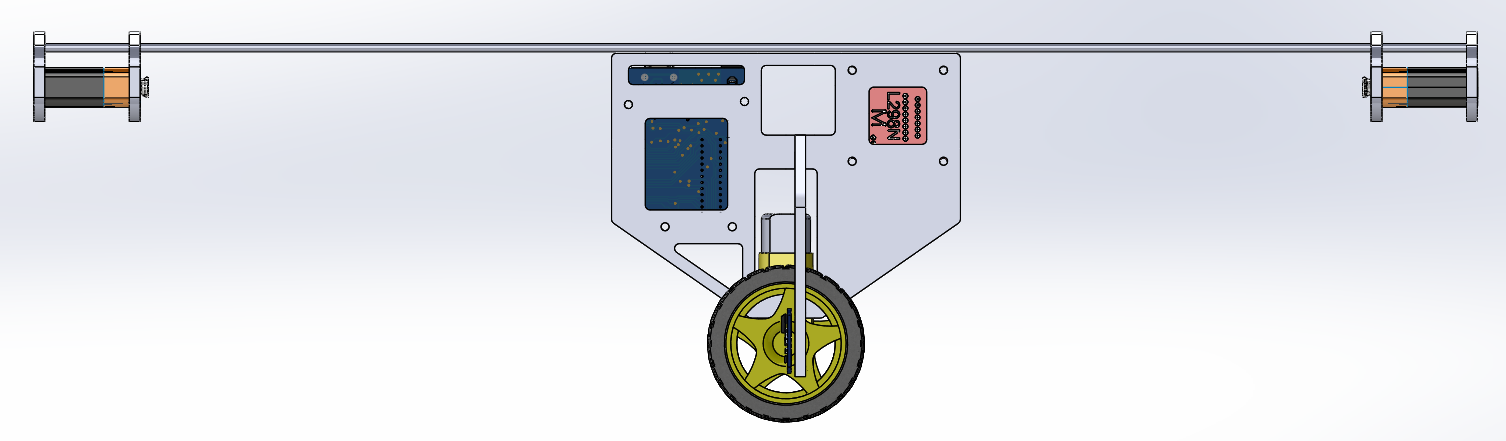

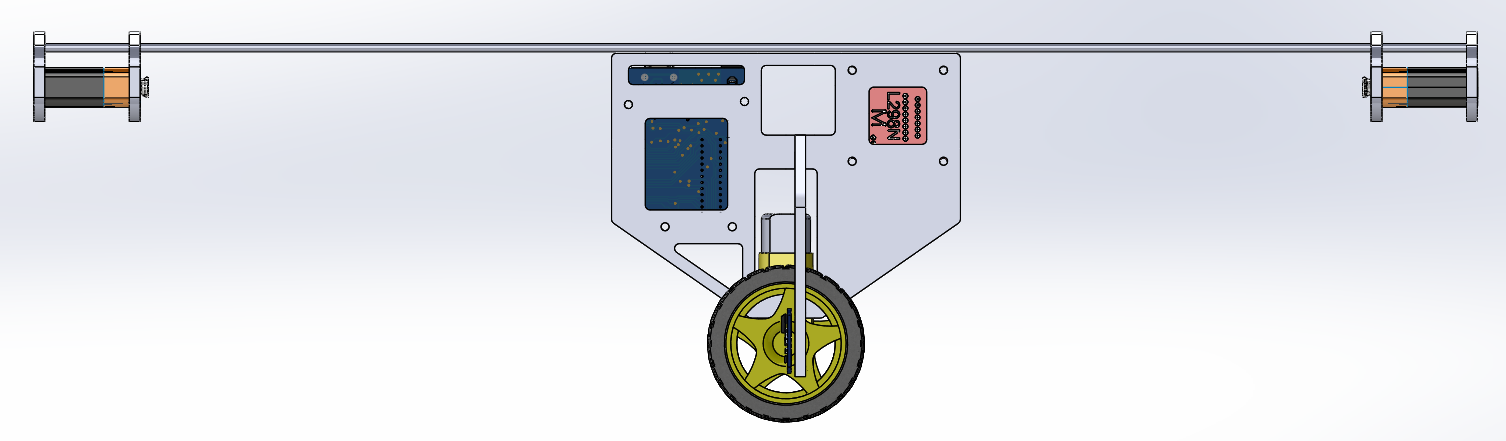

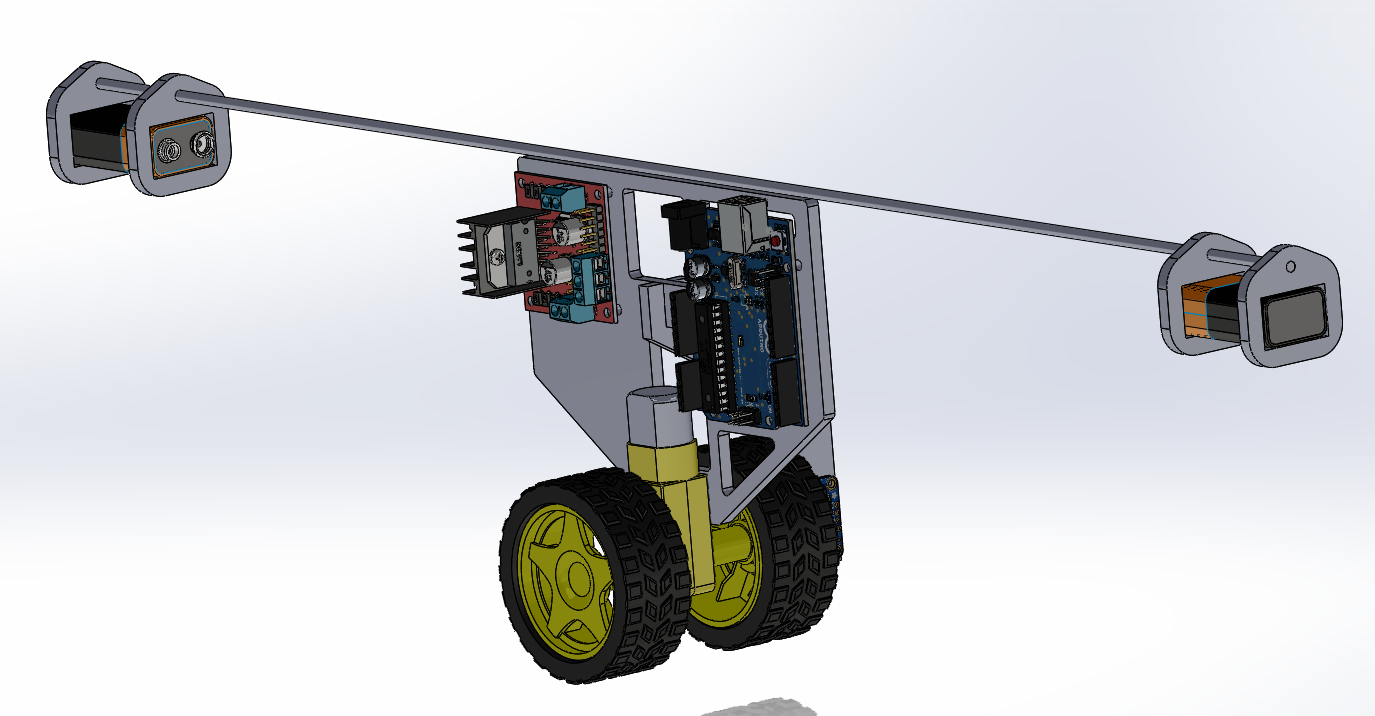

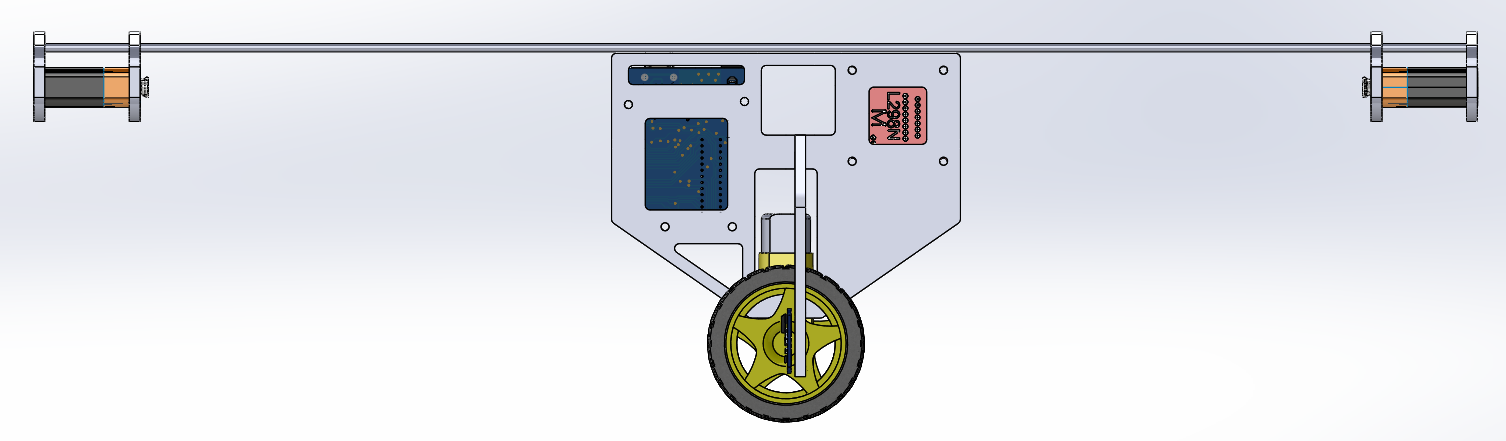

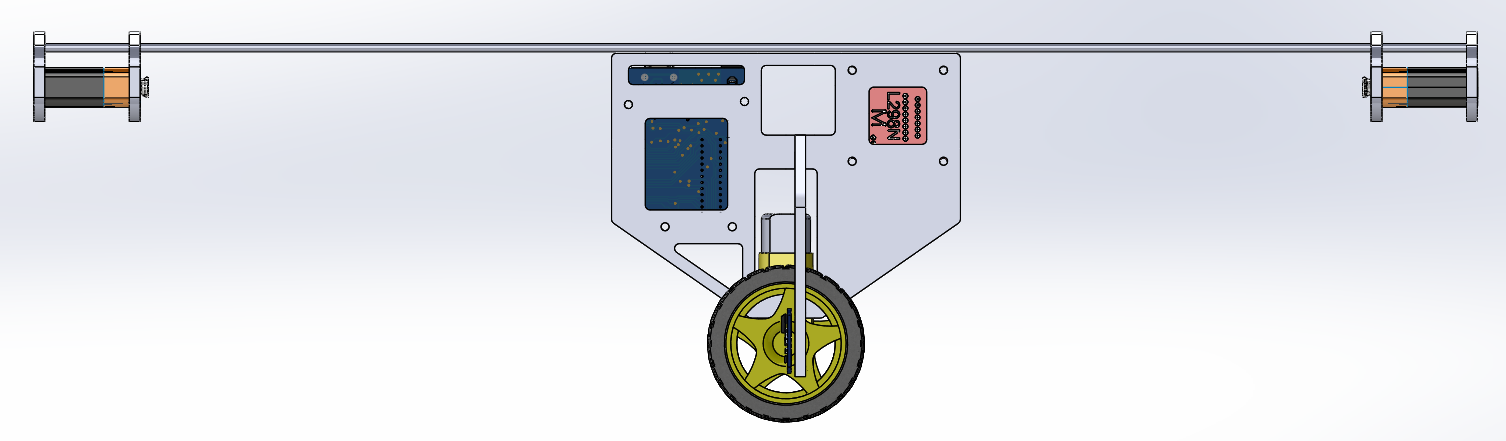

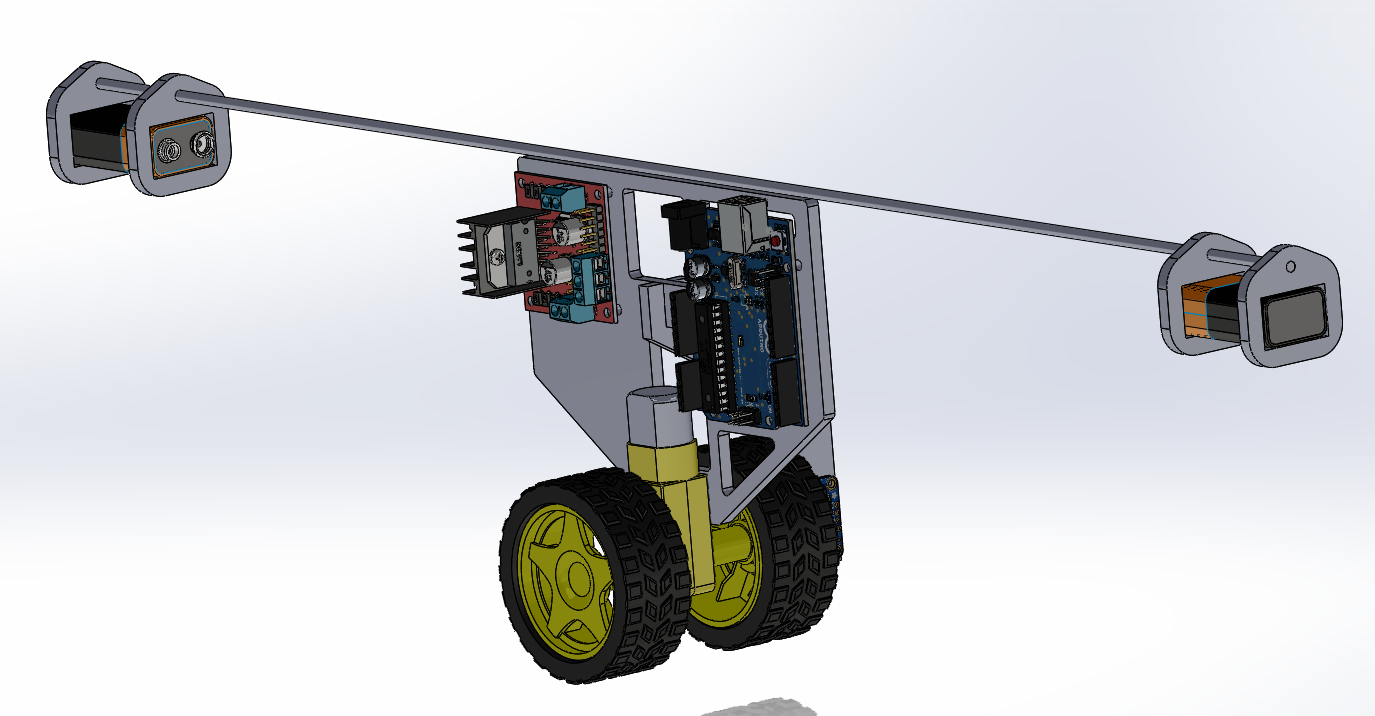

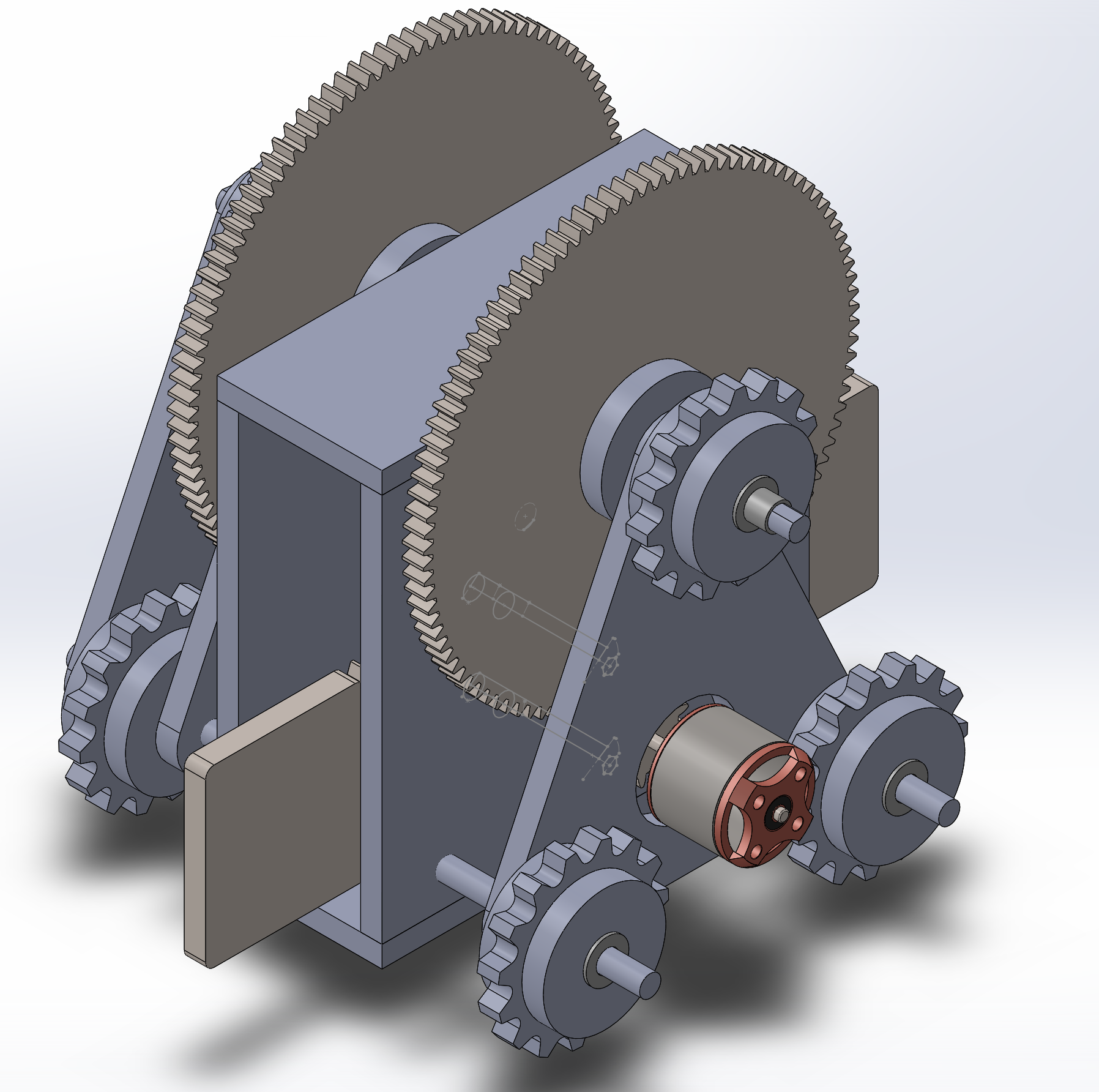

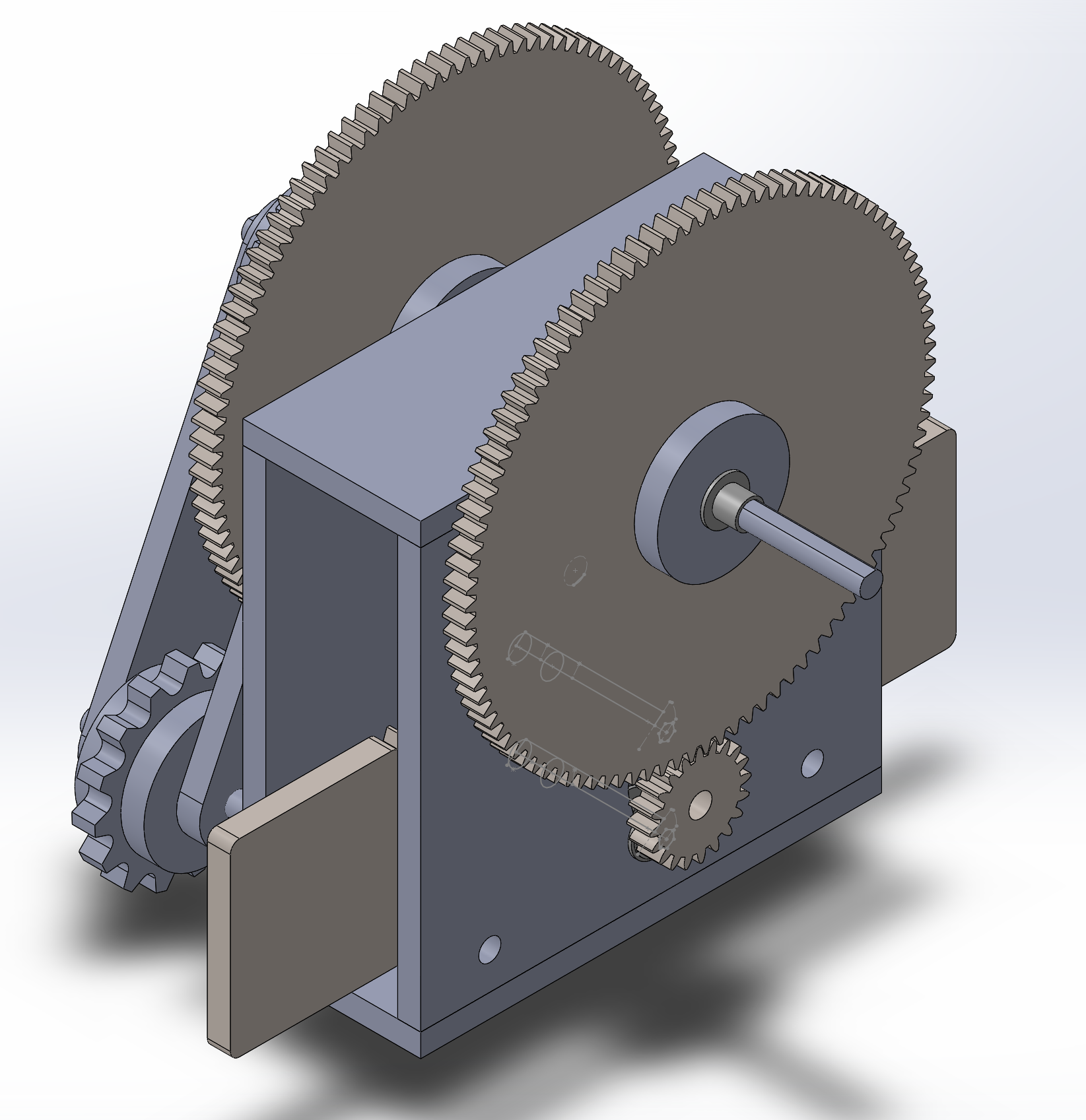

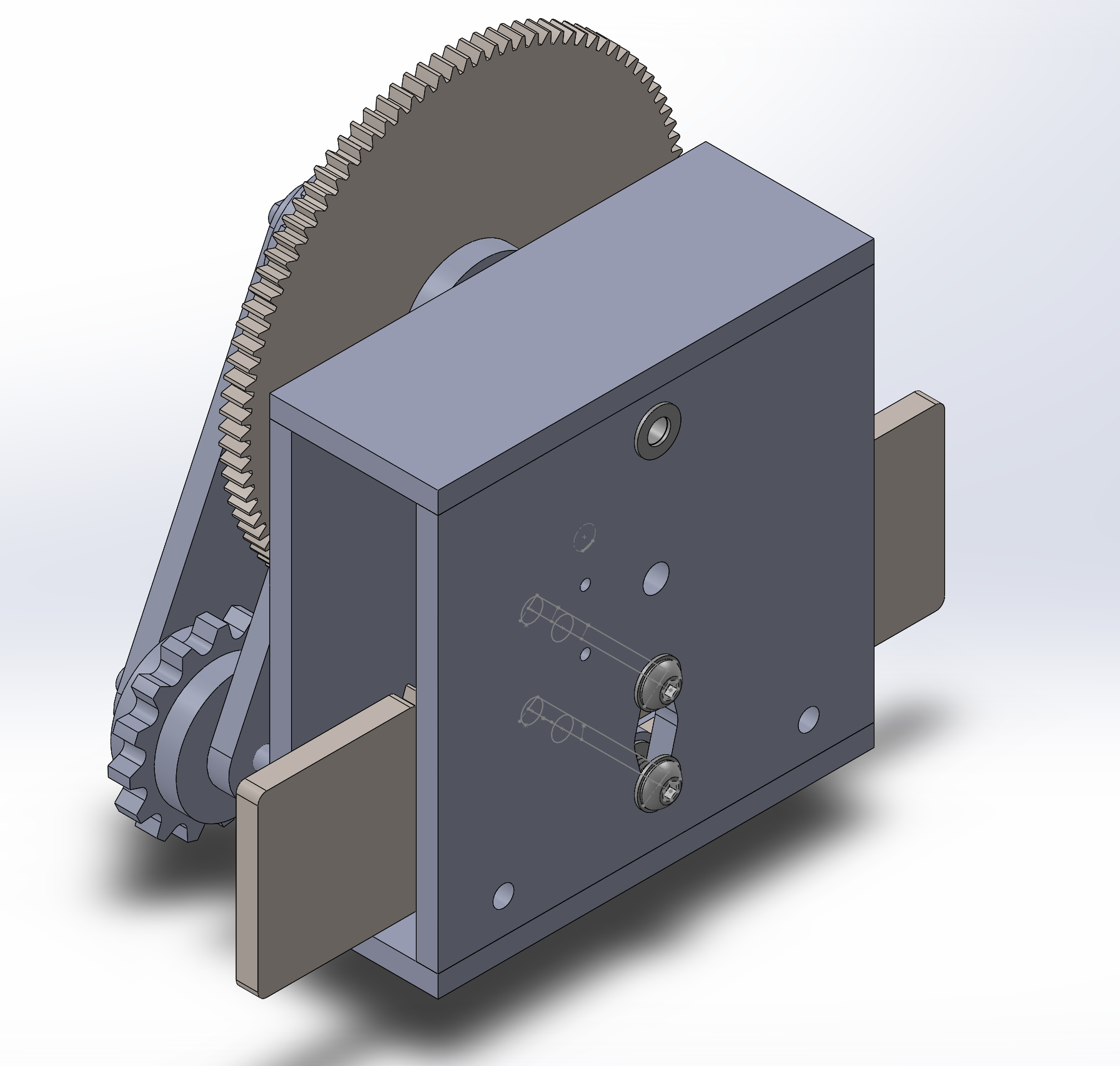

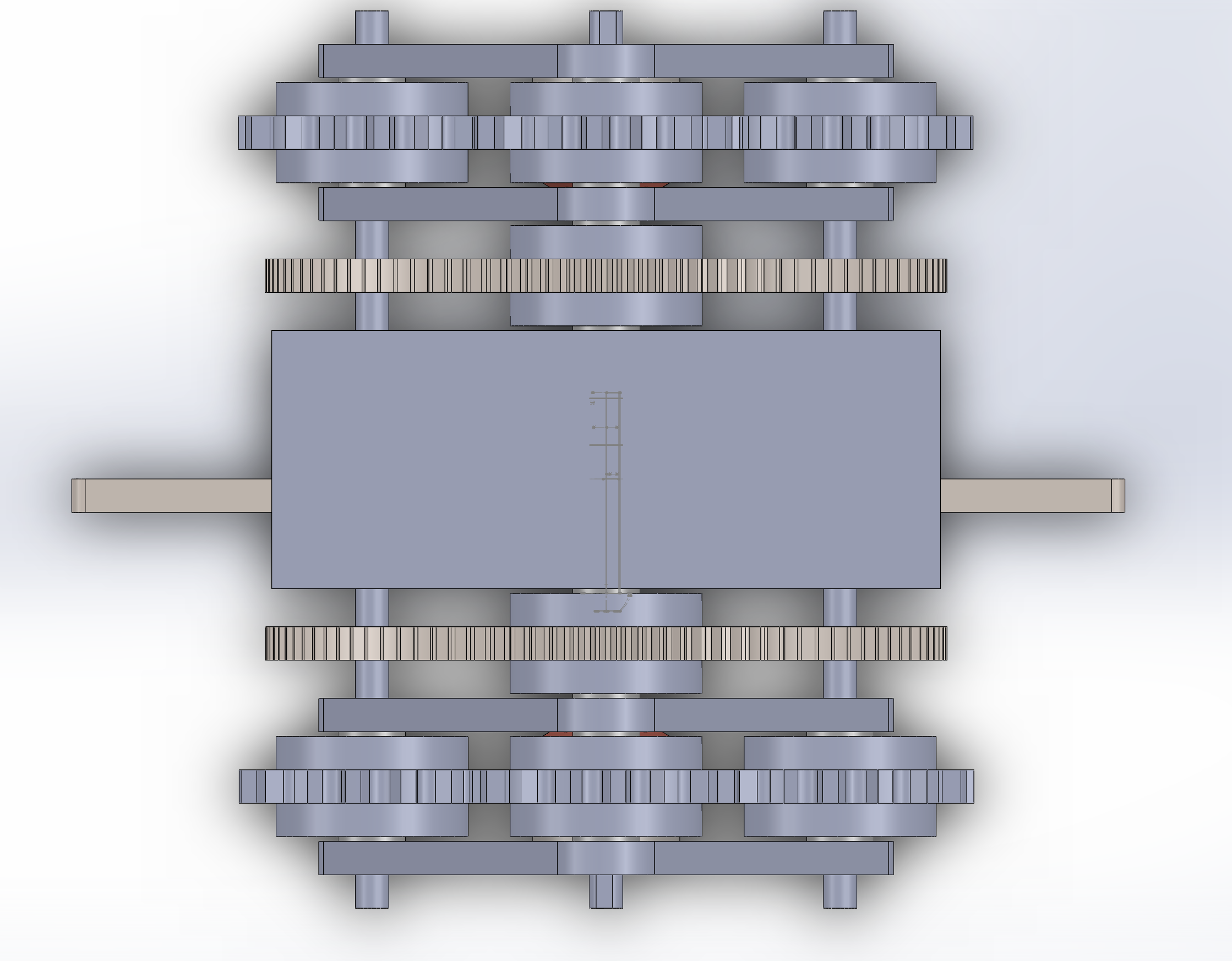

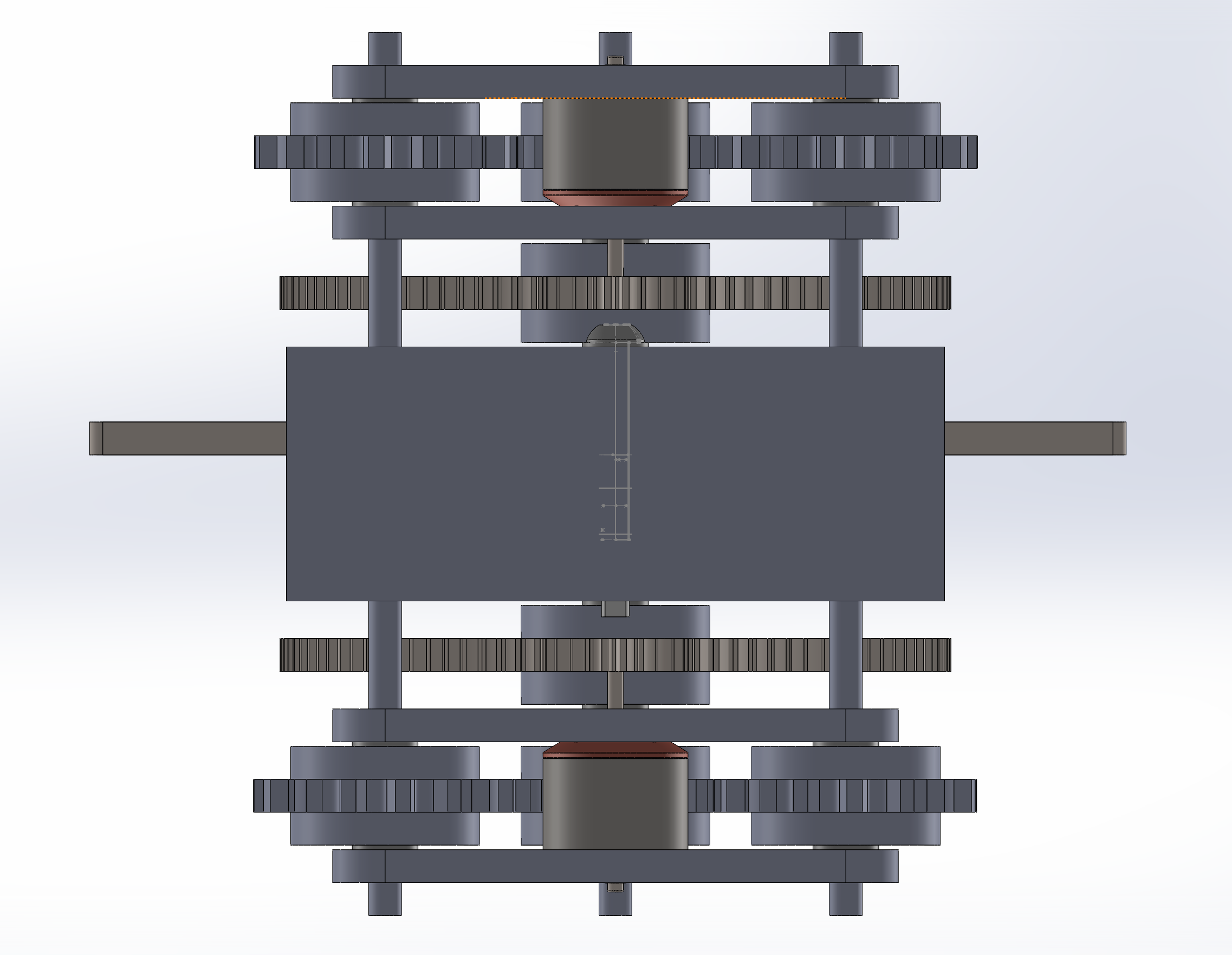

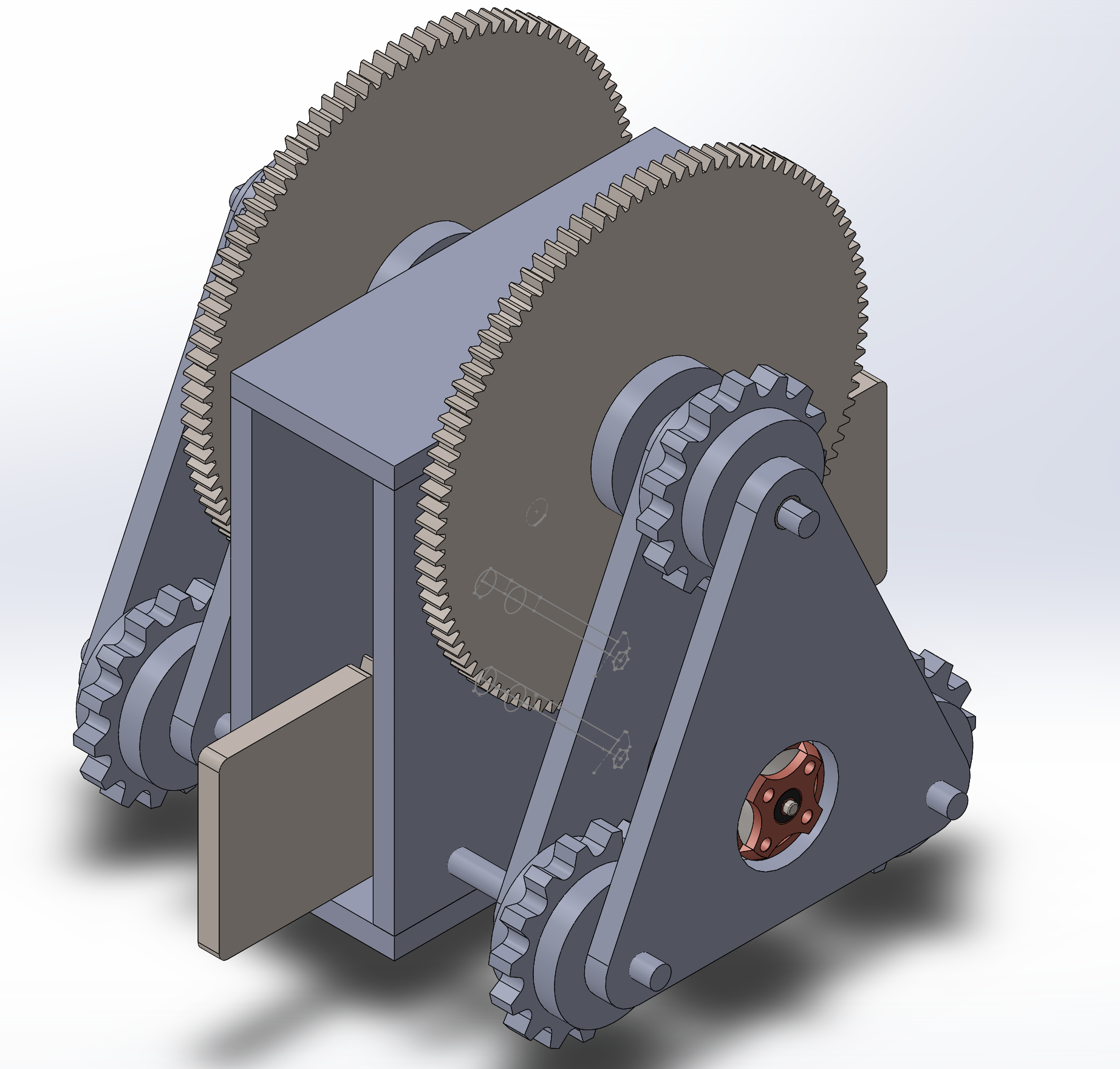

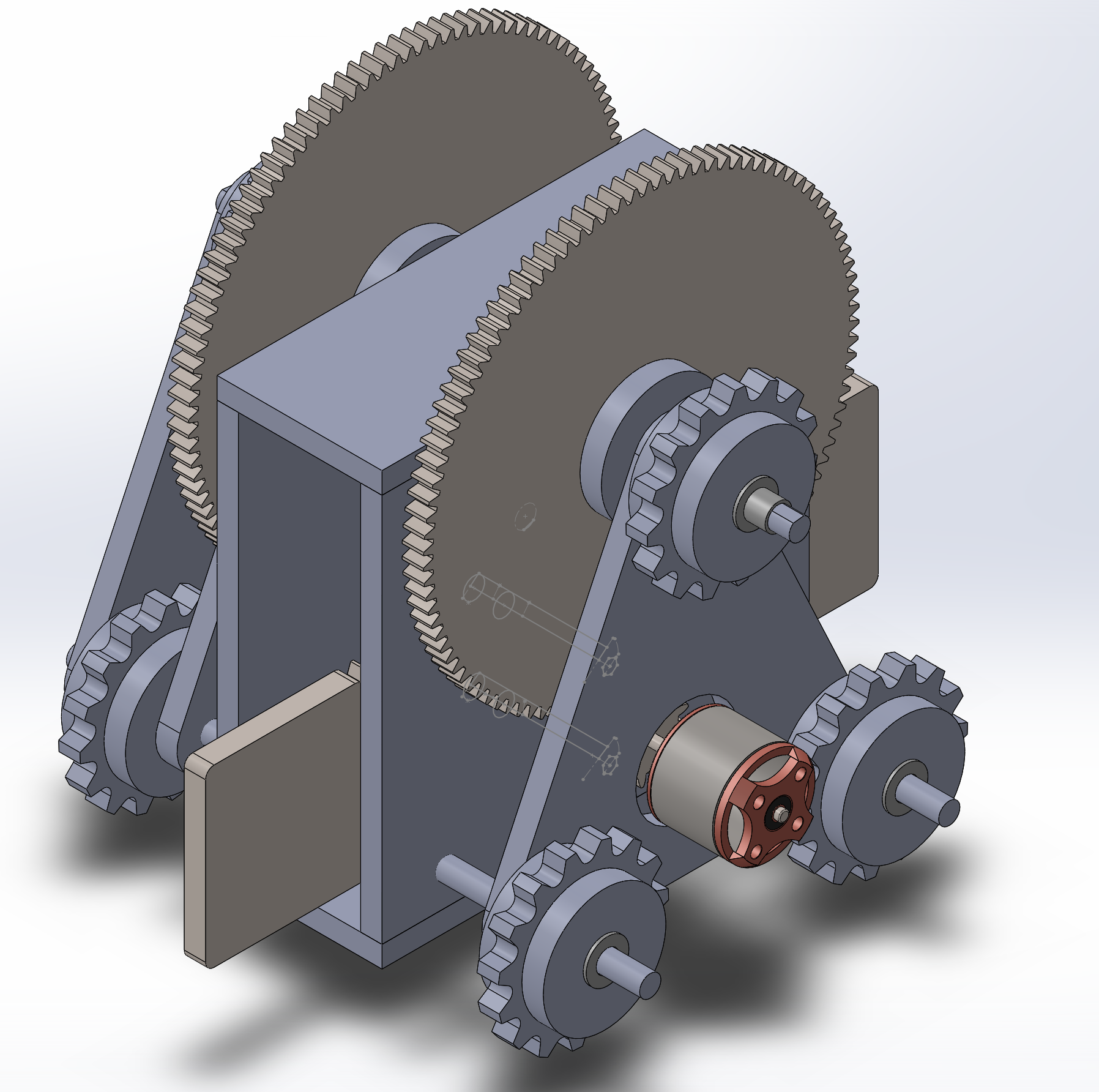

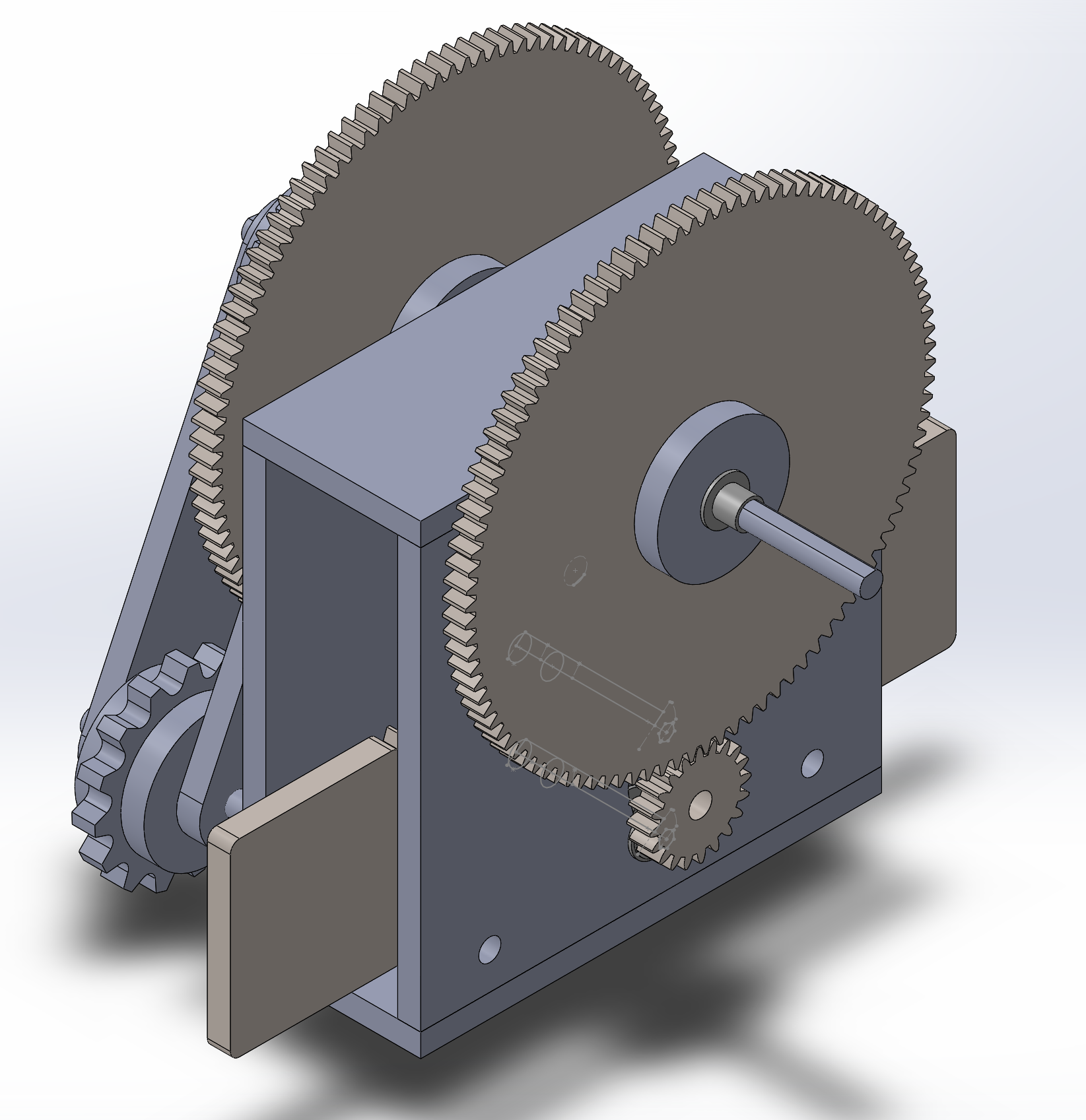

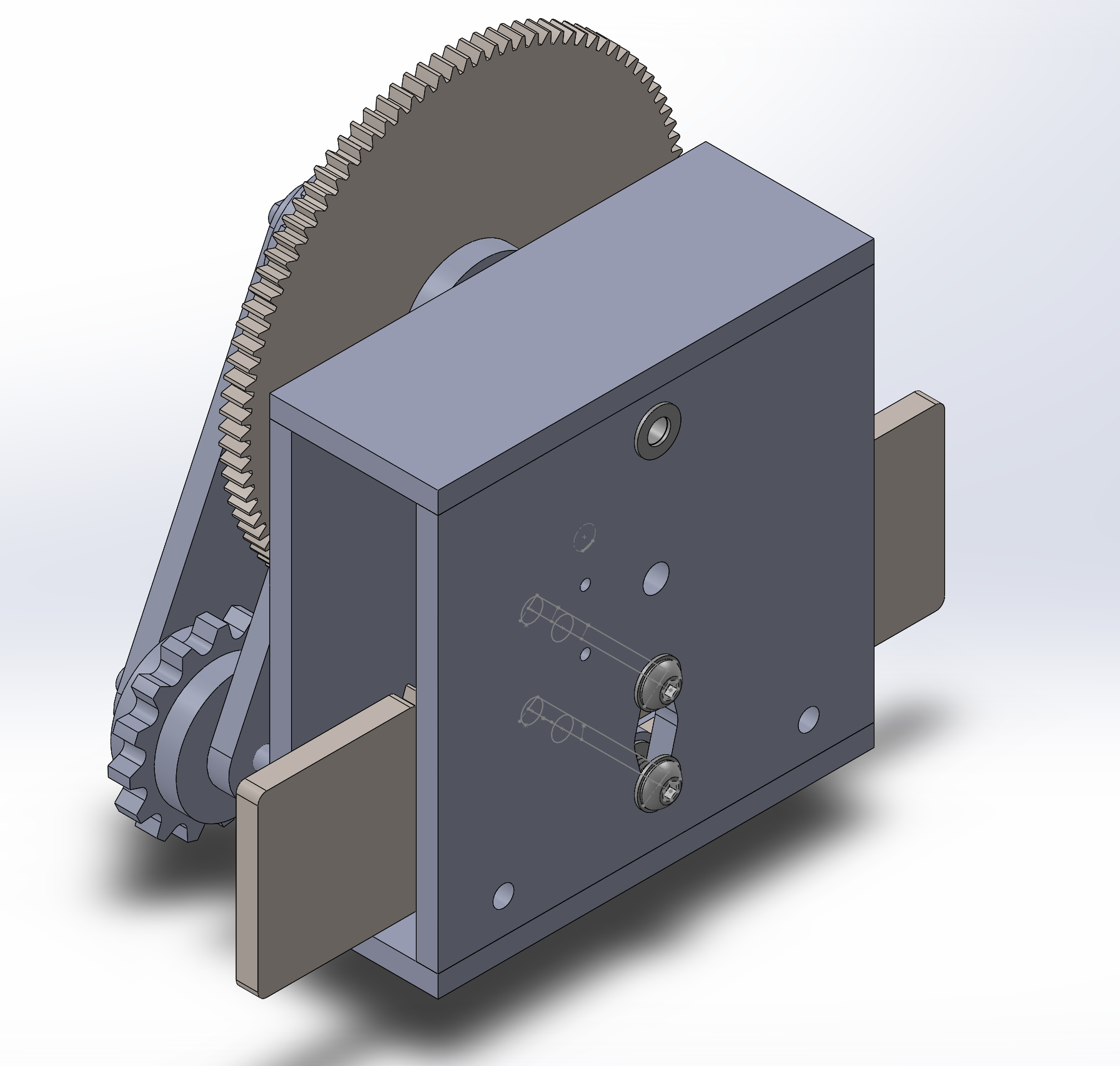

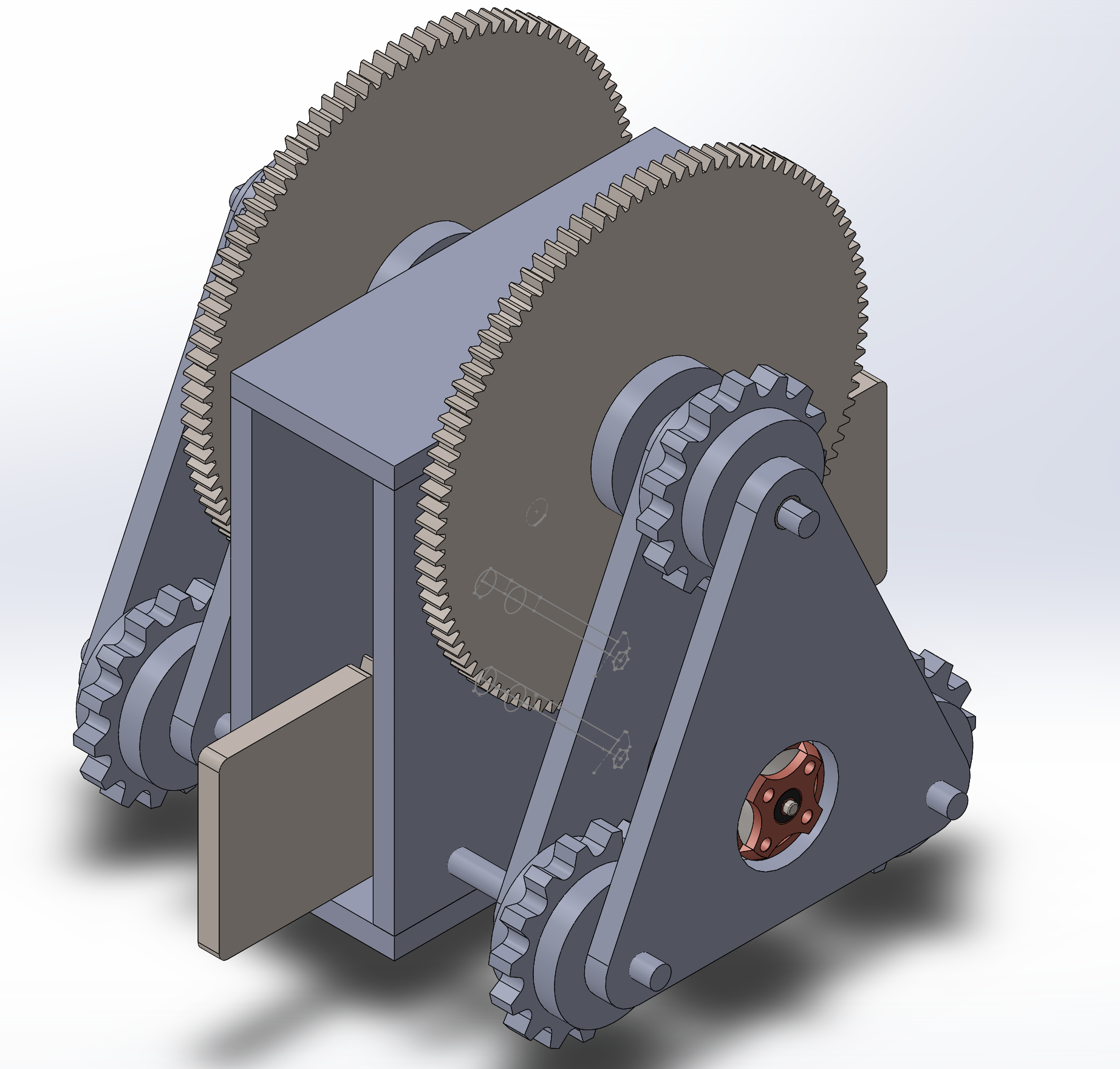

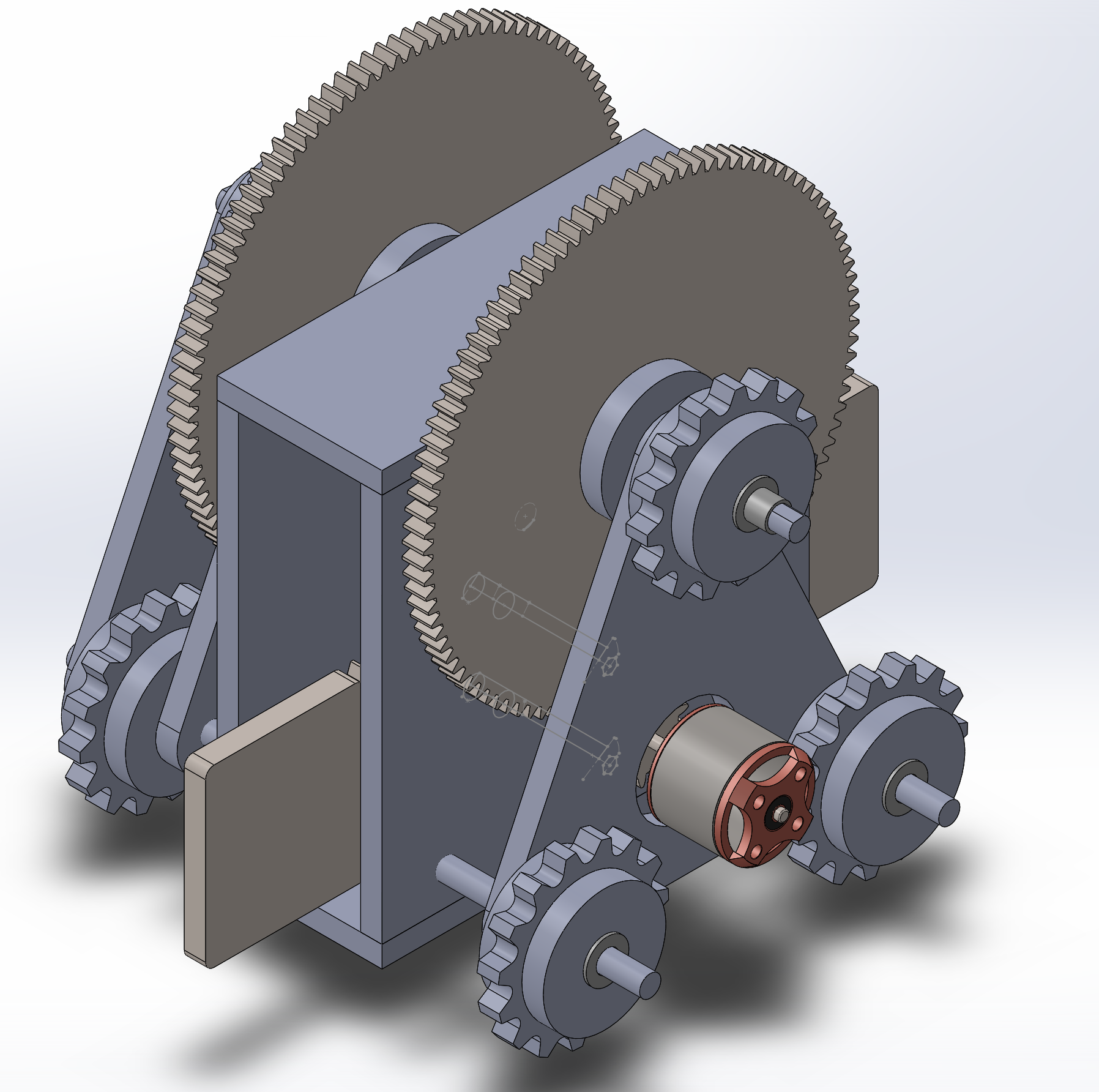

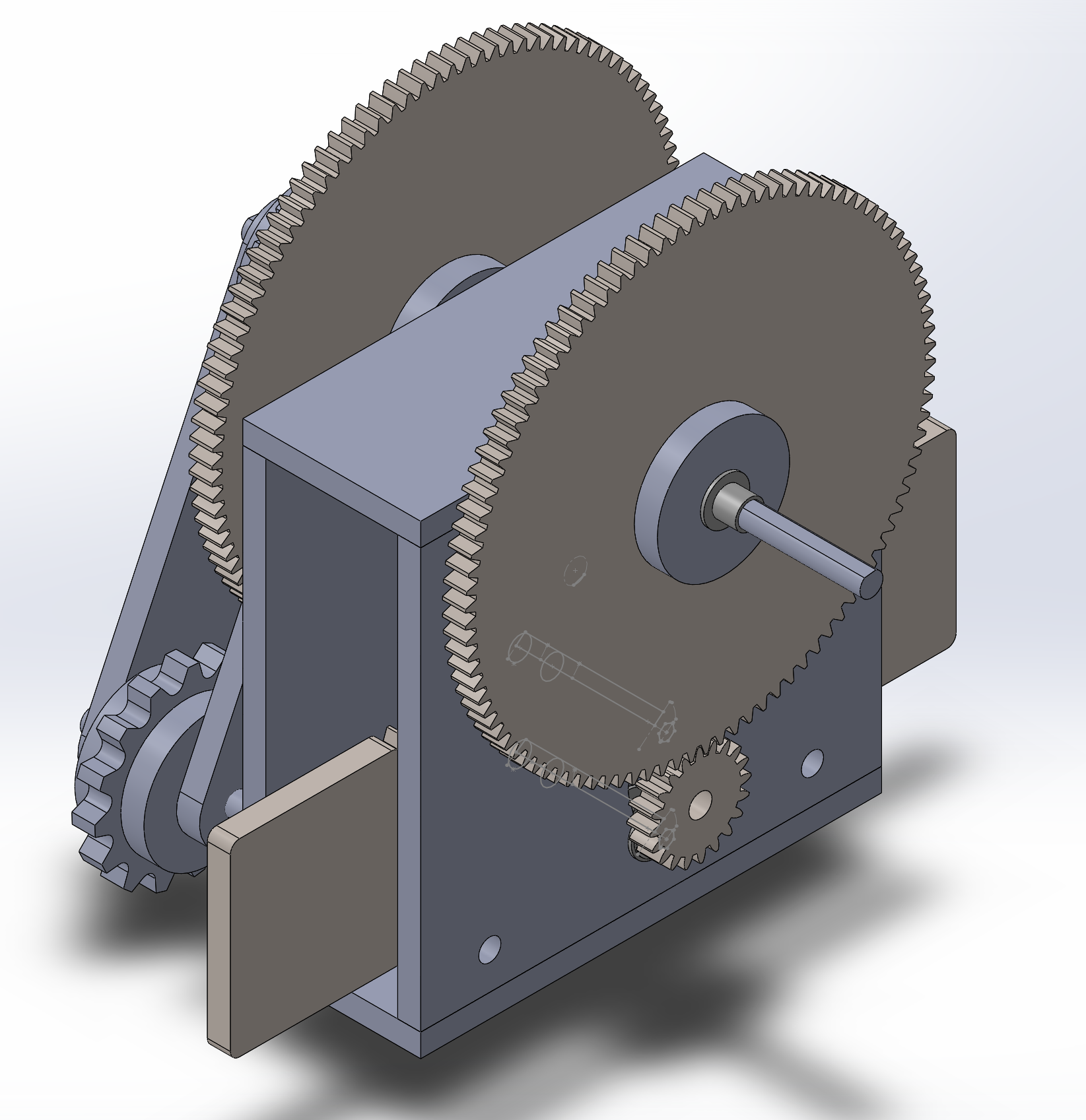

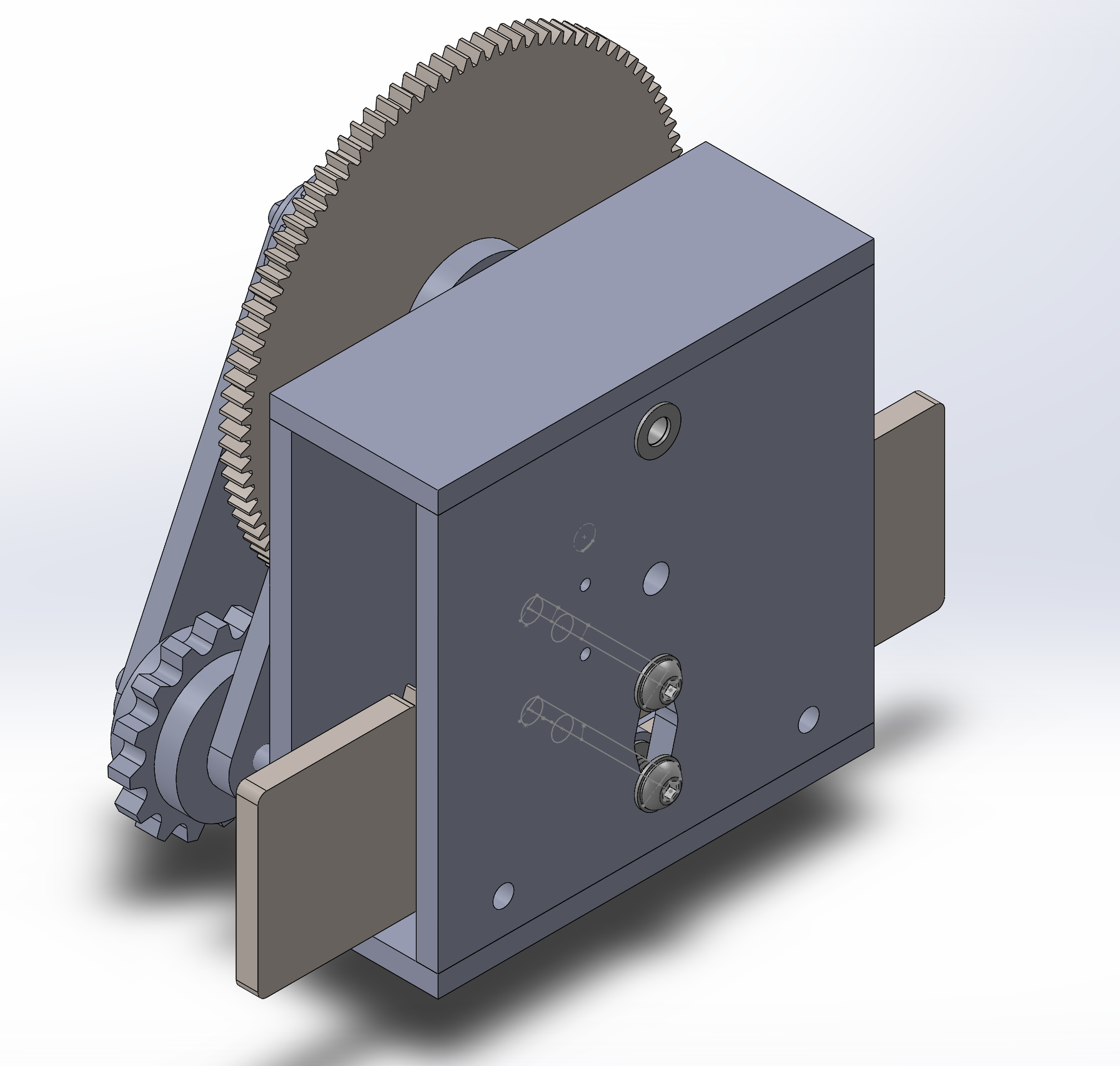

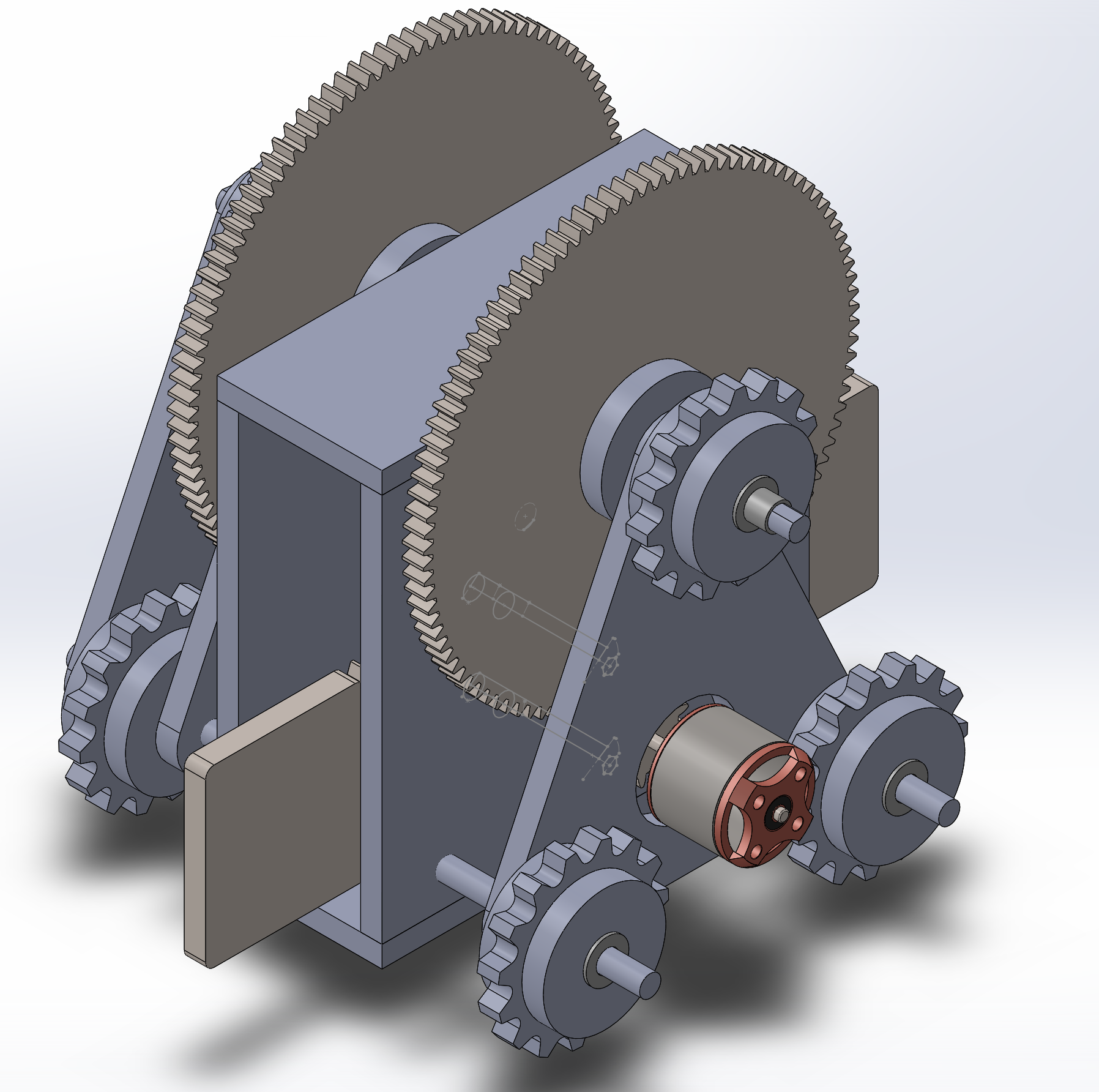

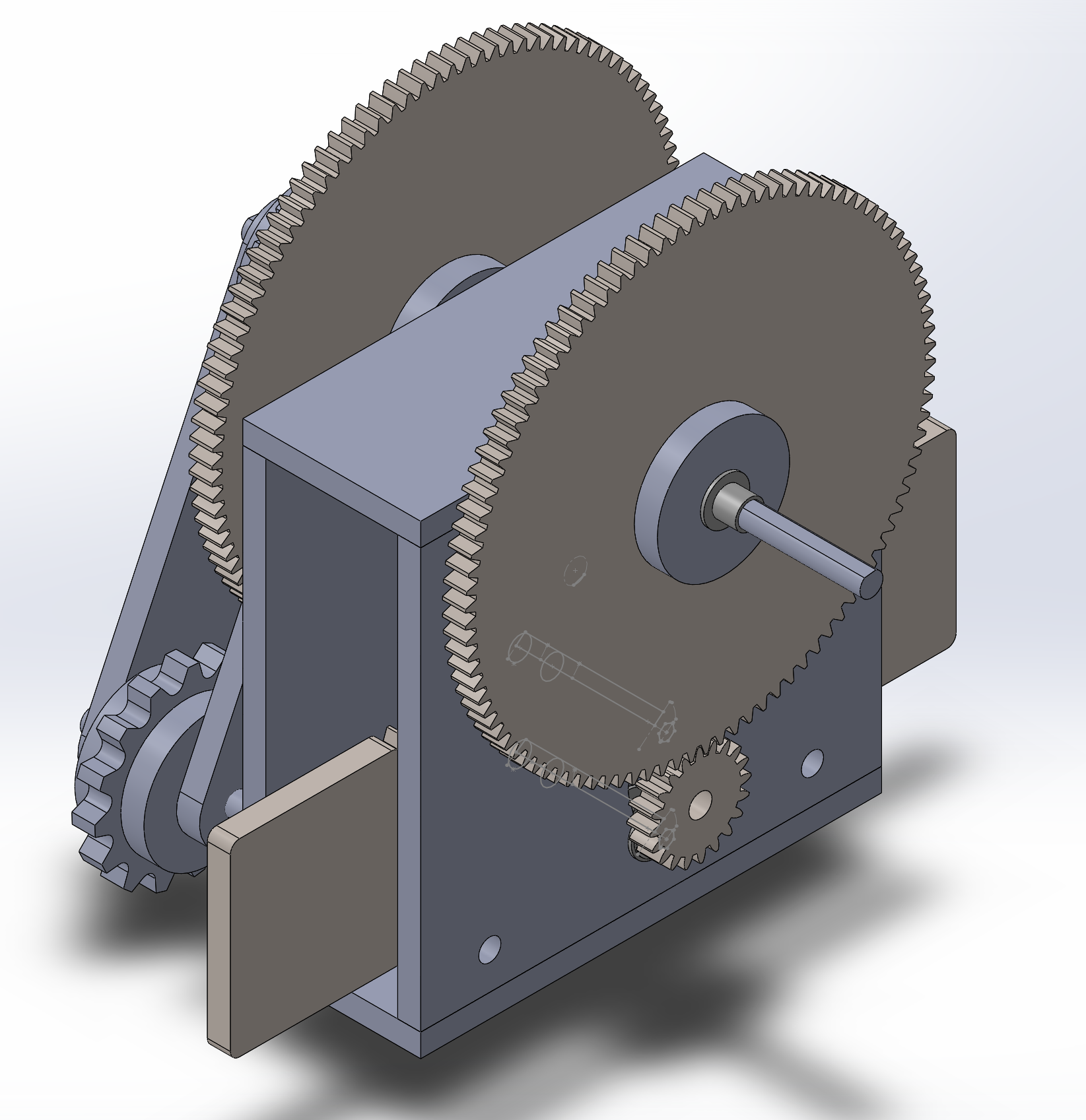

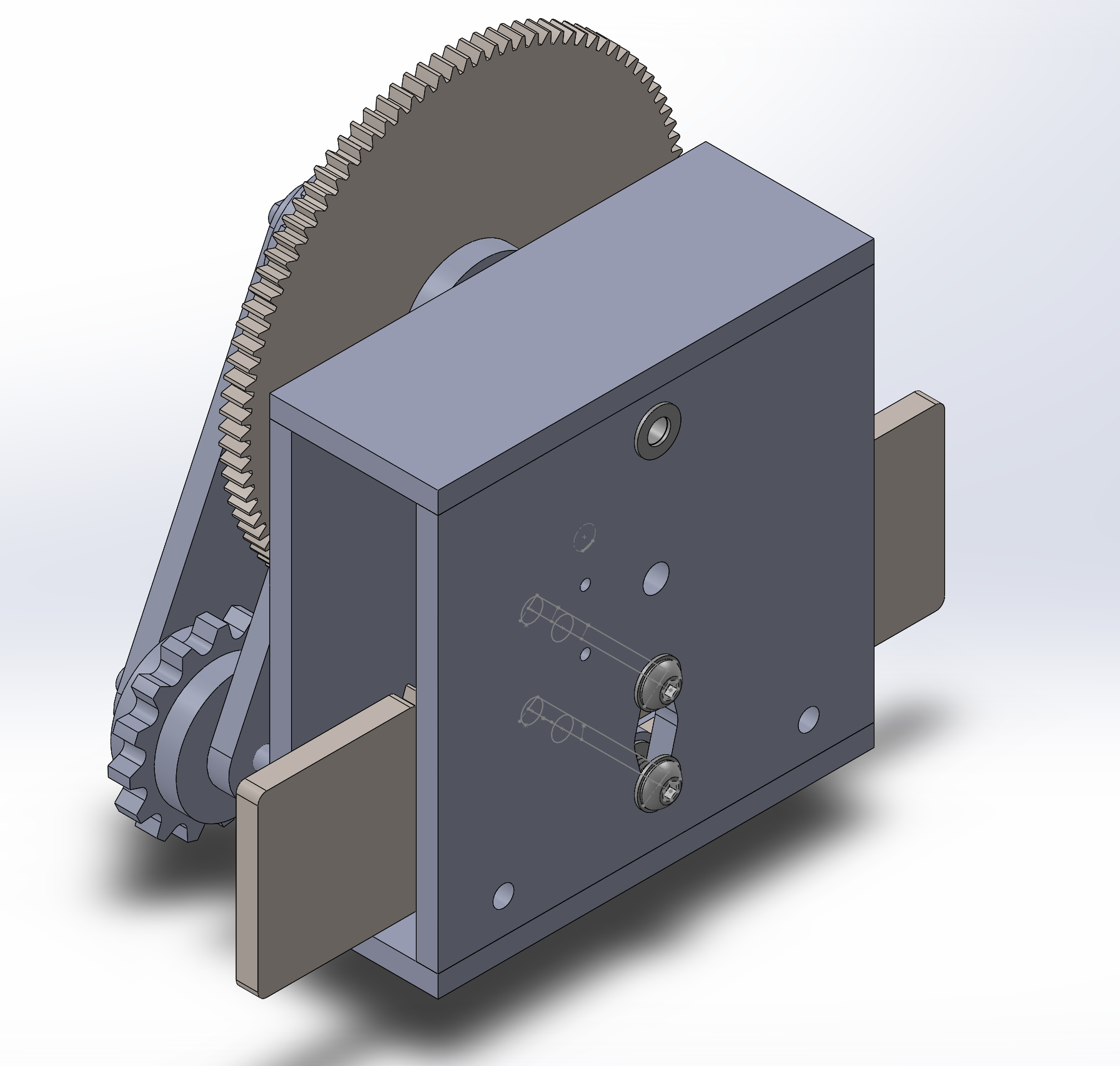

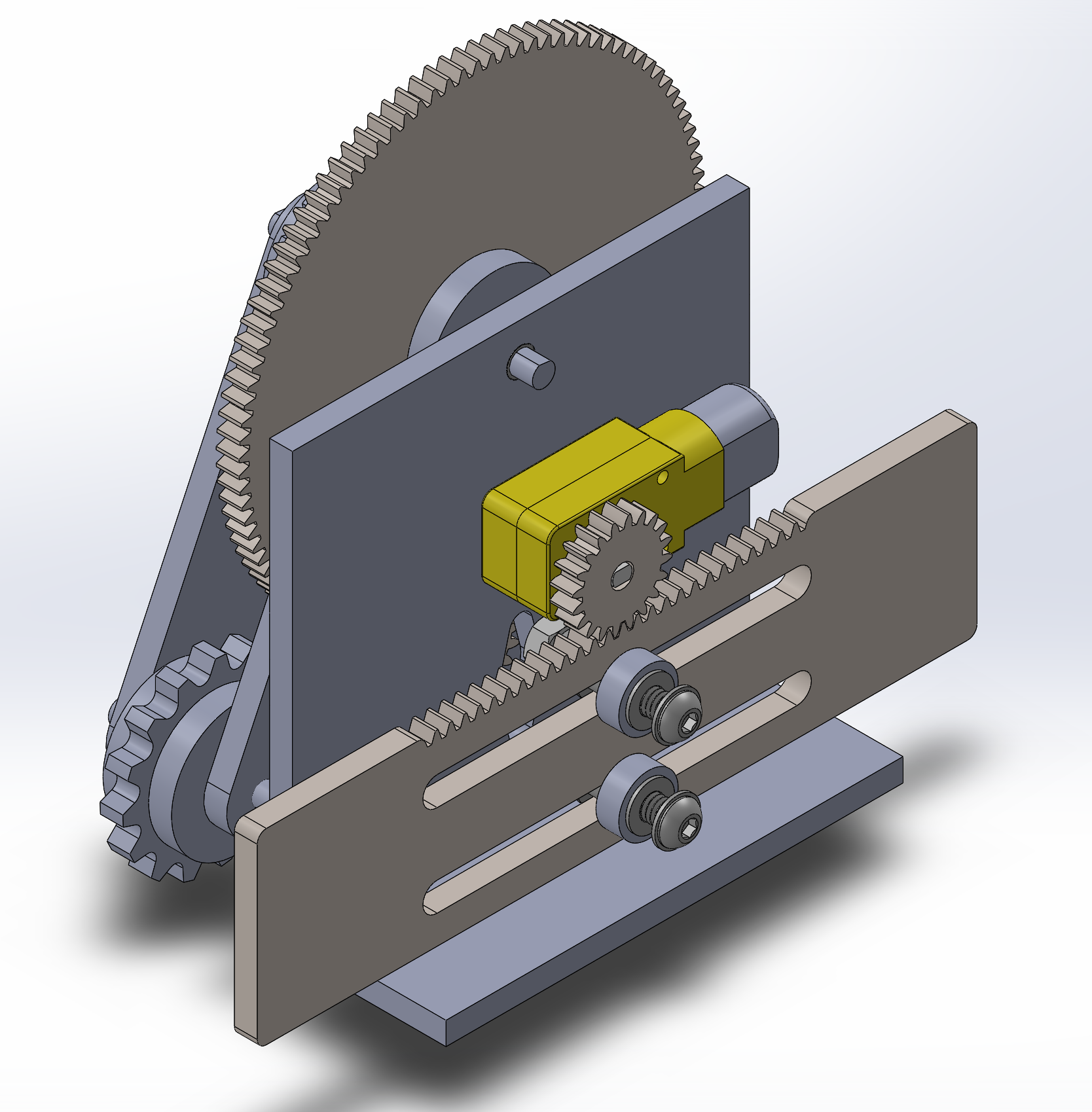

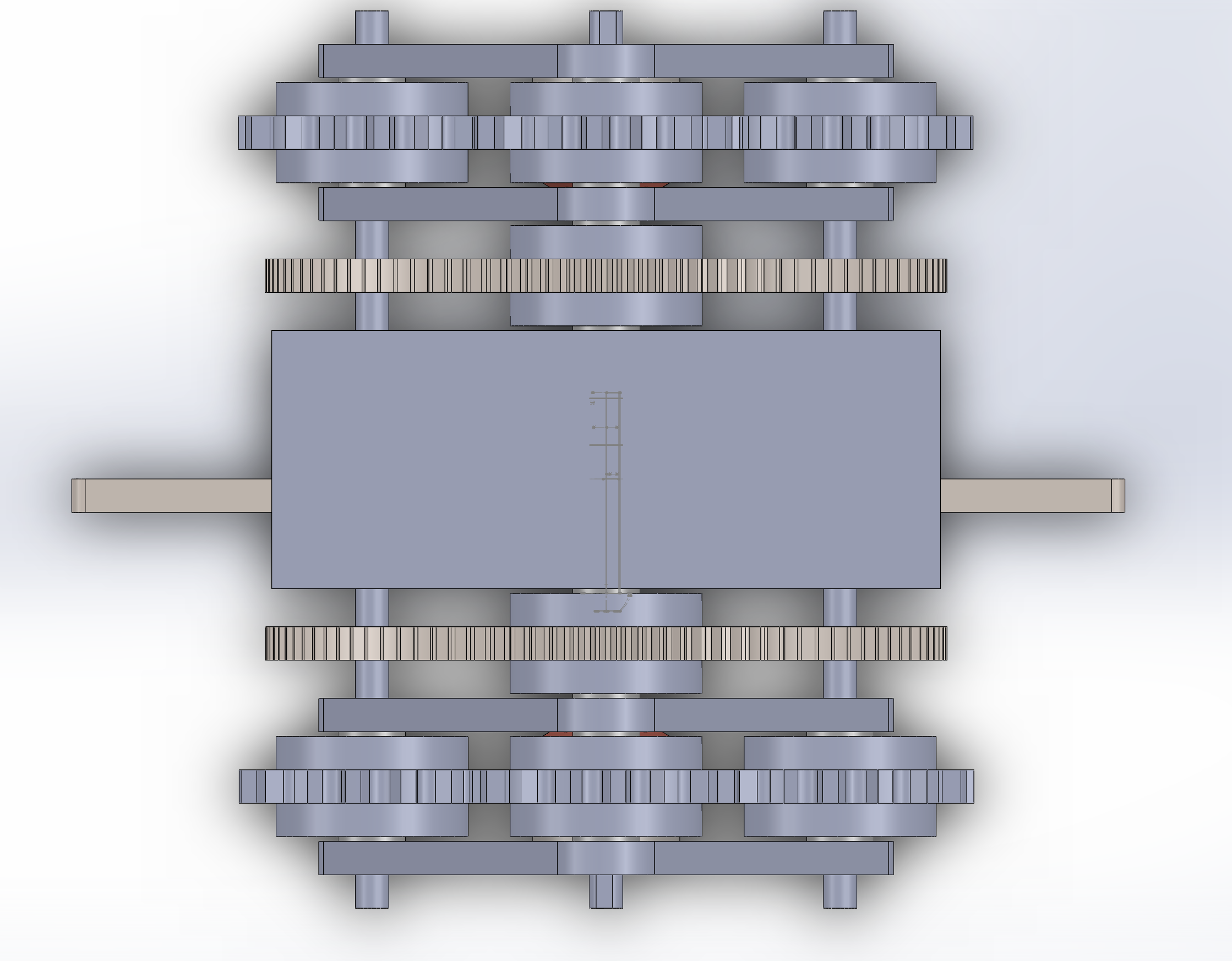

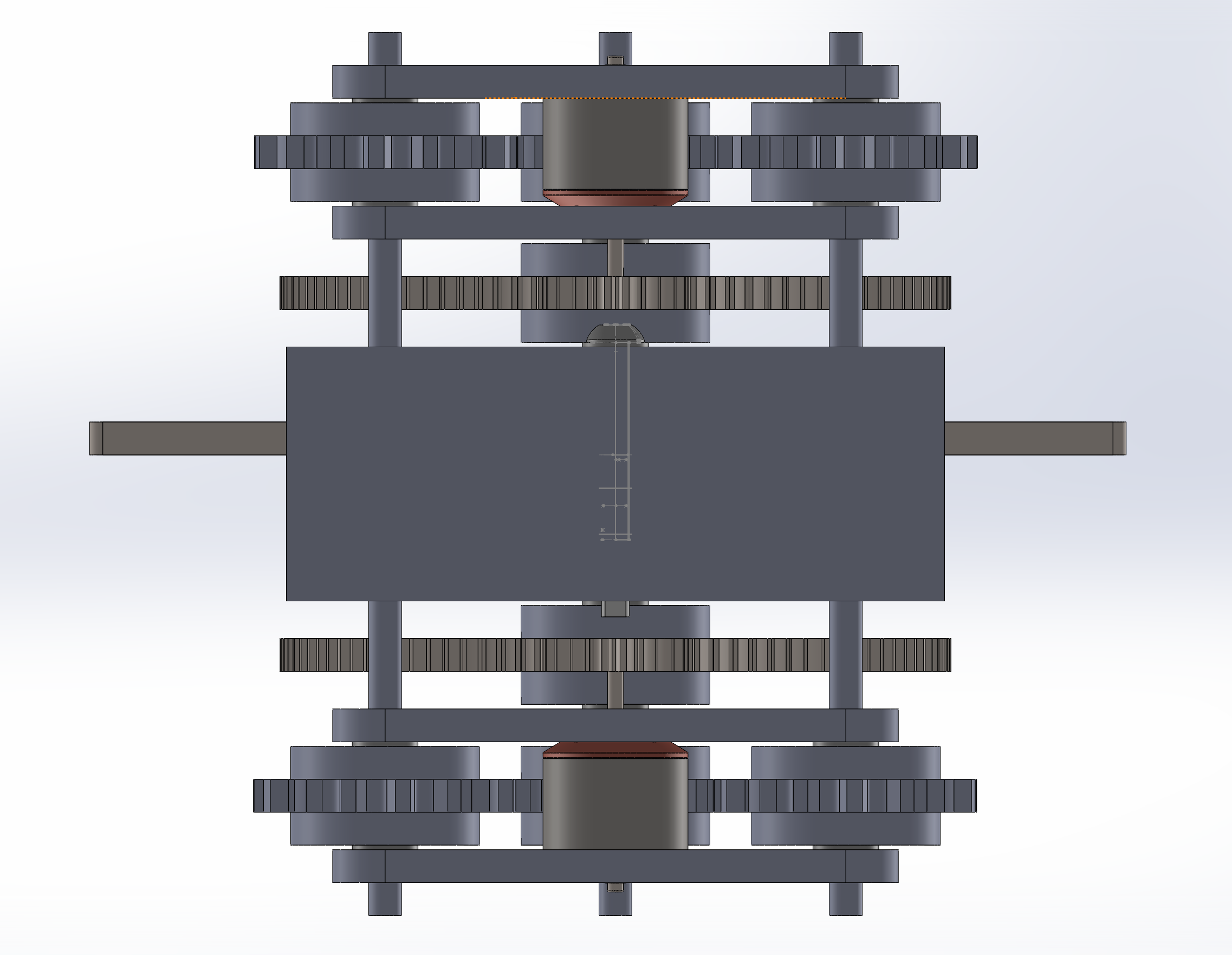

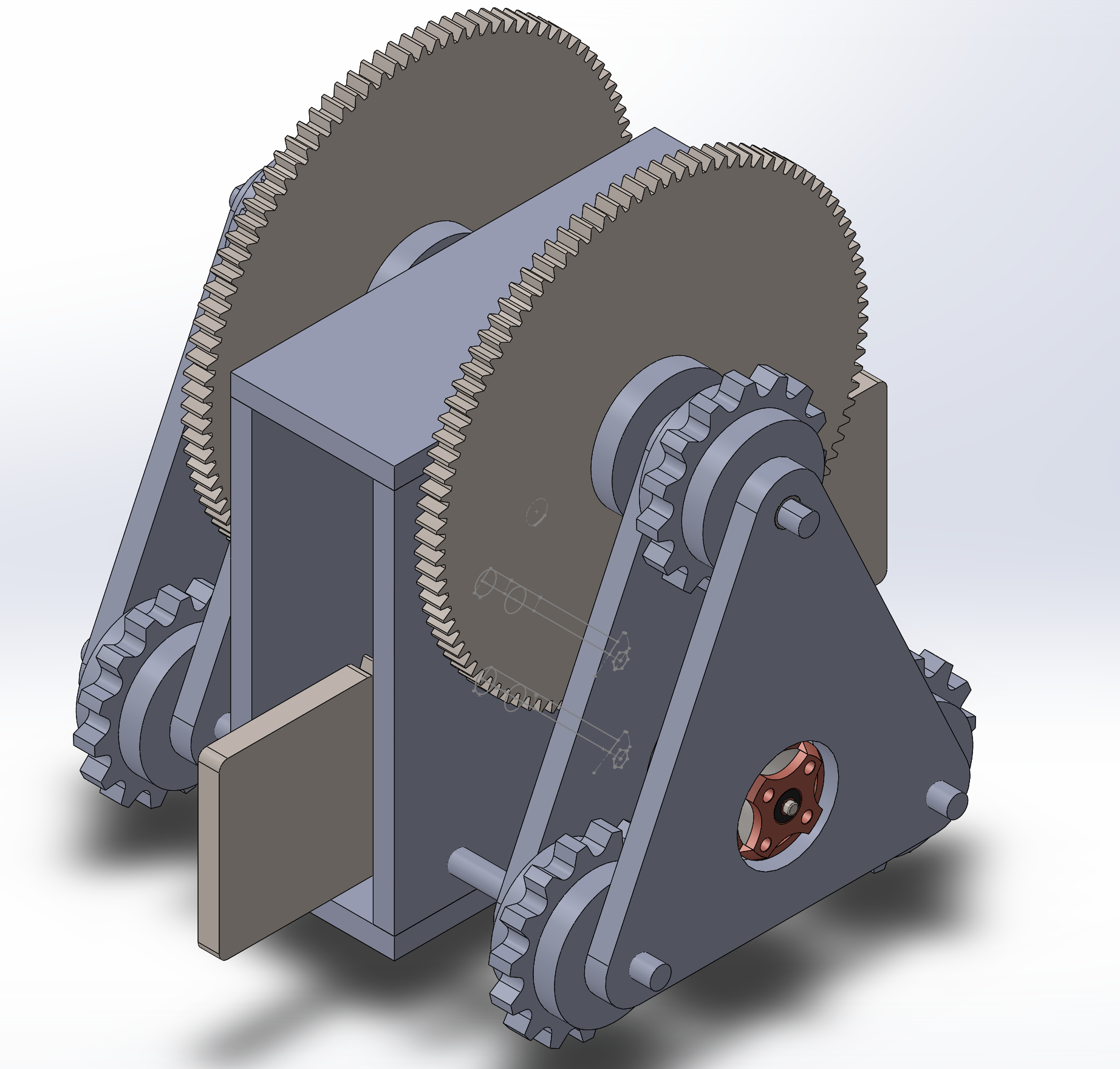

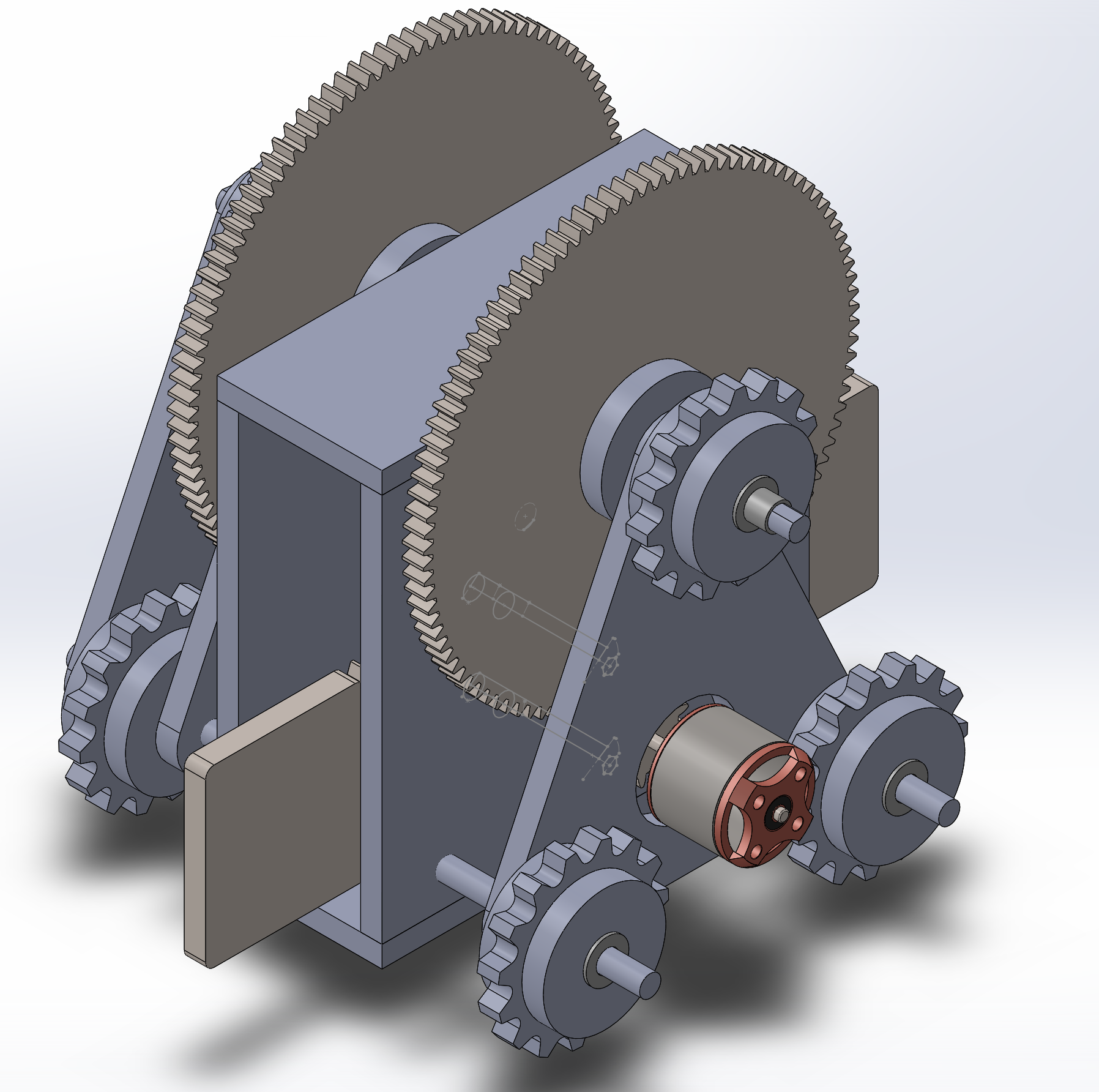

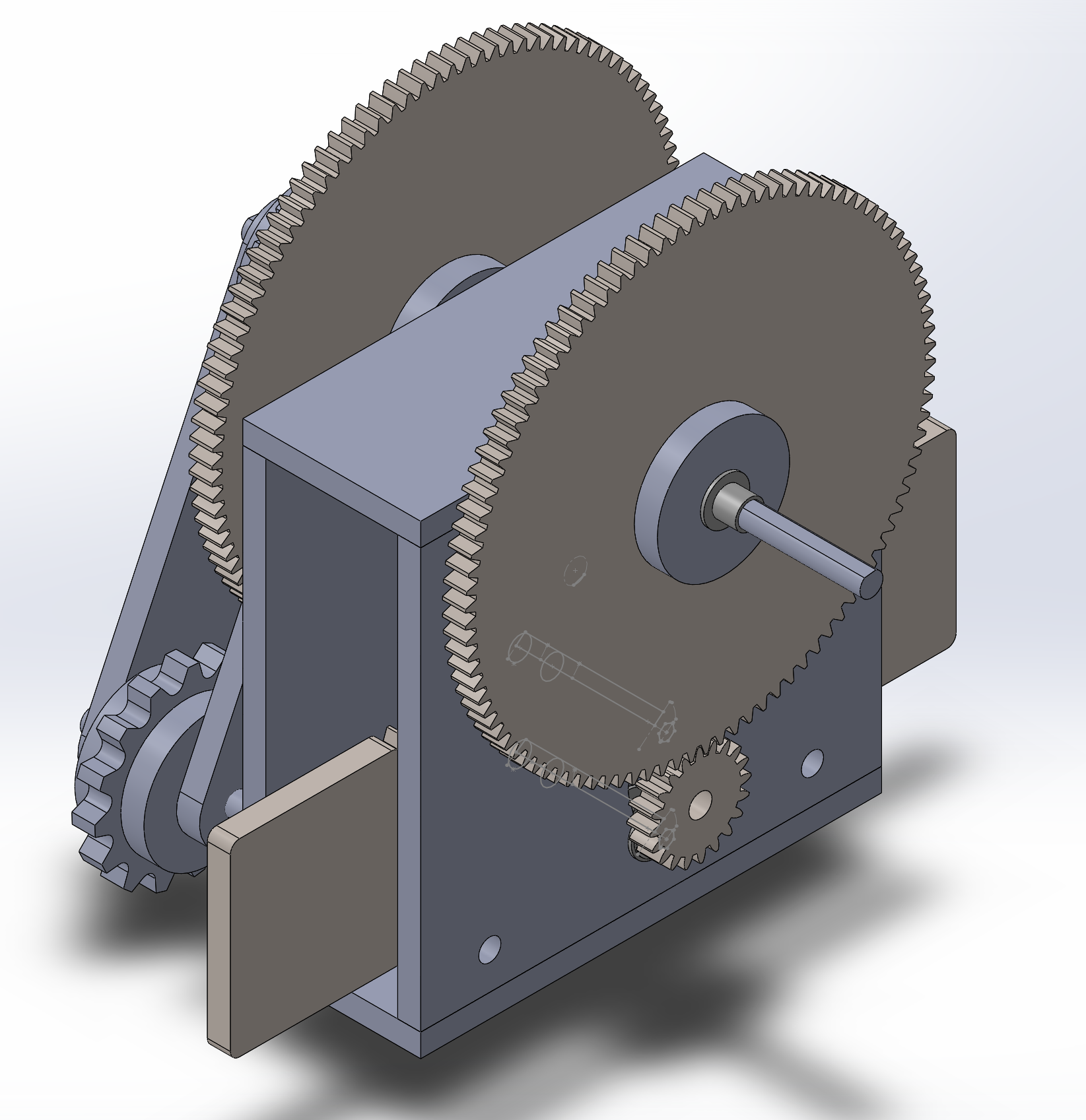

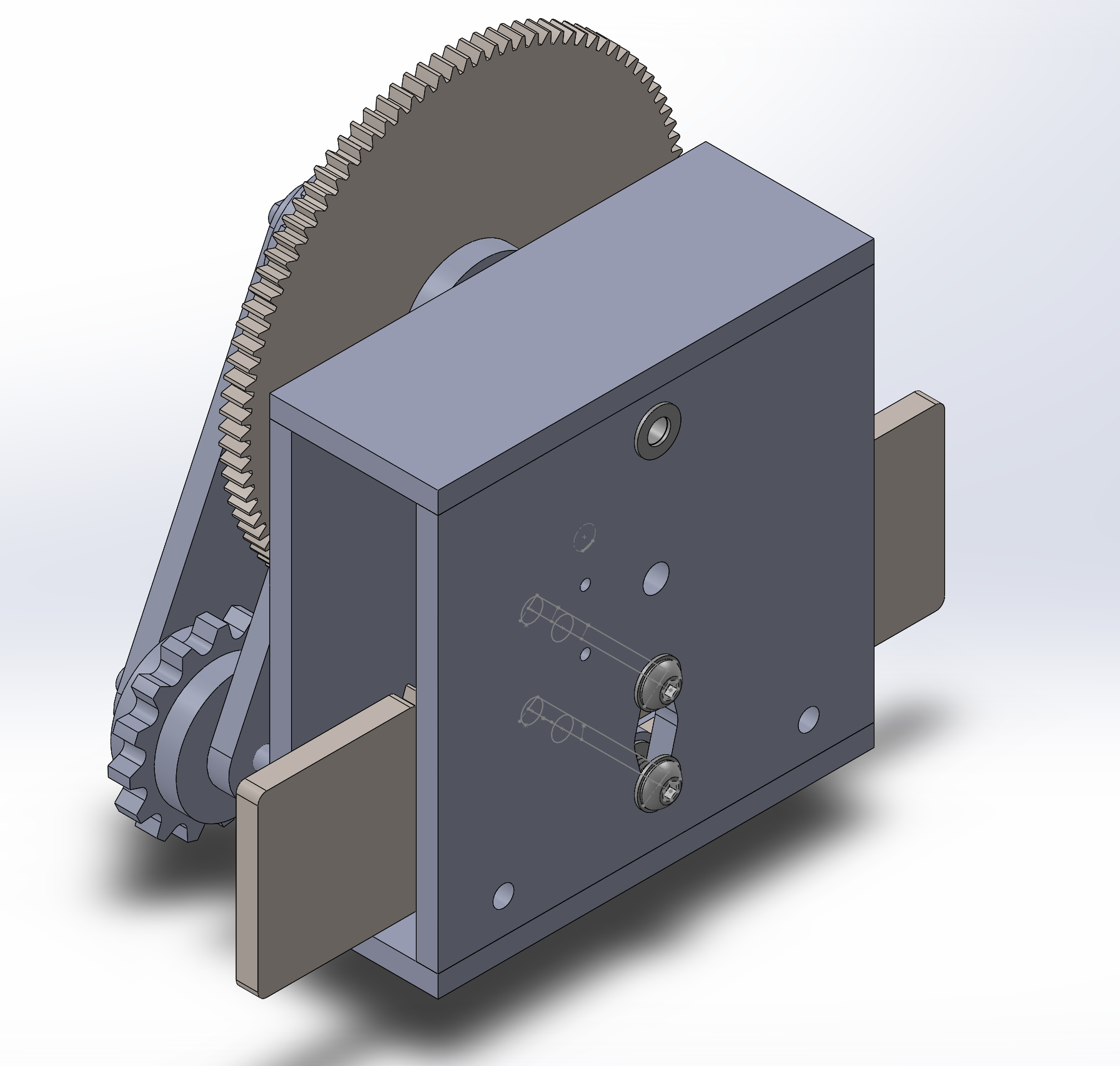

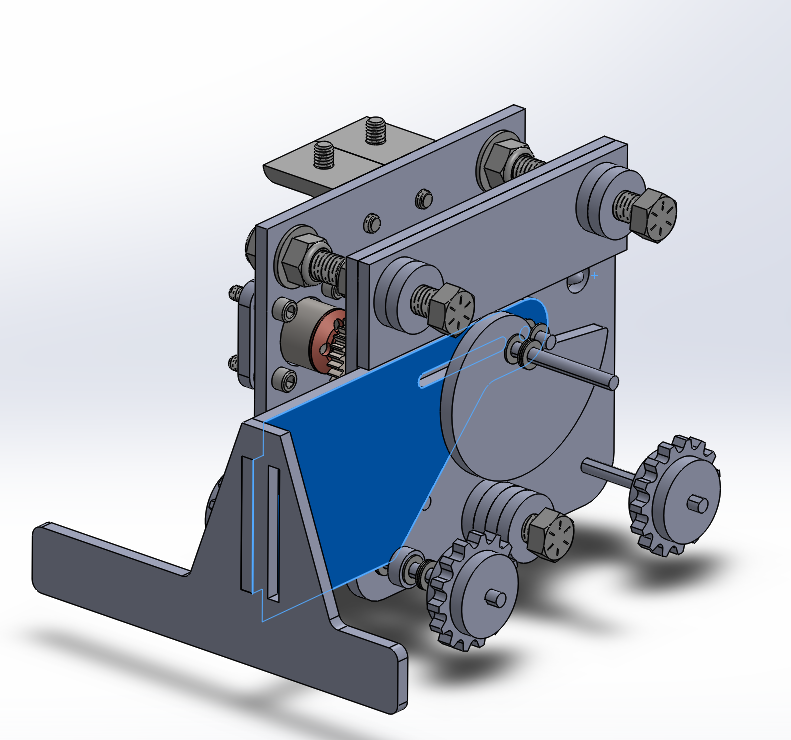

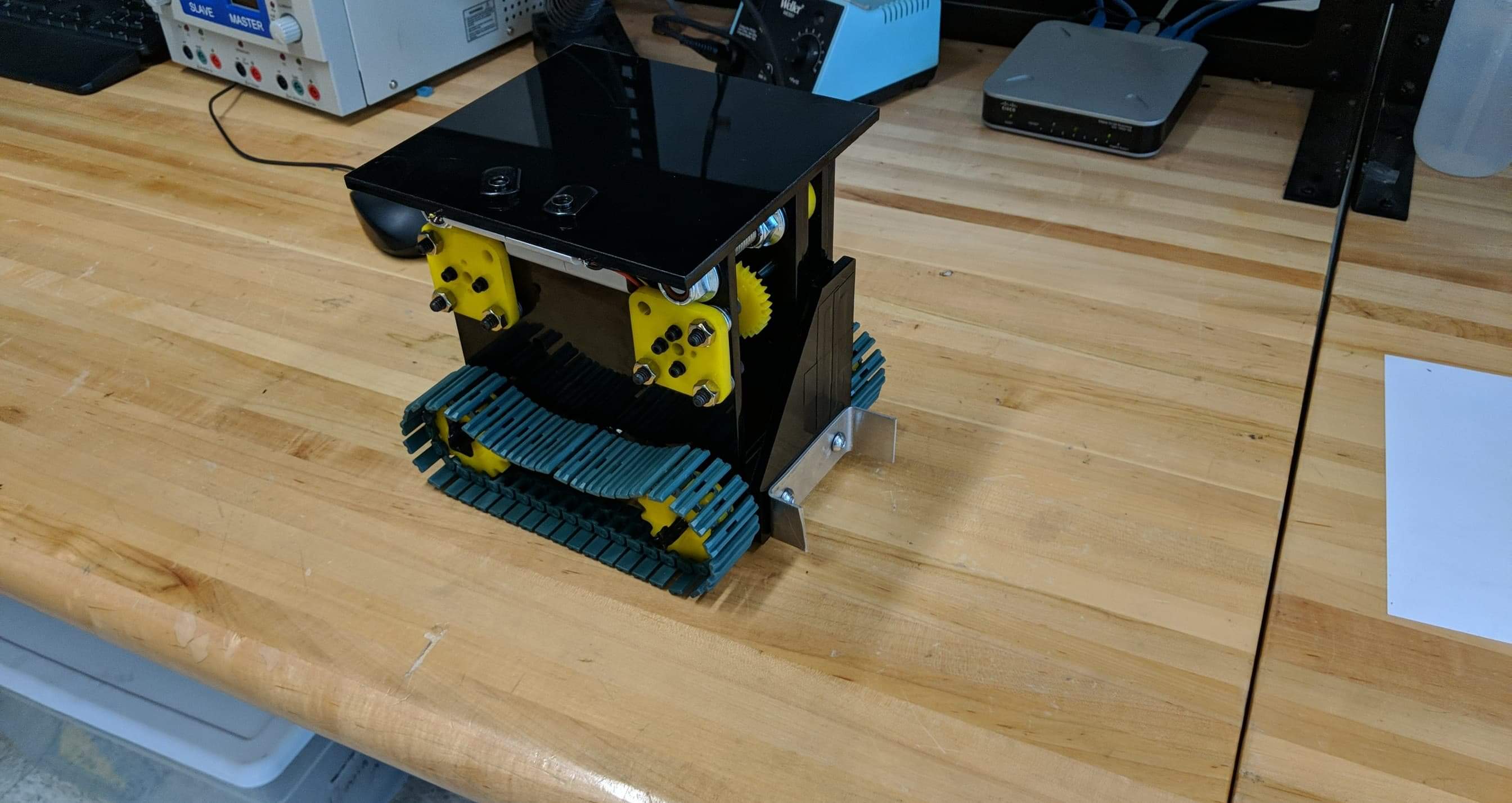

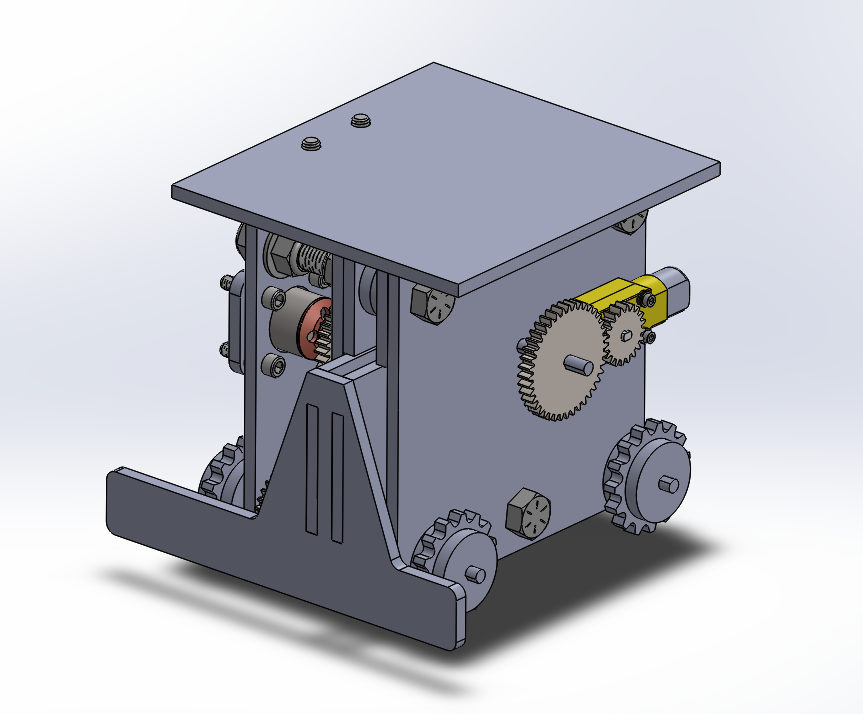

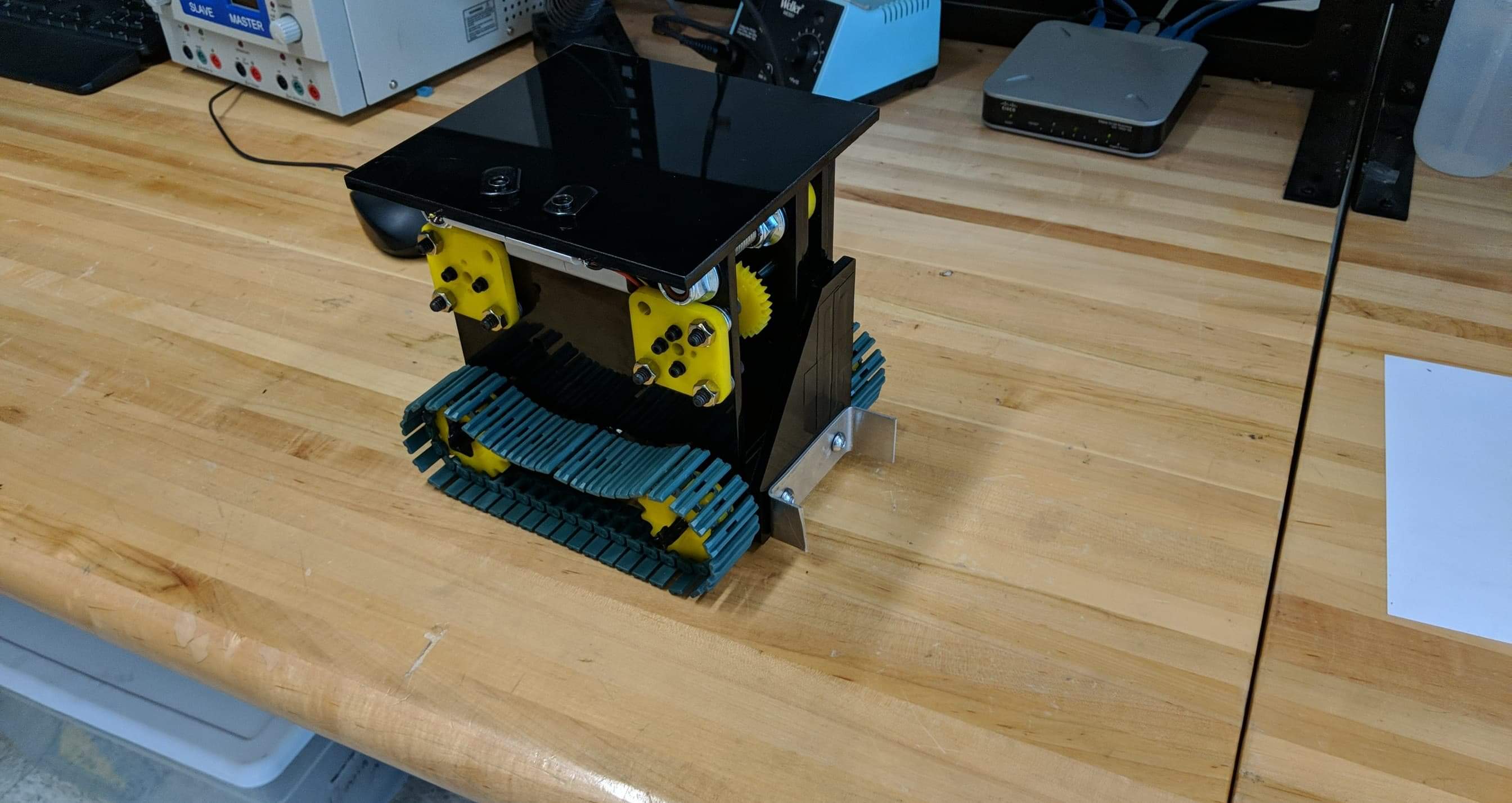

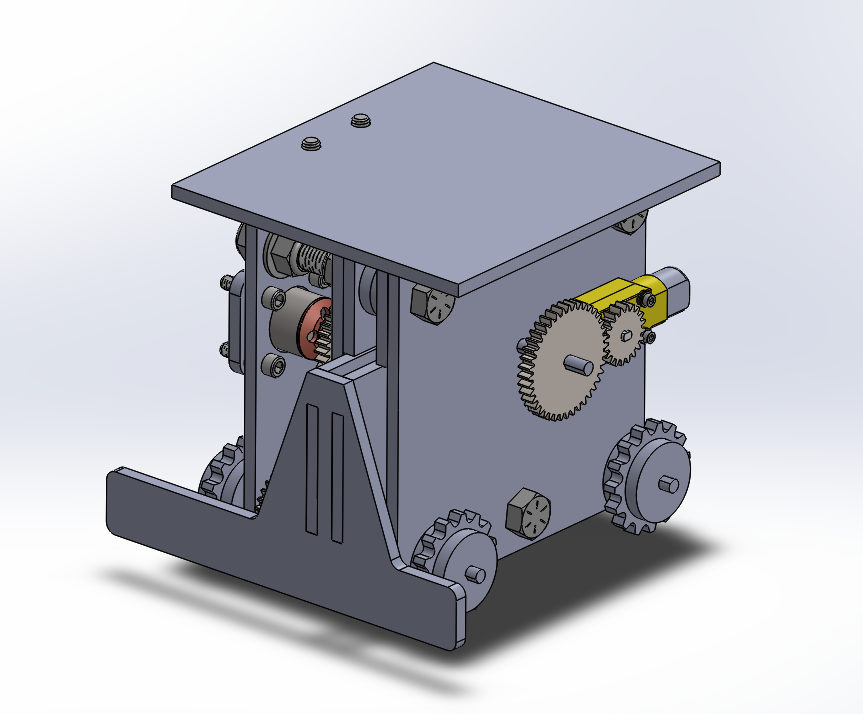

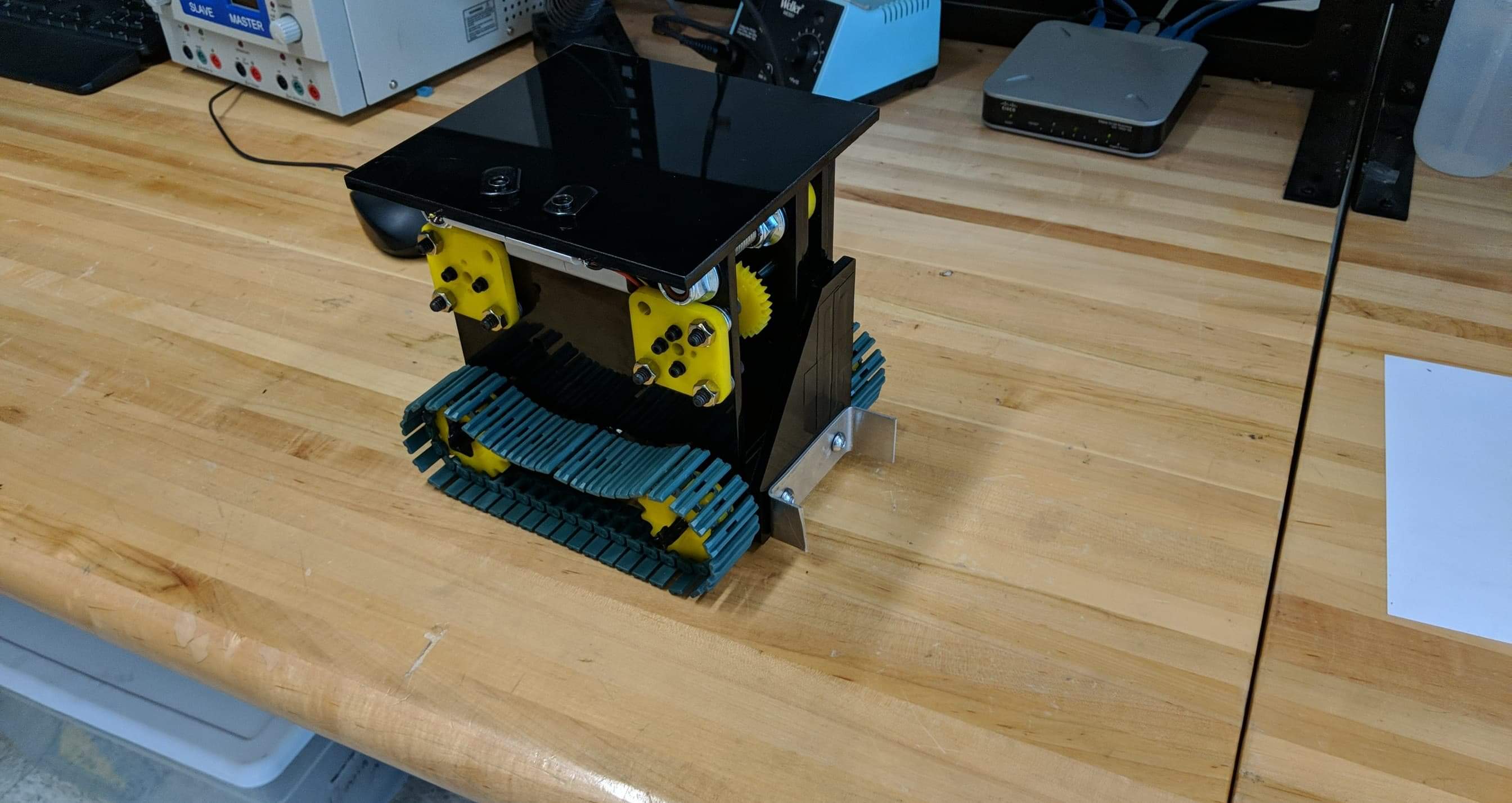

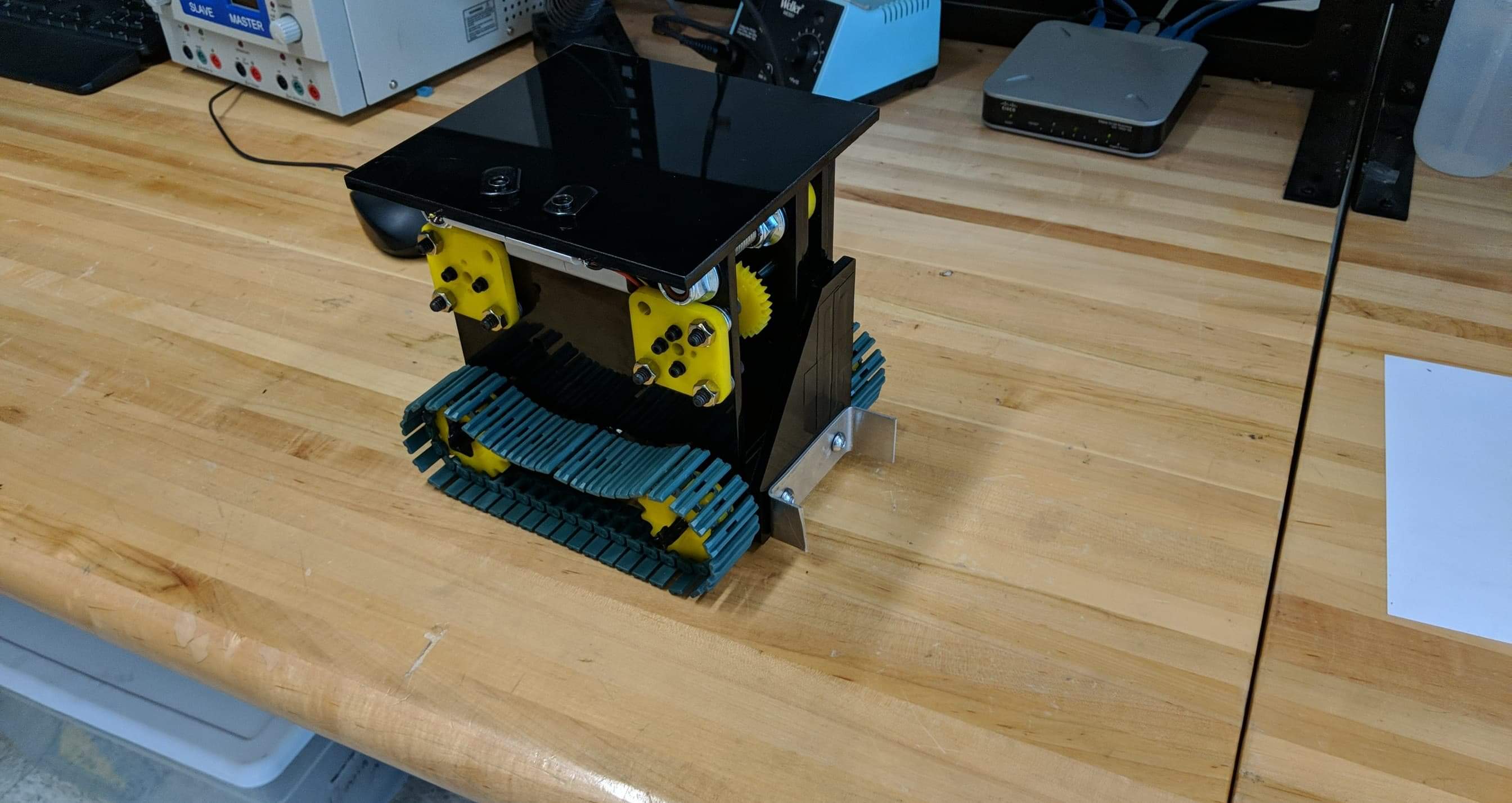

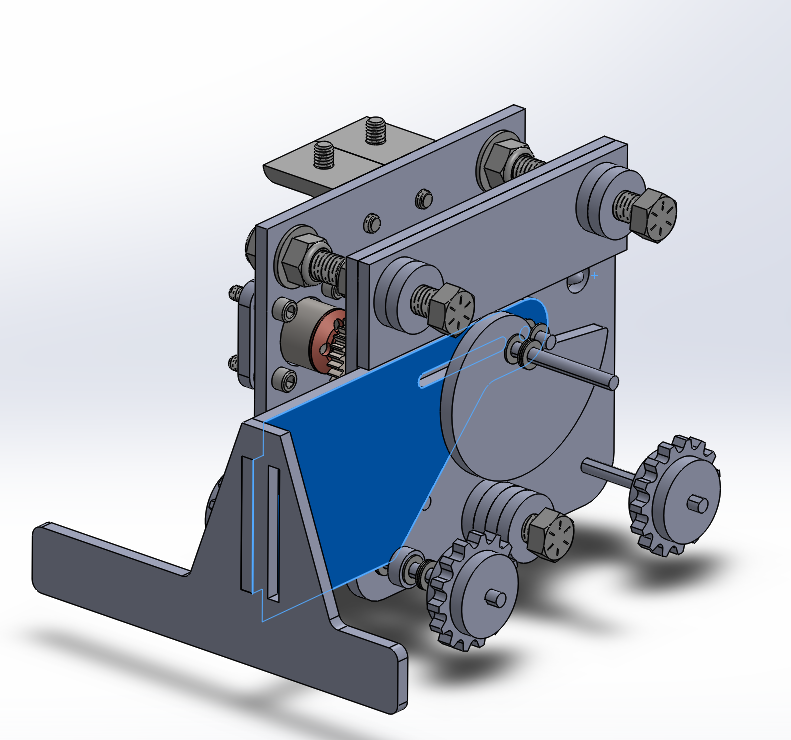

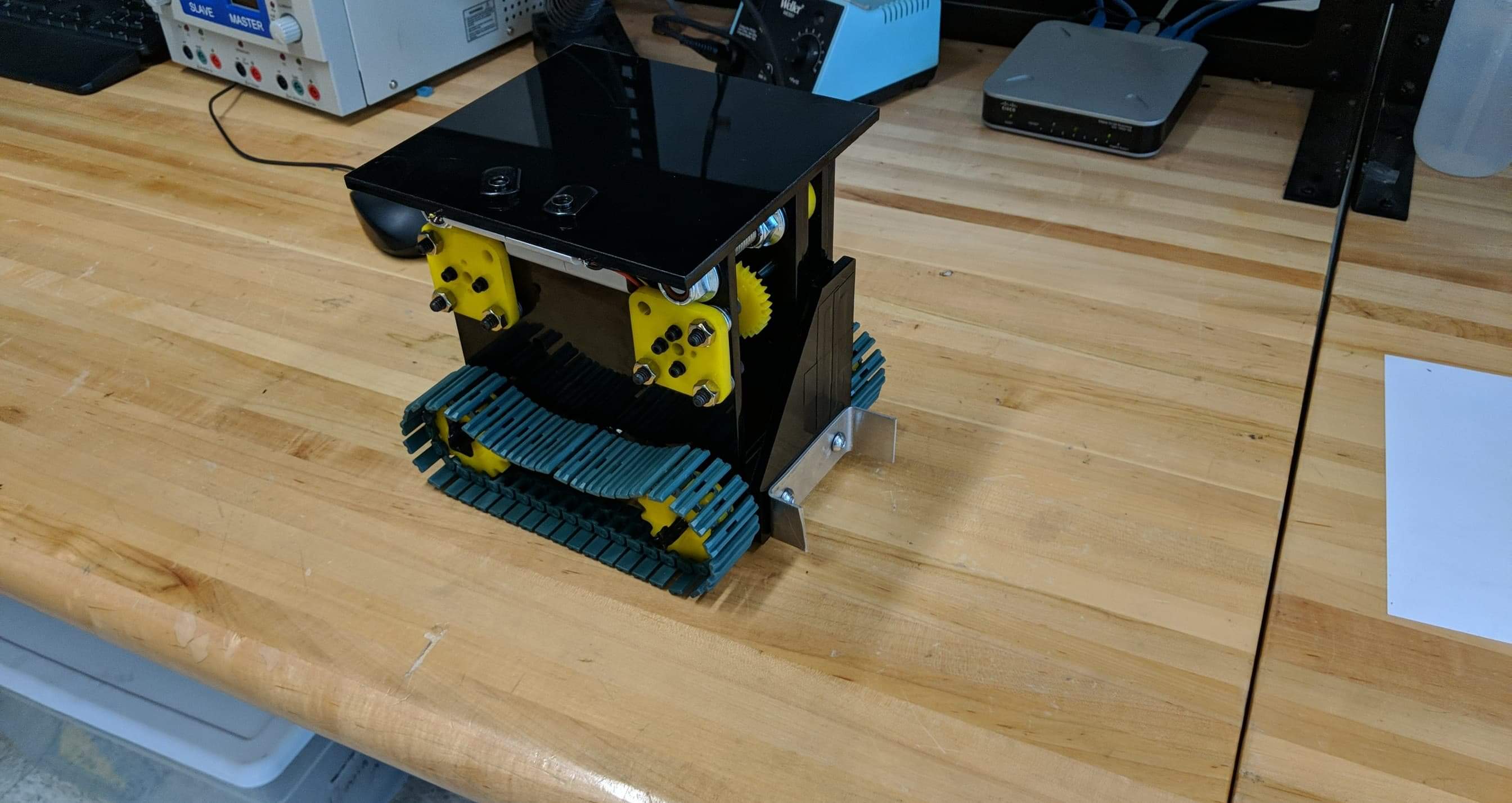

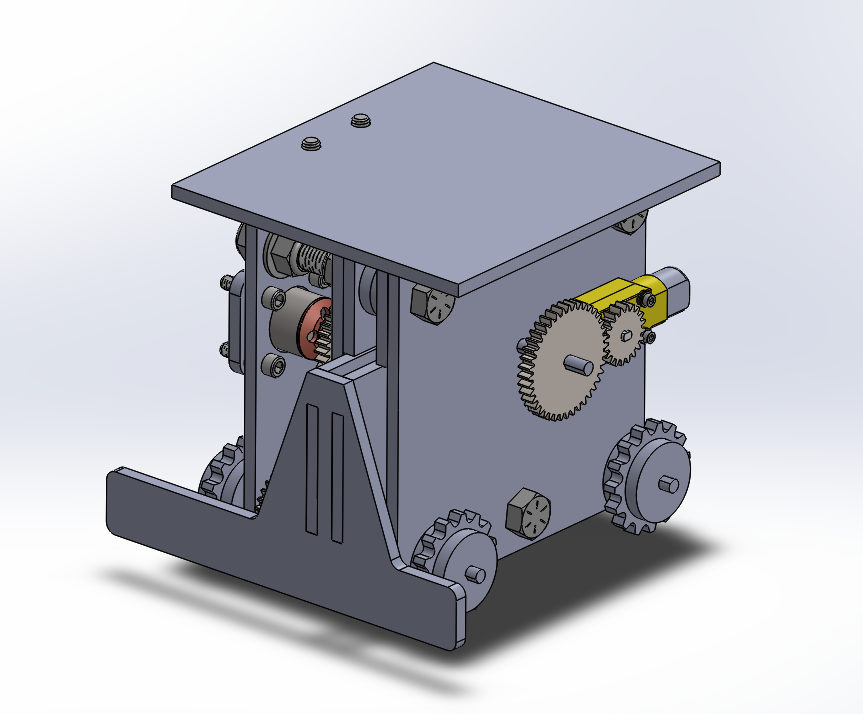

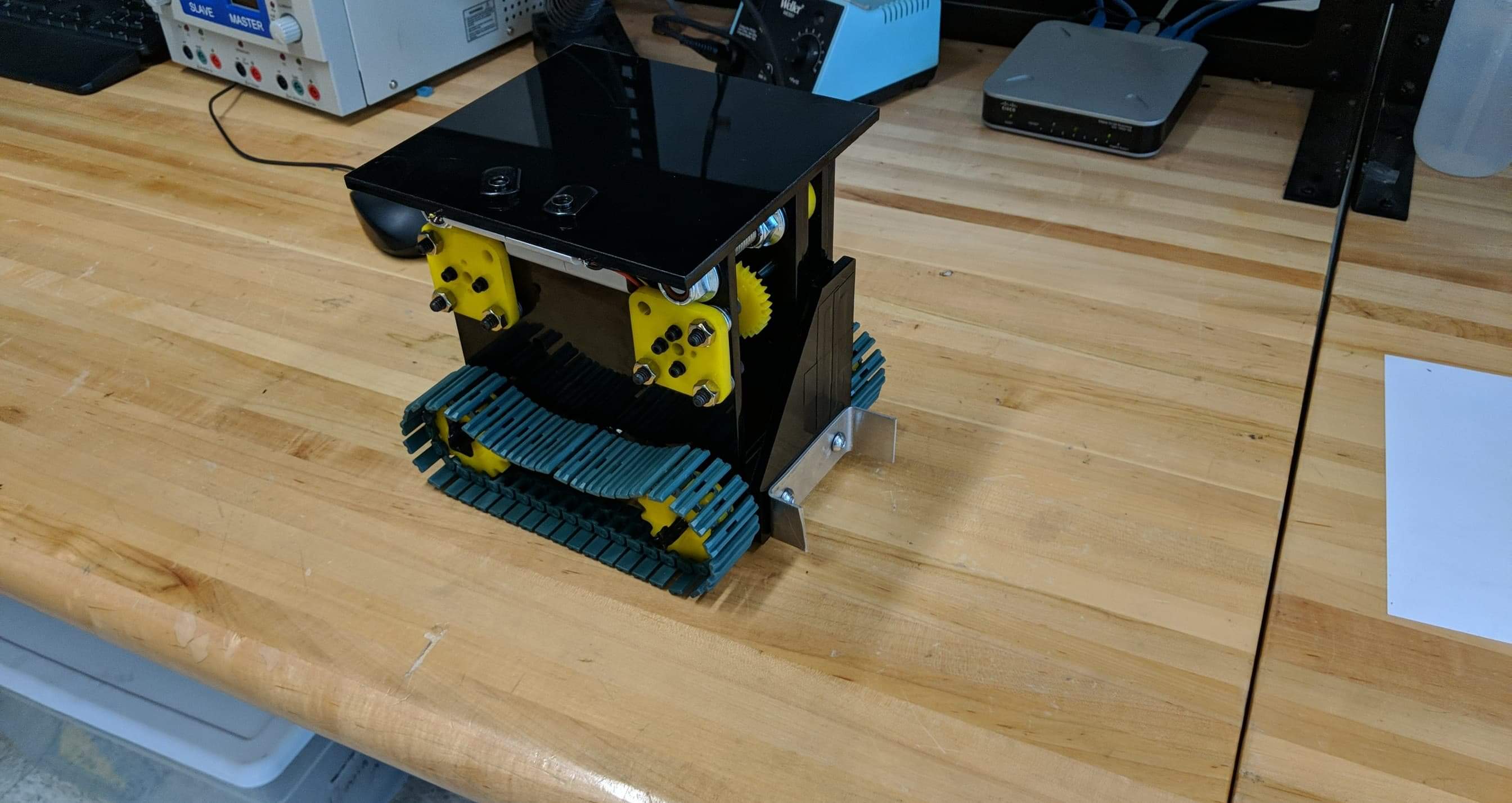

The capstone project for the course involved building two robots to autonomously play hockey against another pair of robots. For this project, I worked on a team of three, where I again was mainly tasked with designing and fabricating the robots. For the hockey match, each team was to build a goalie robot, and a striker robot. The design constraints were pretty flexible, mainly just limiting the size of the robots. Ultimately due to time constraints, the actual hockey tournament was cancelled, but my team's robots turned out quite well, especially the striker.

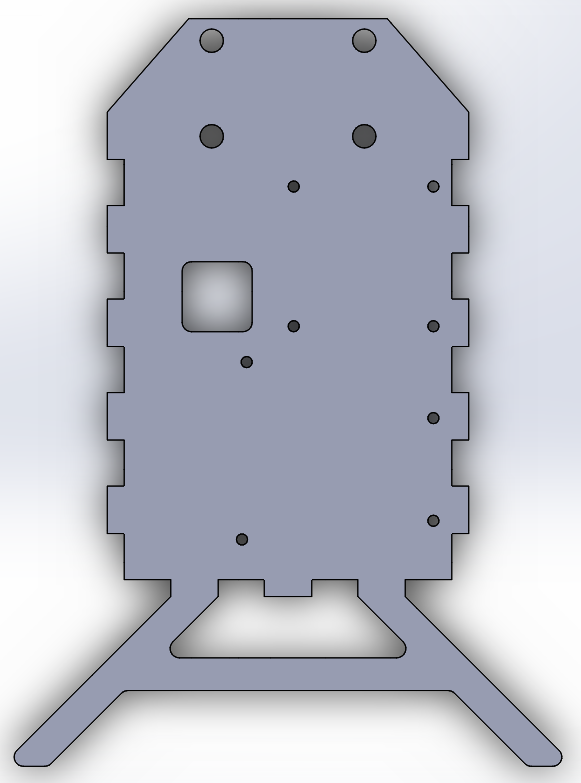

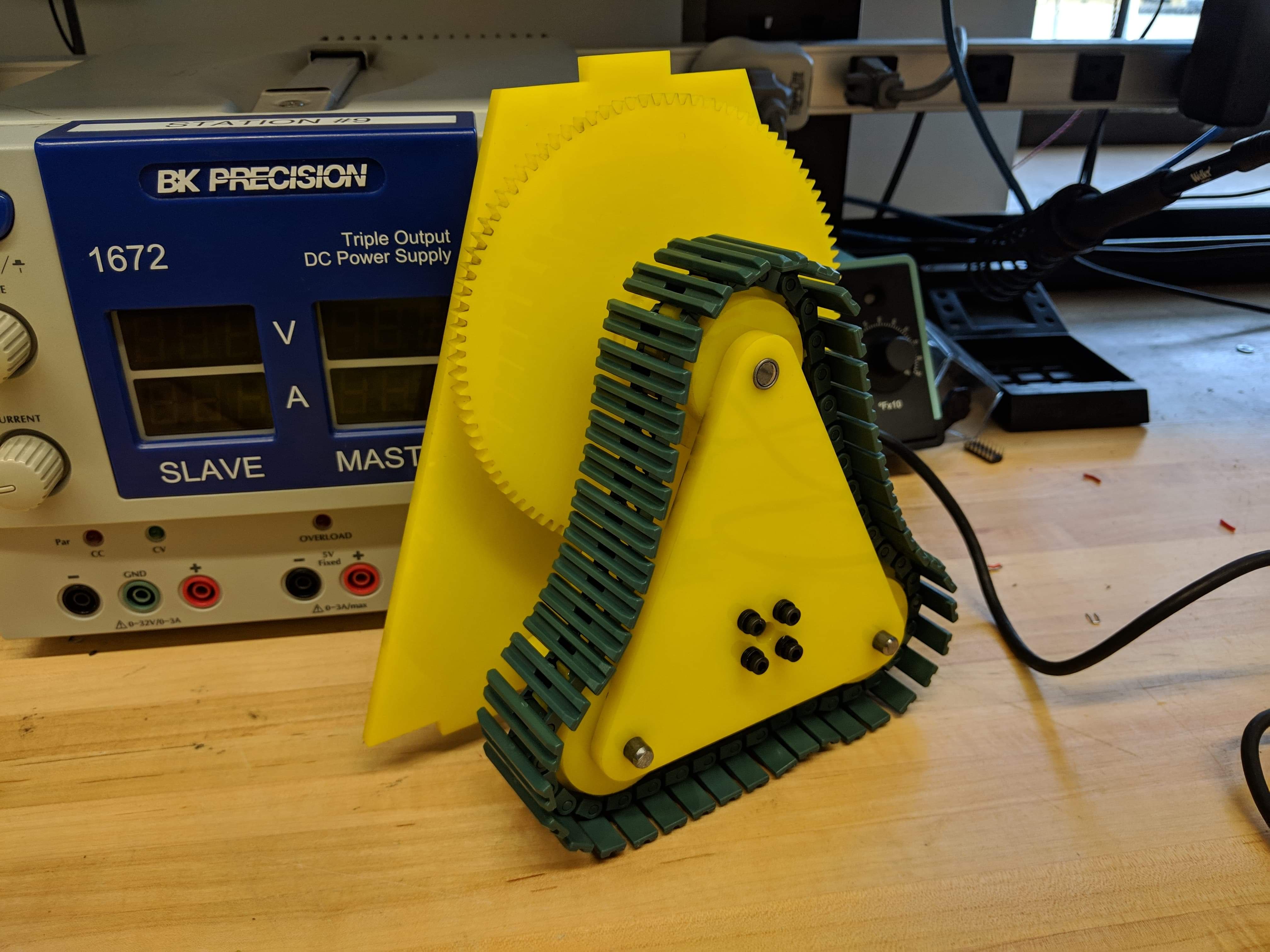

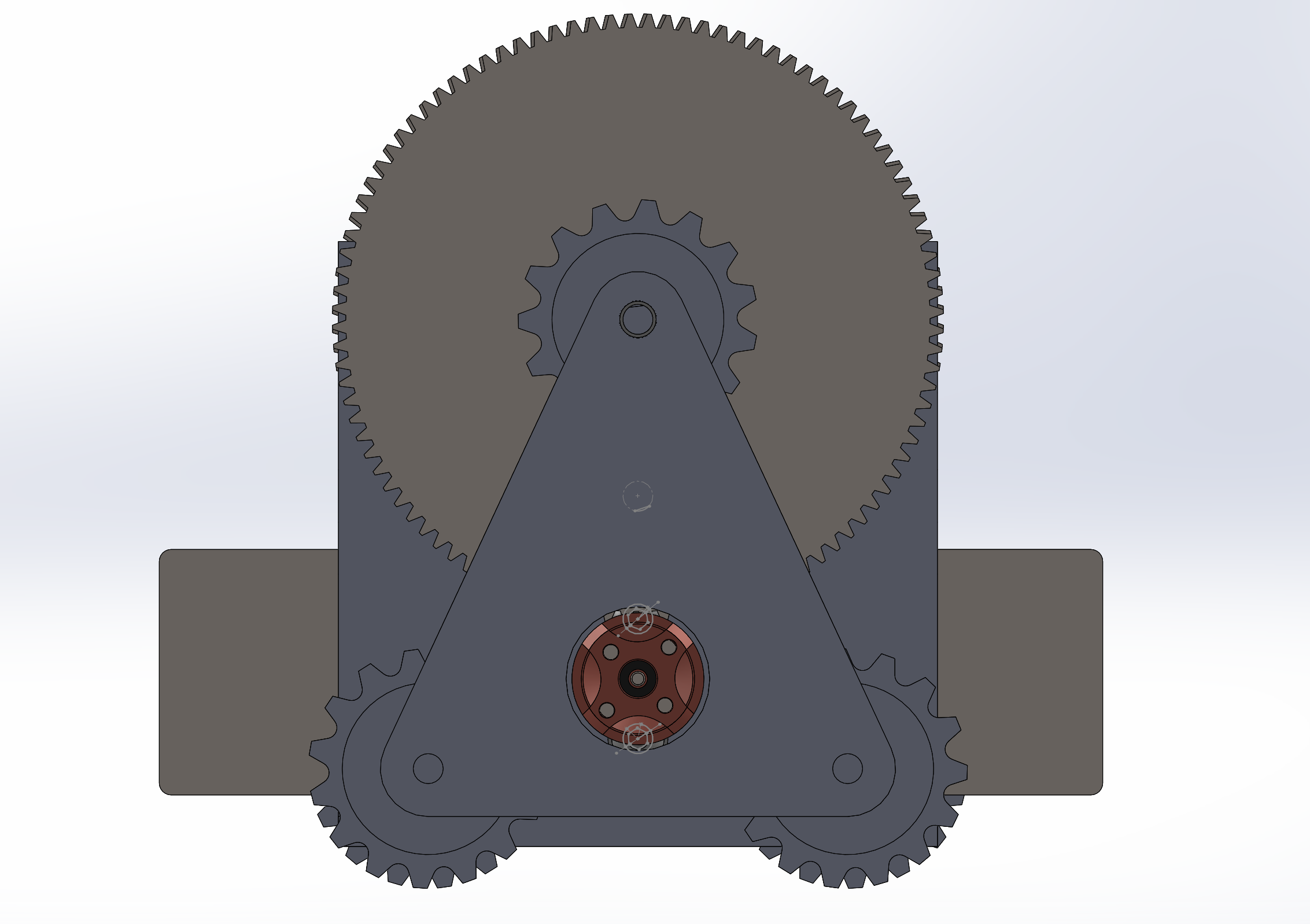

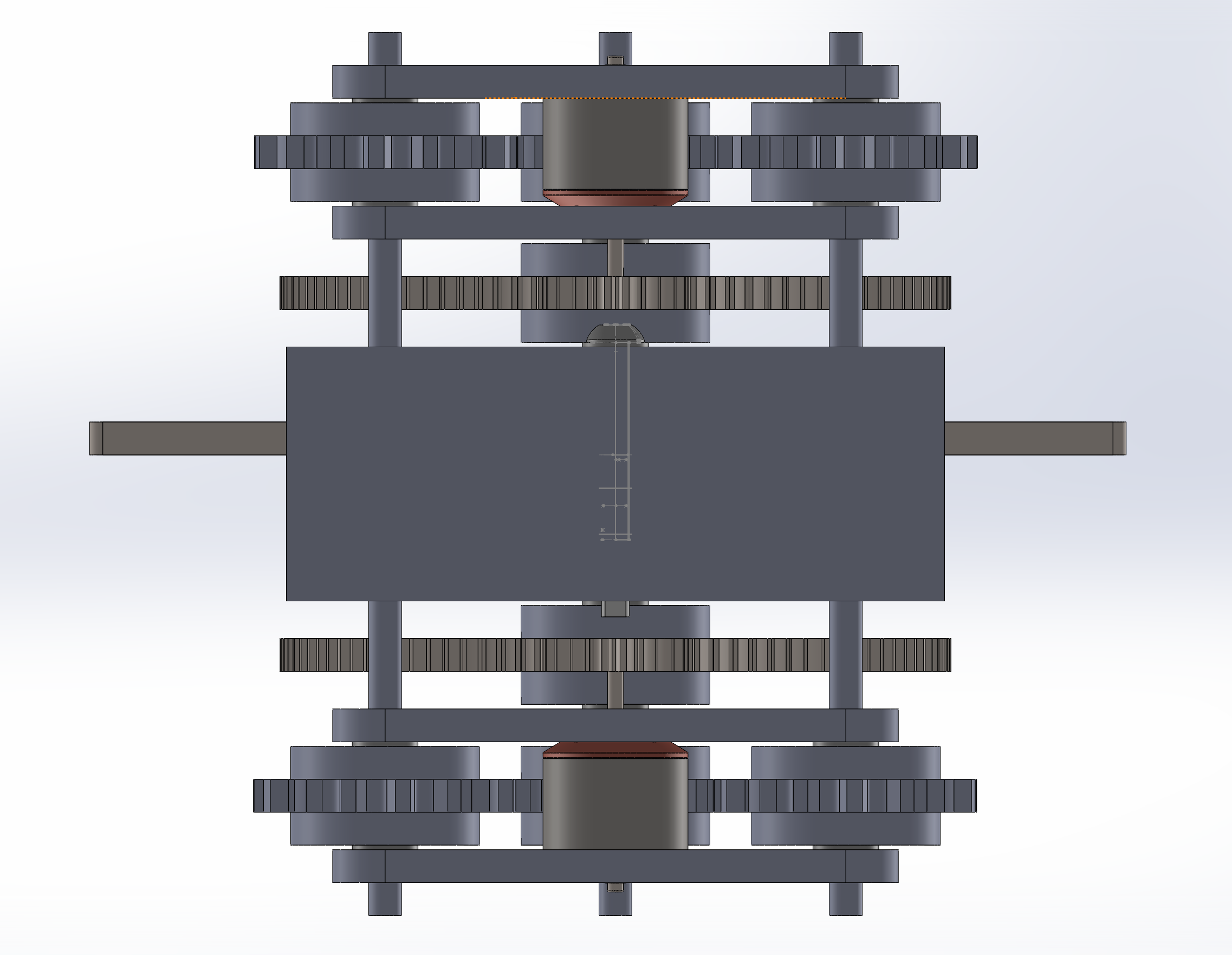

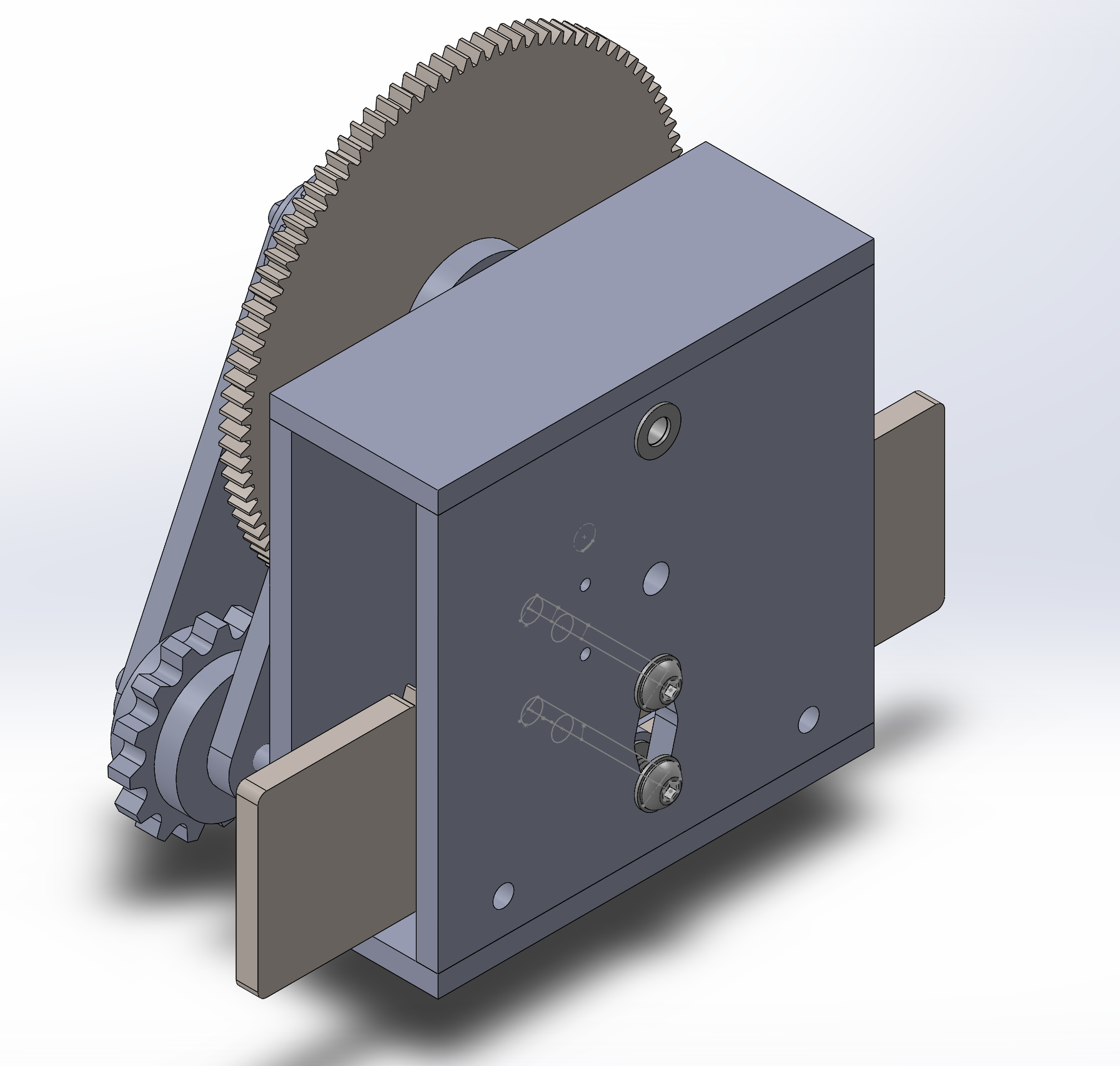

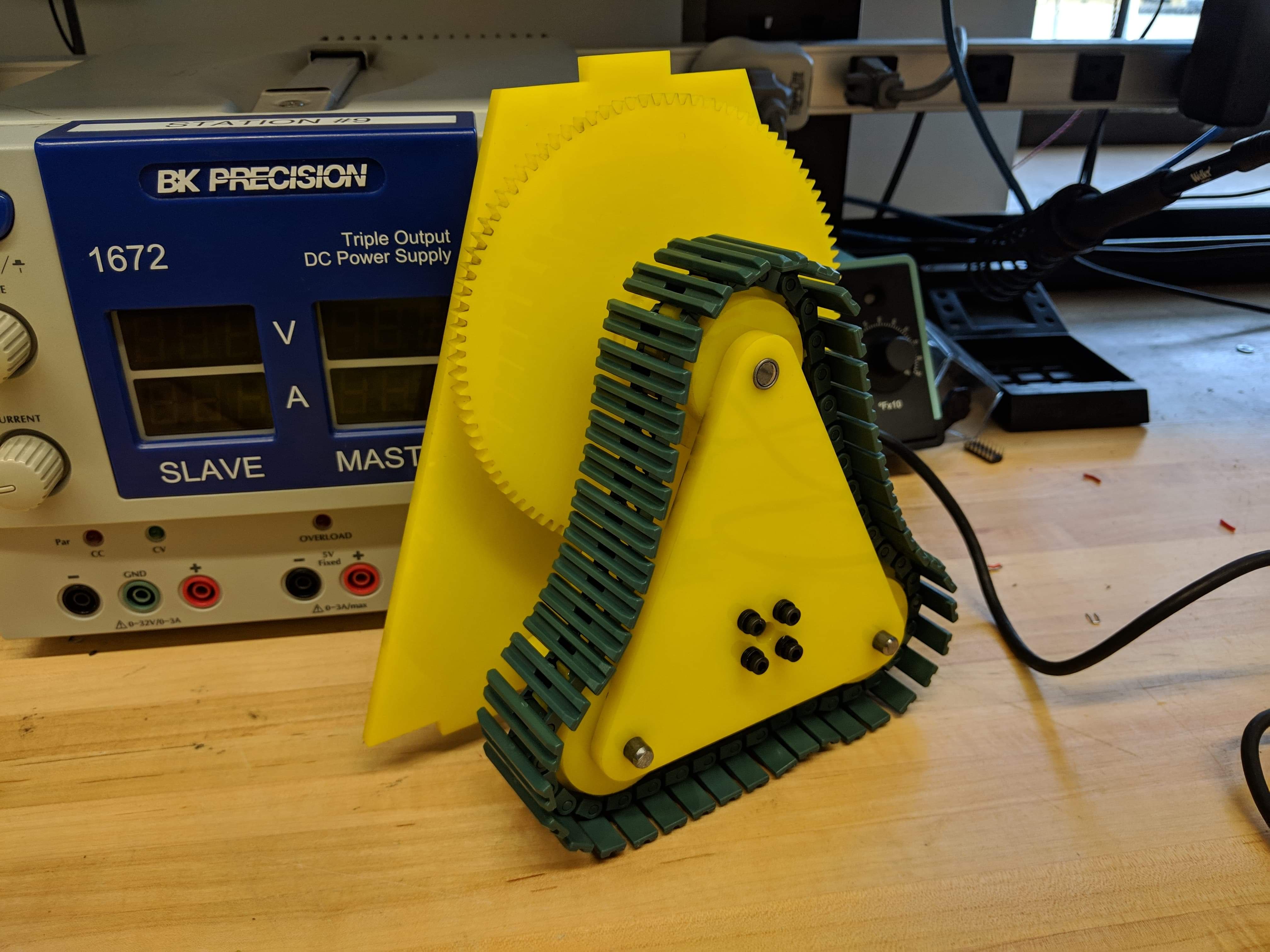

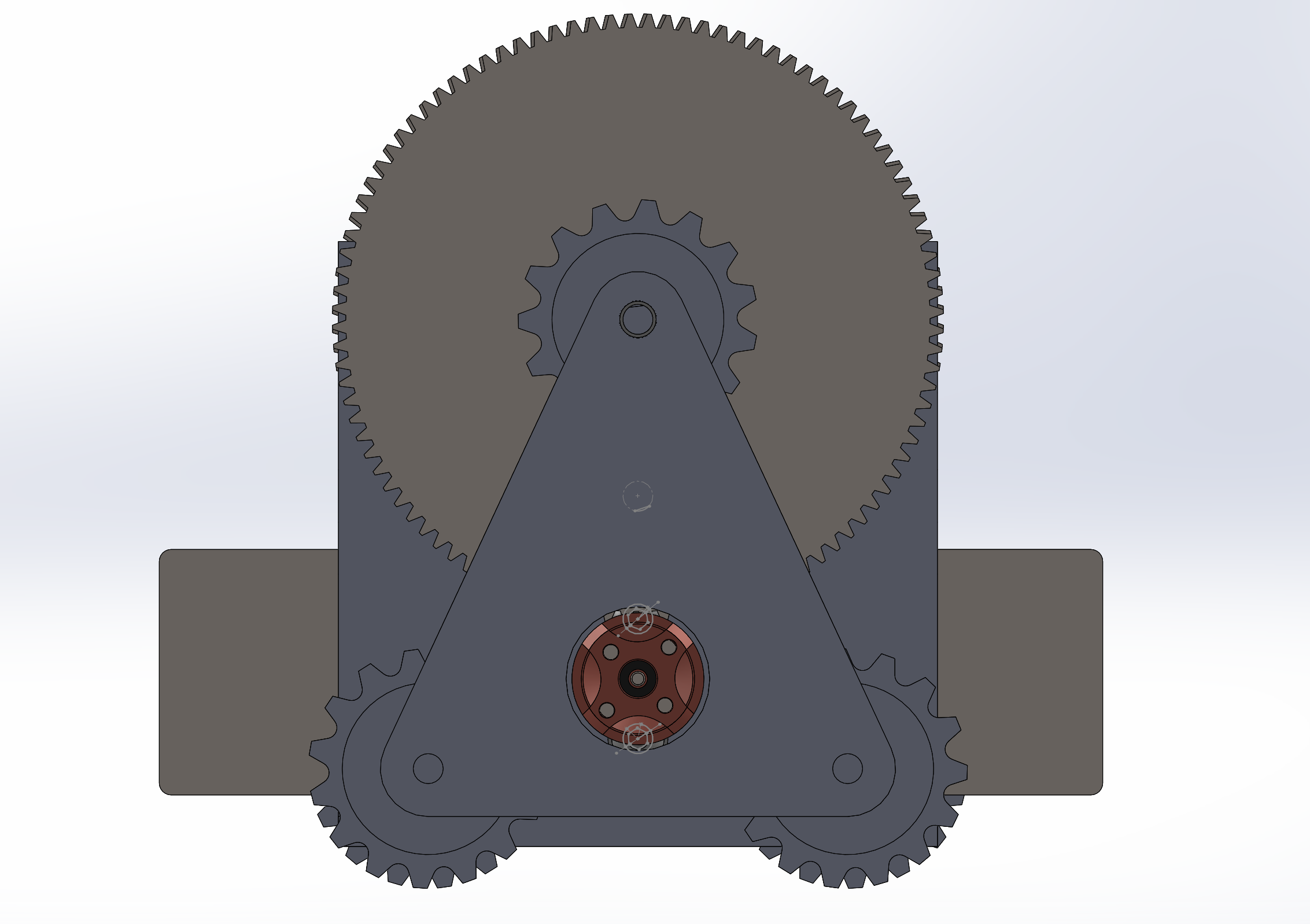

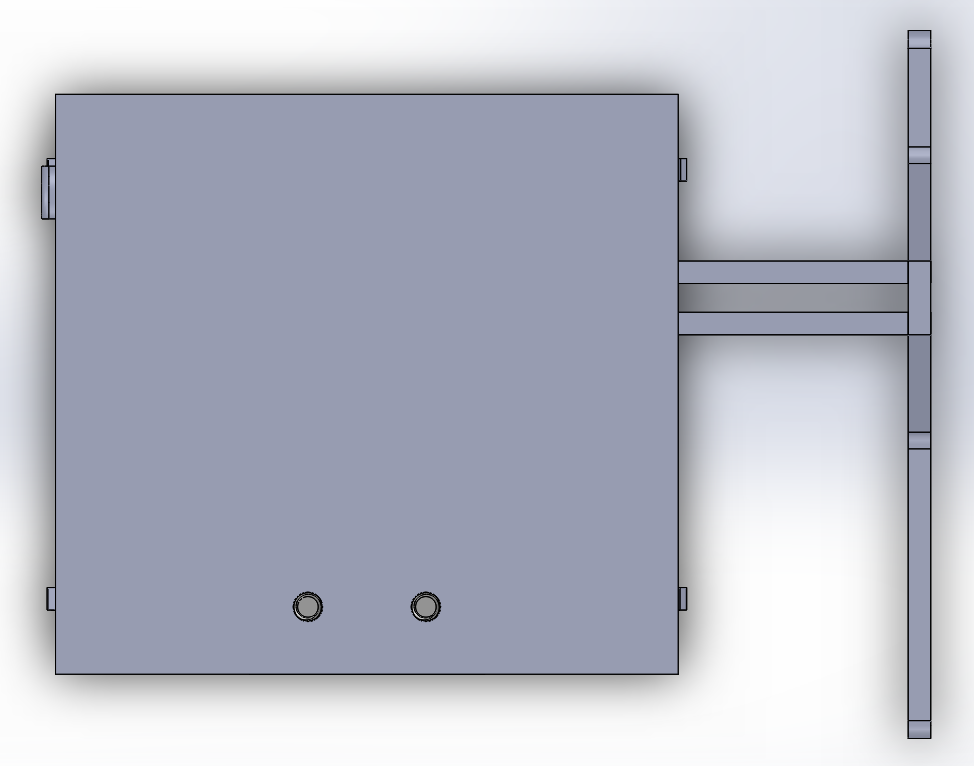

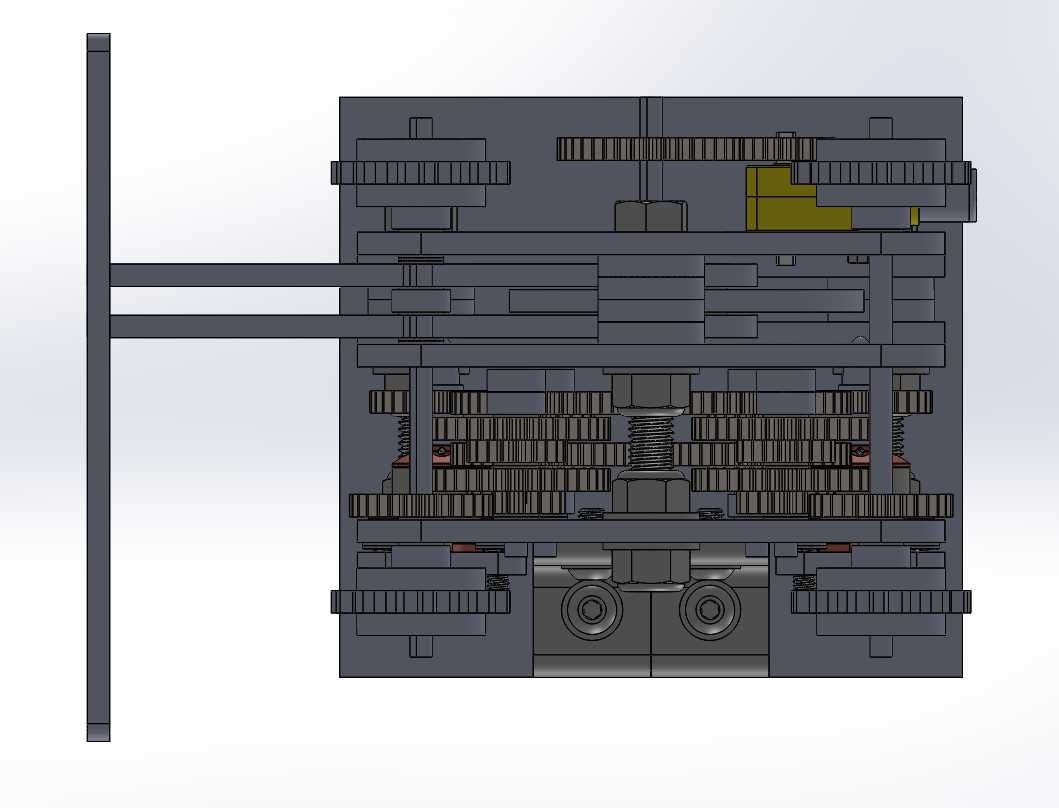

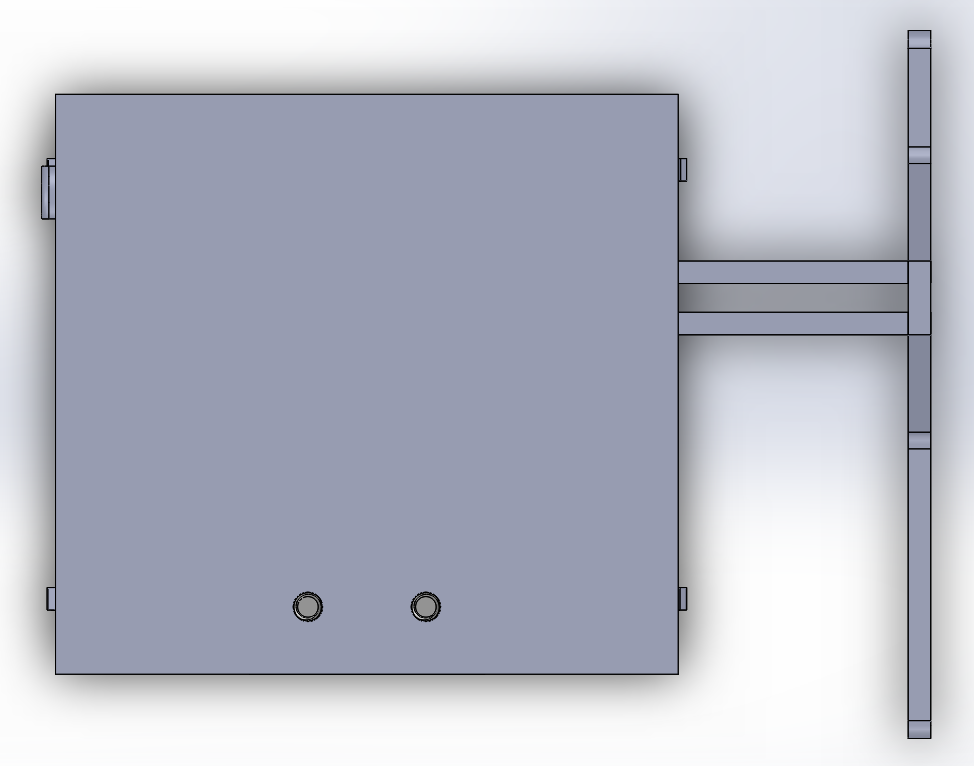

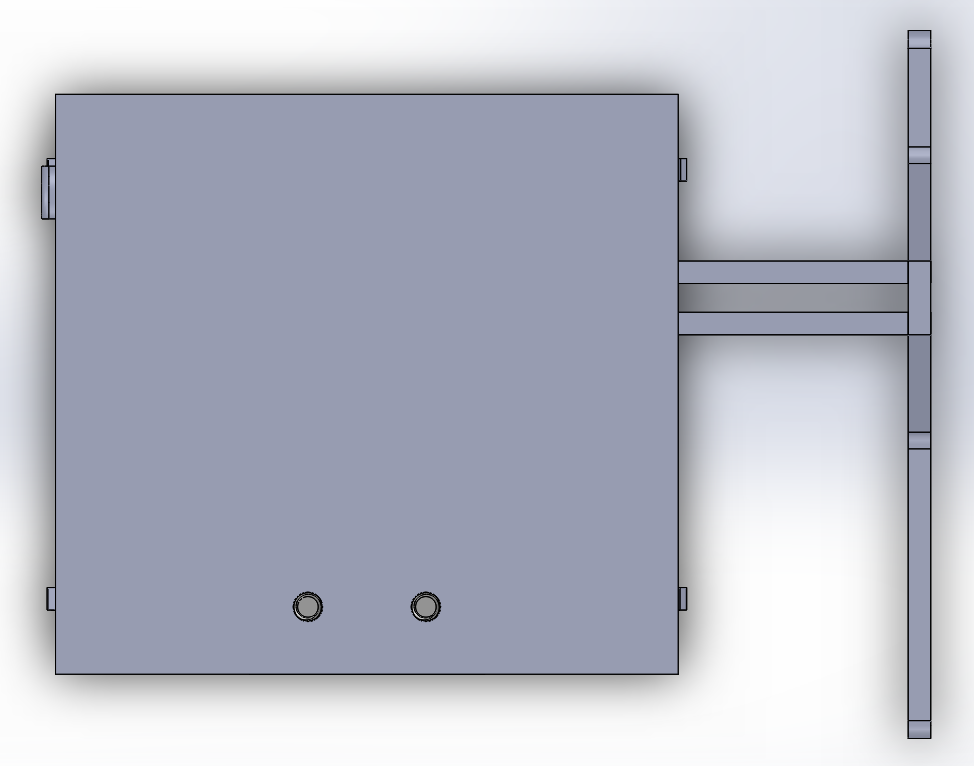

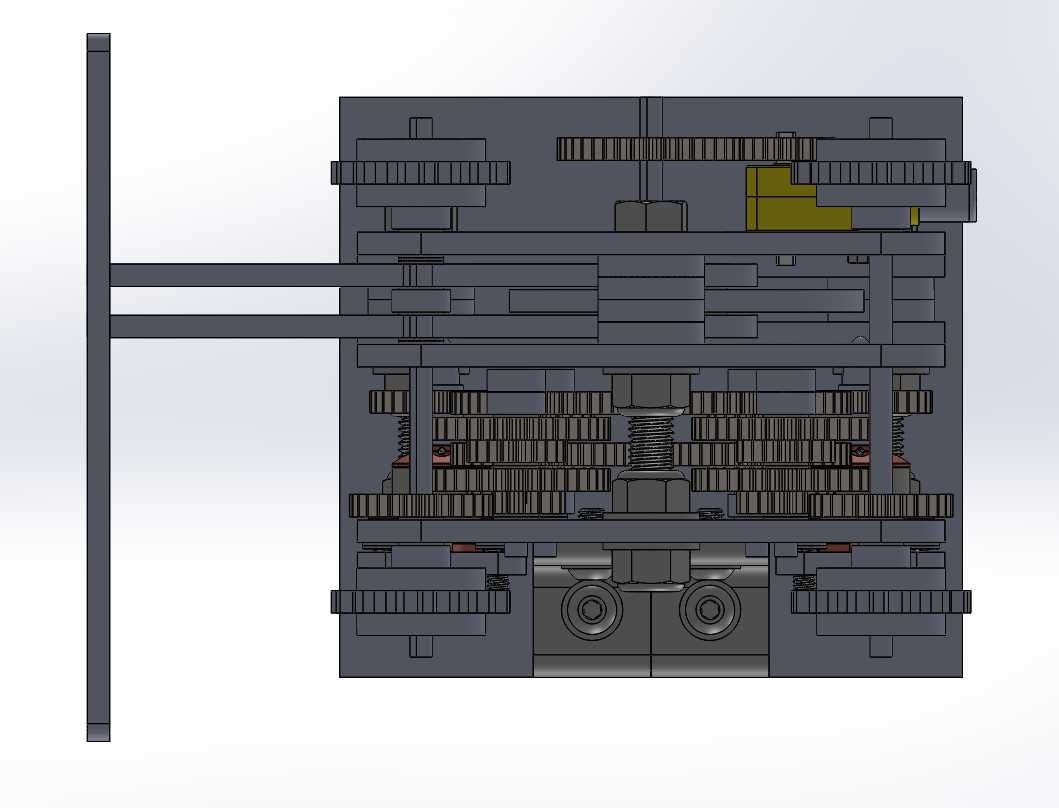

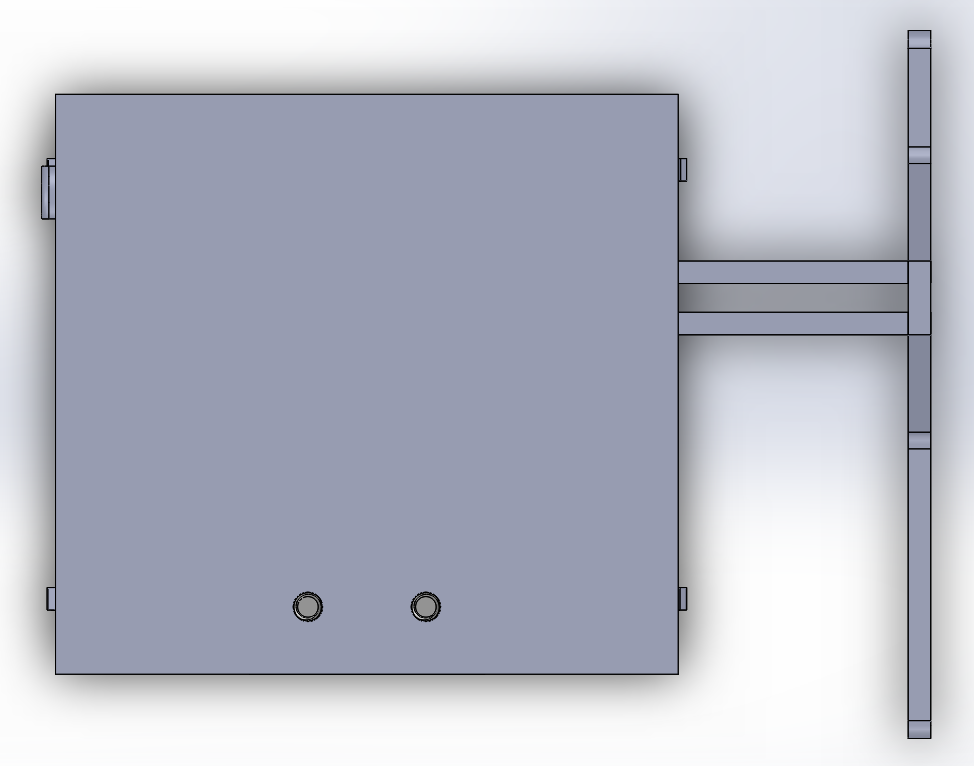

Goalie

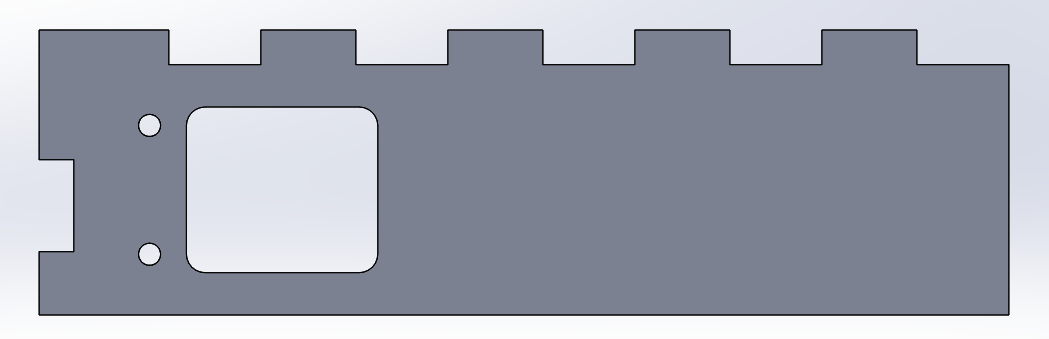

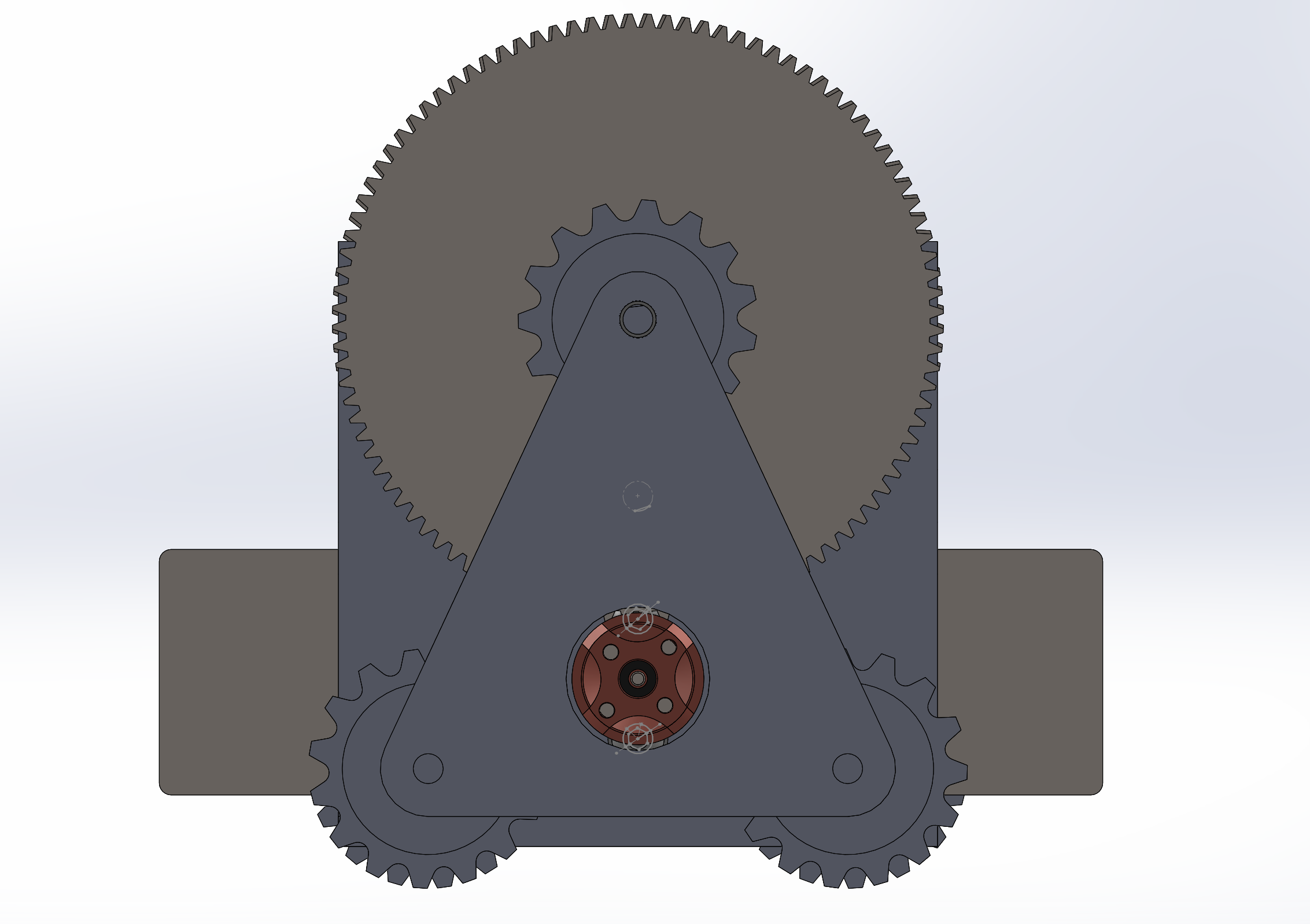

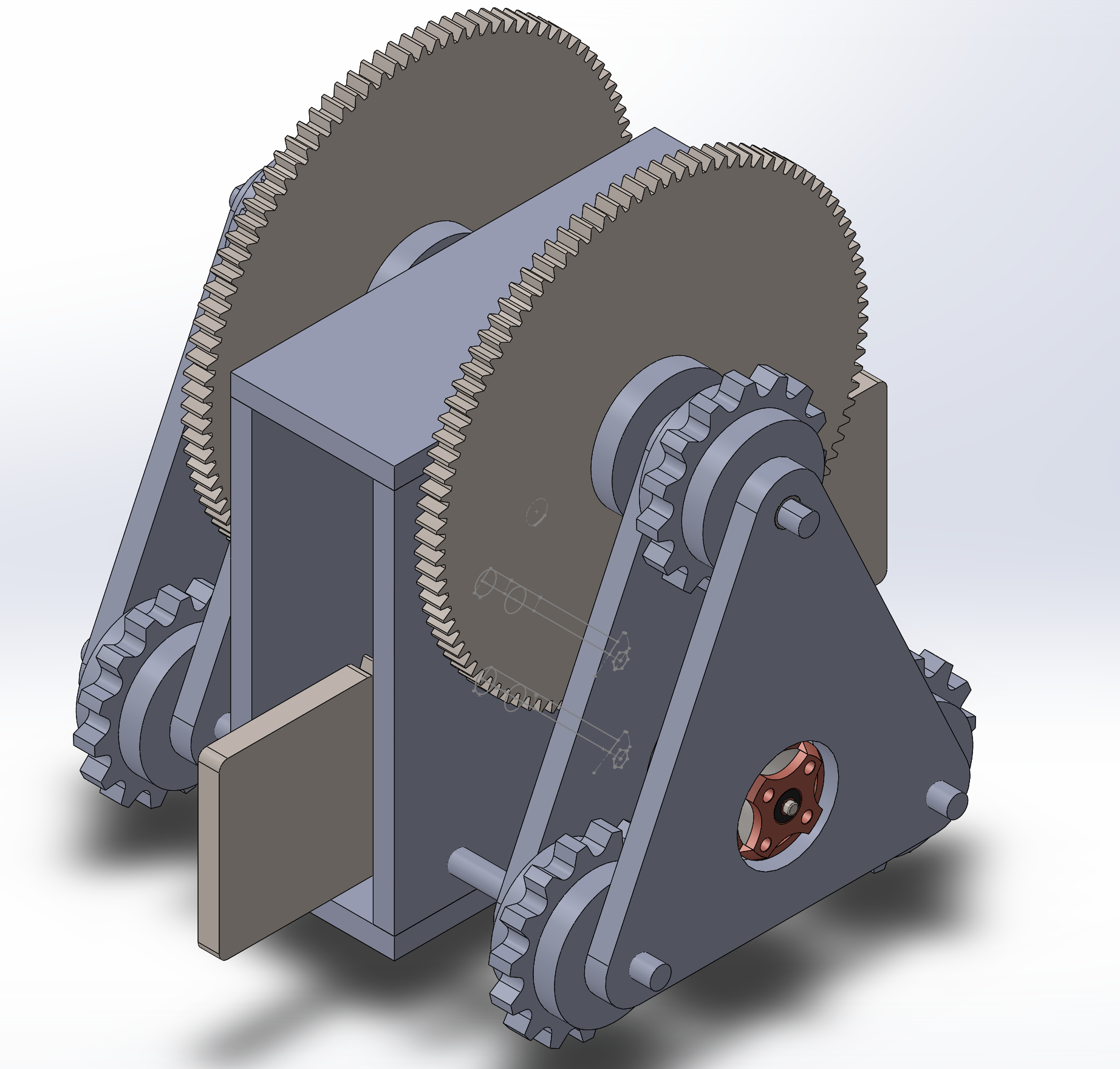

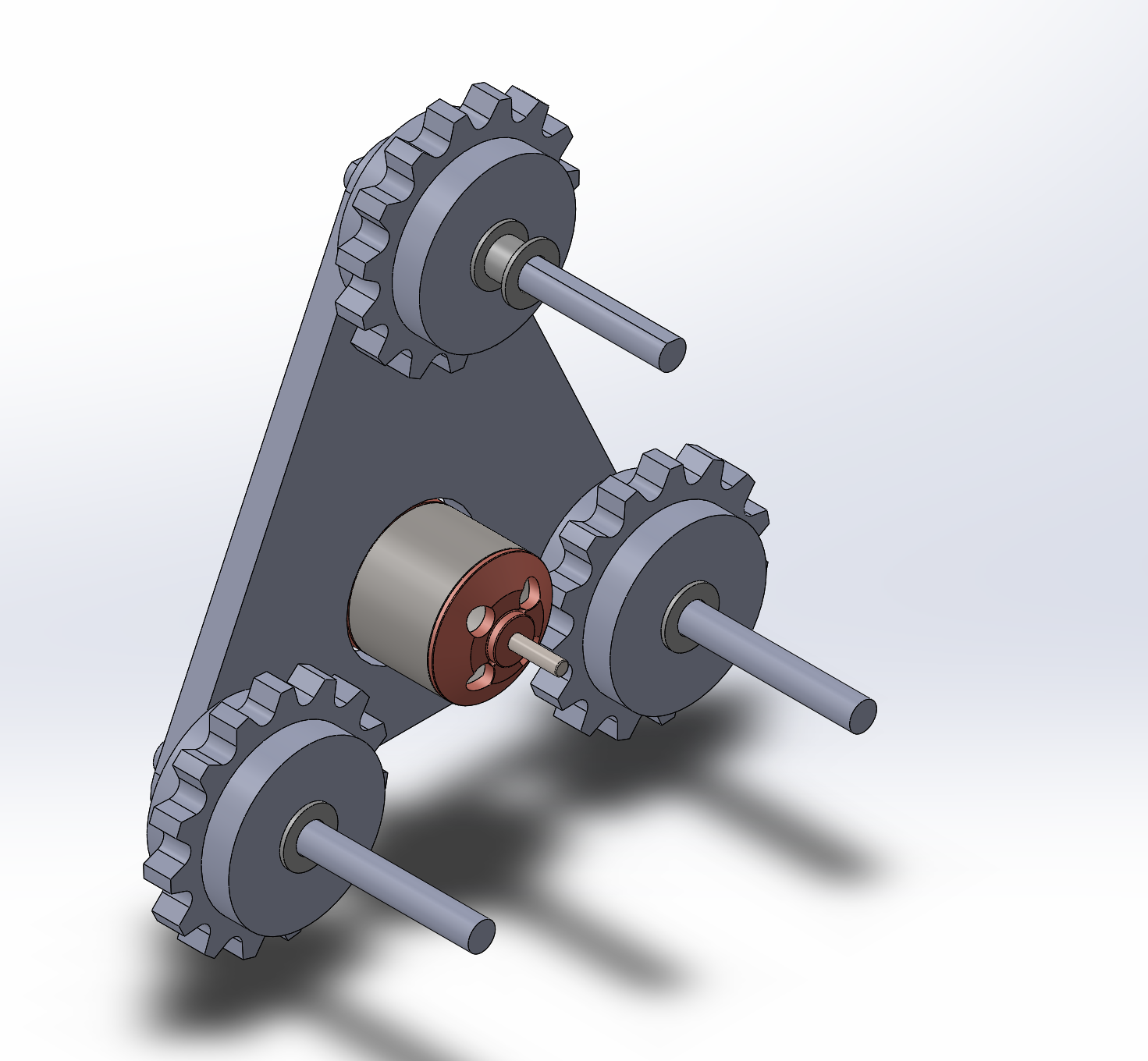

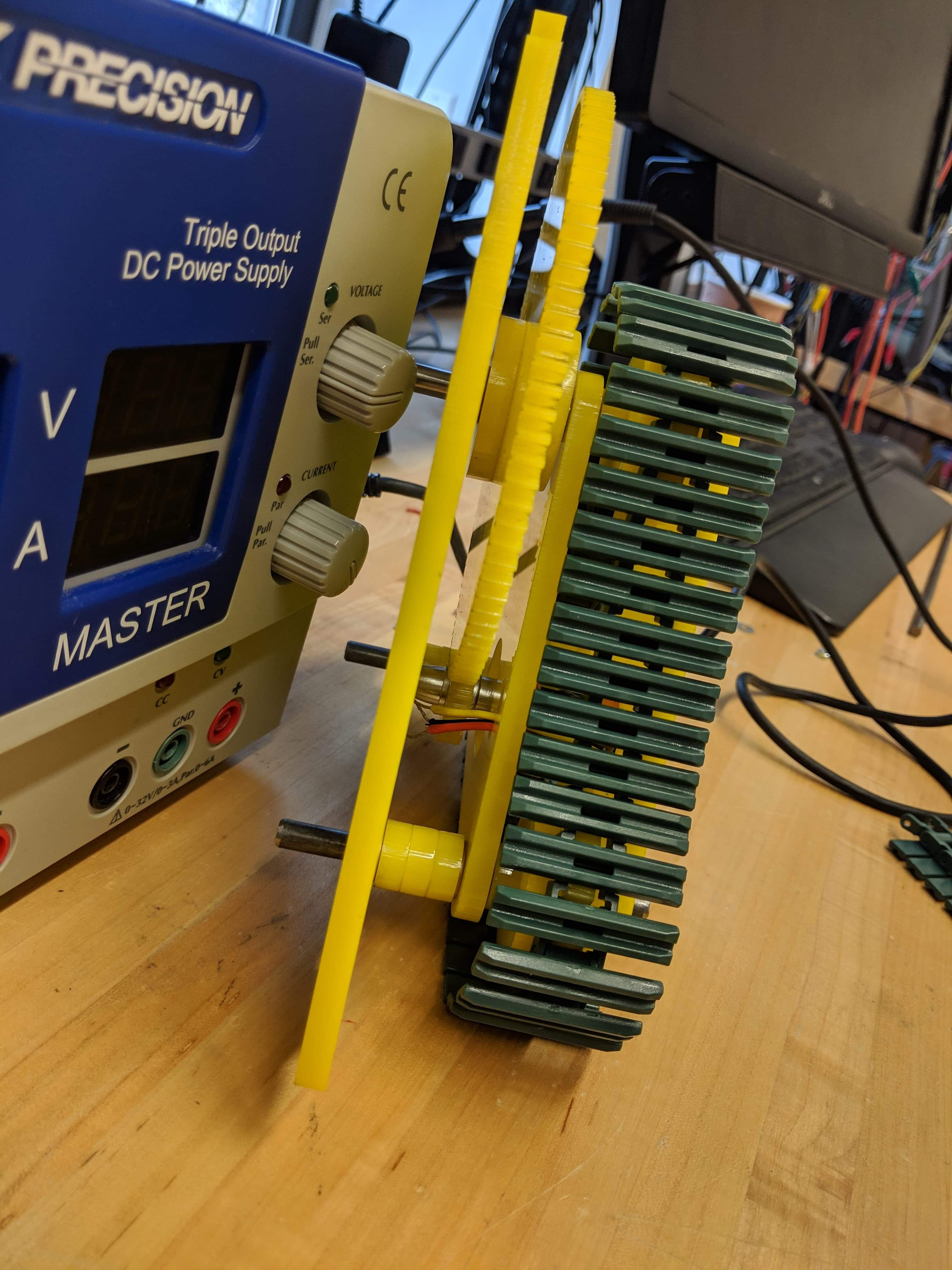

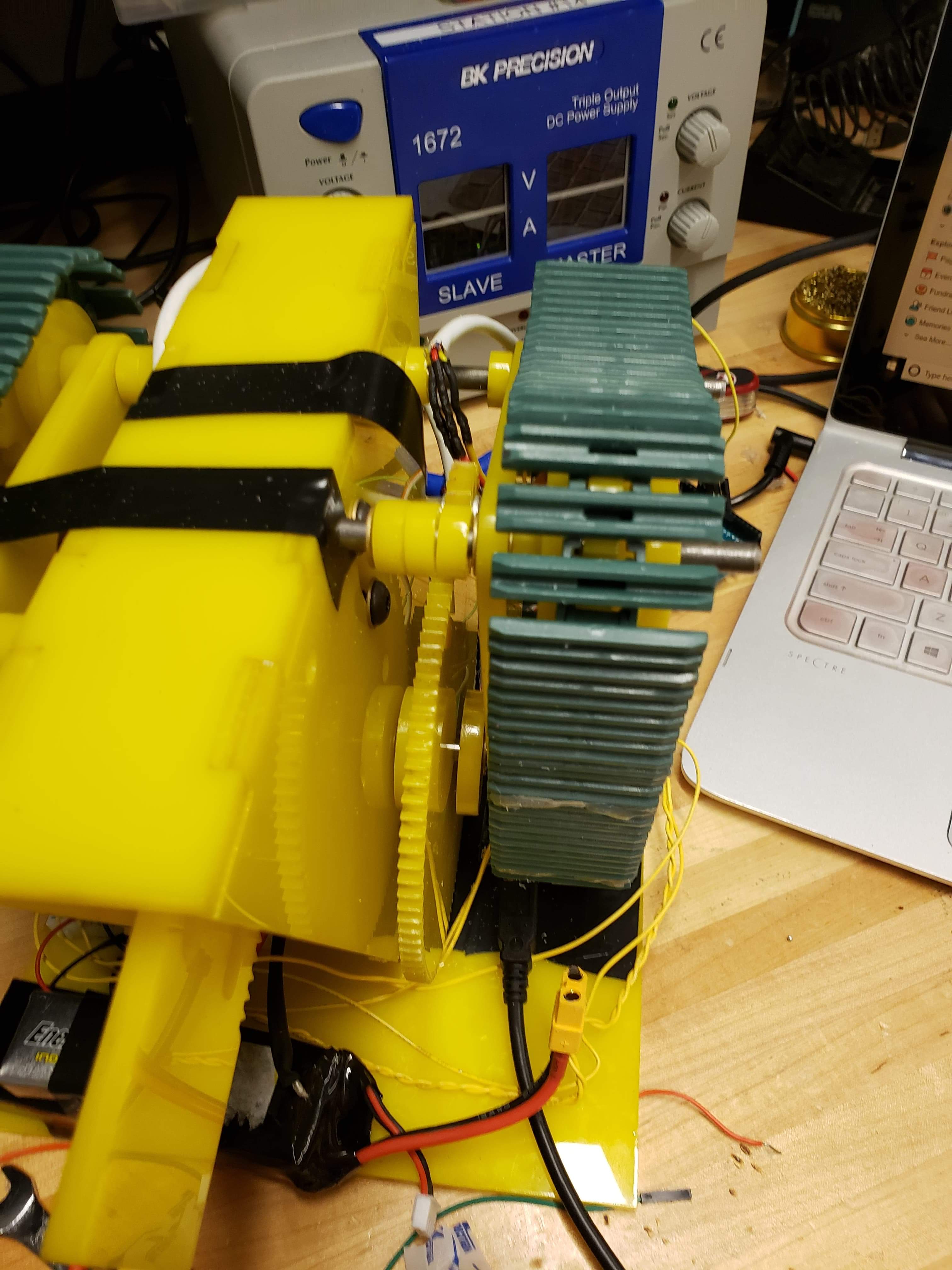

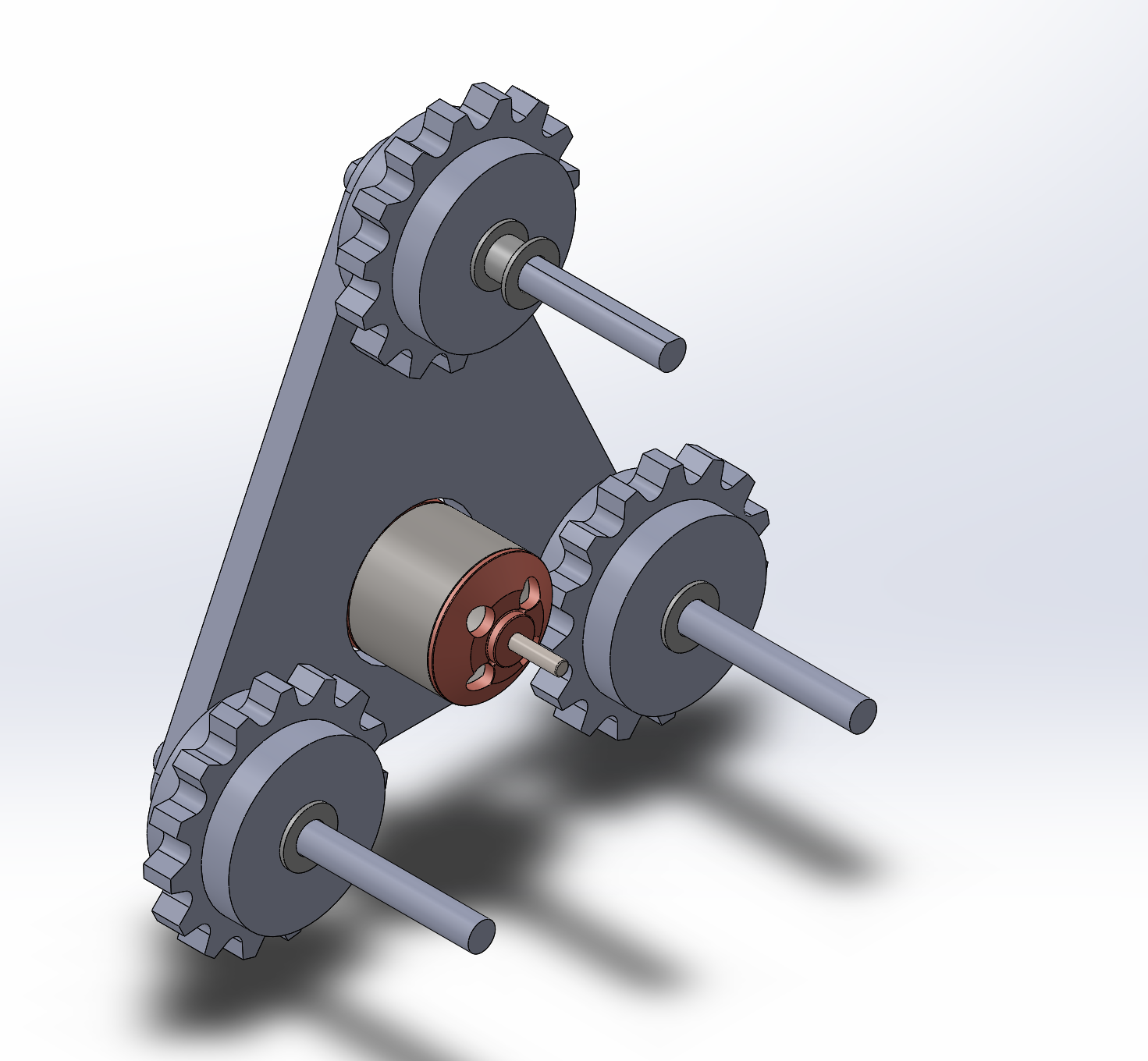

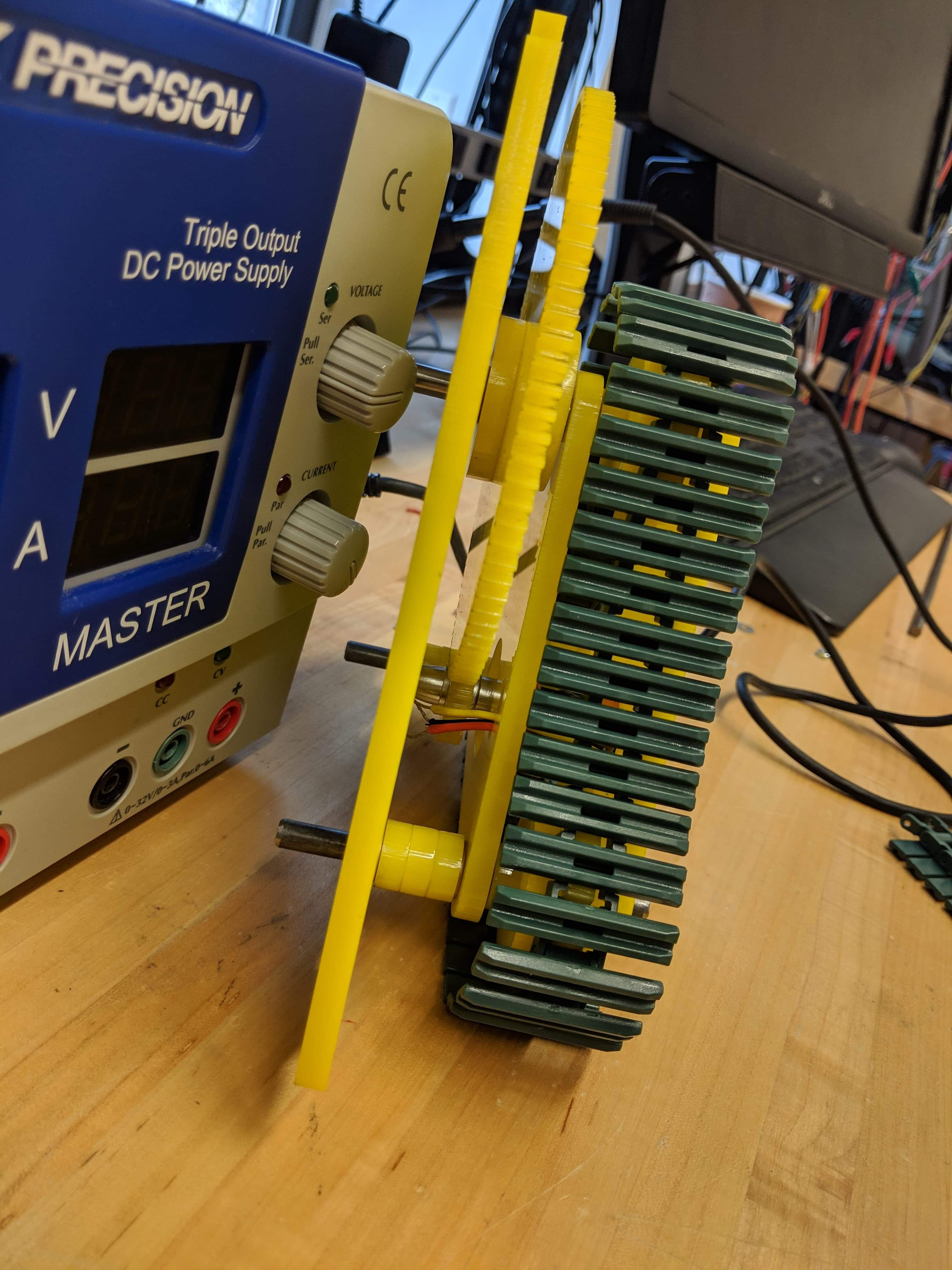

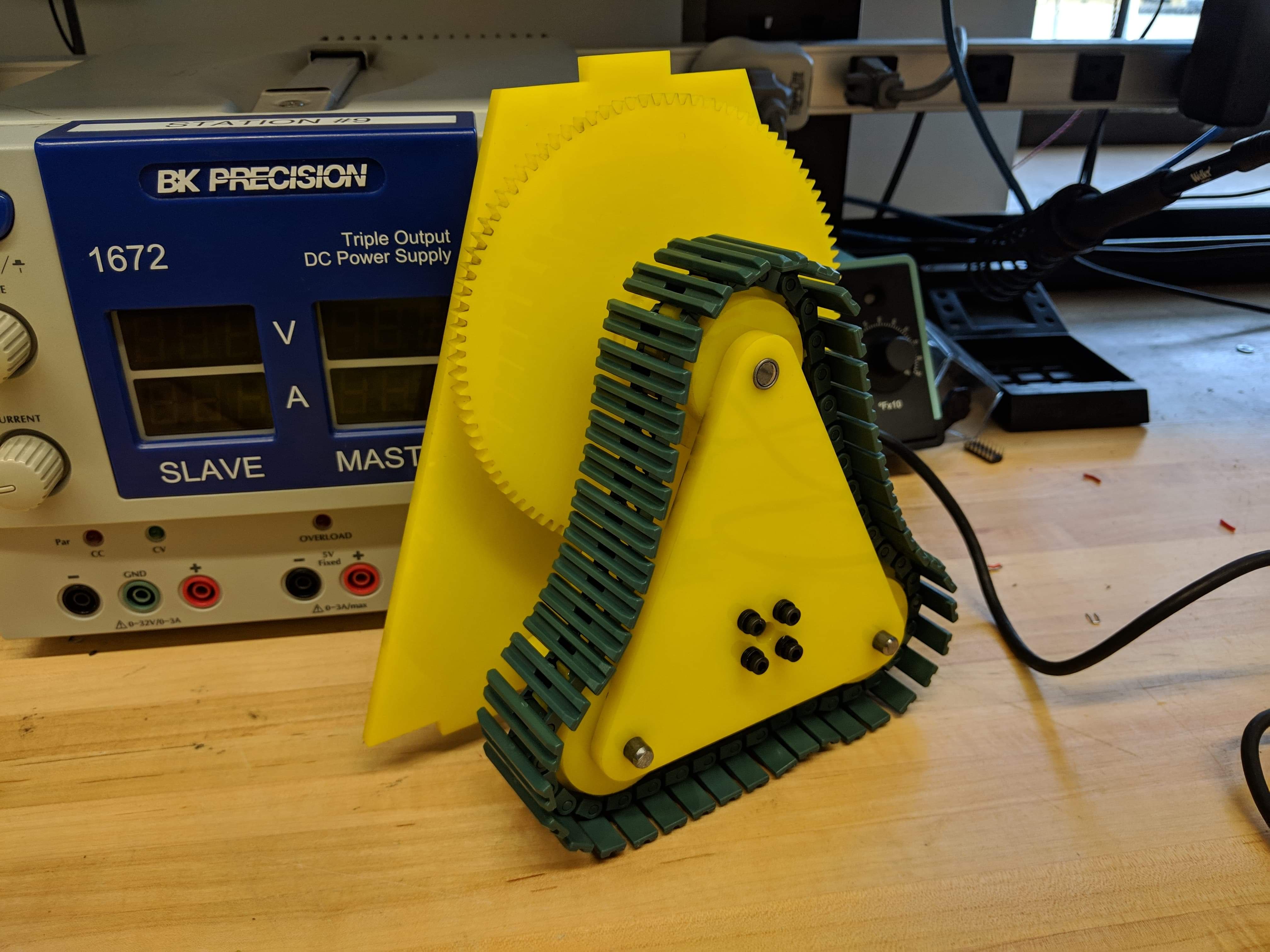

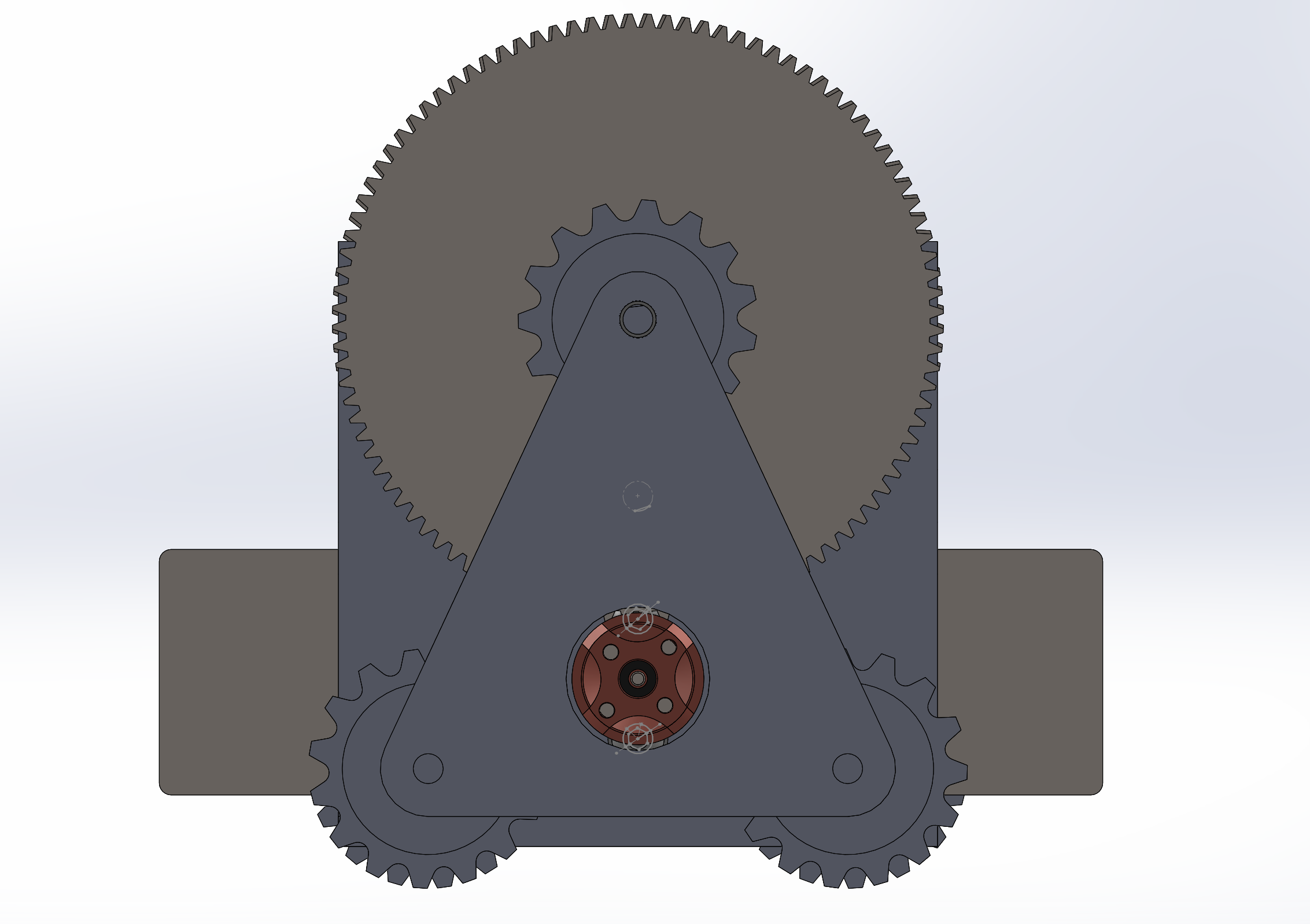

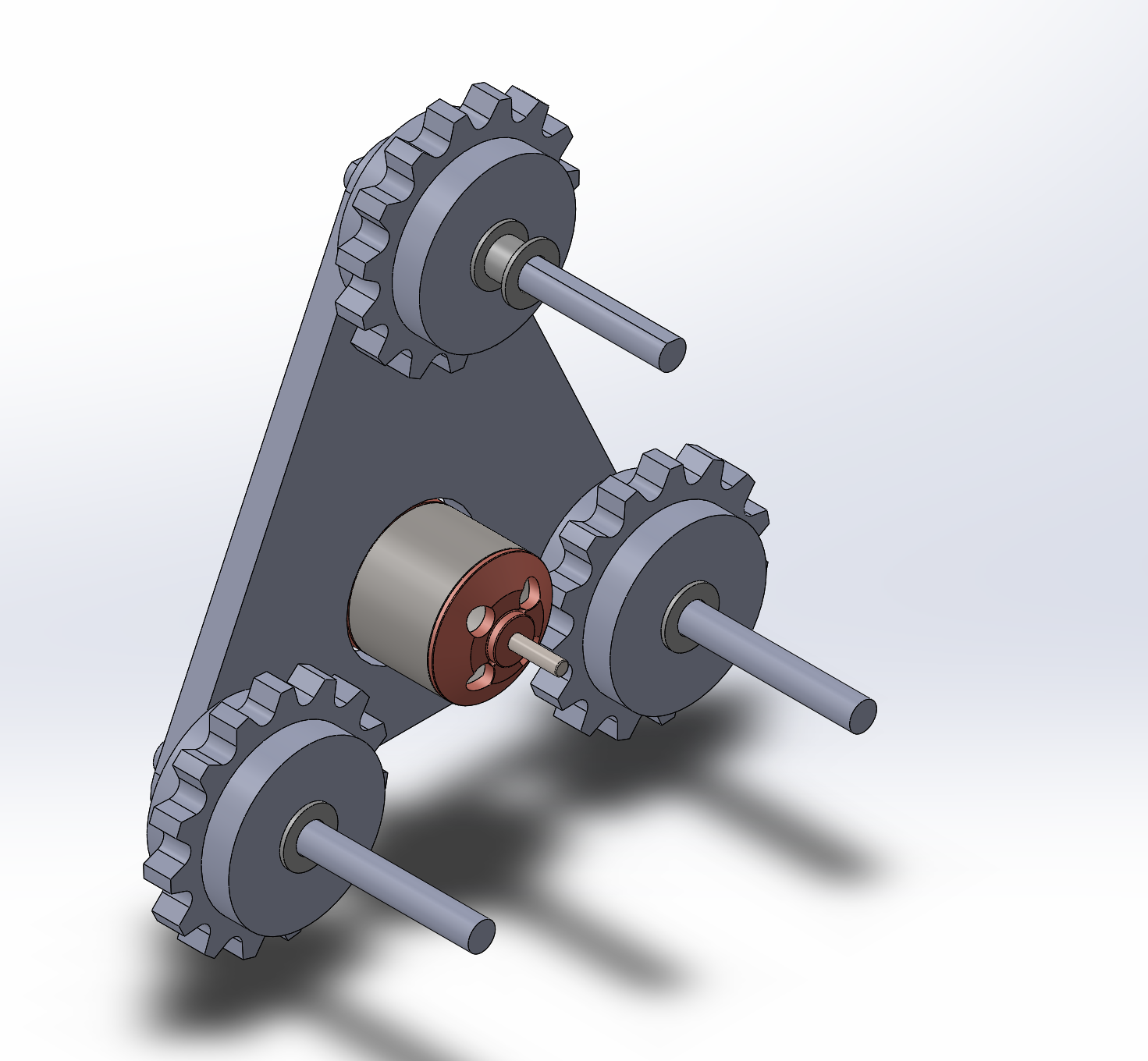

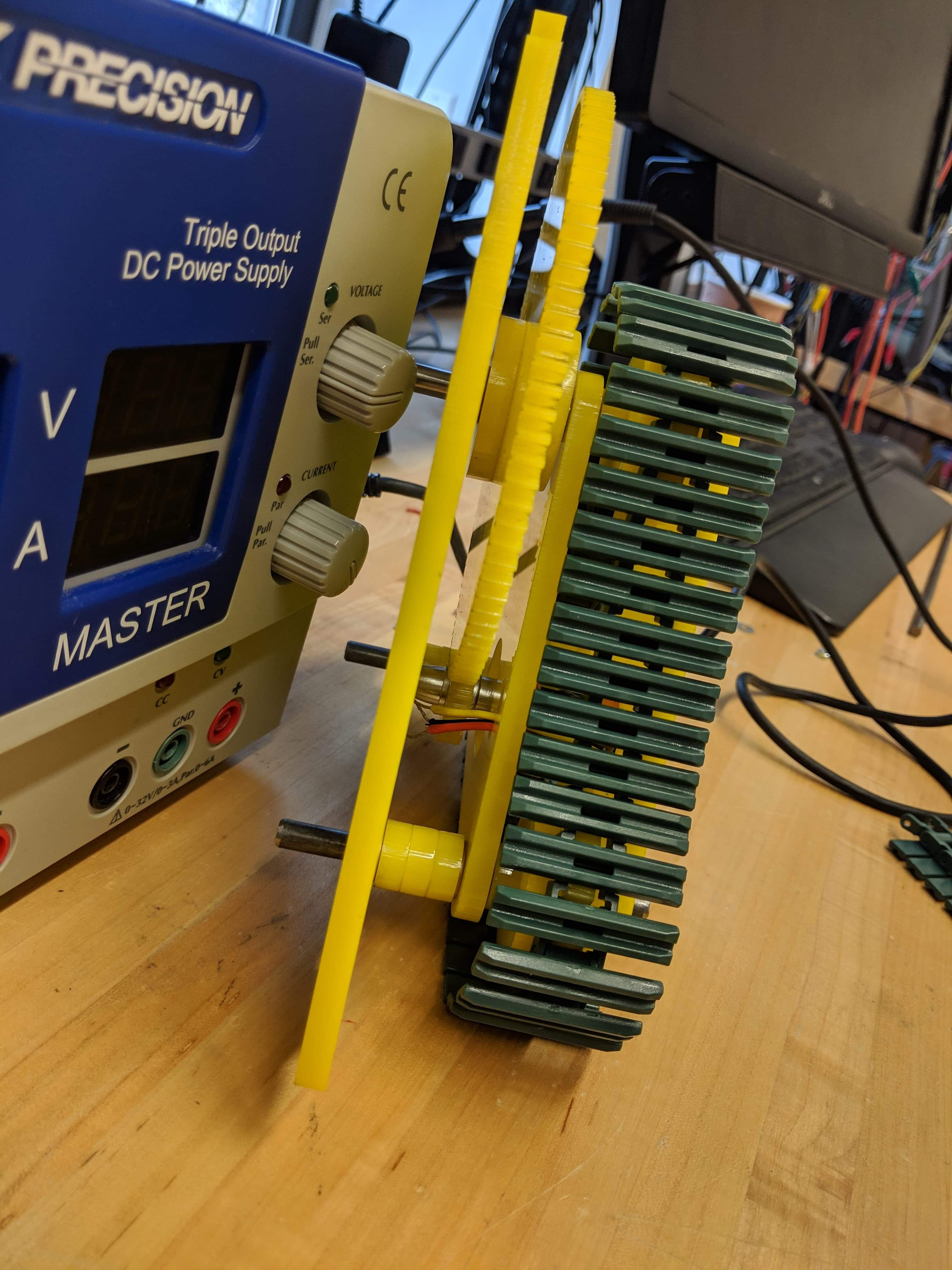

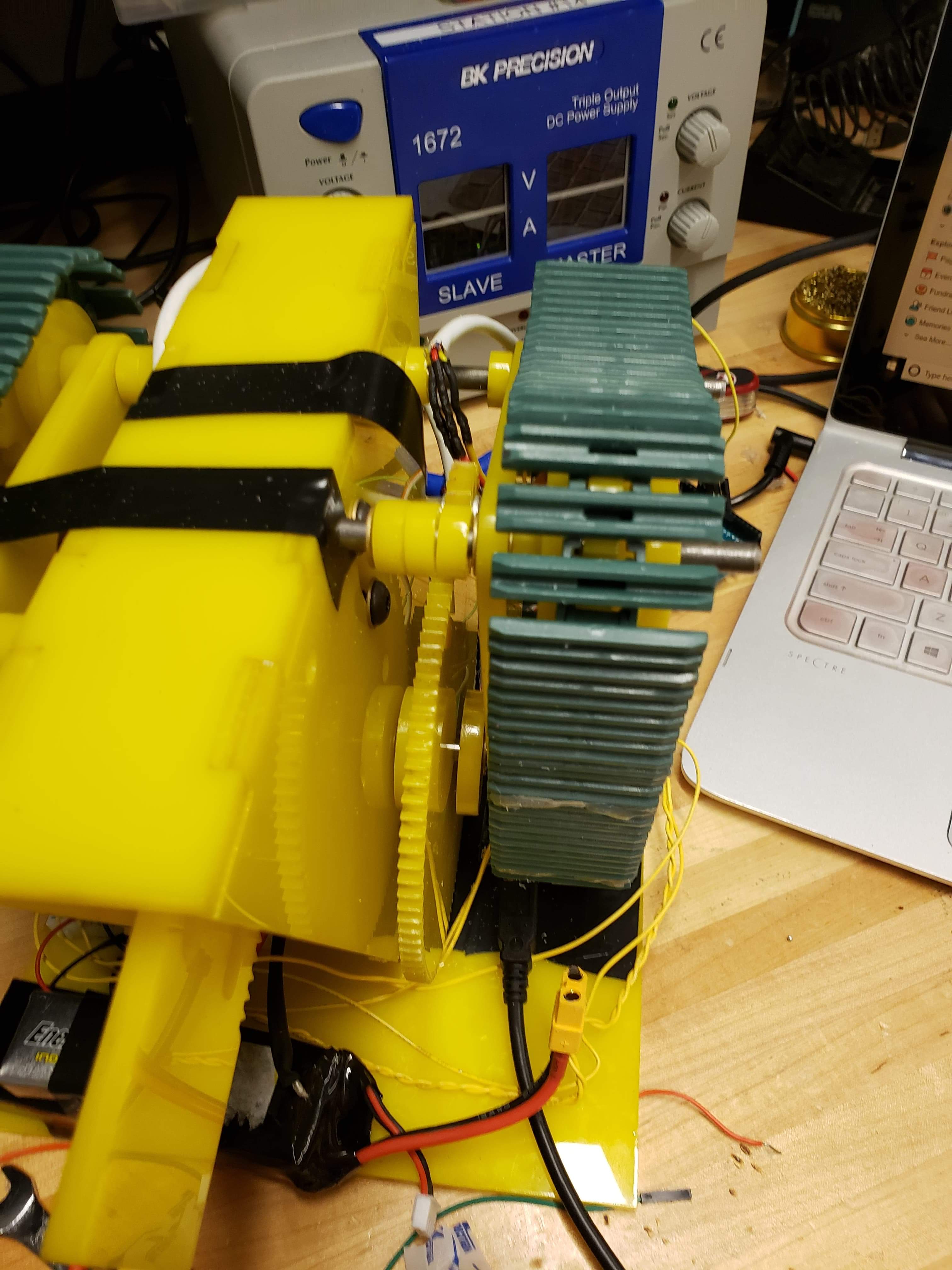

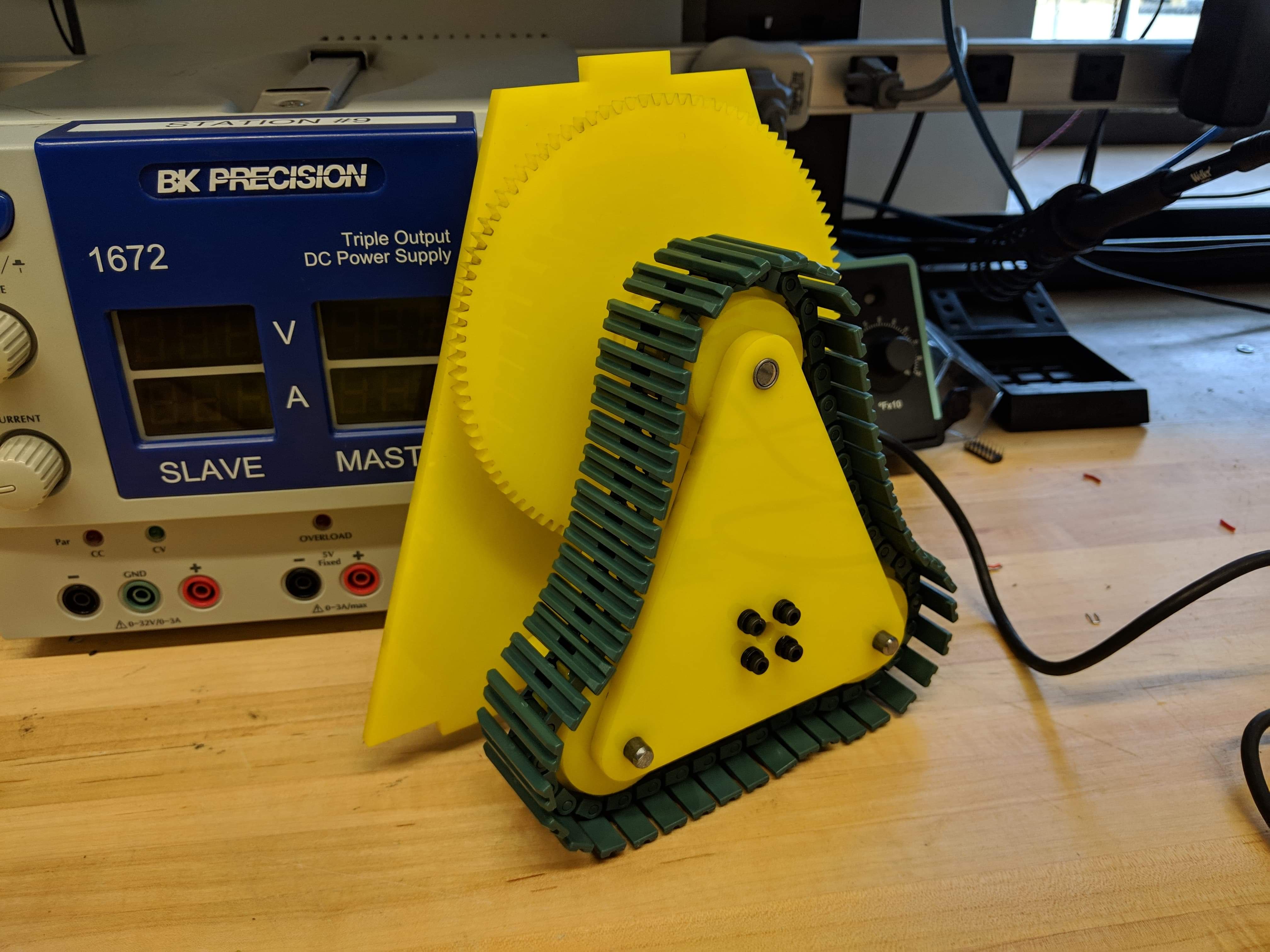

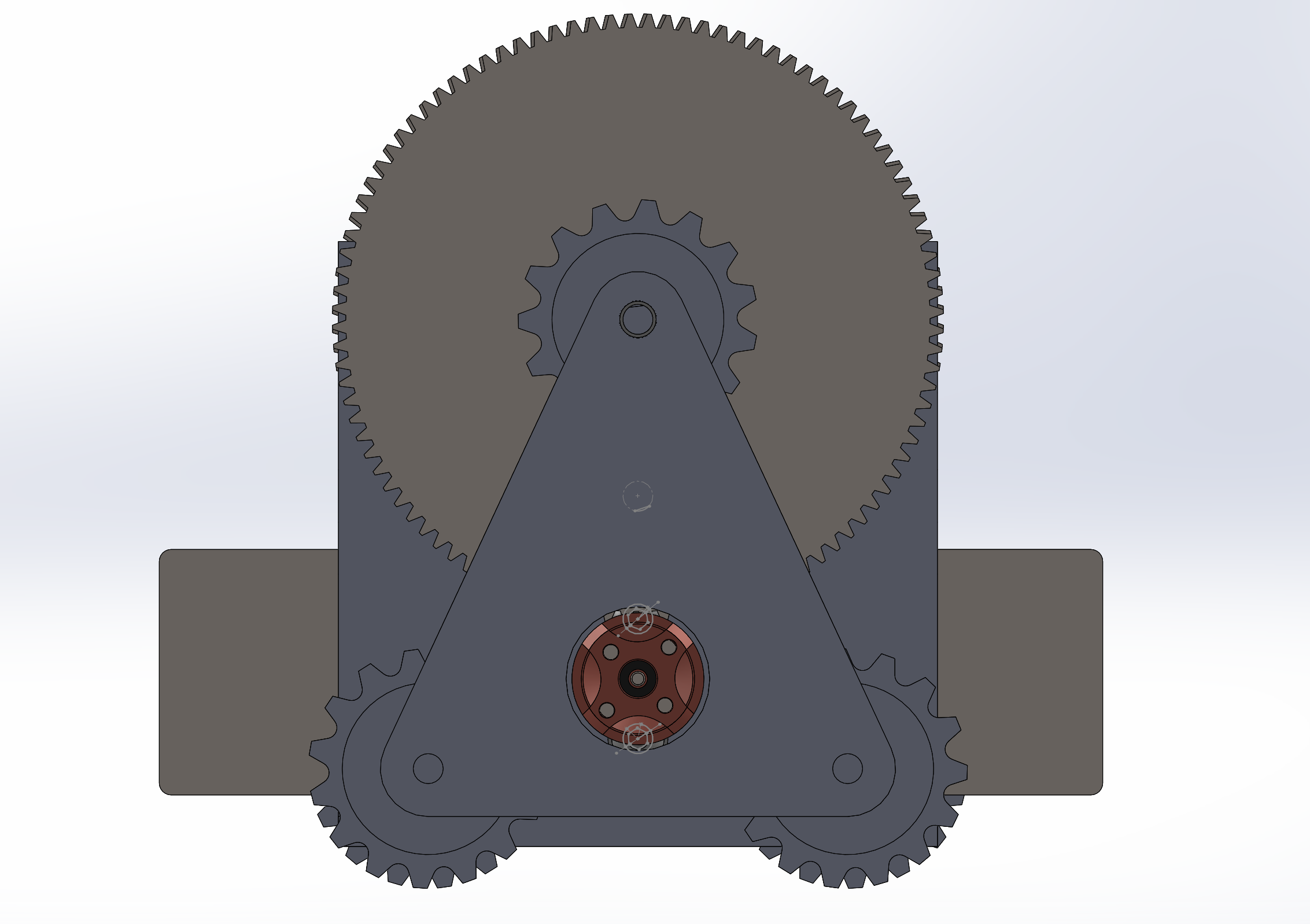

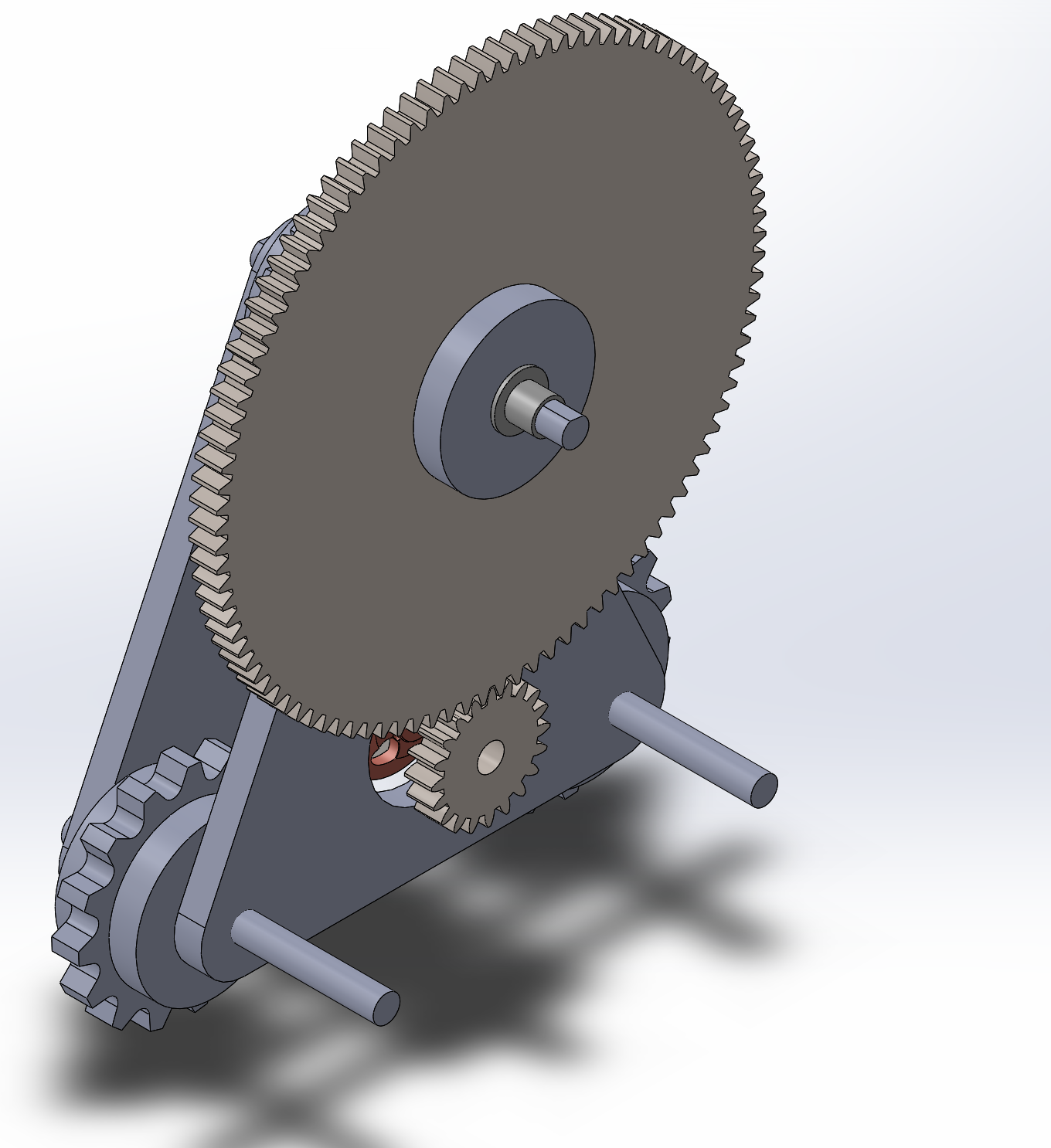

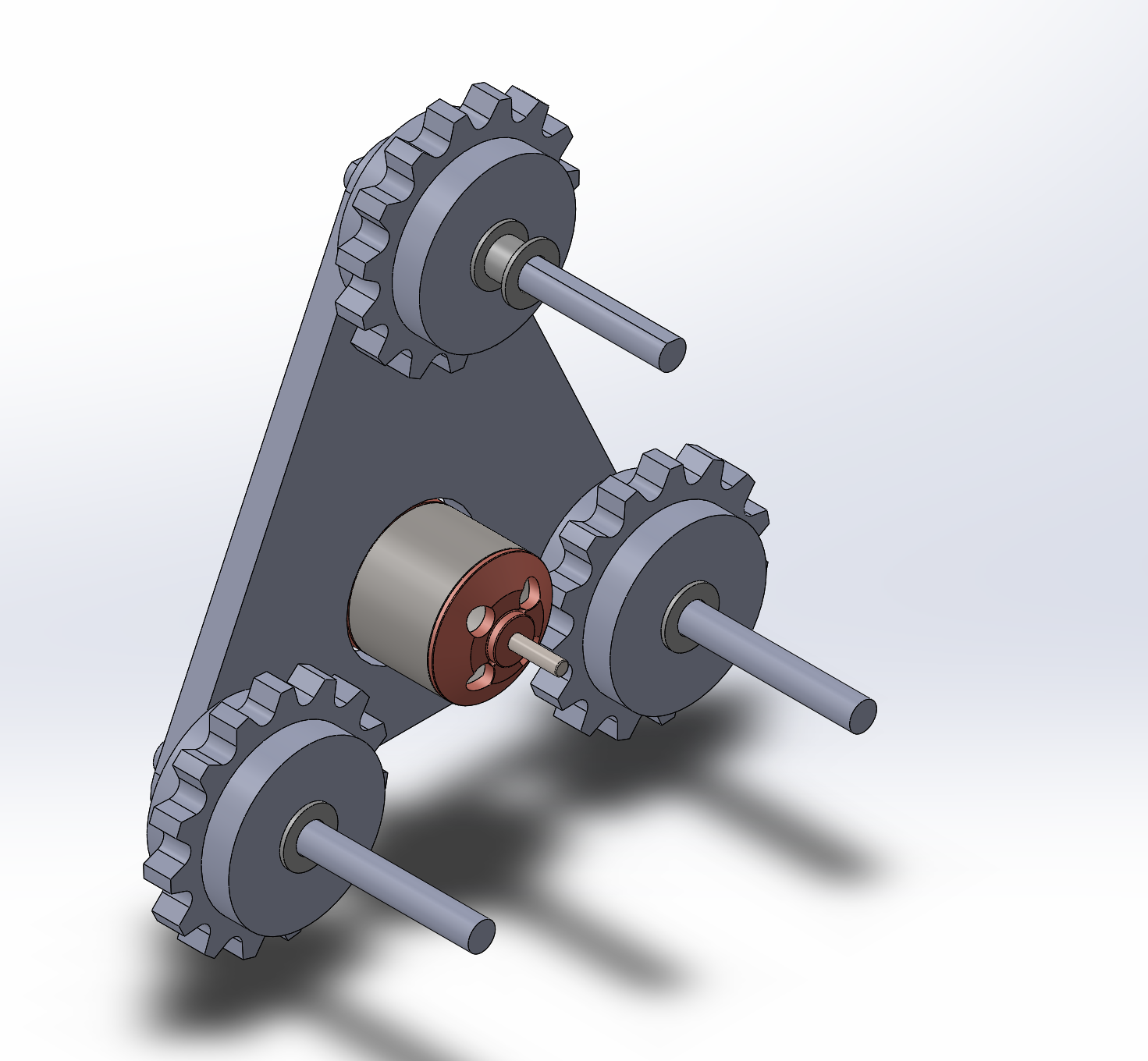

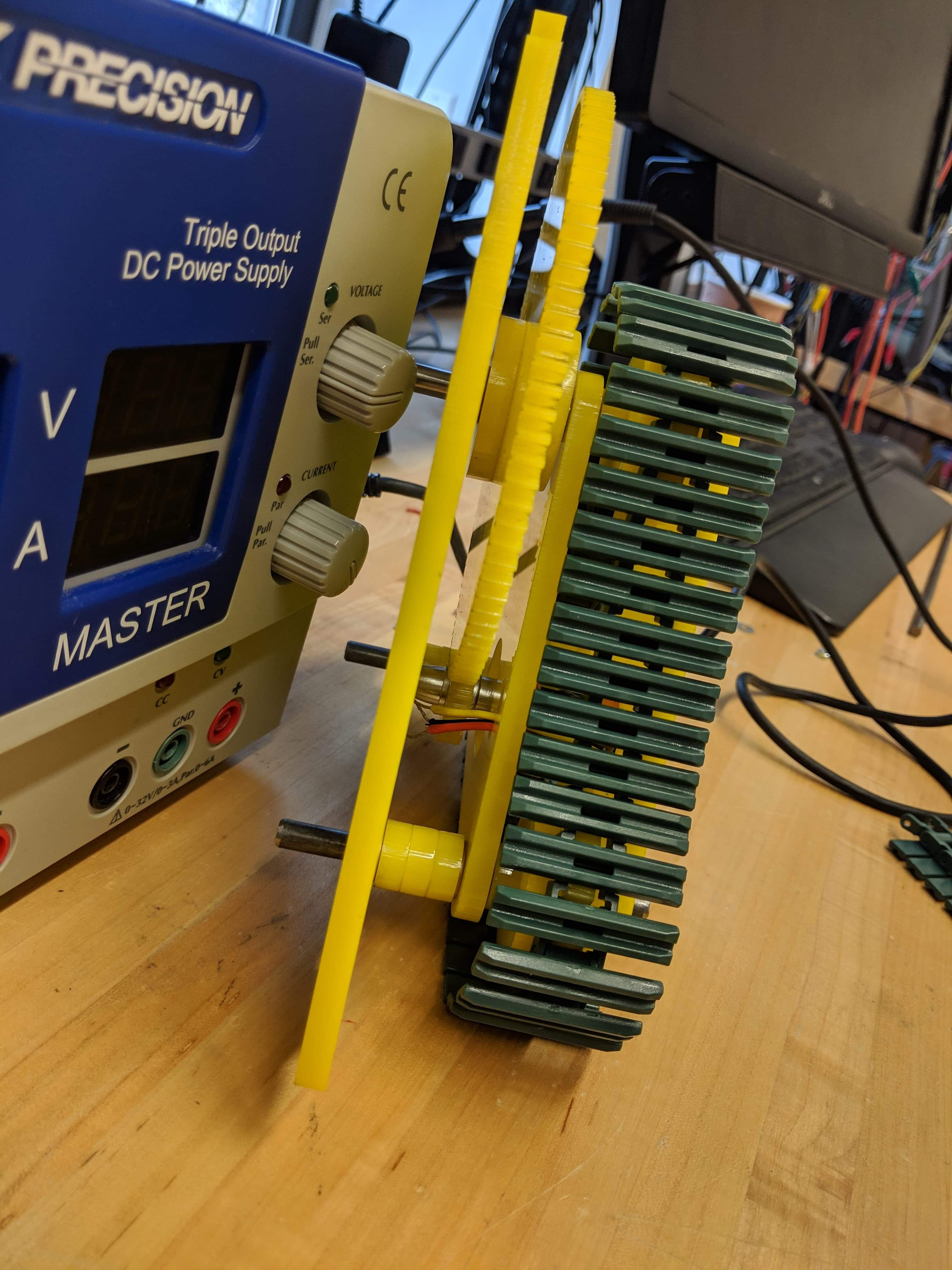

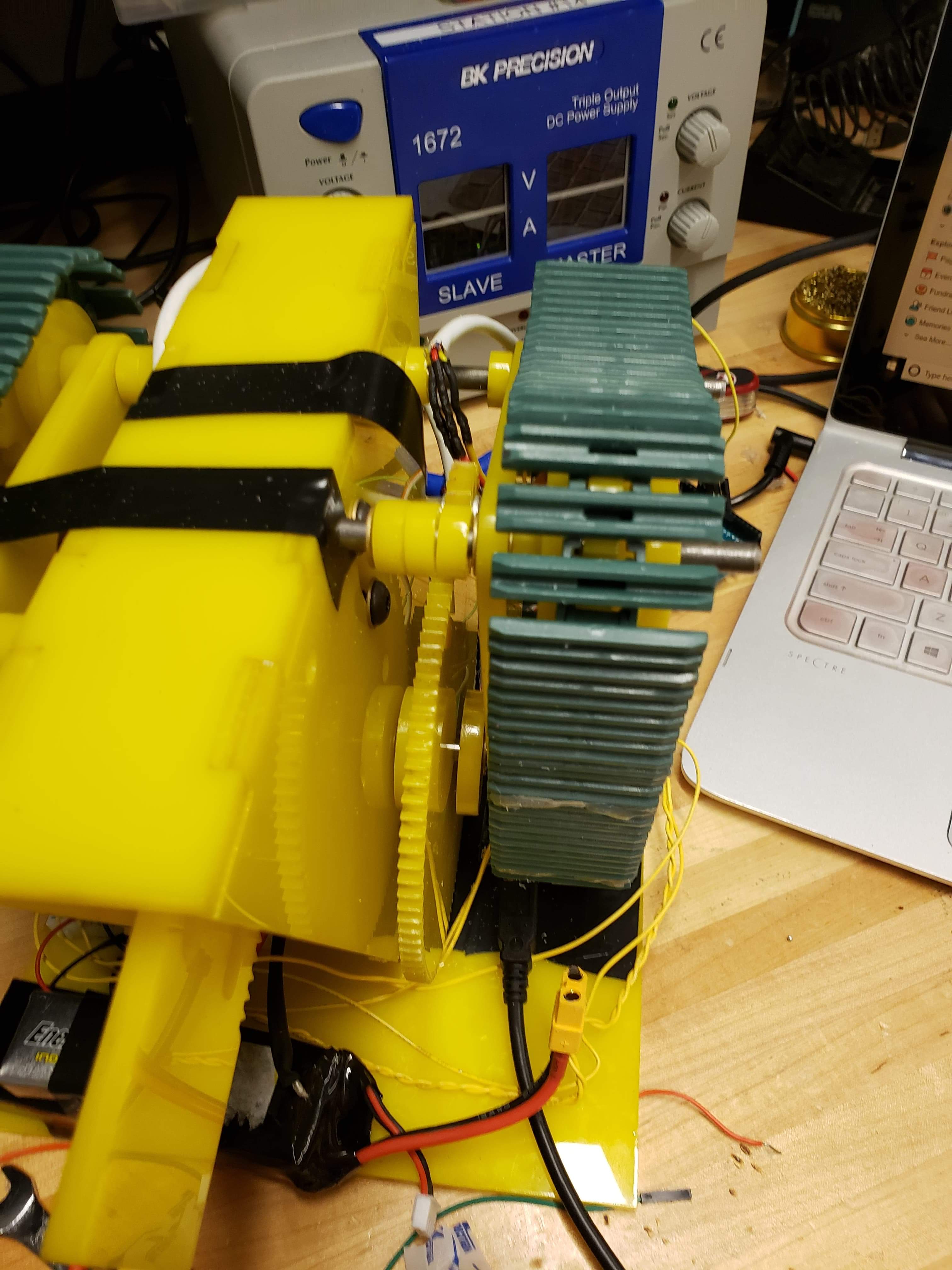

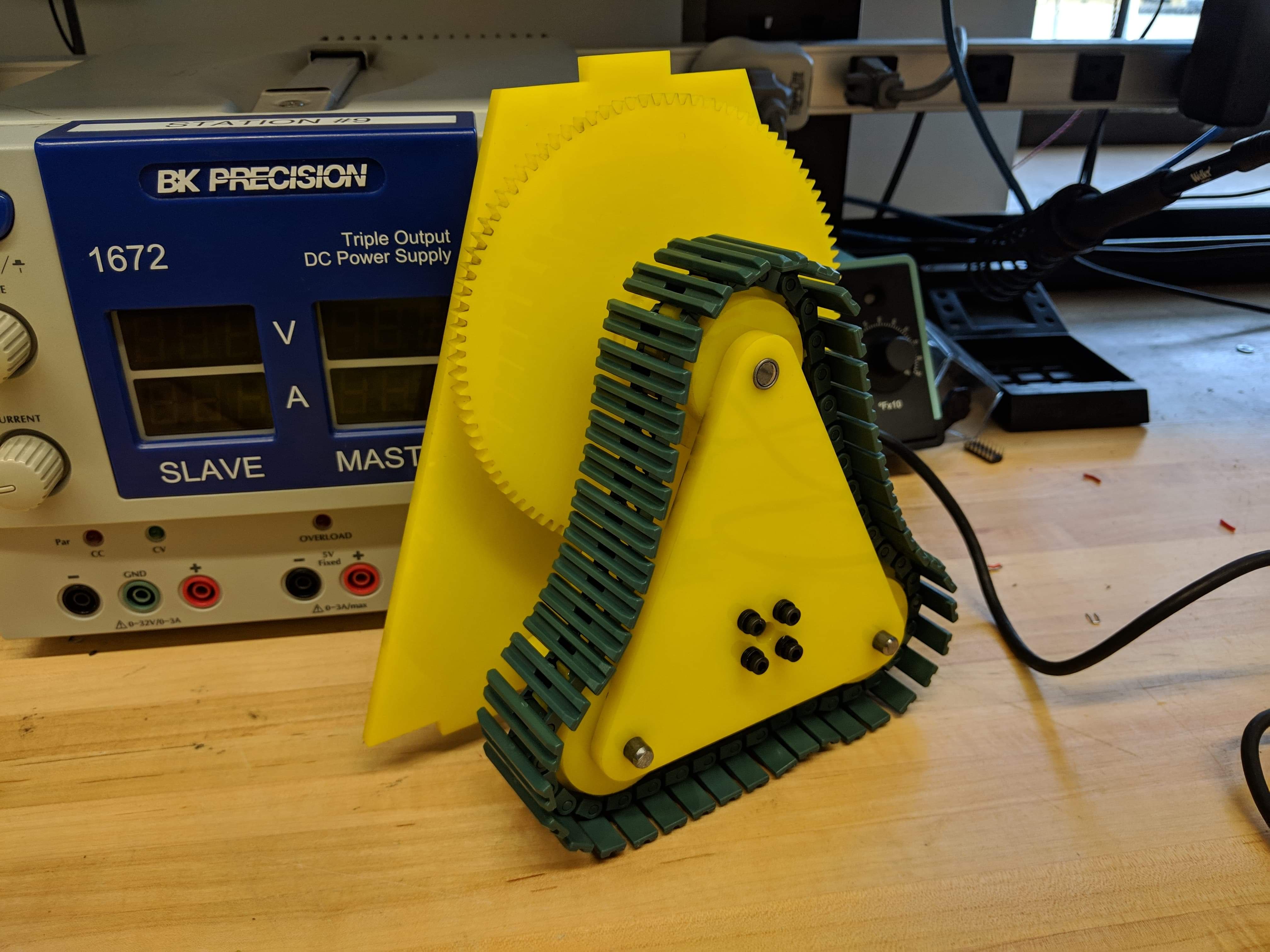

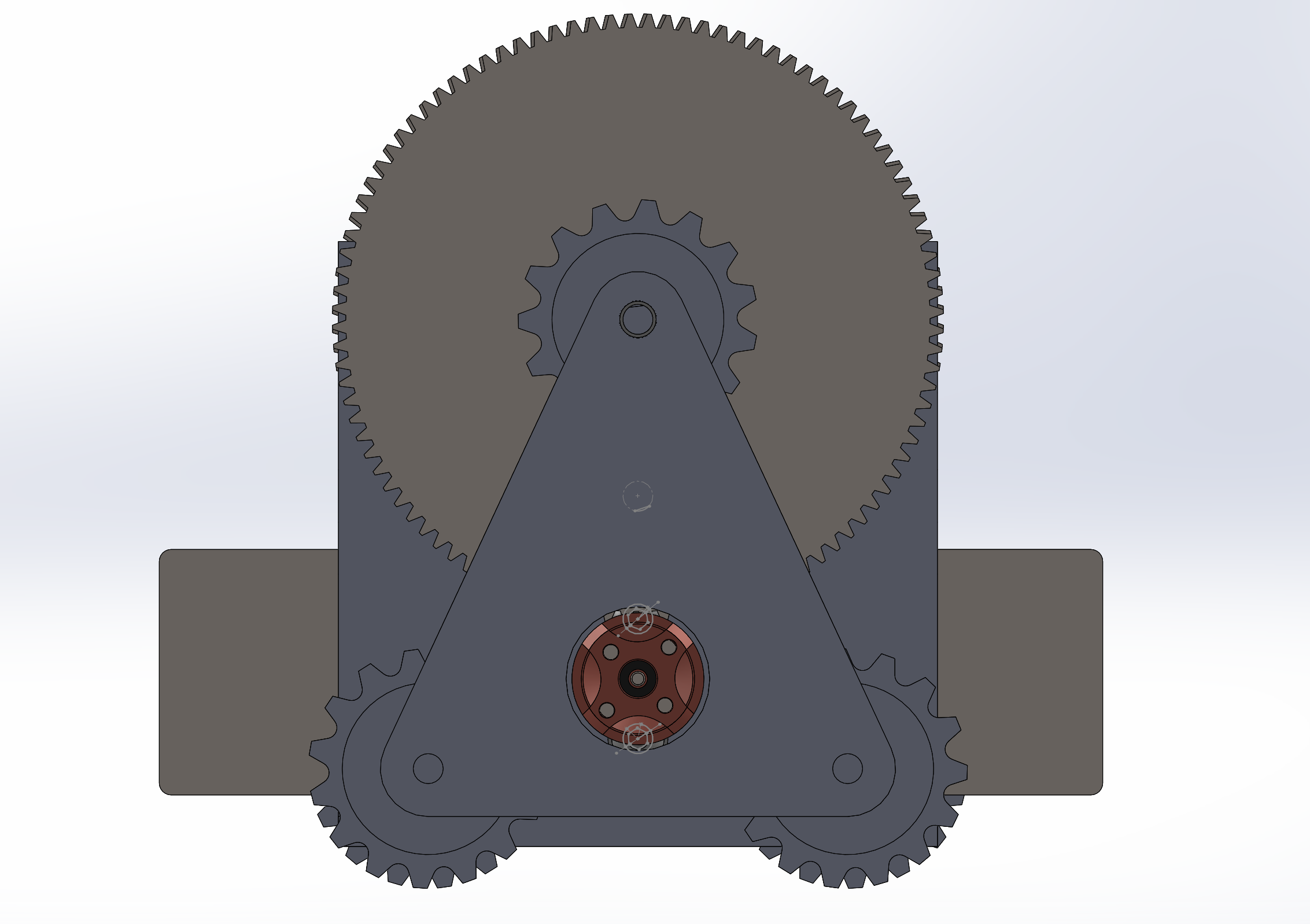

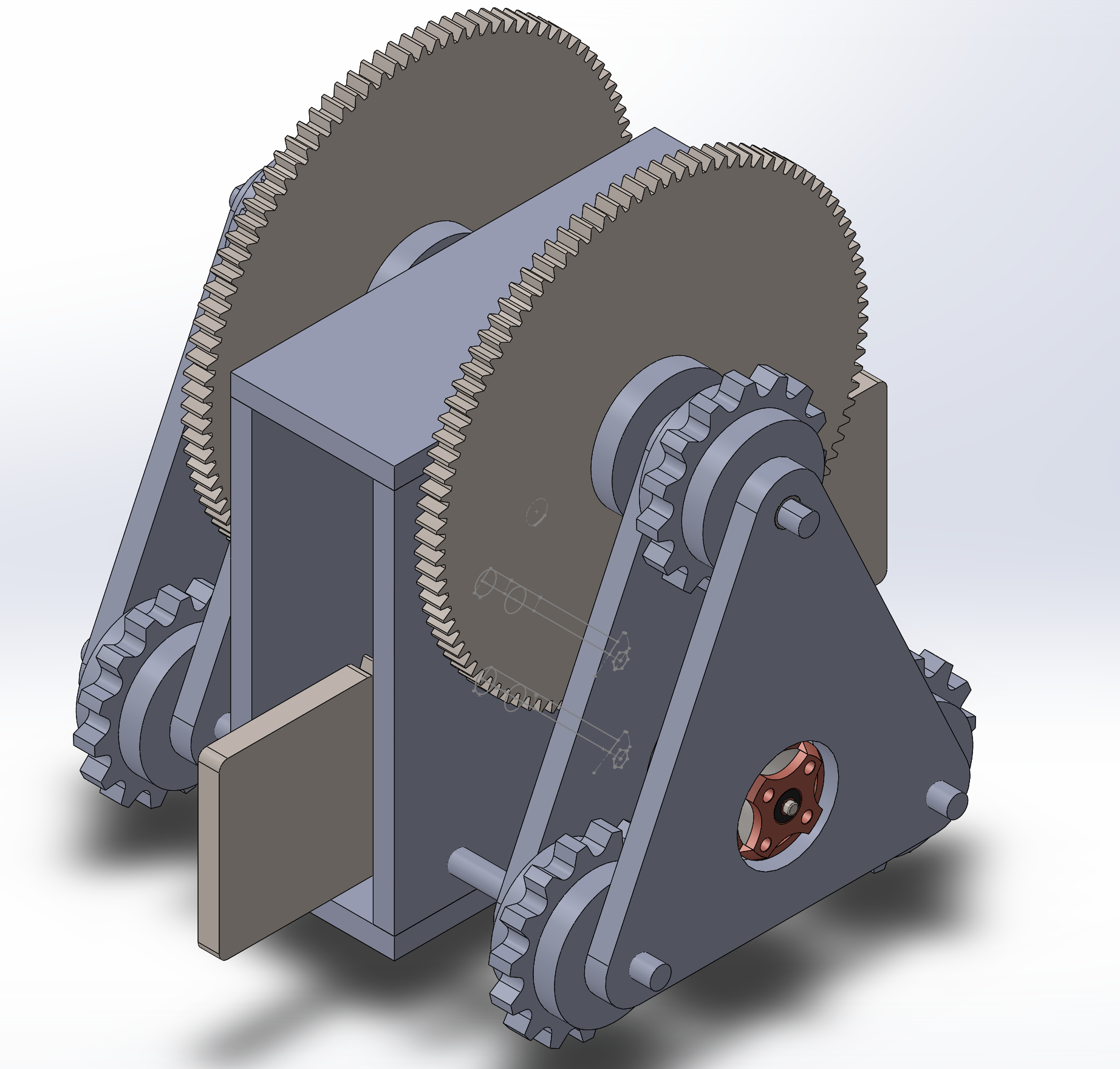

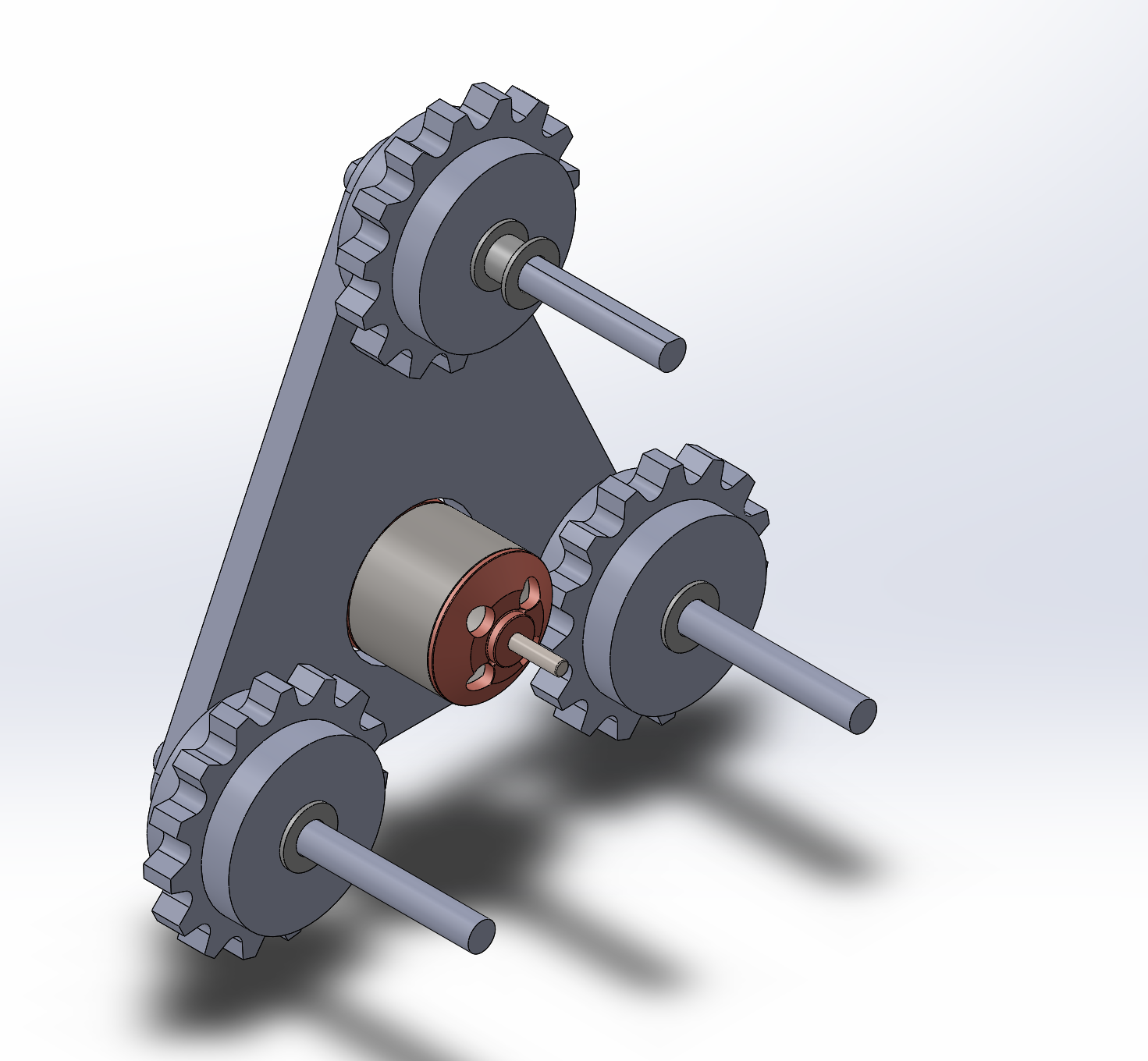

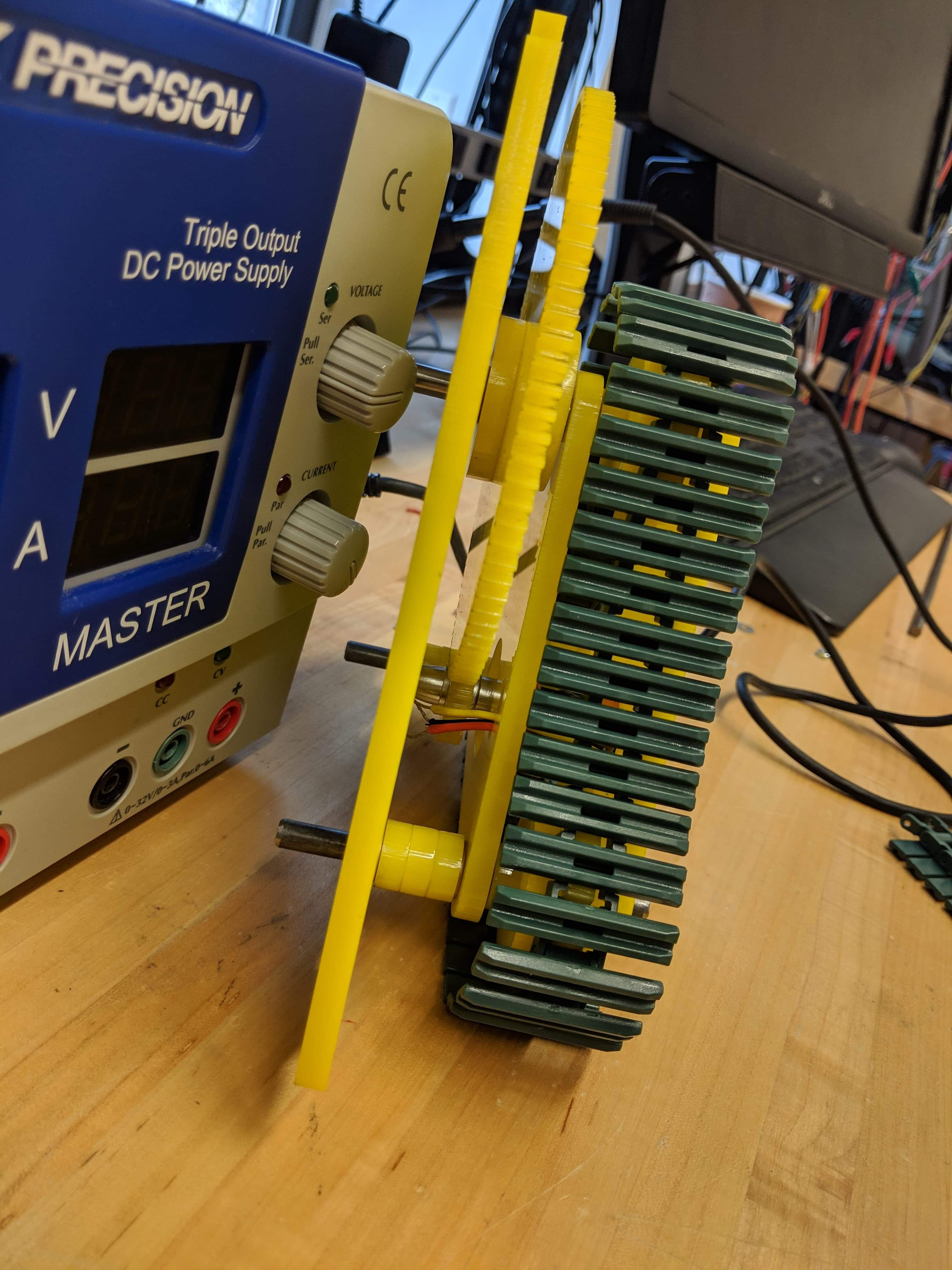

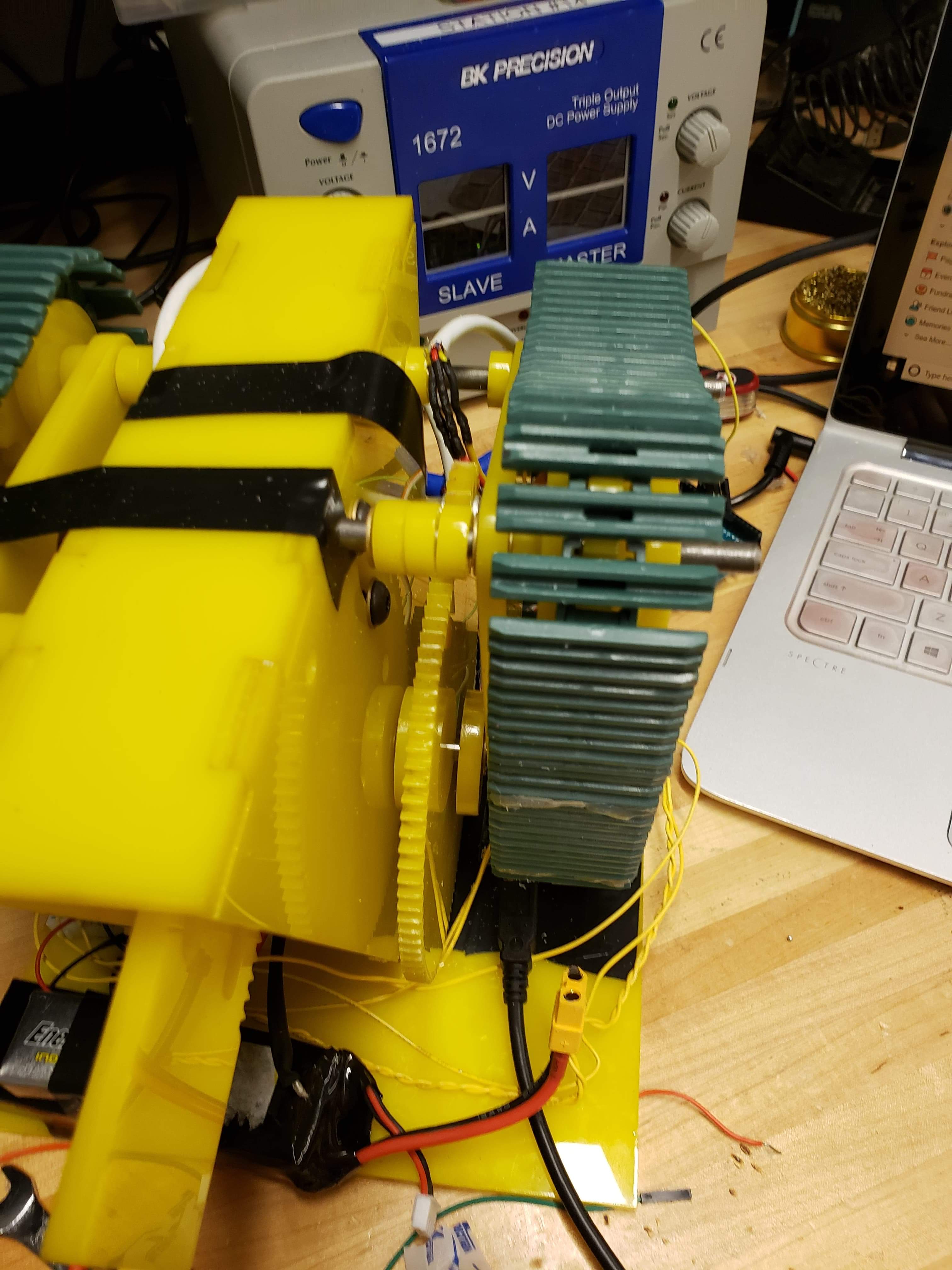

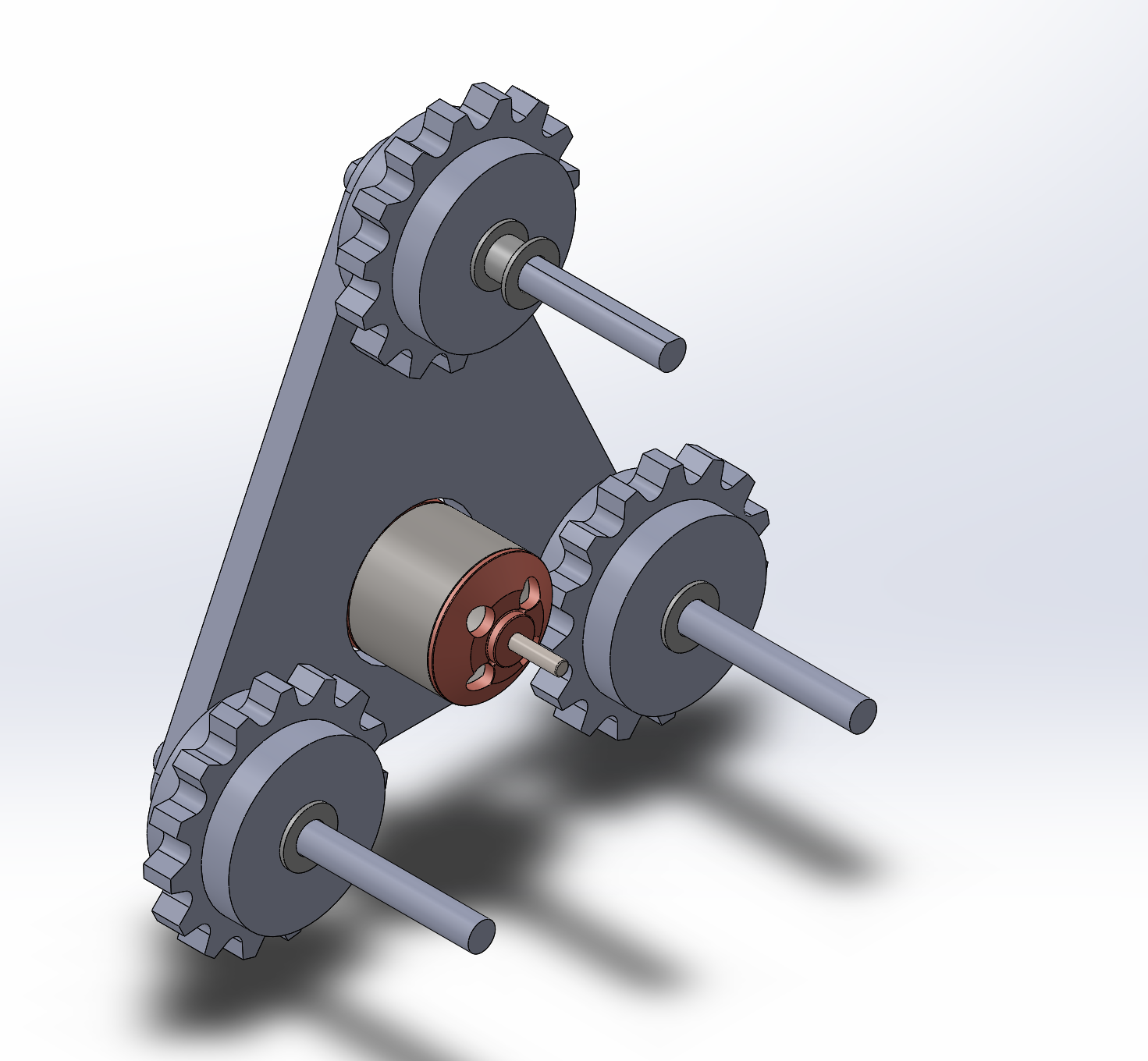

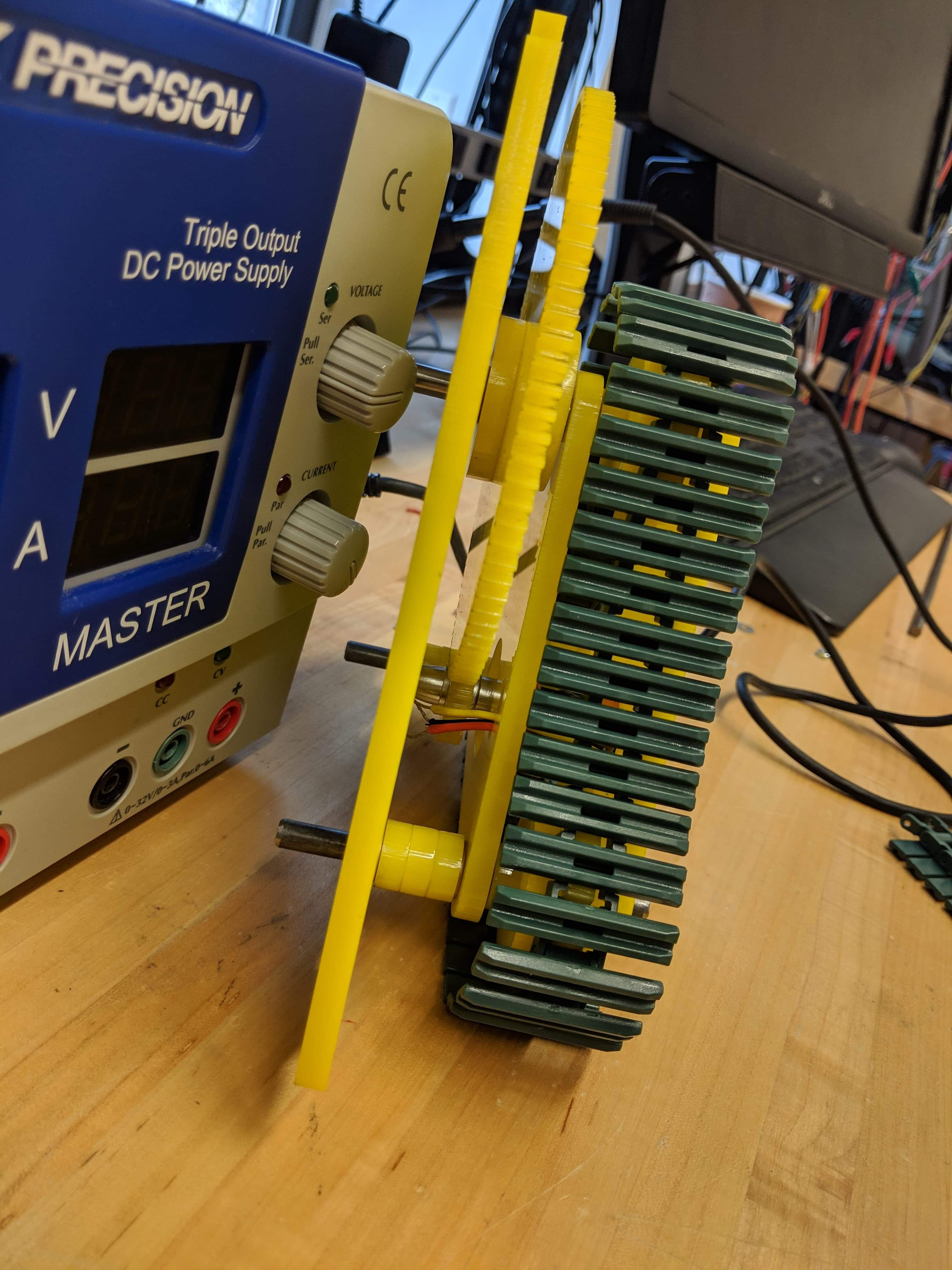

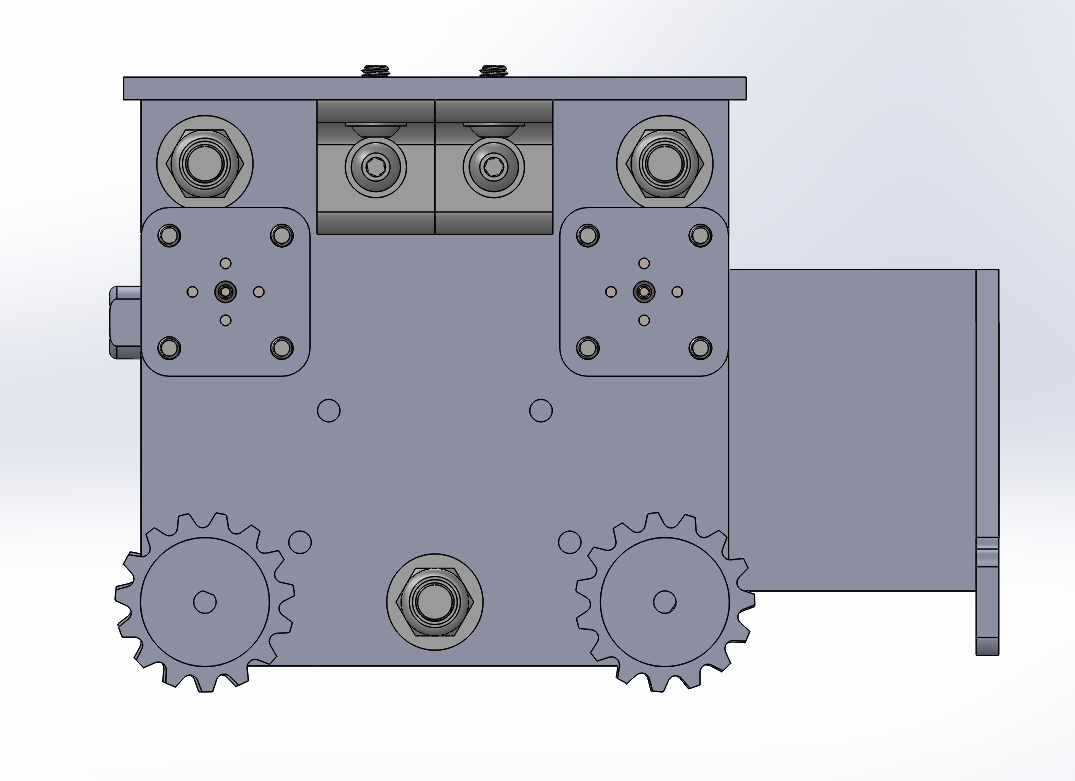

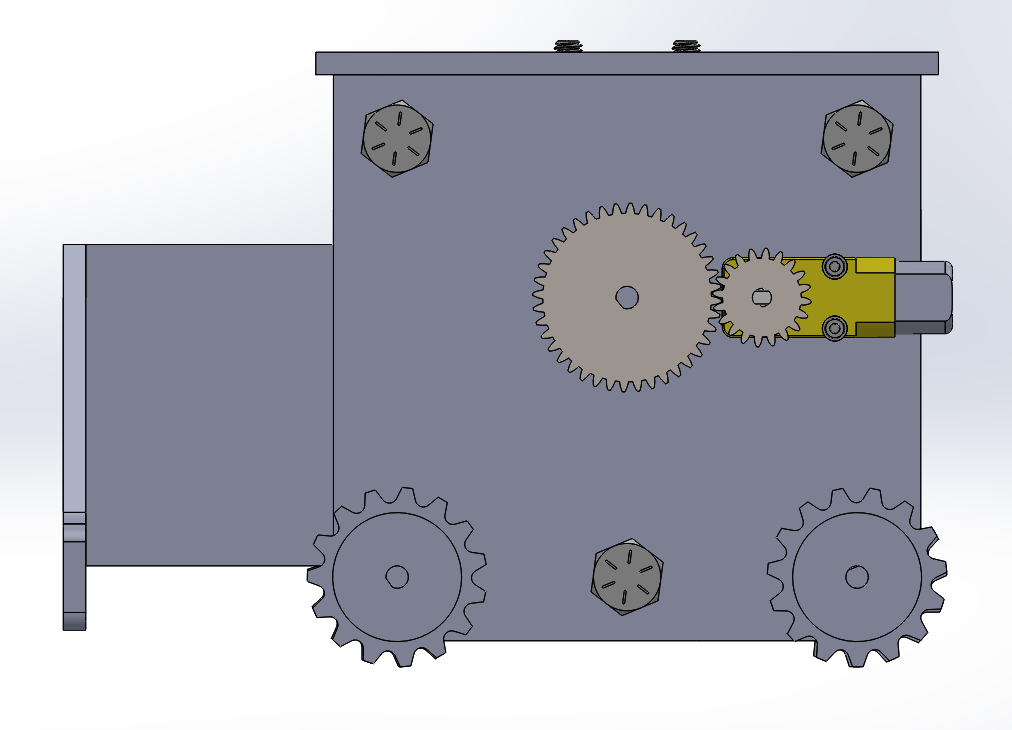

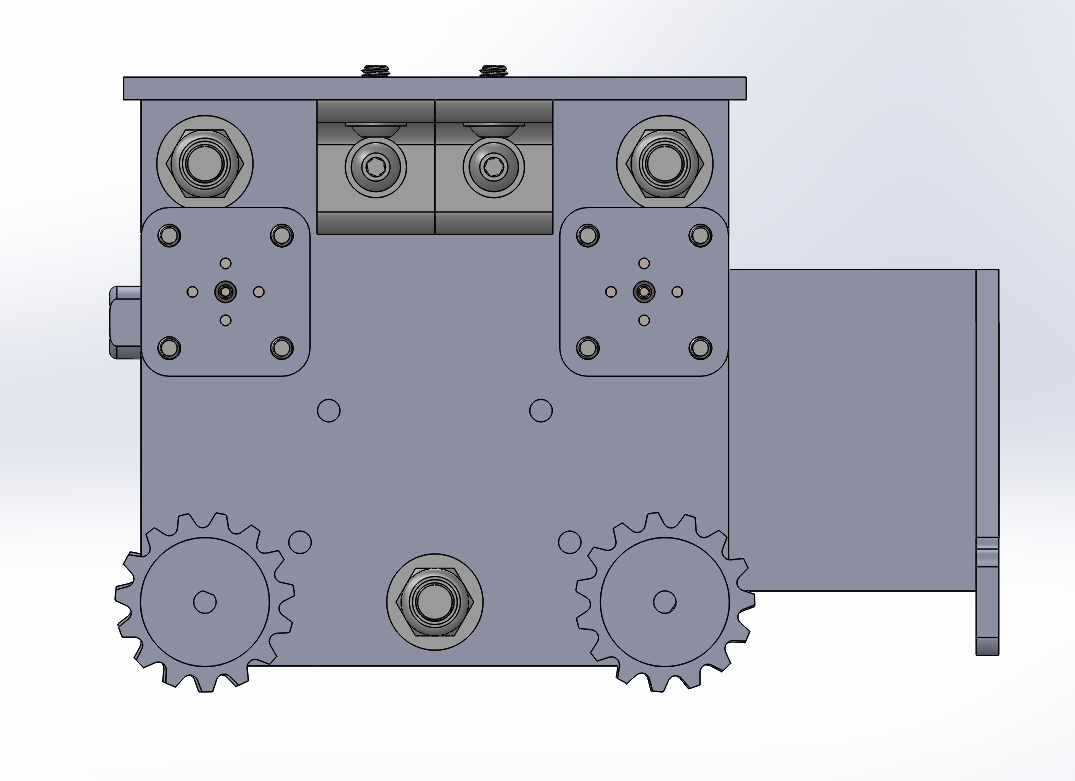

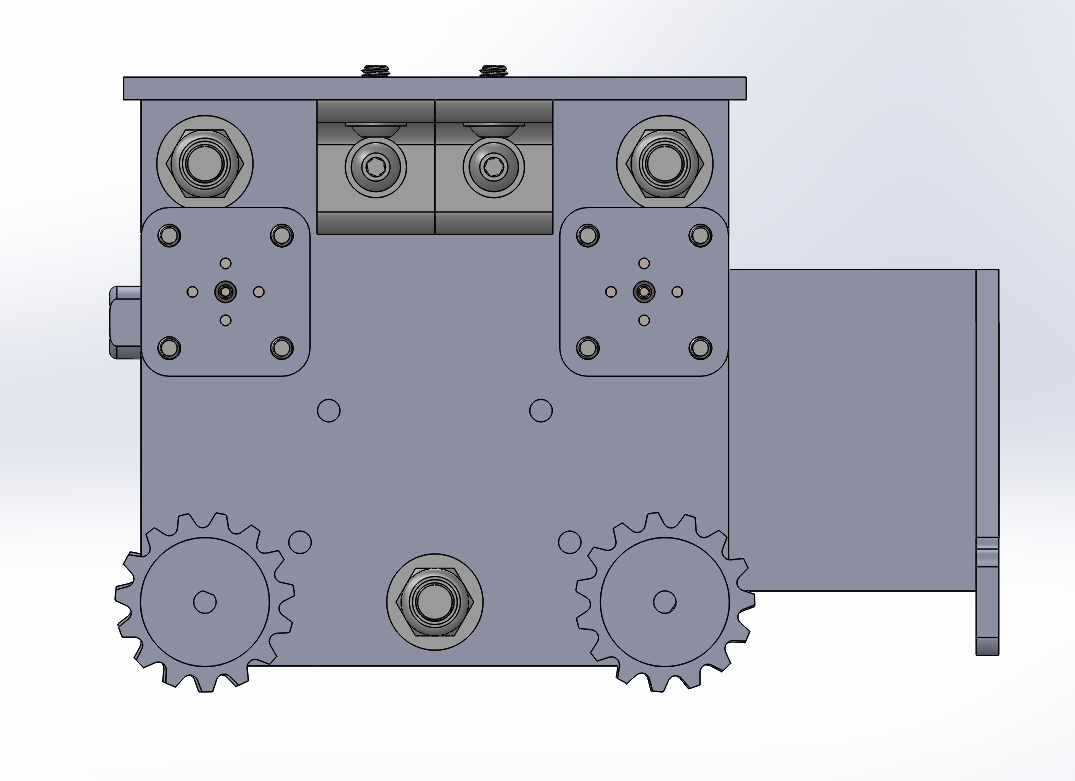

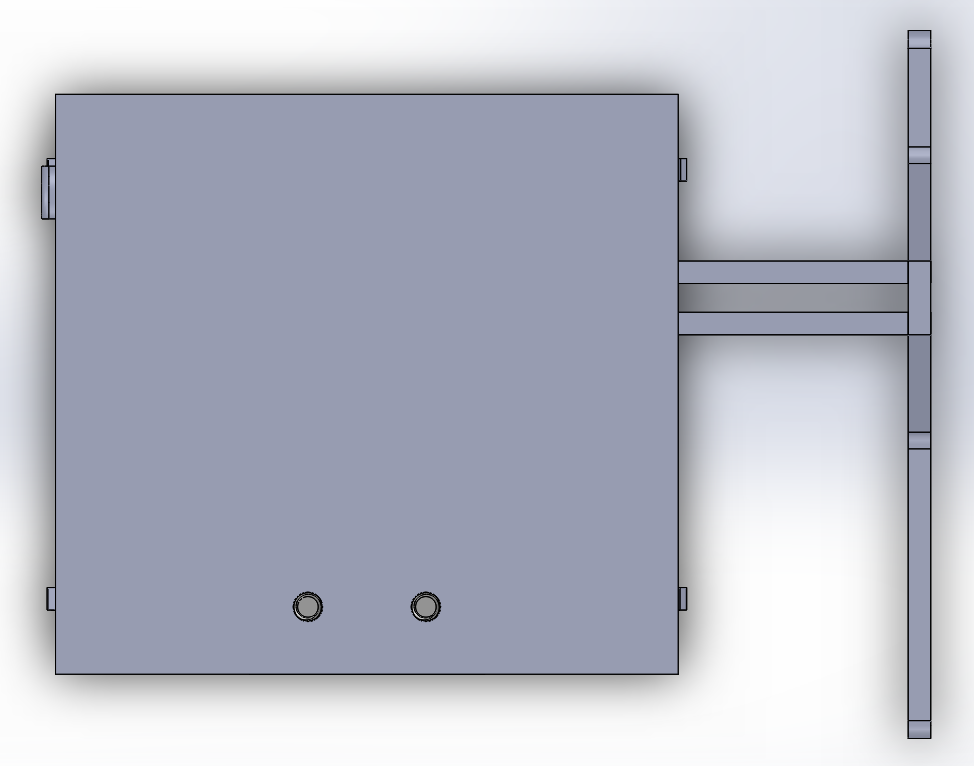

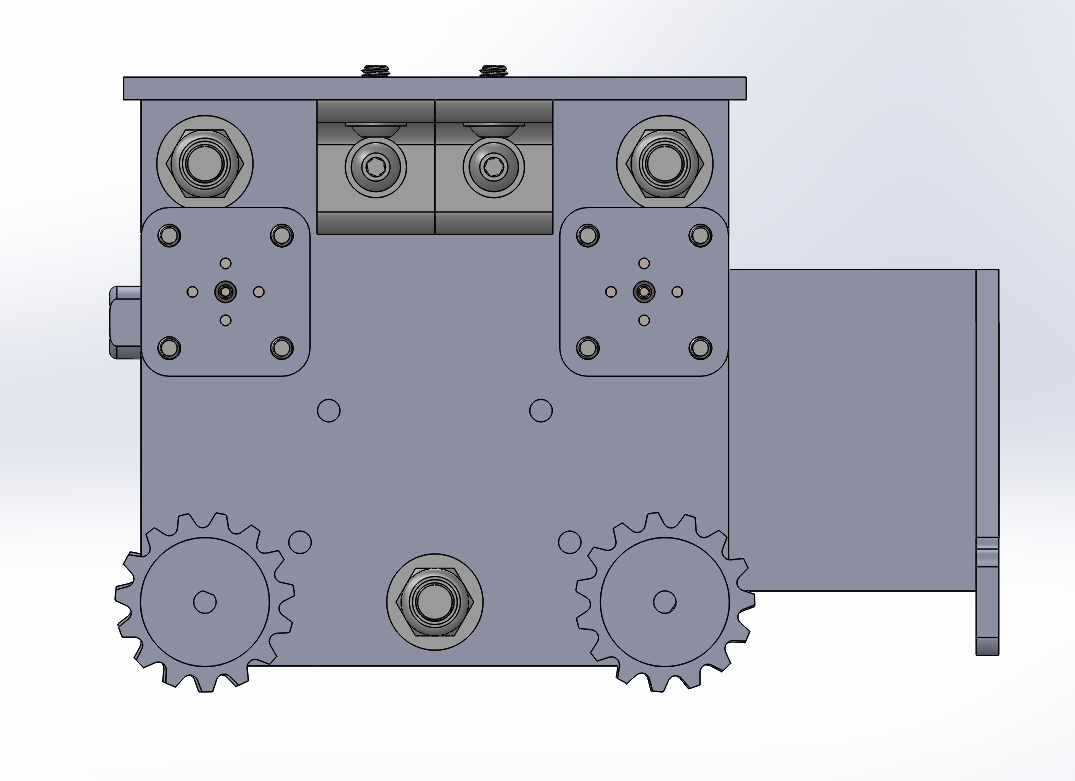

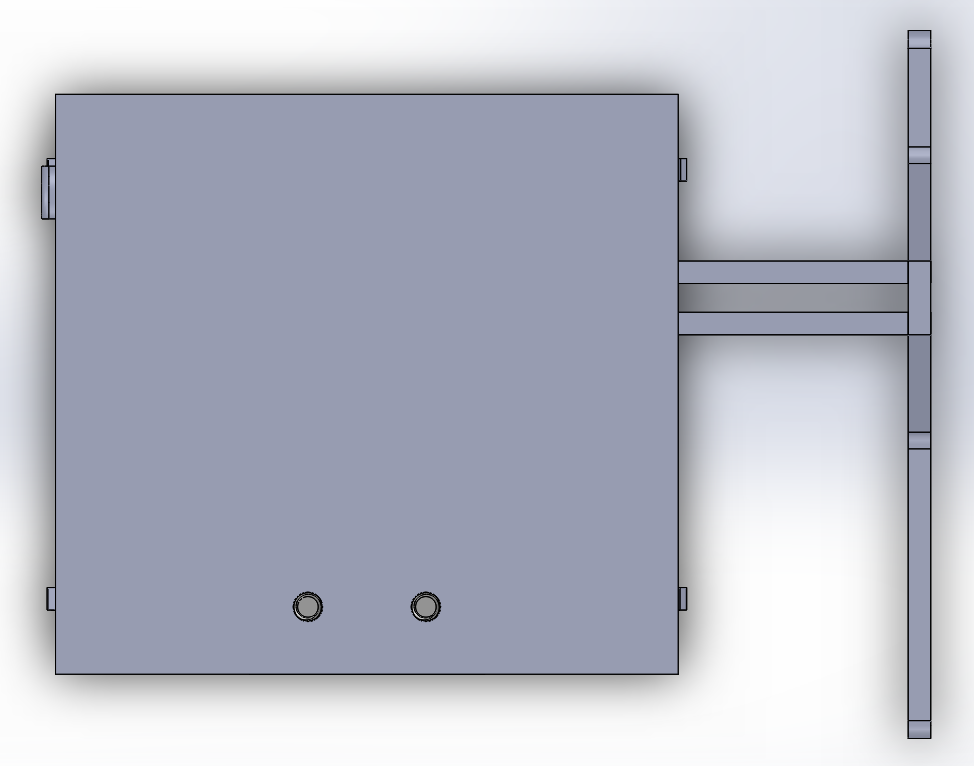

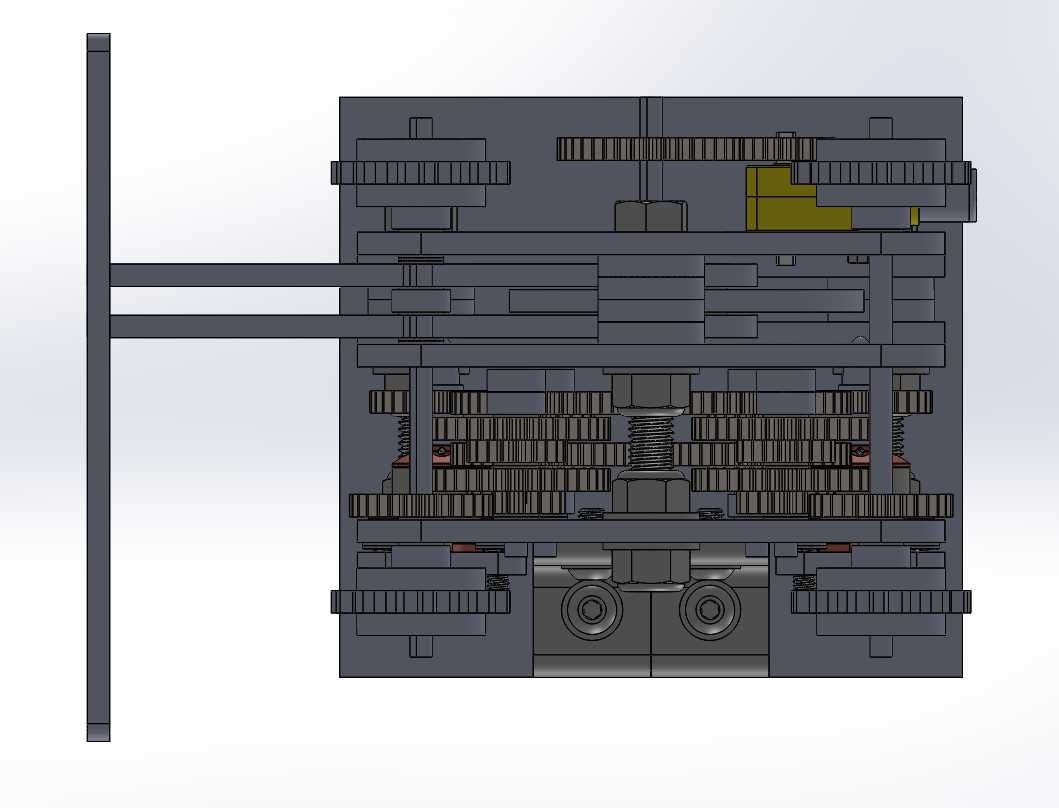

The goalie is relatively simple. Its main strategy is to simply drive back and forth in front of the goal, and extend an inner panel for extra reach. It uses the same tread drive as the striker, but in a triangular pattern, mainly to accommodate having a large gear in the single-stage reduction from the motors (and definitely not because it made it look more like WALL-E).

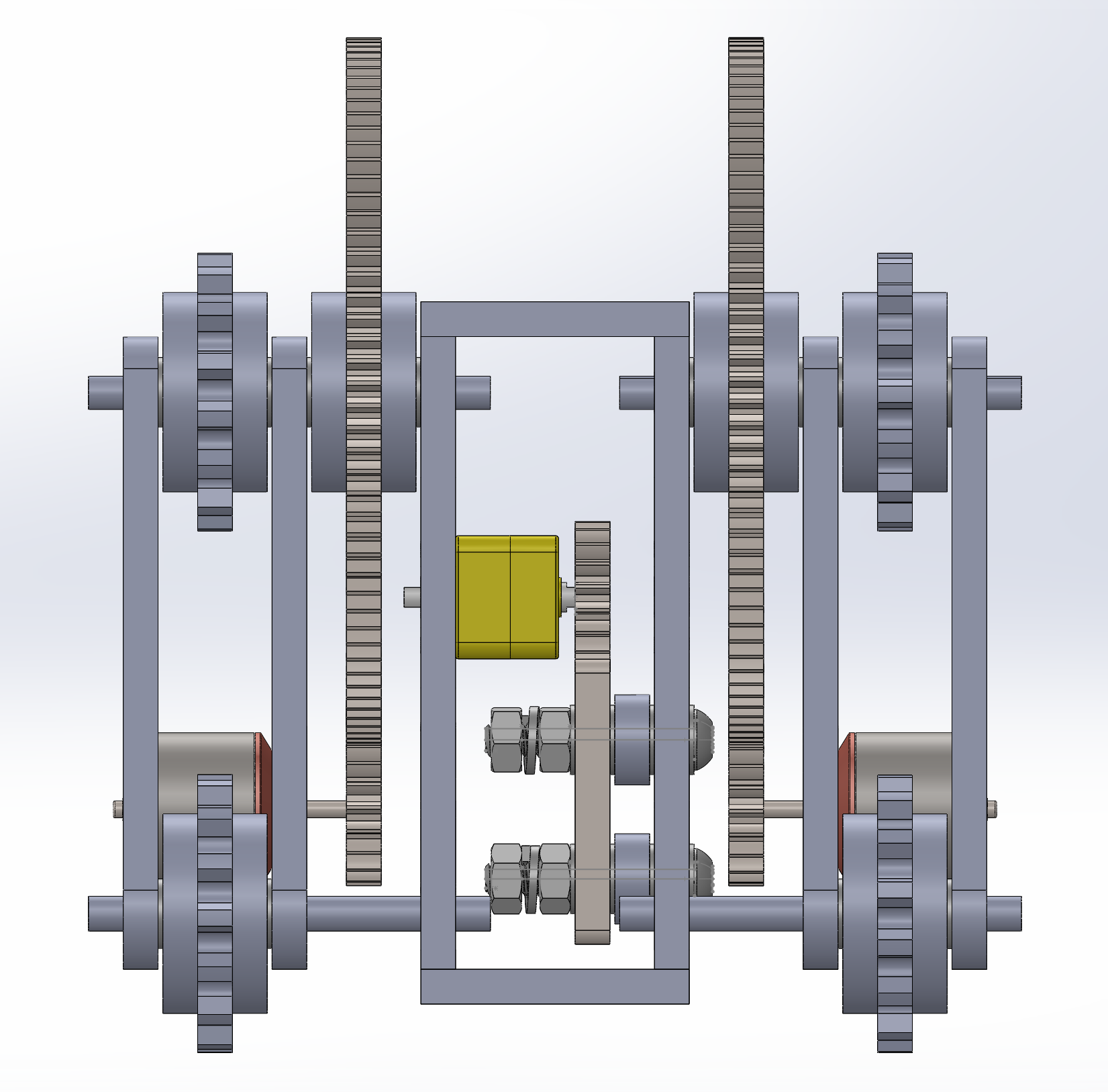

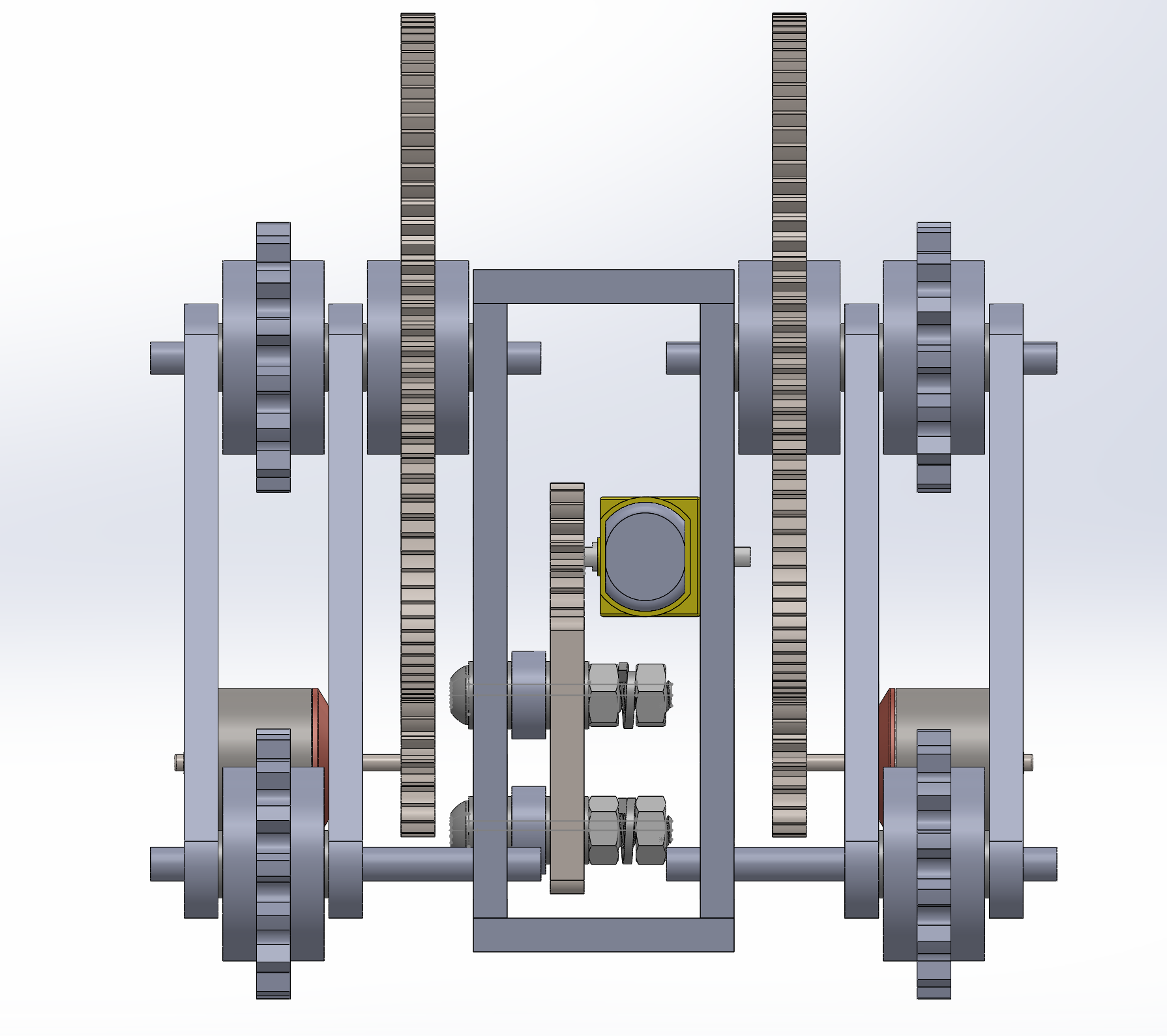

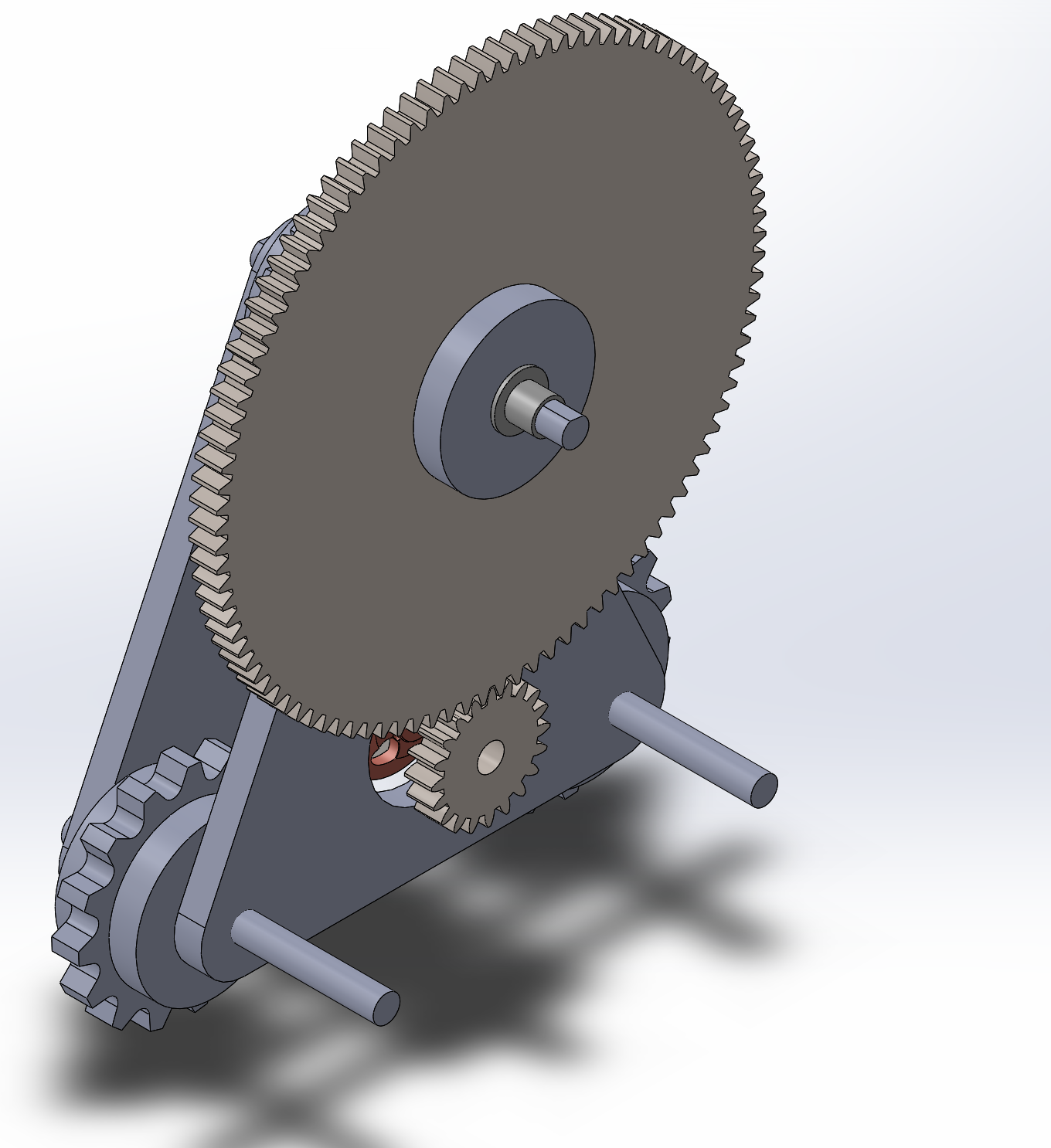

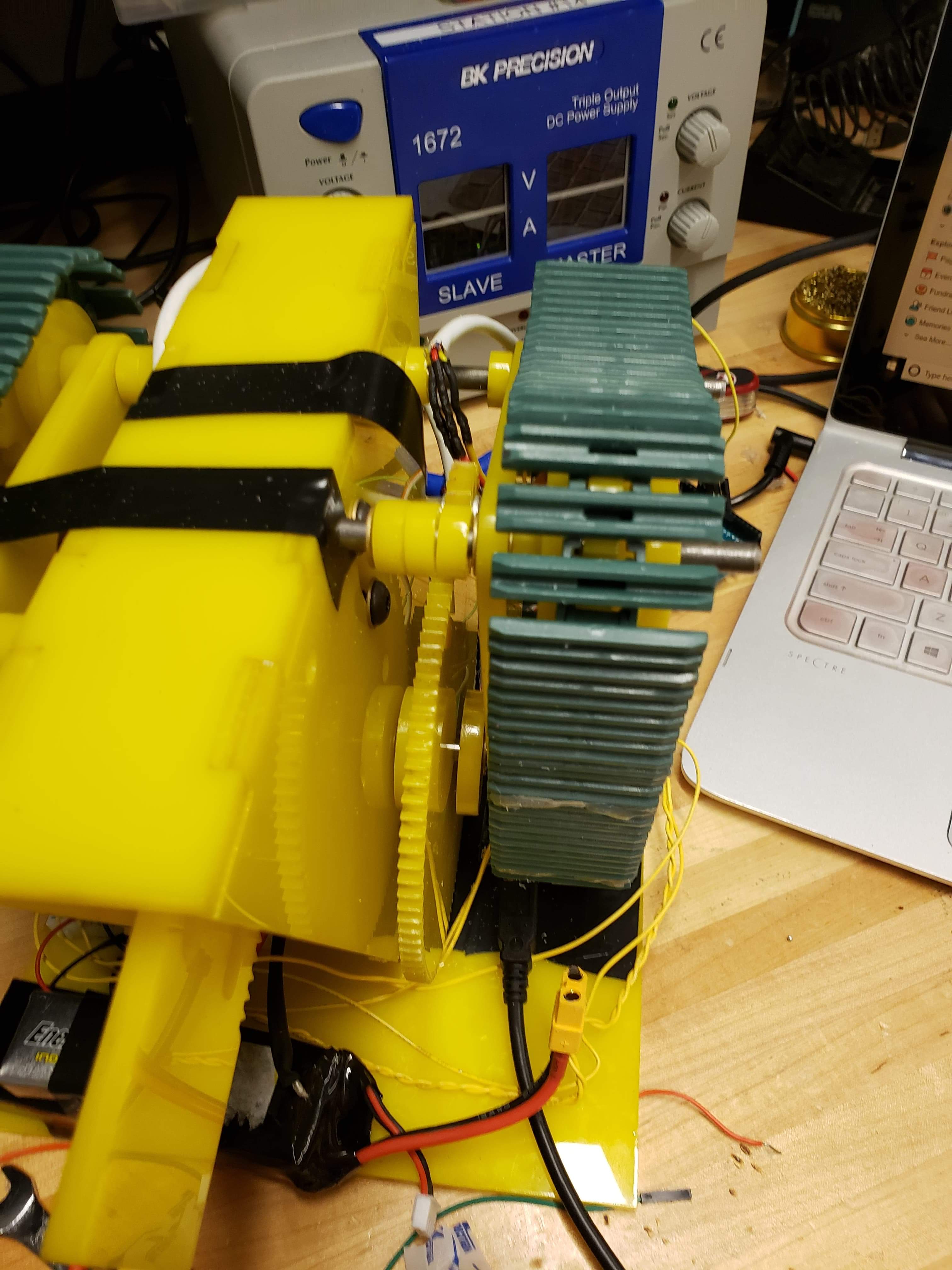

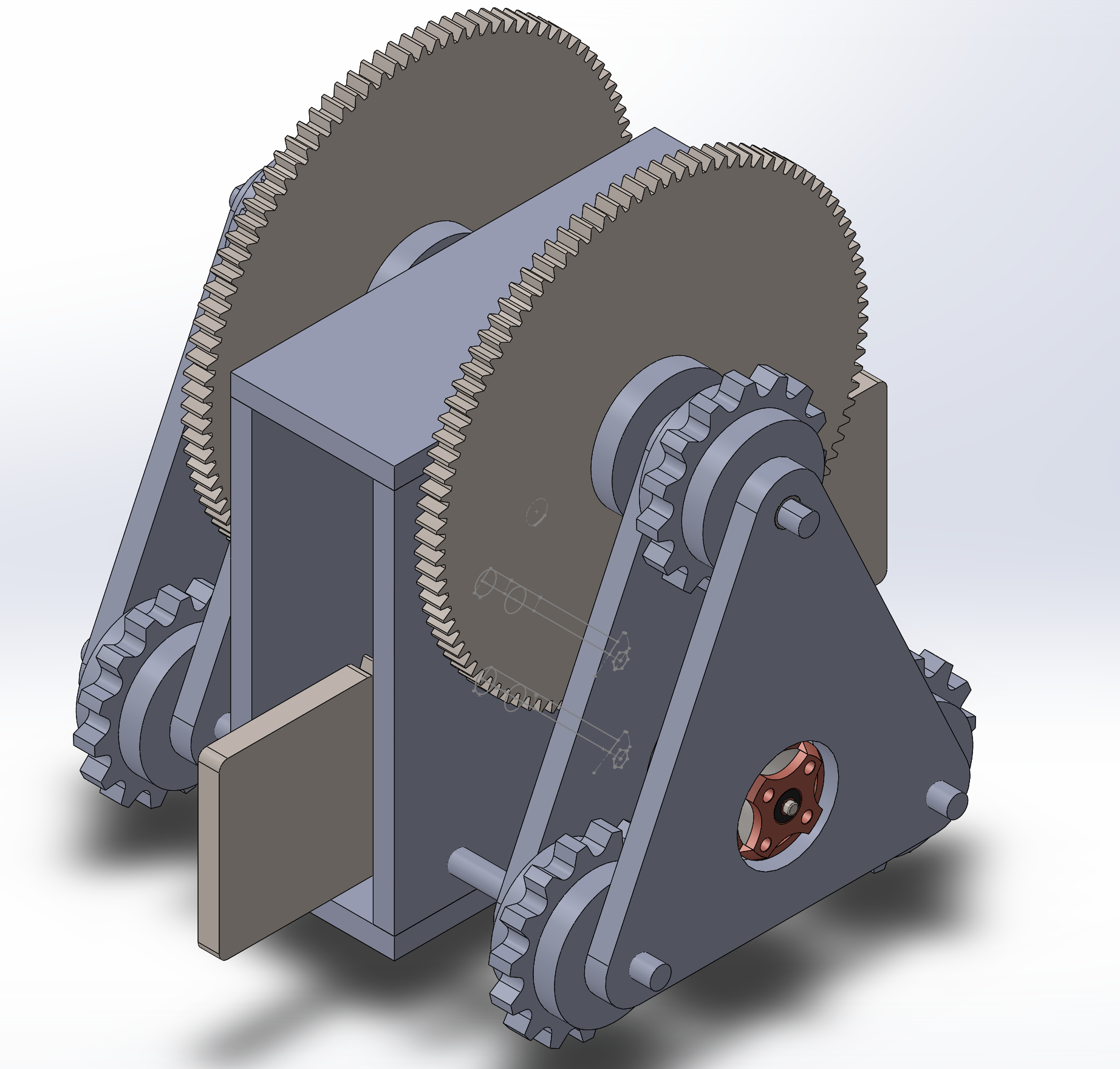

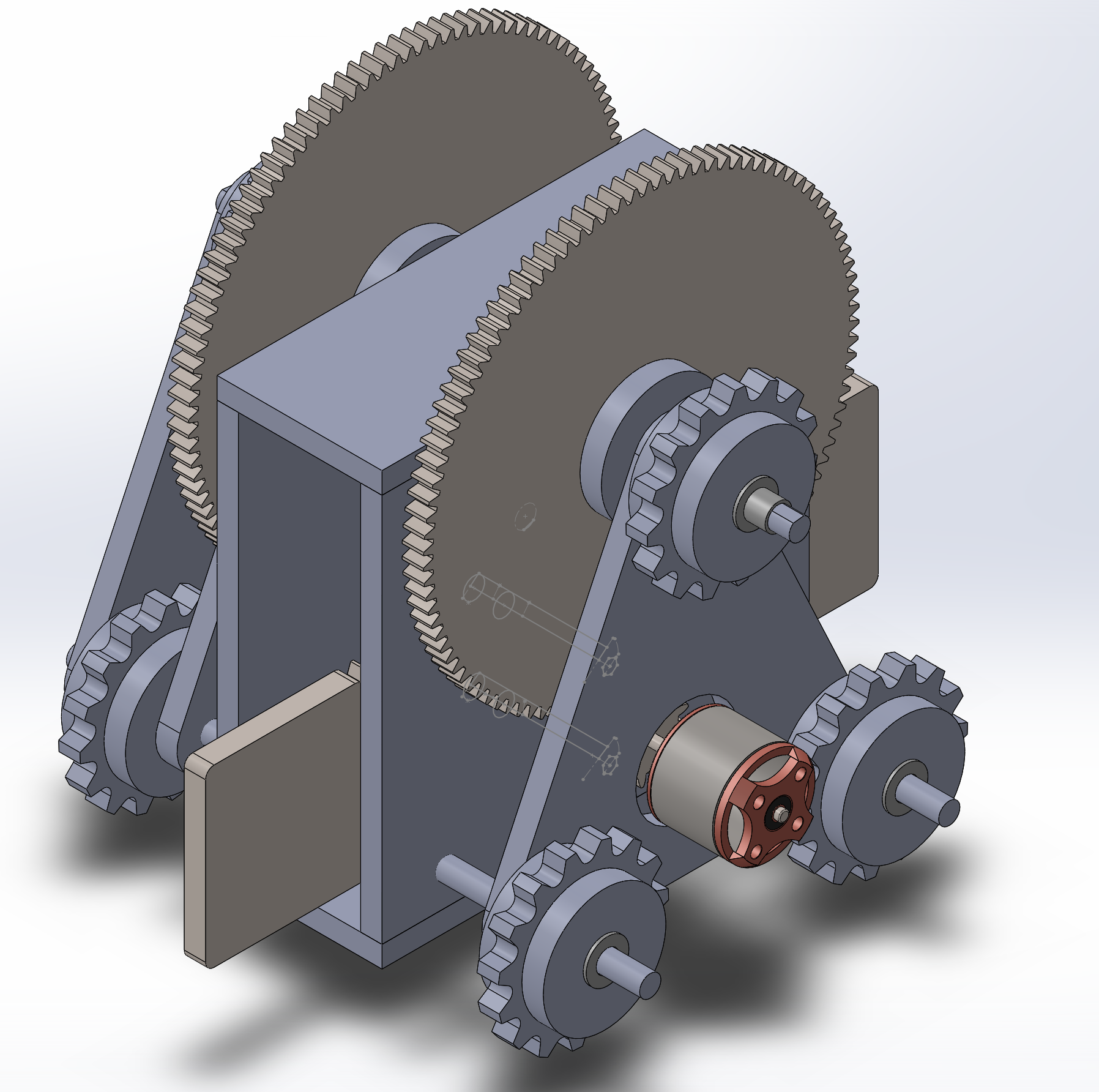

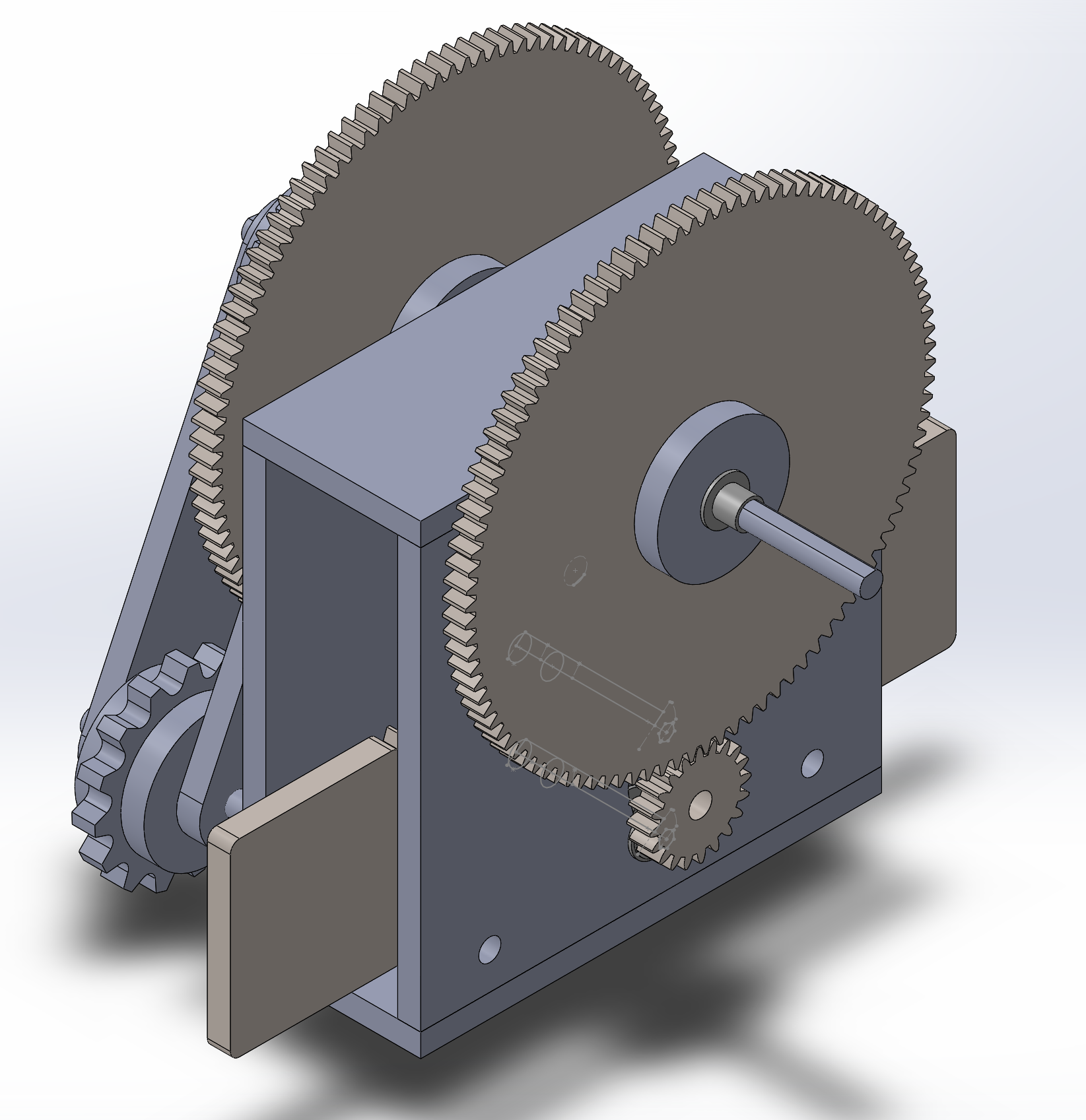

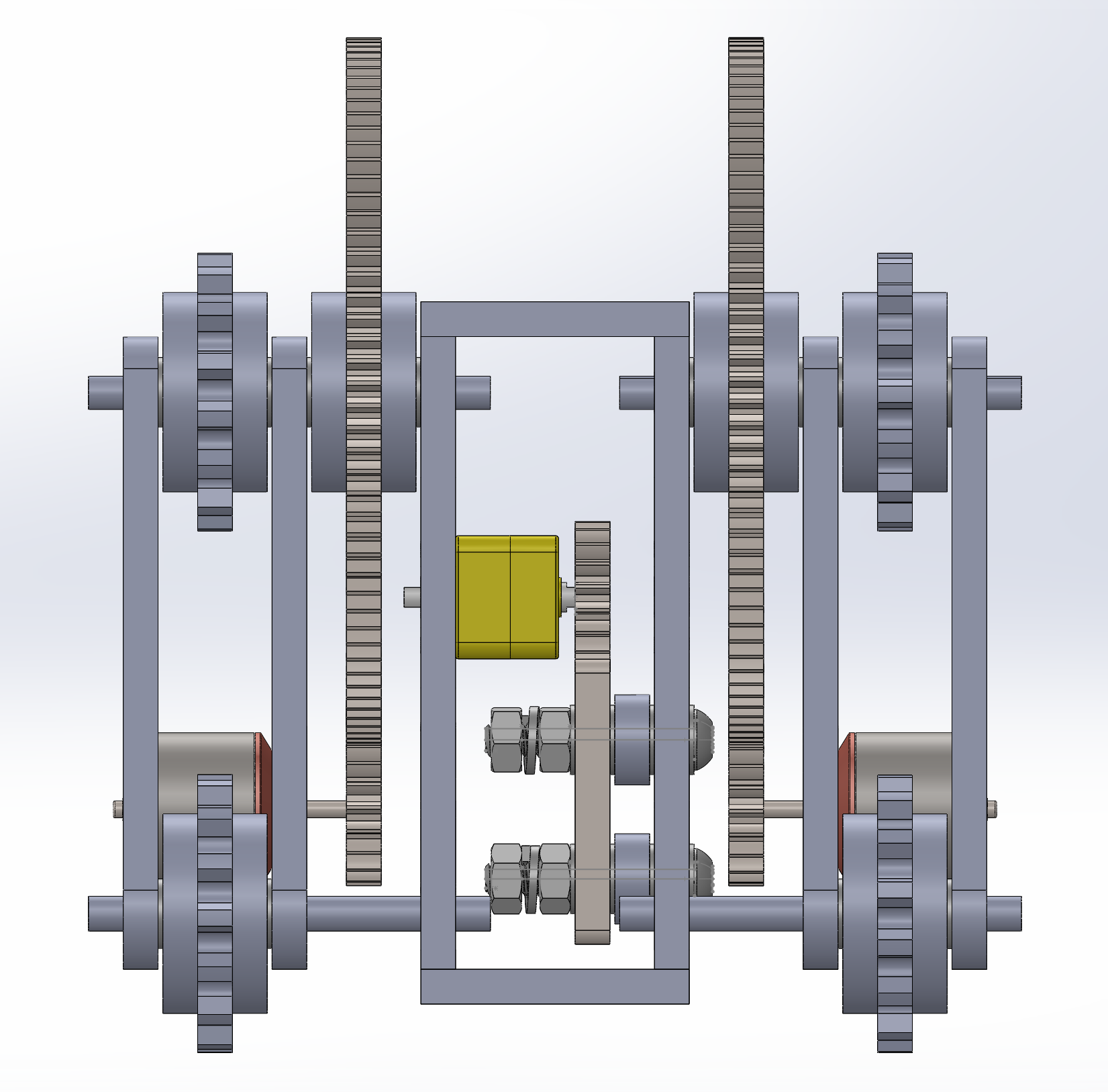

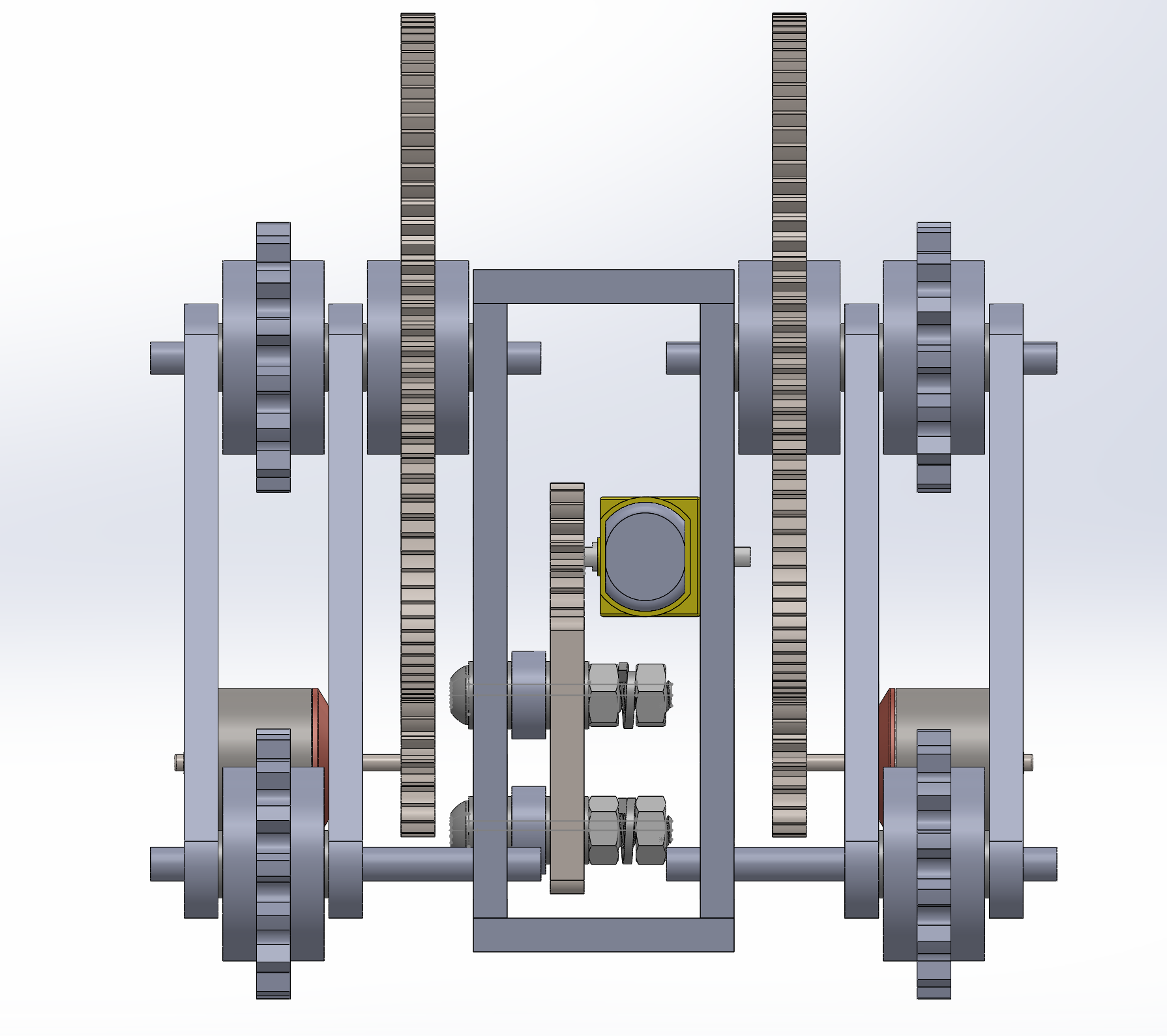

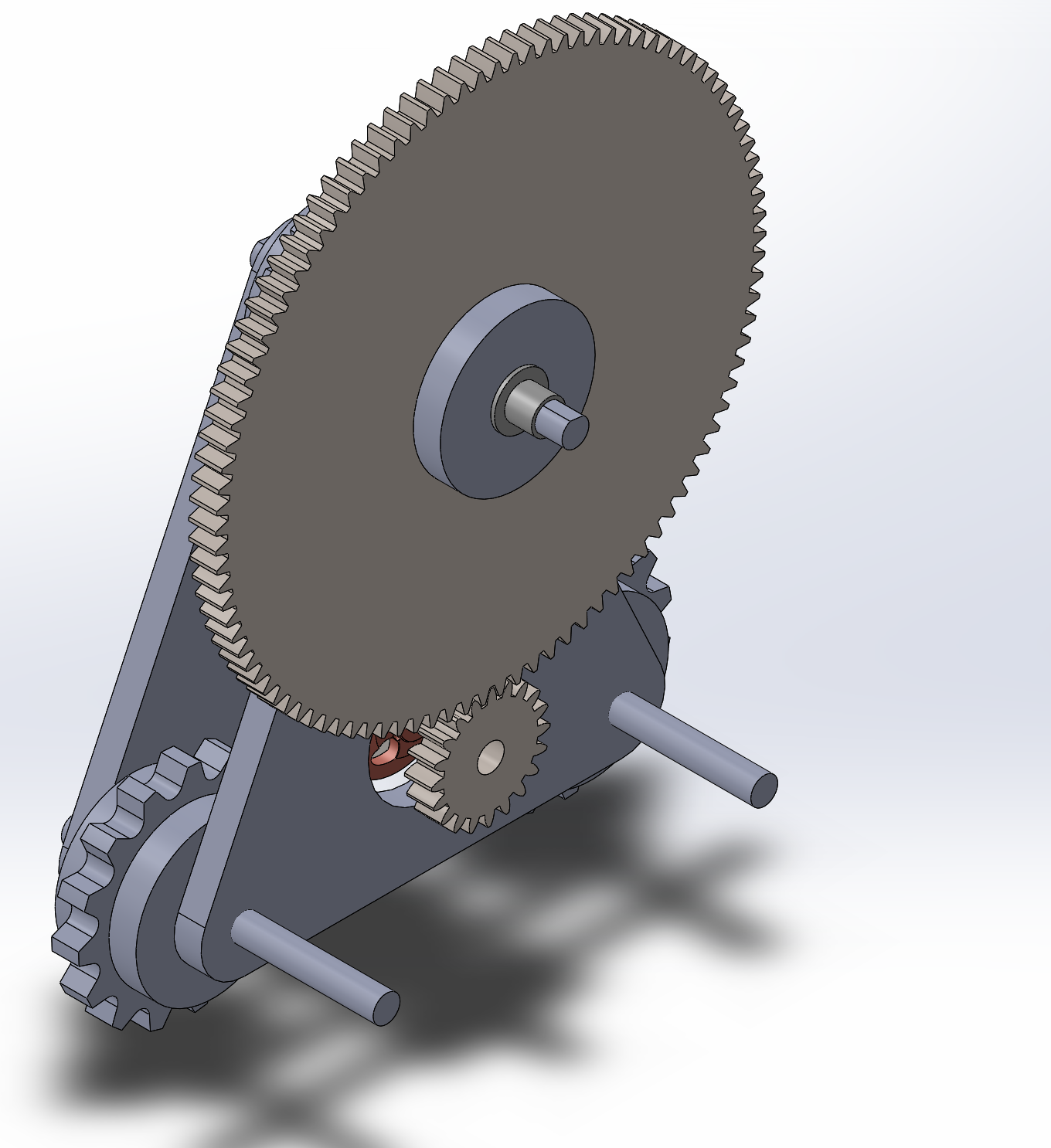

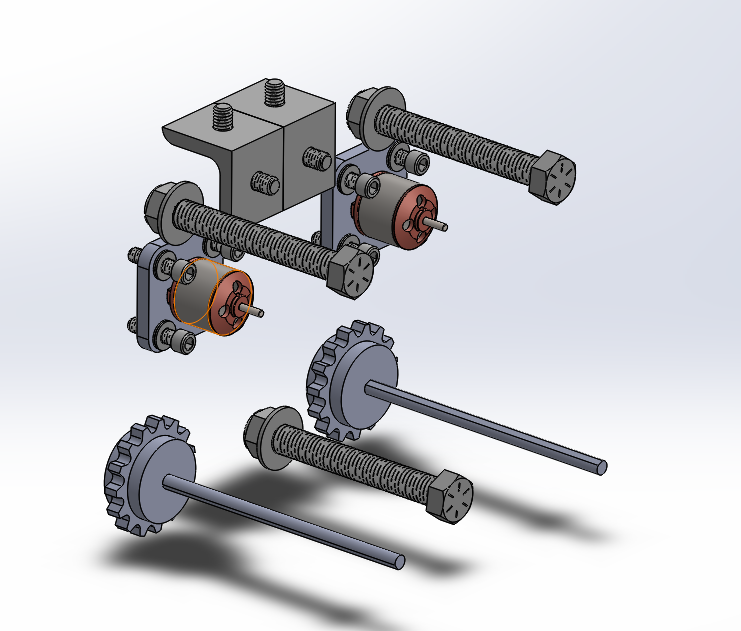

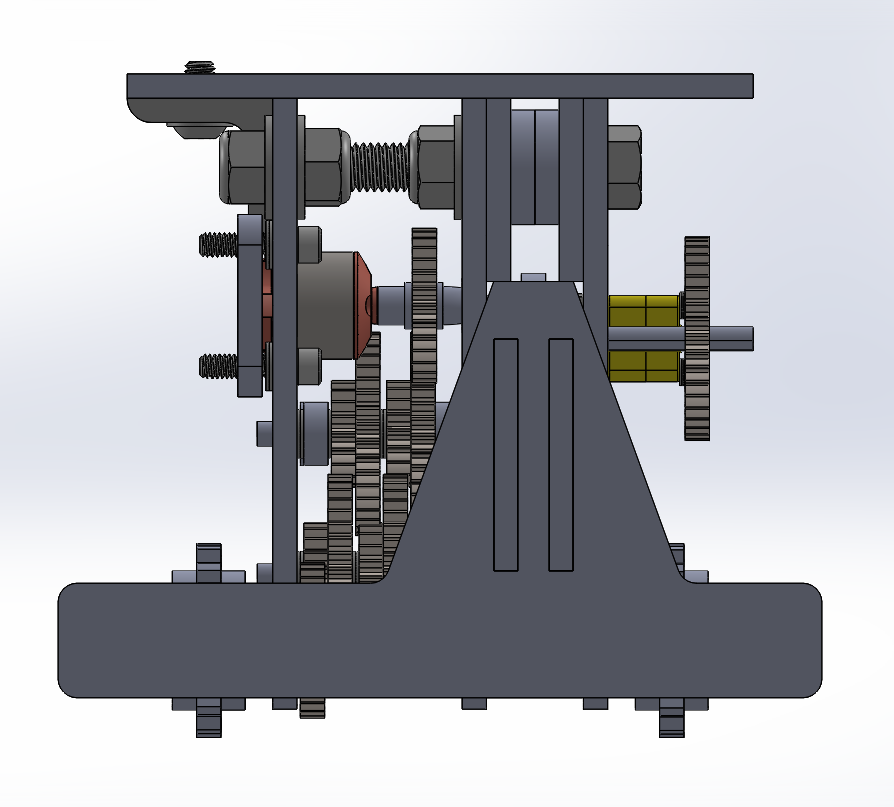

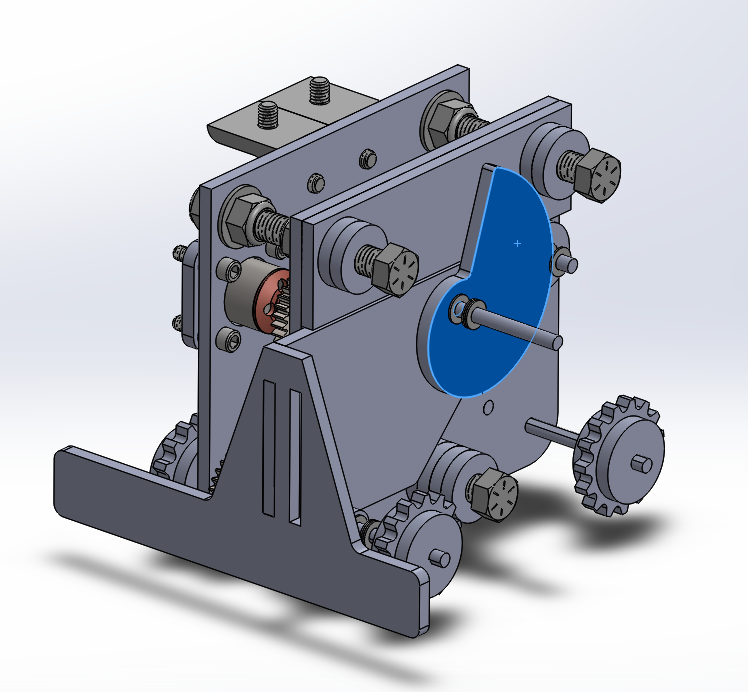

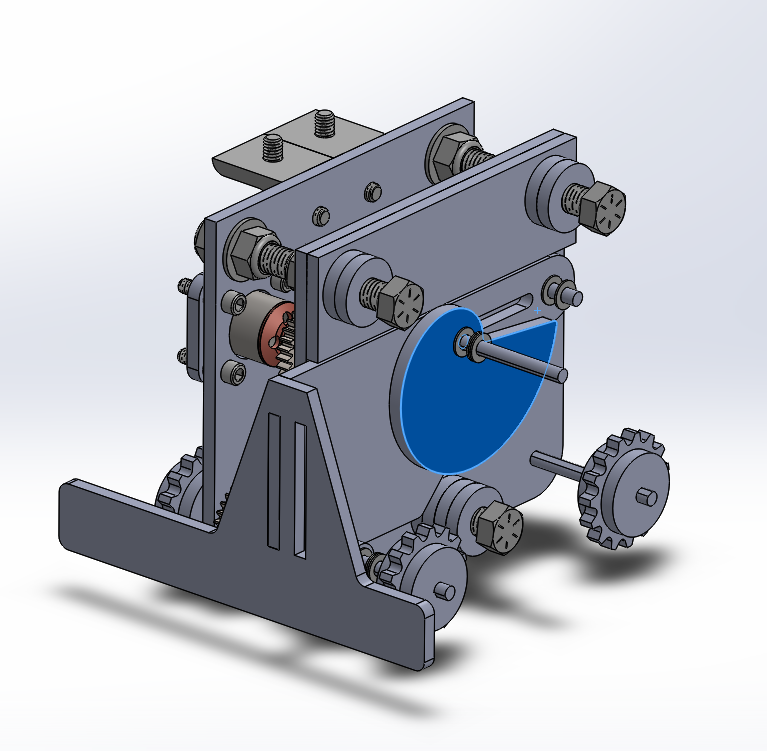

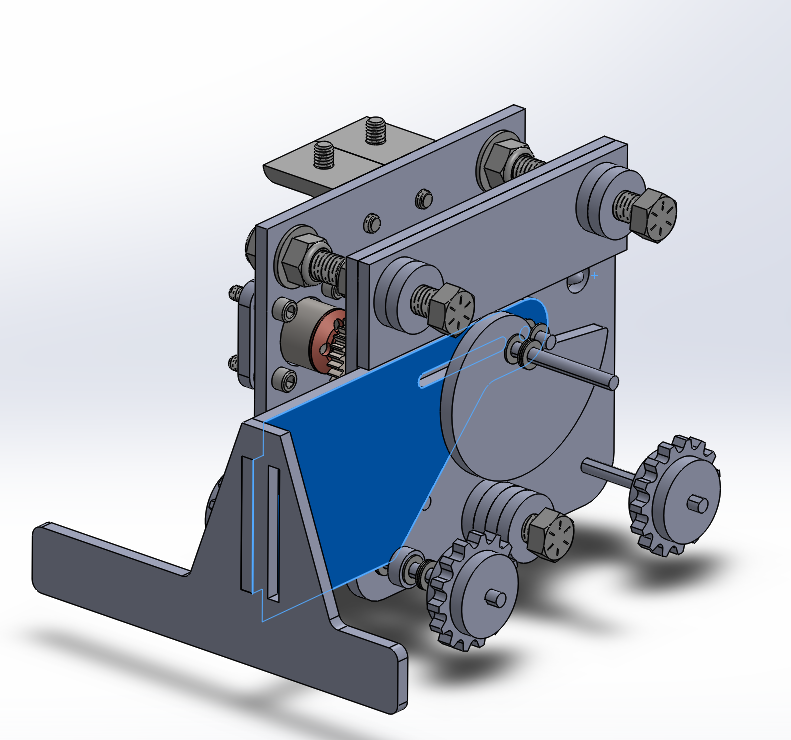

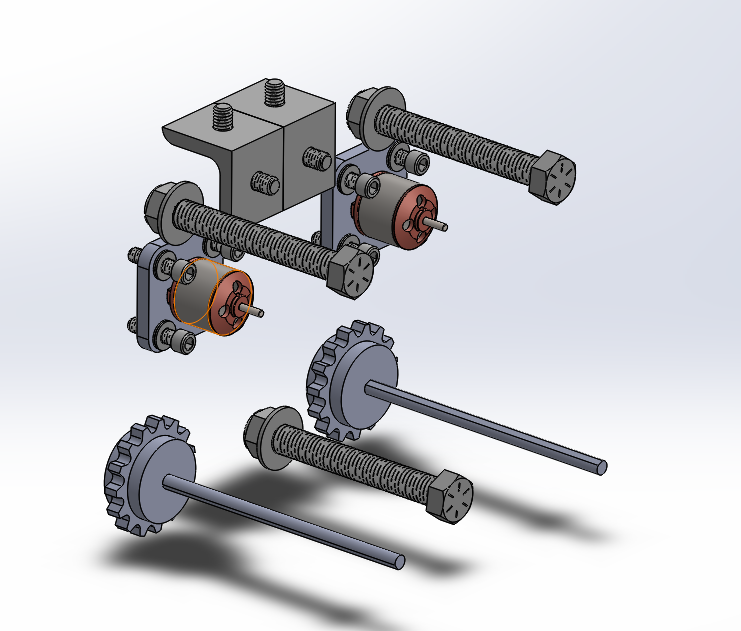

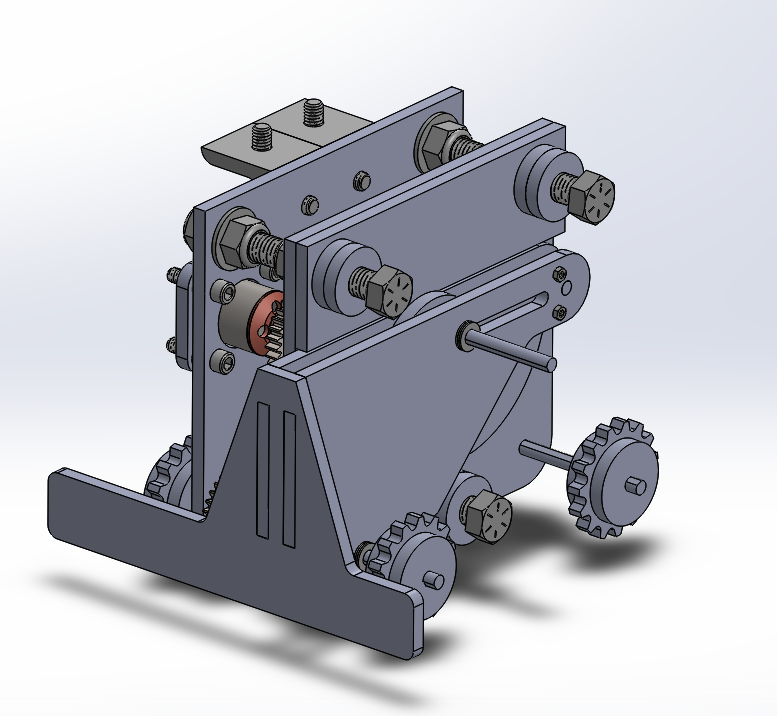

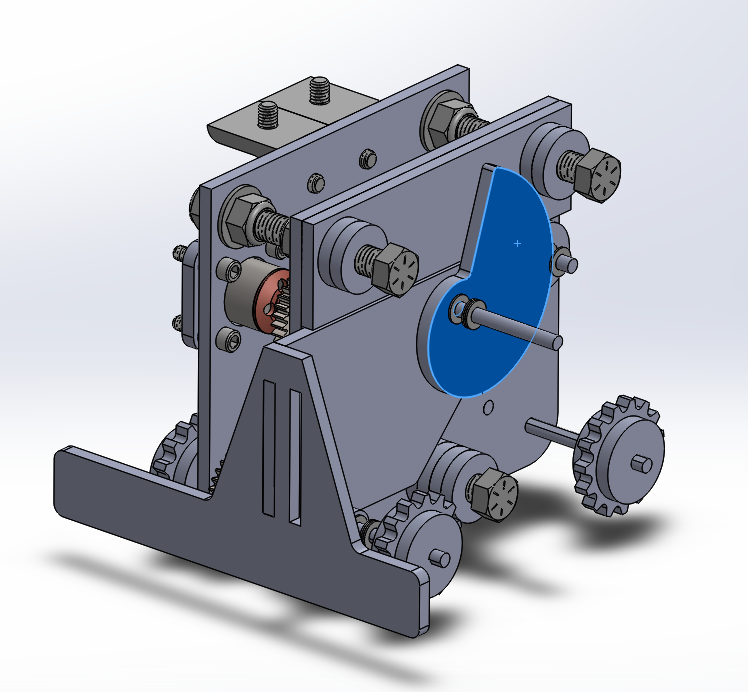

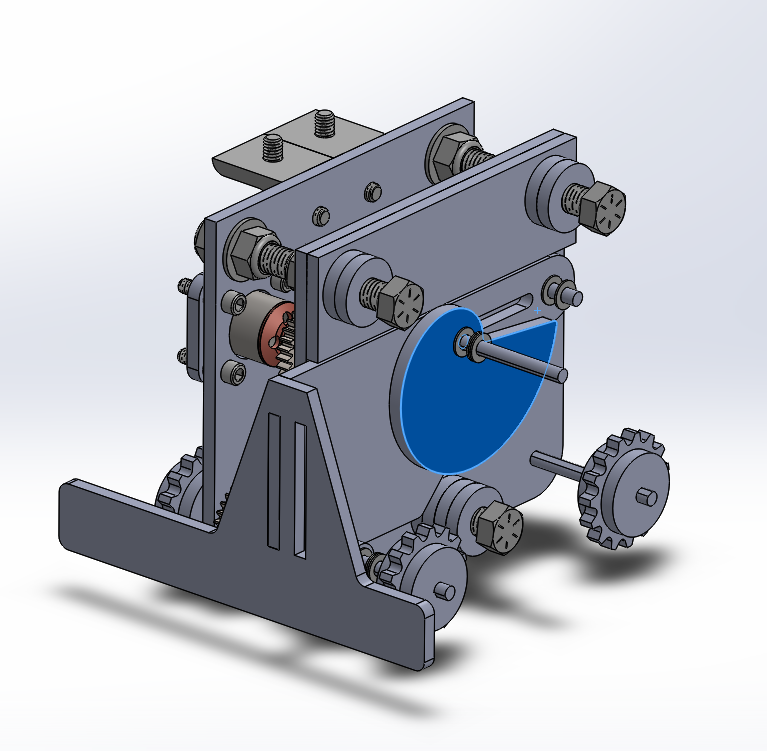

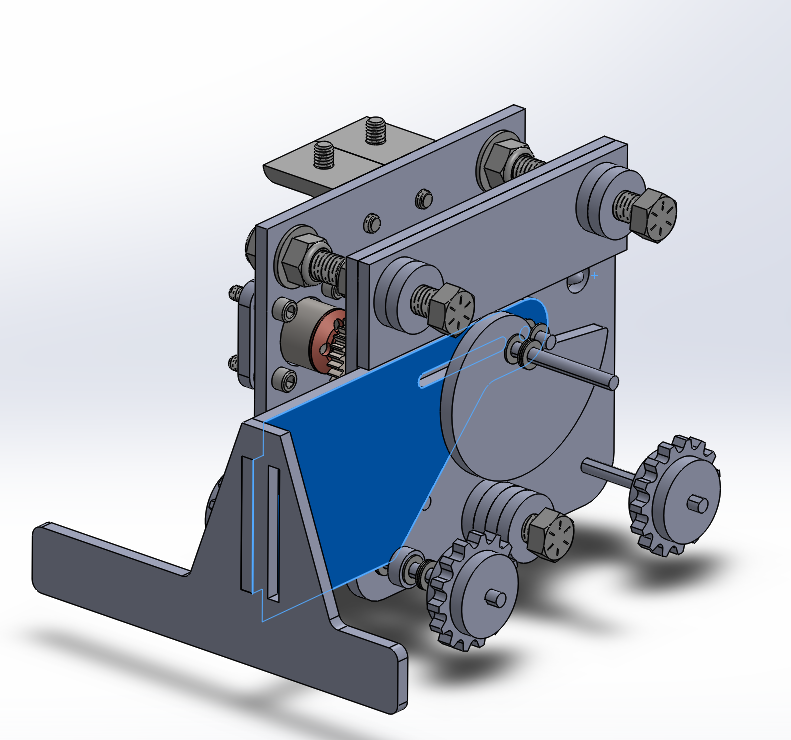

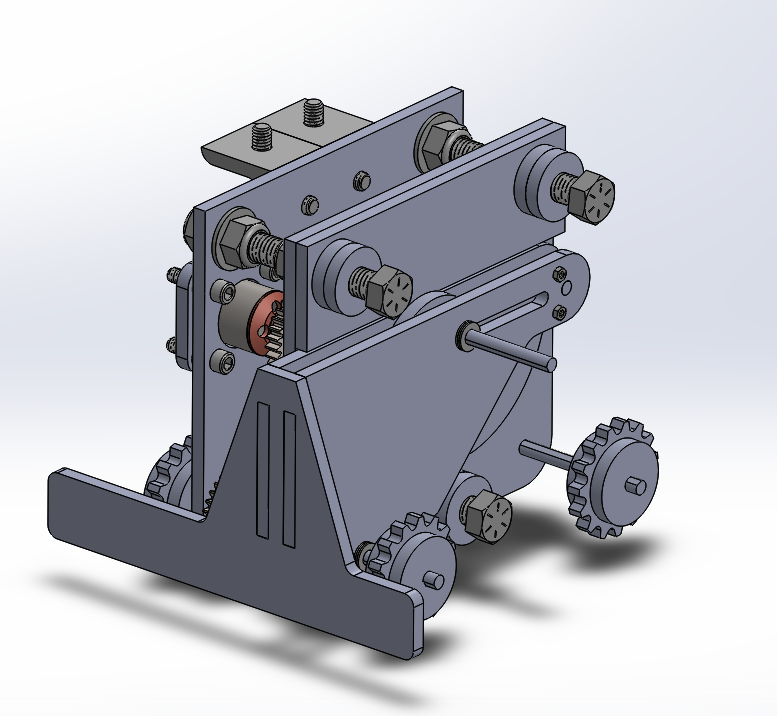

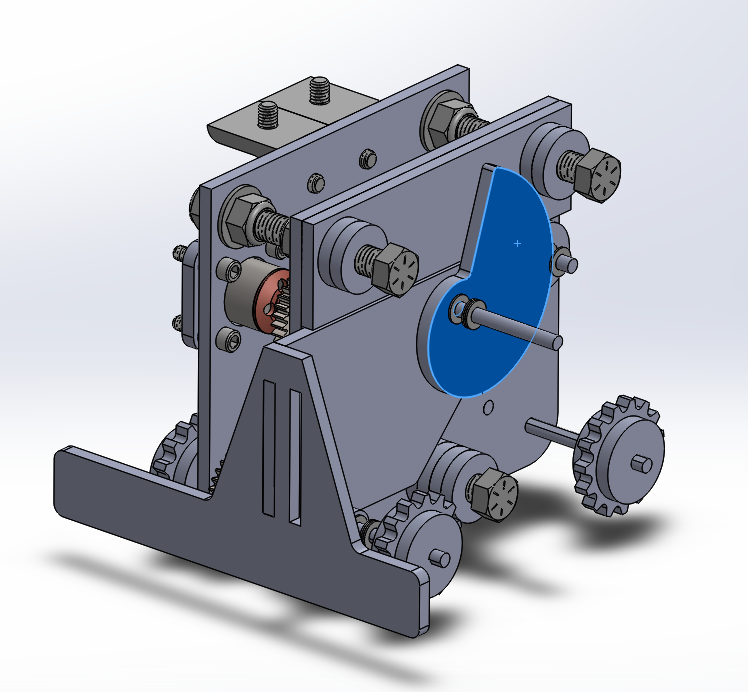

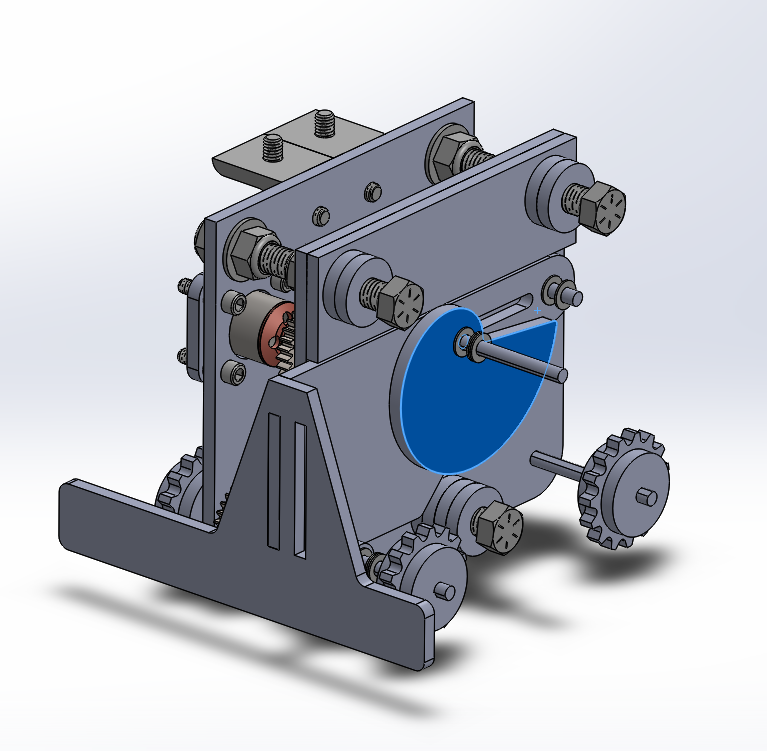

Striker

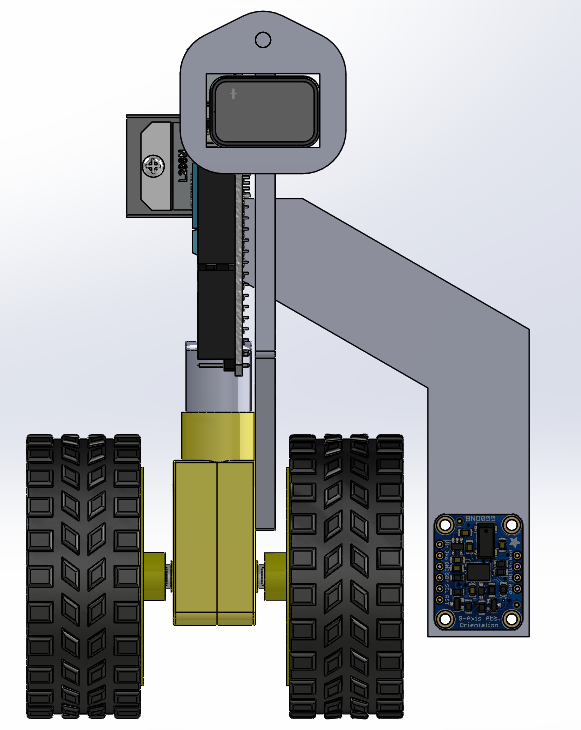

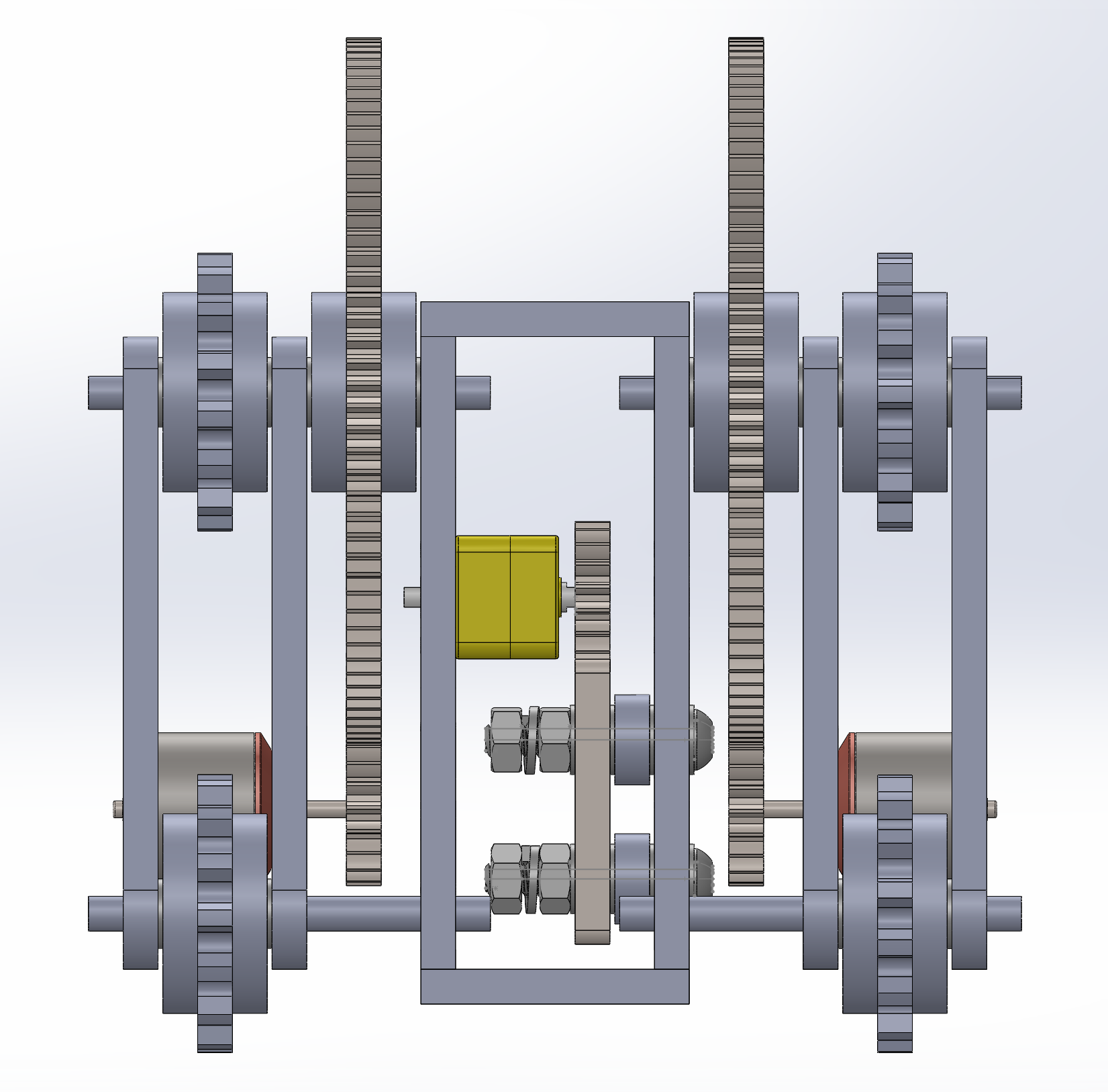

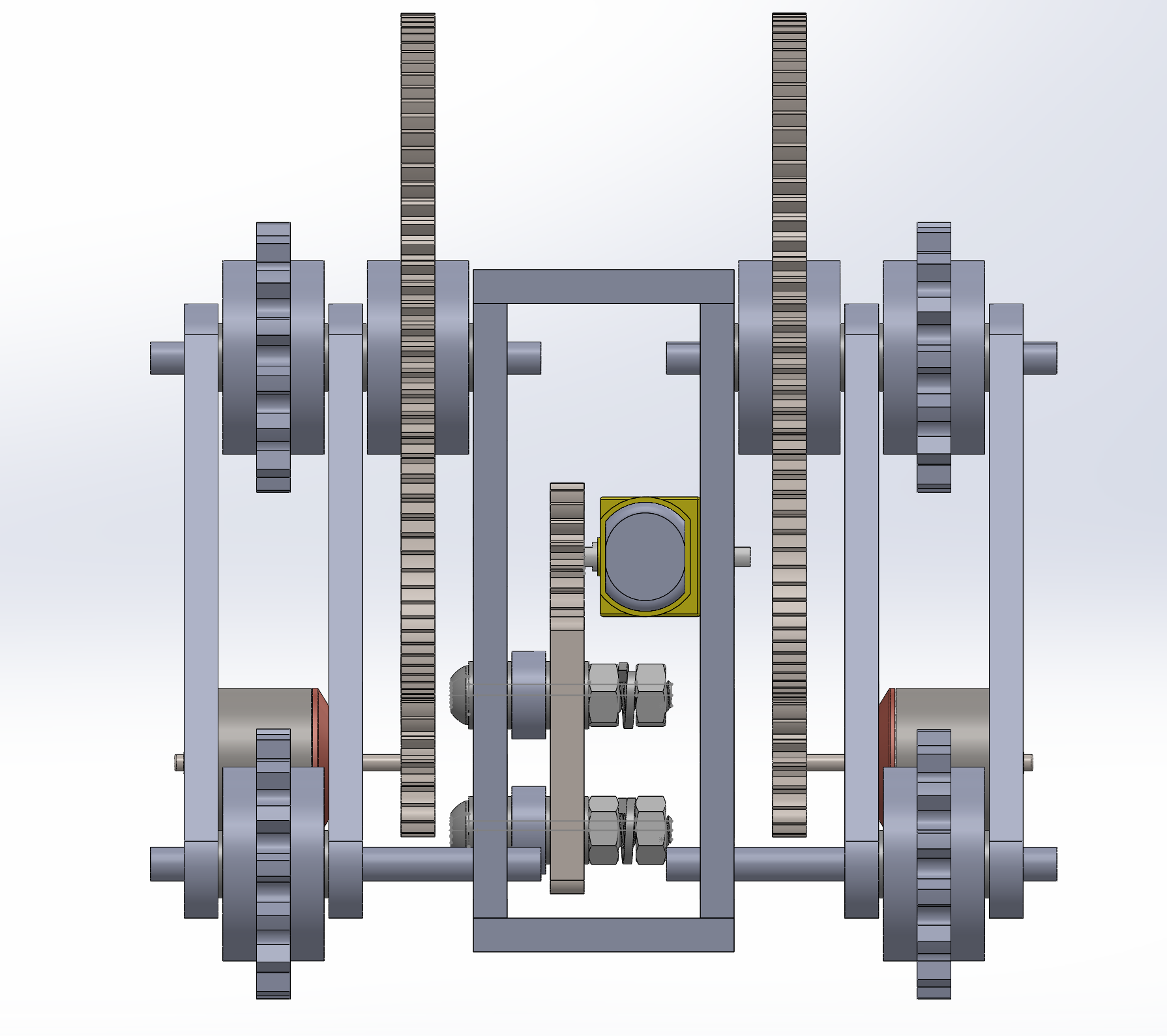

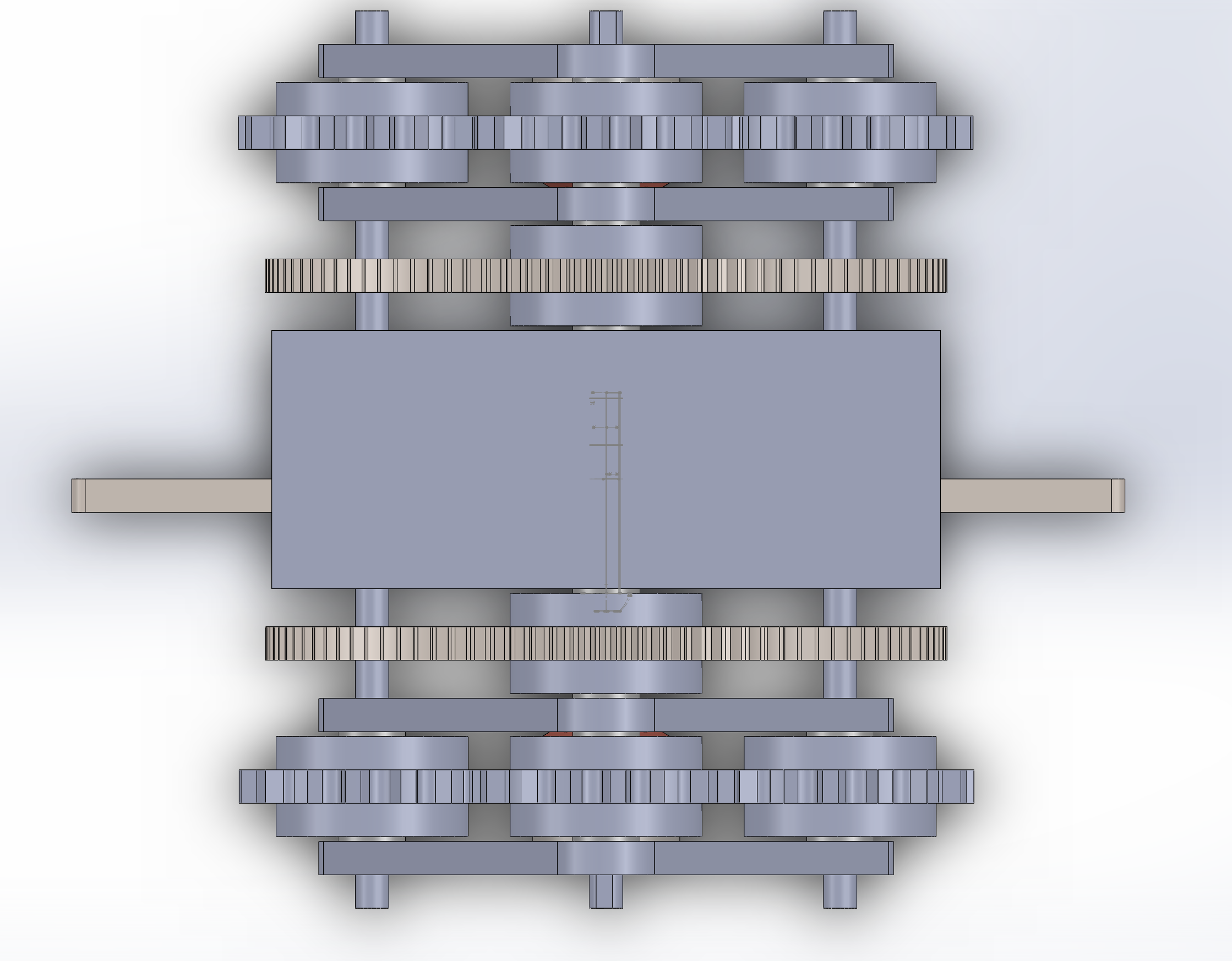

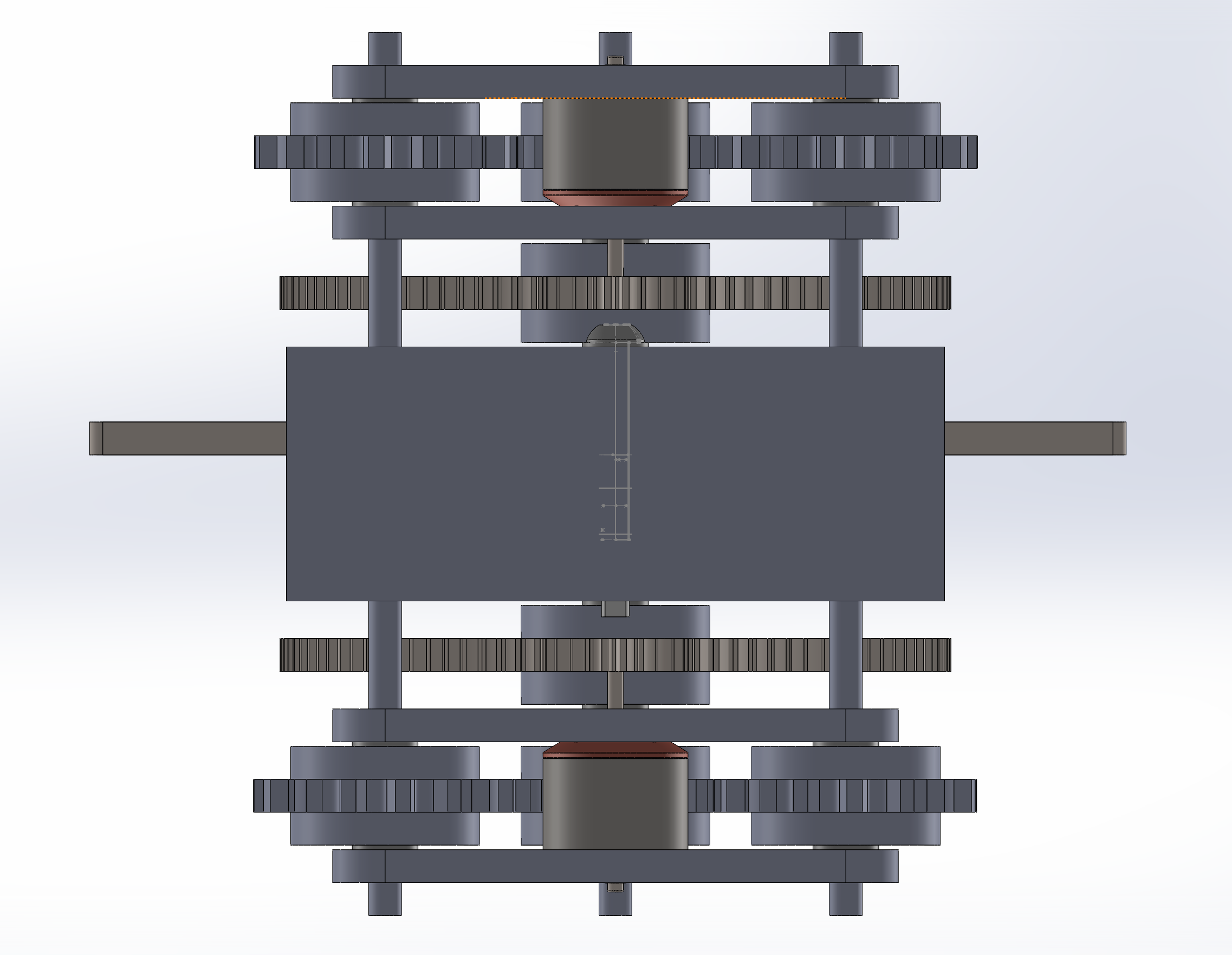

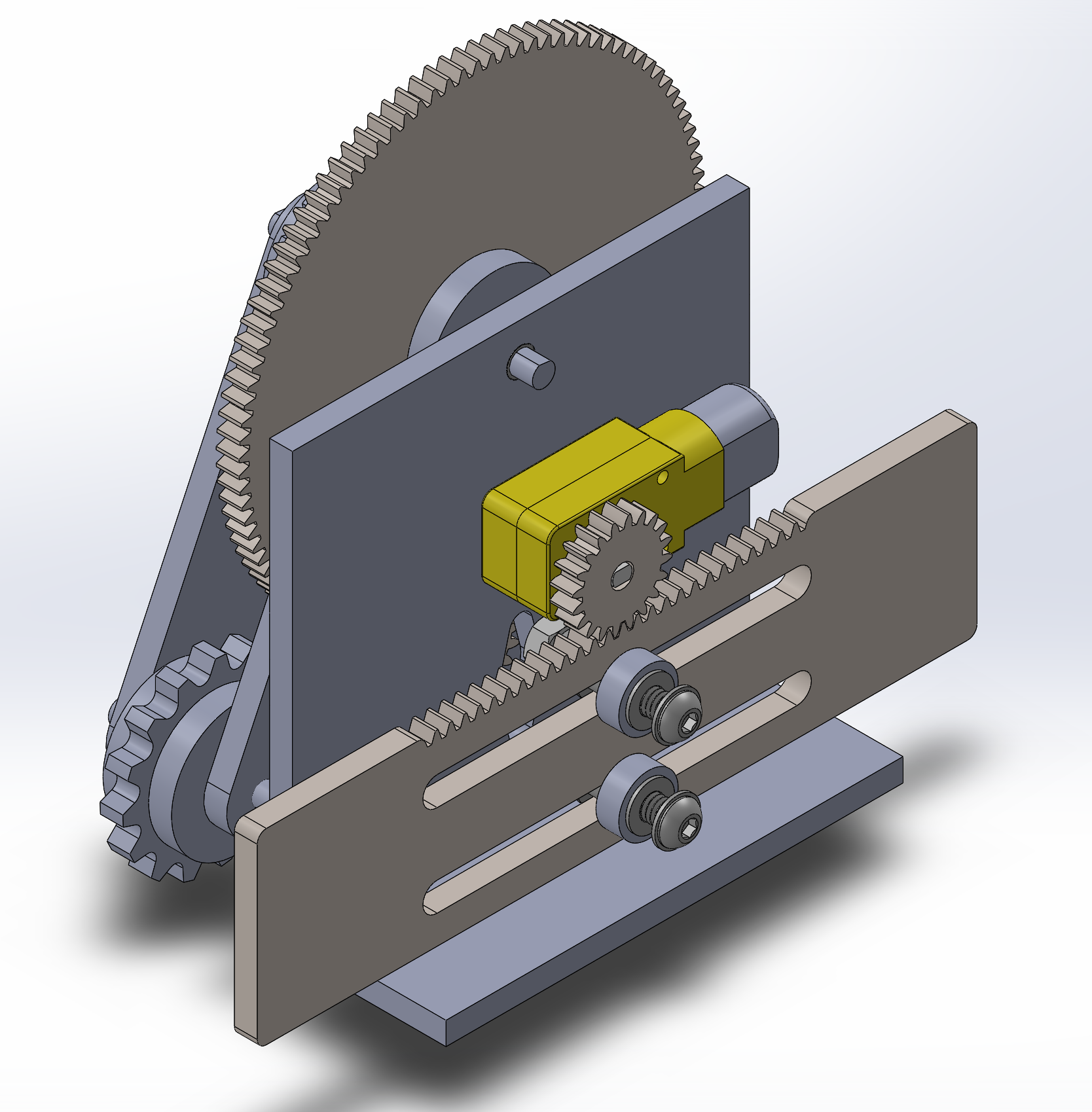

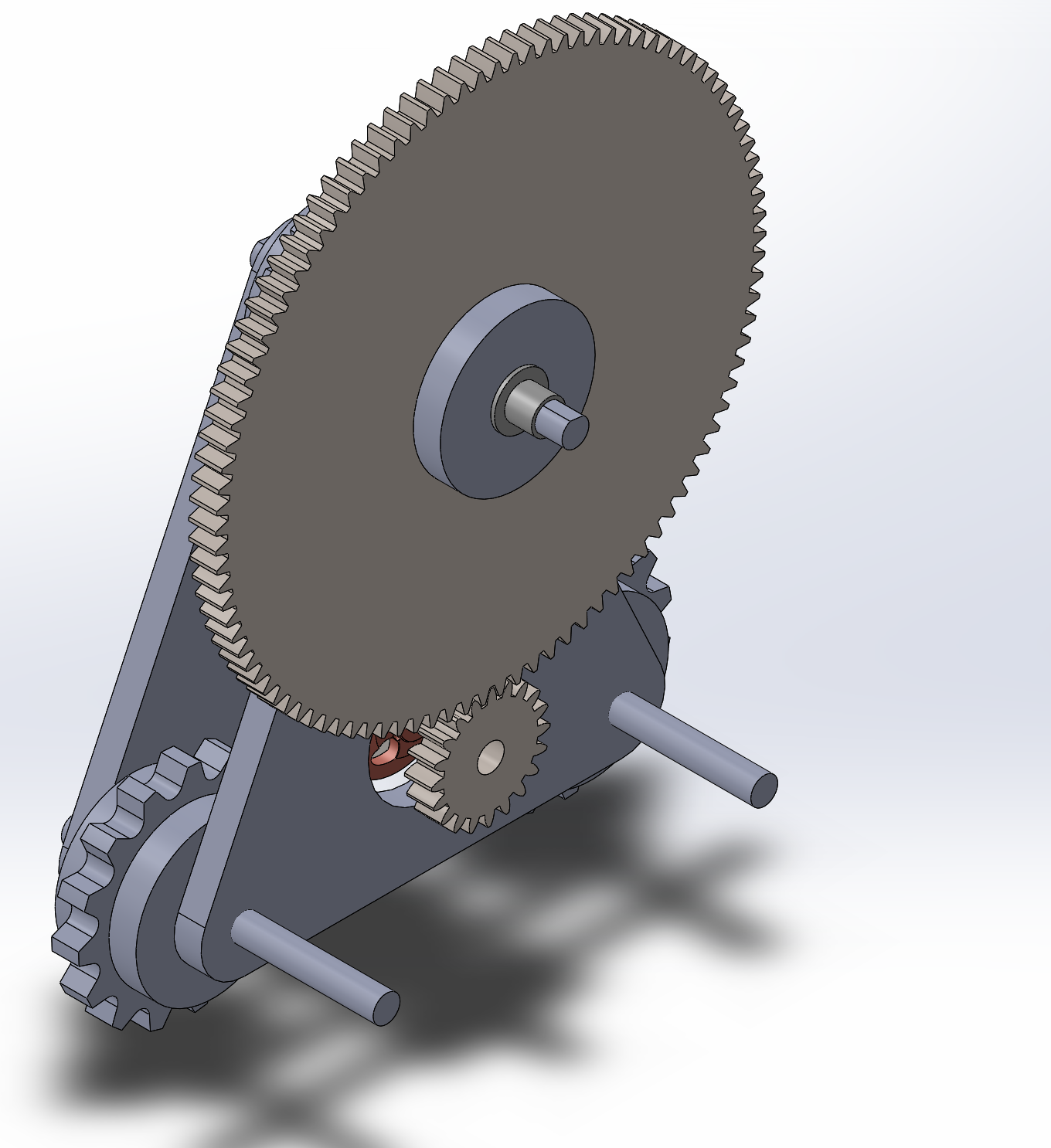

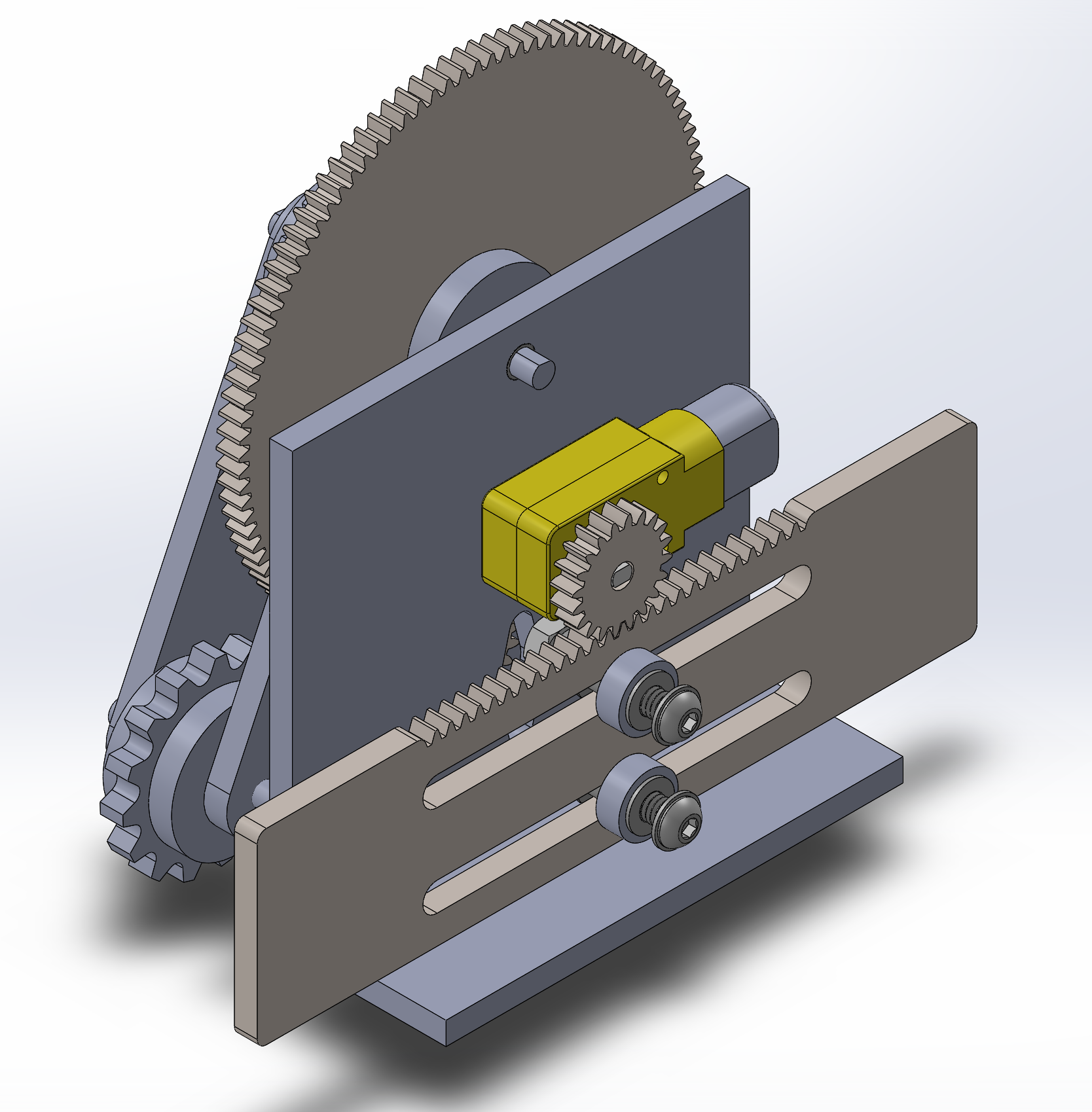

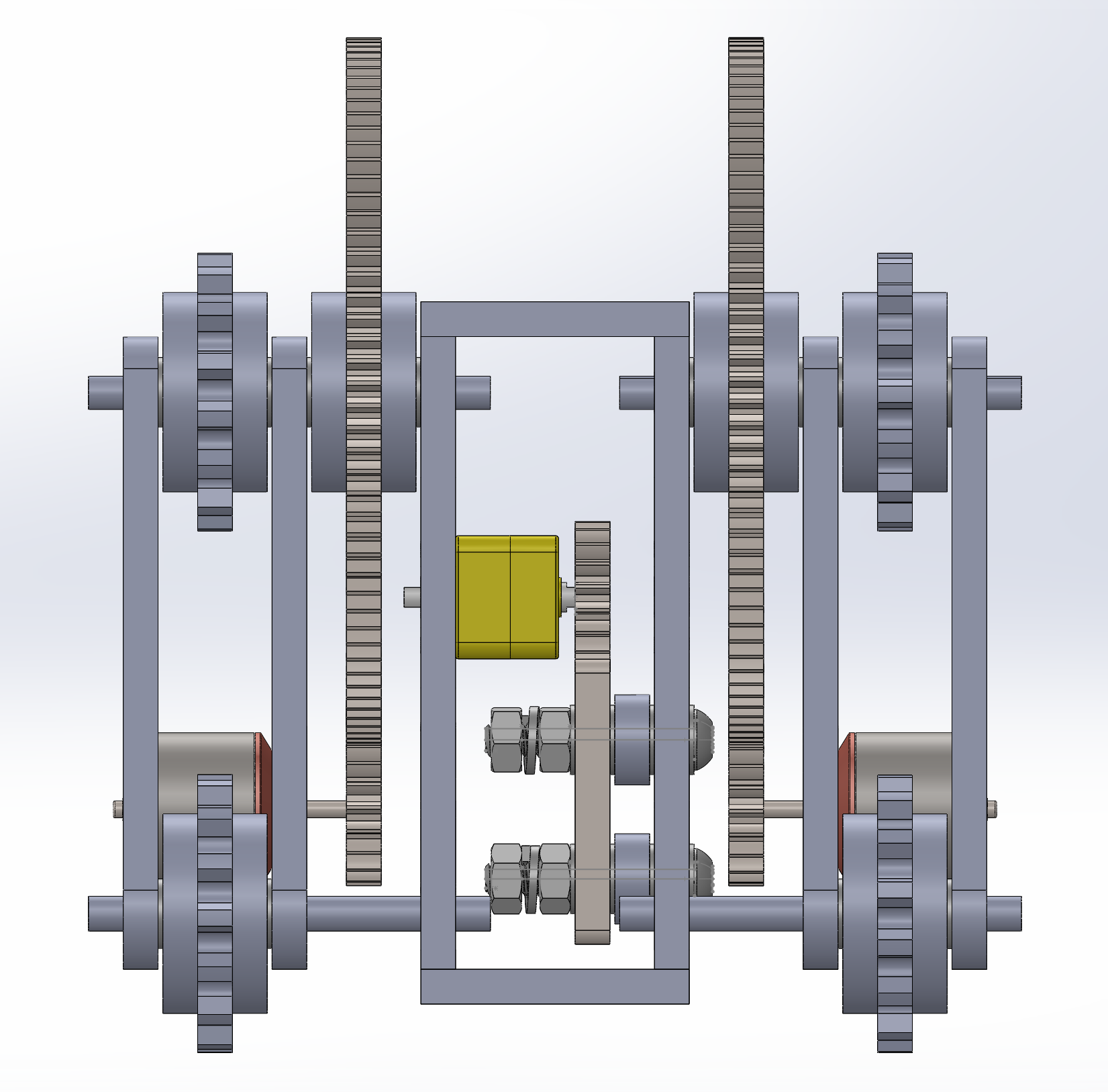

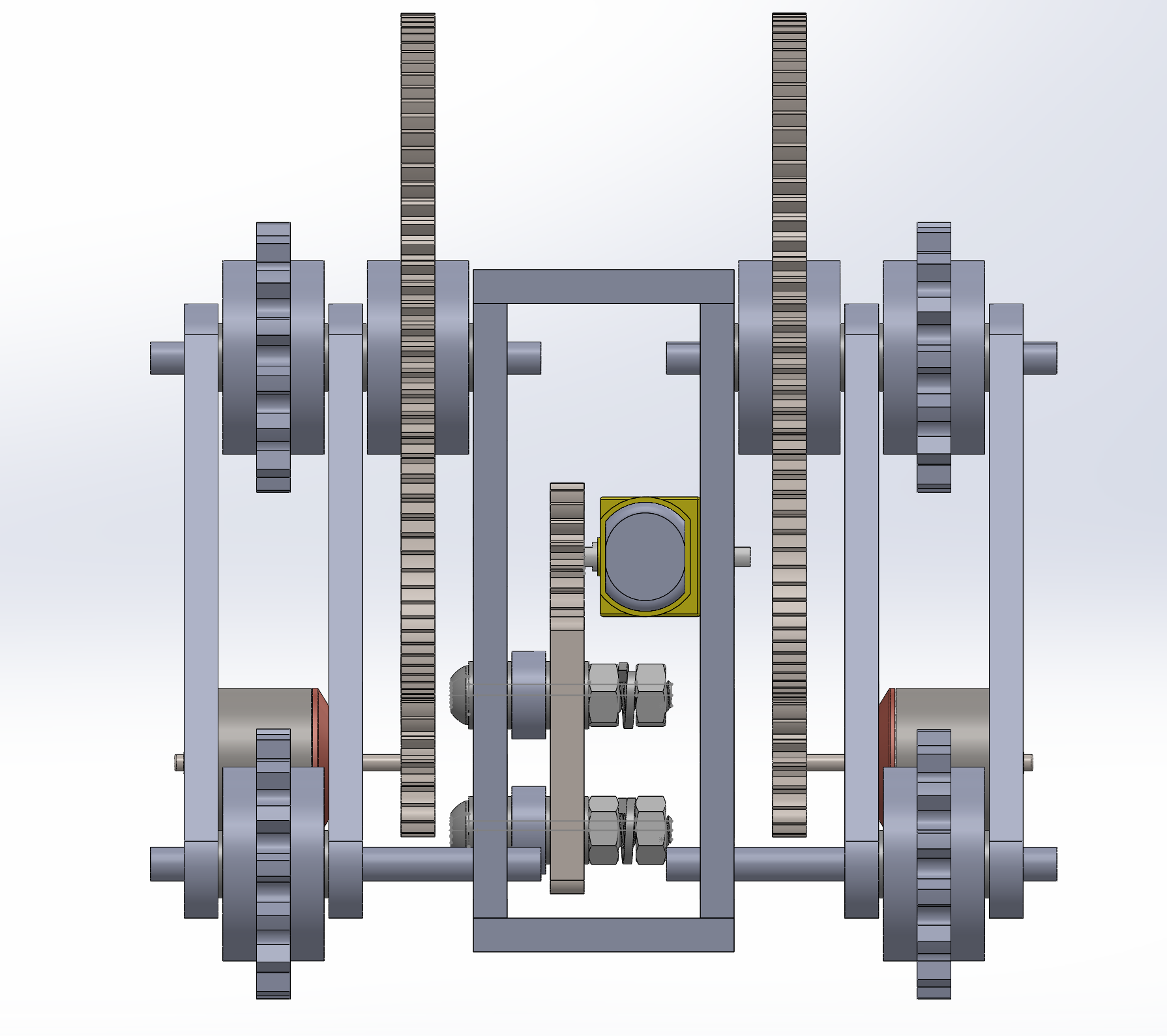

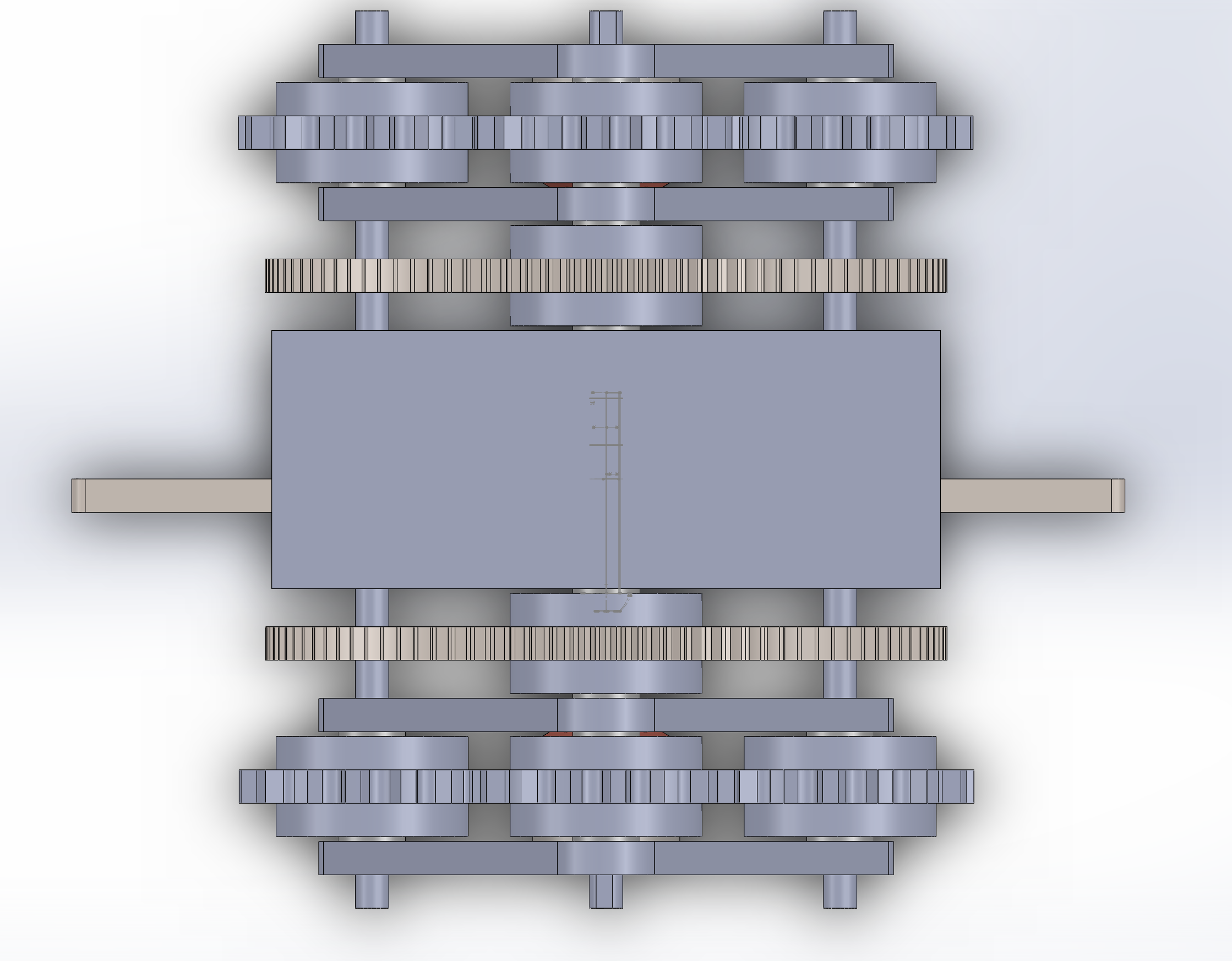

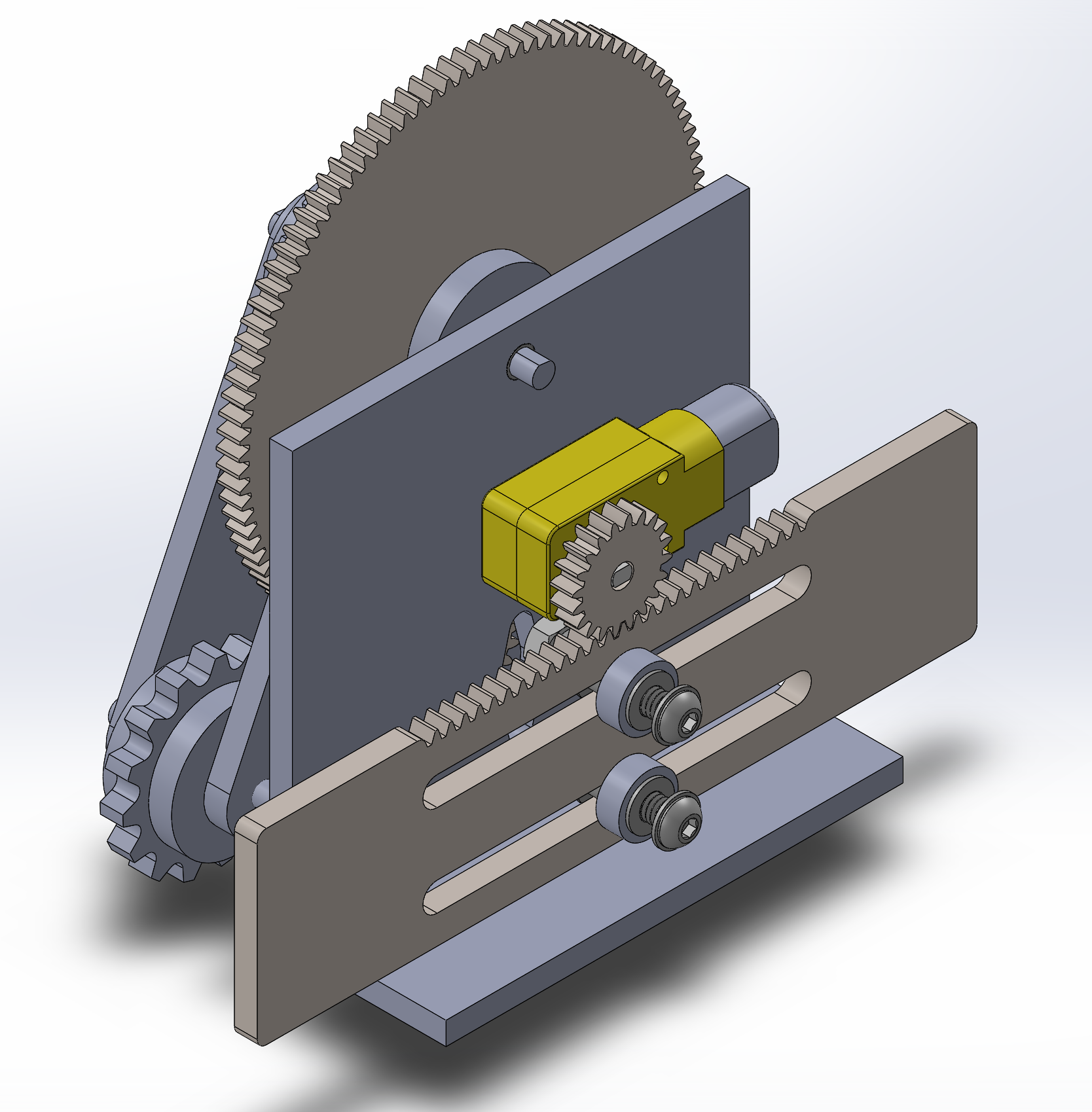

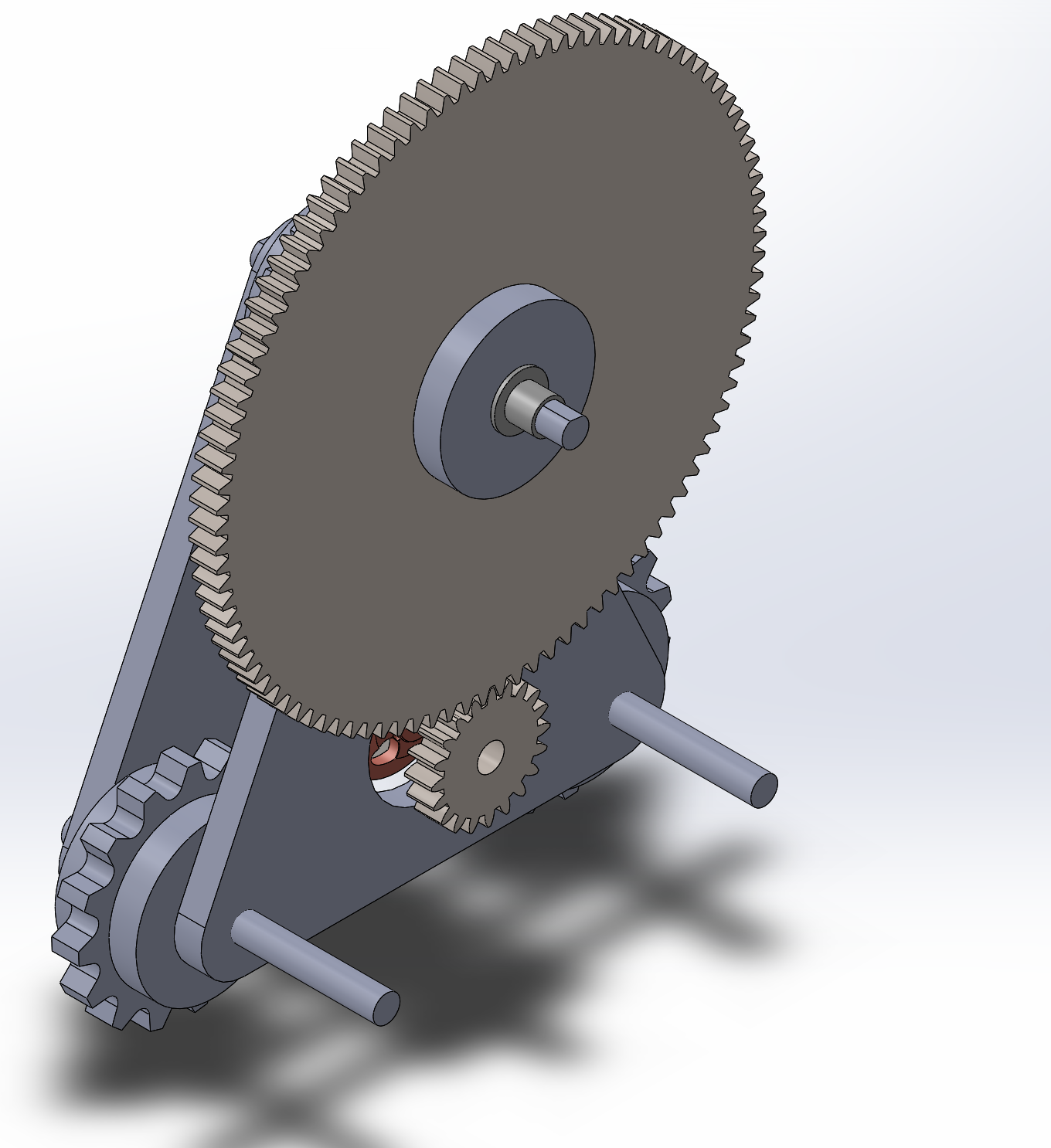

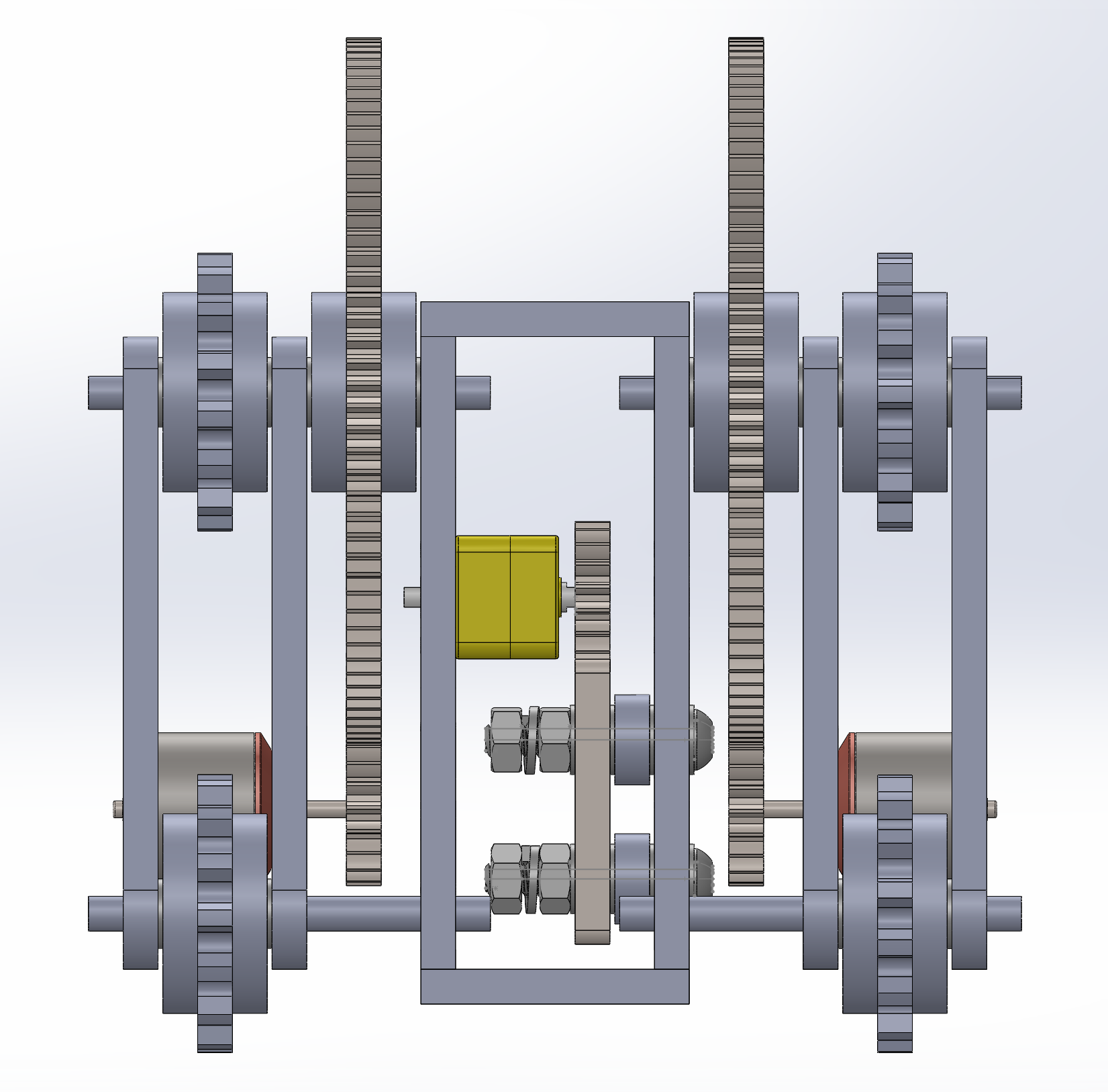

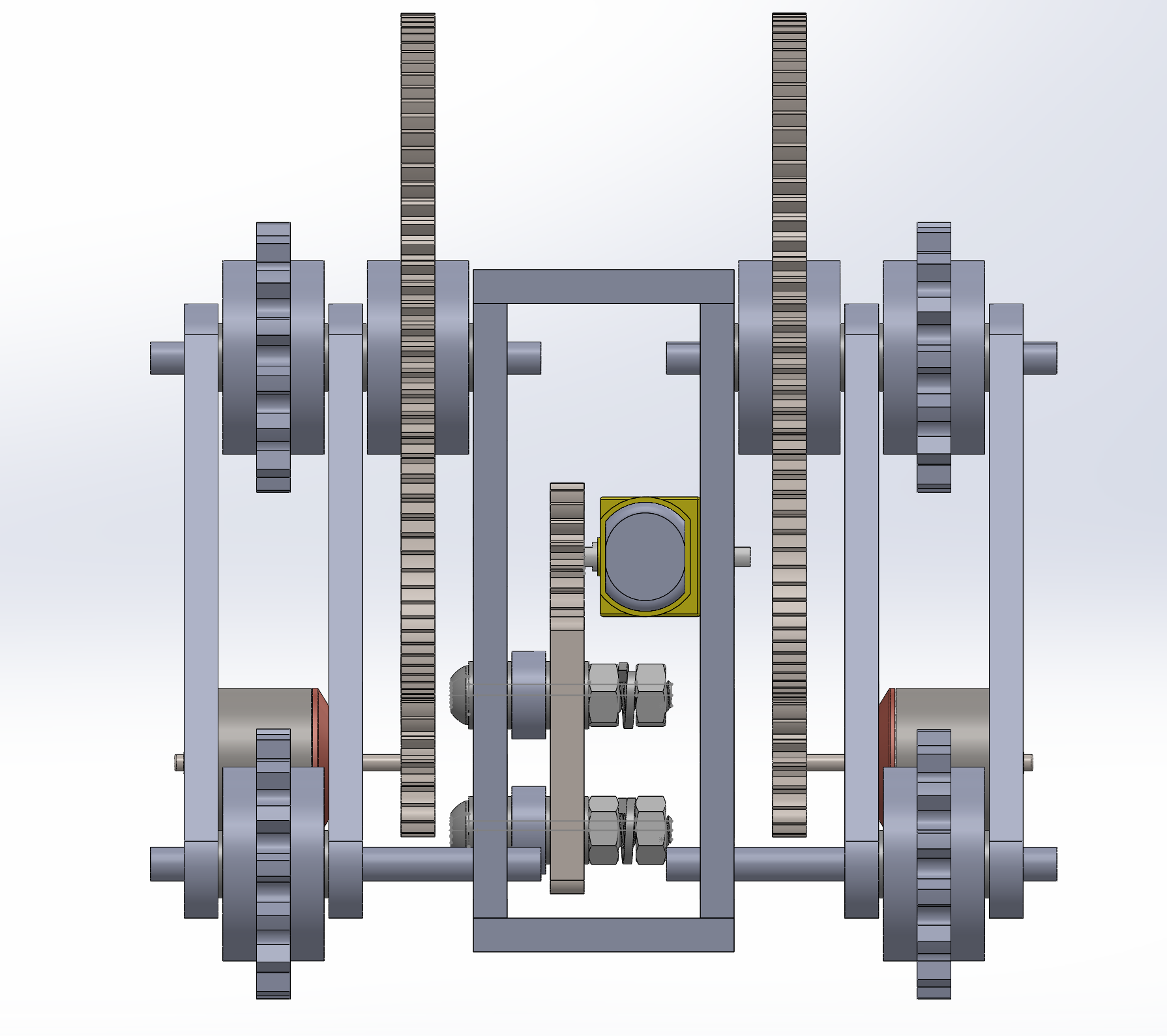

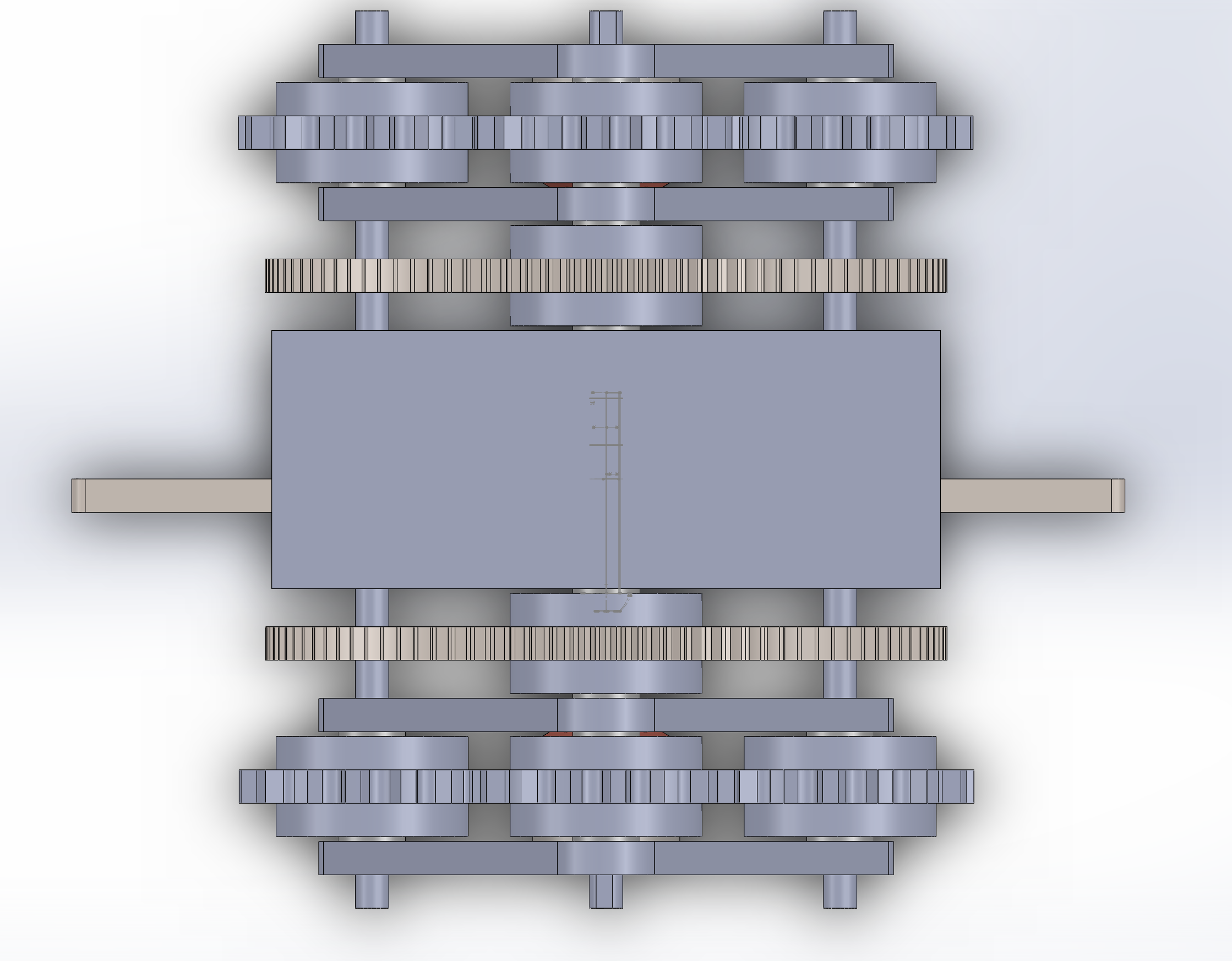

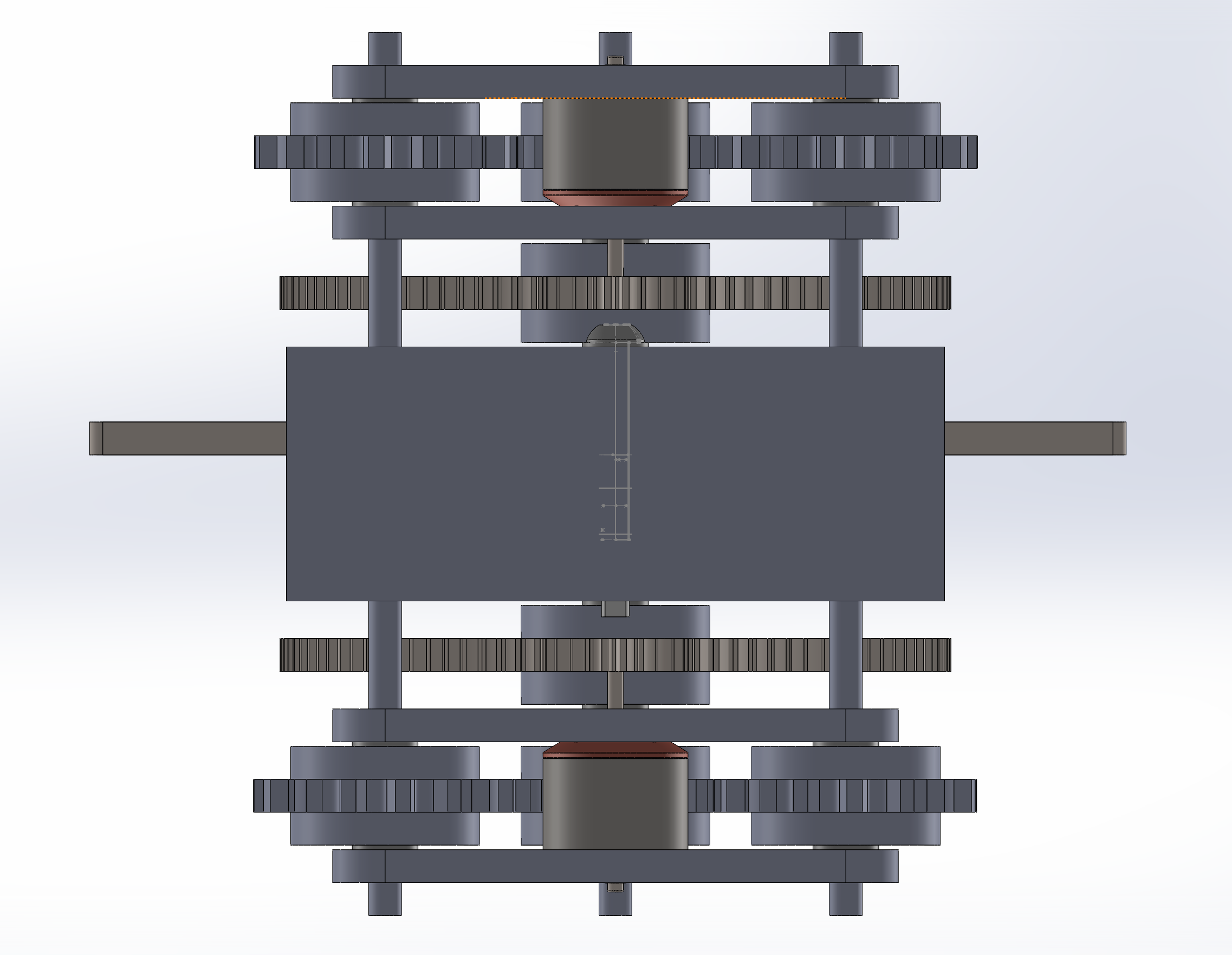

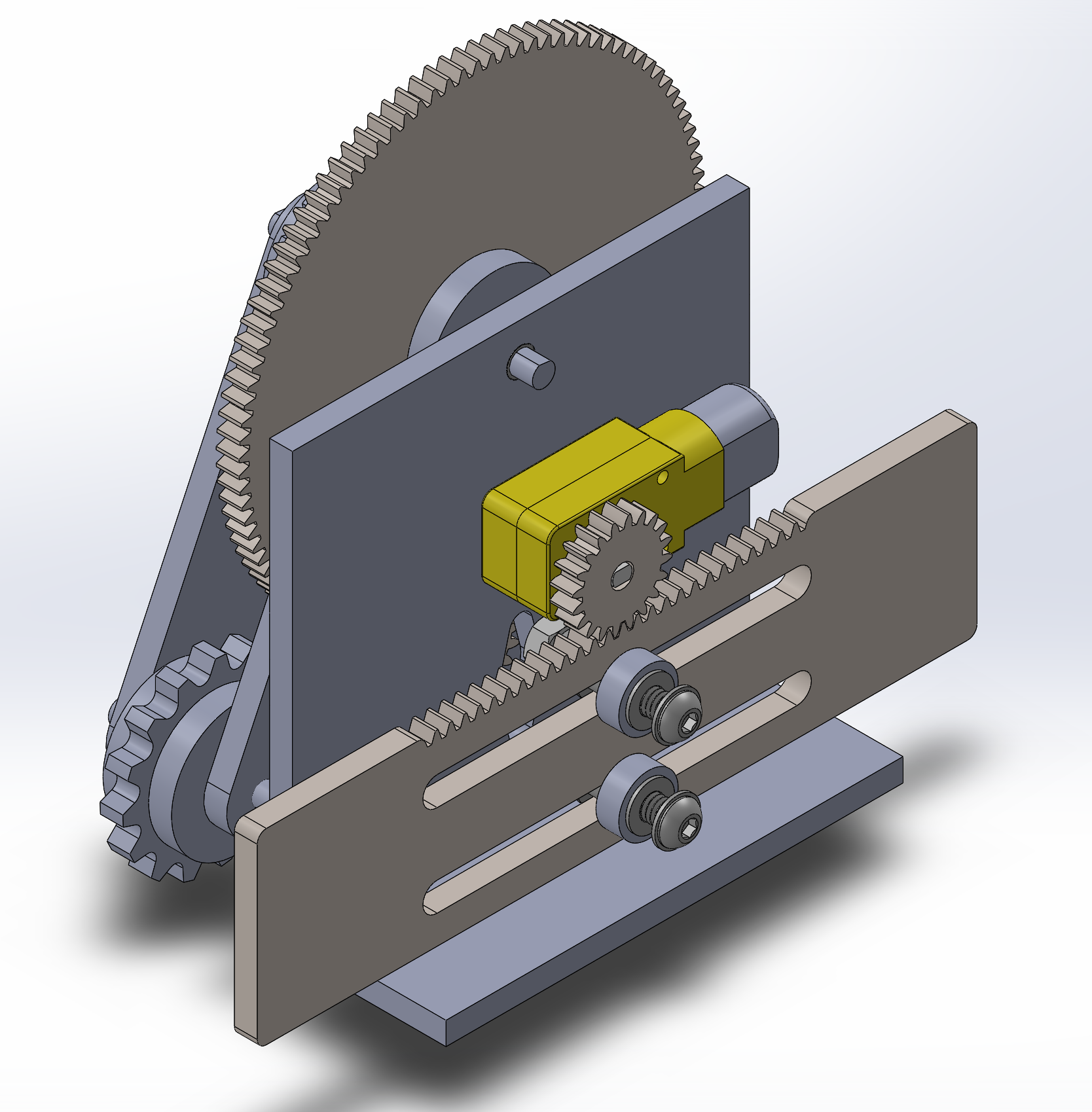

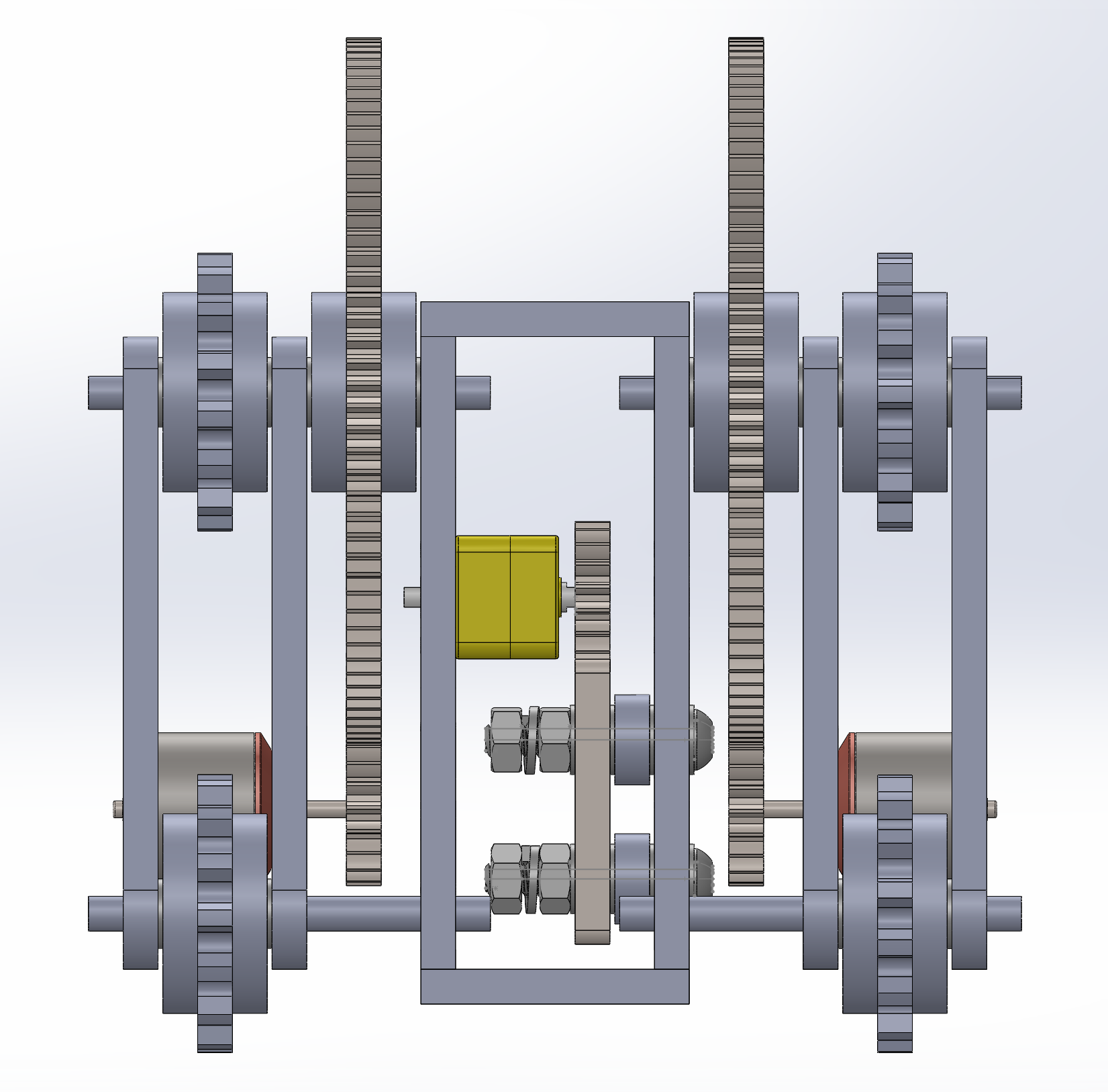

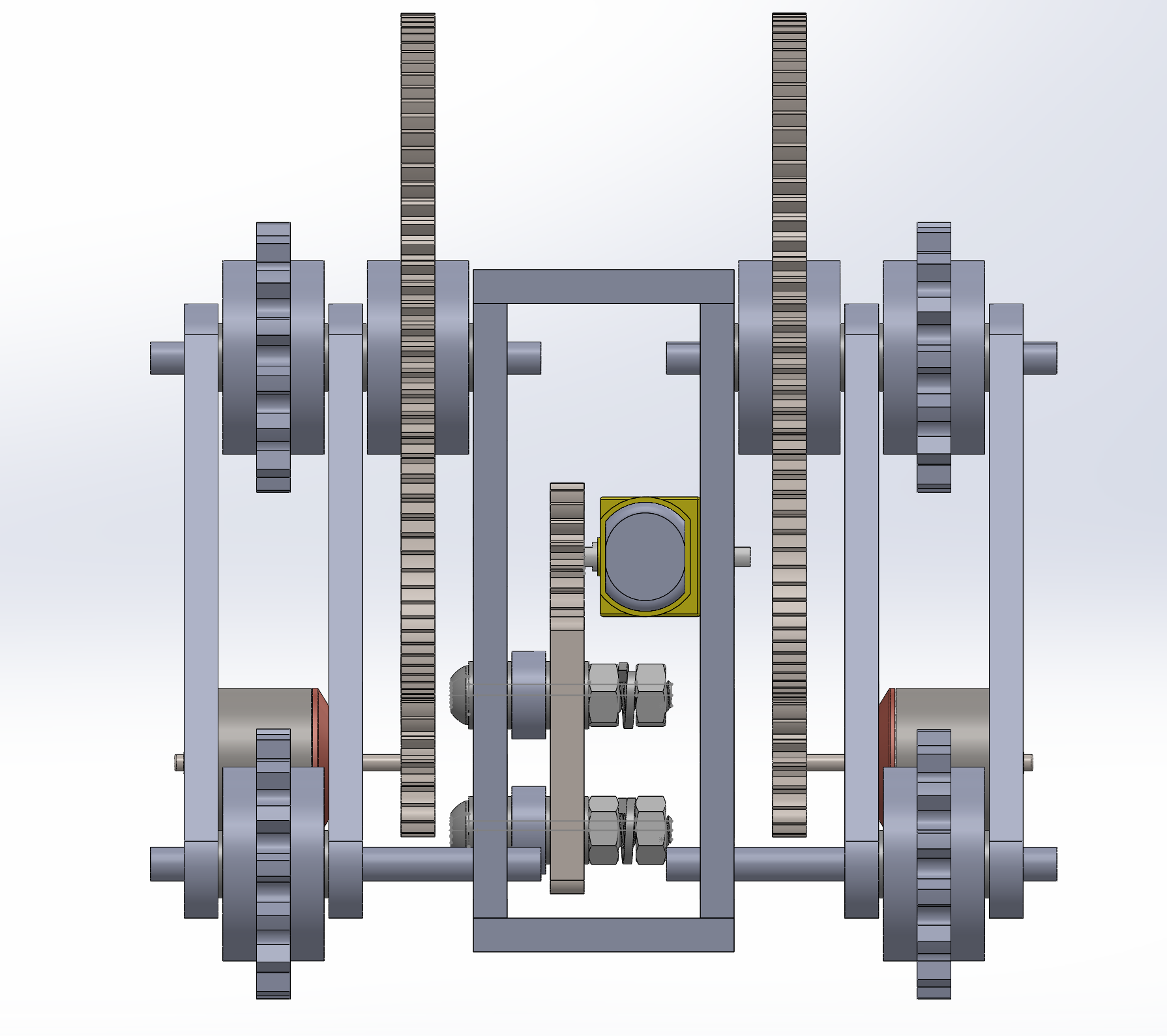

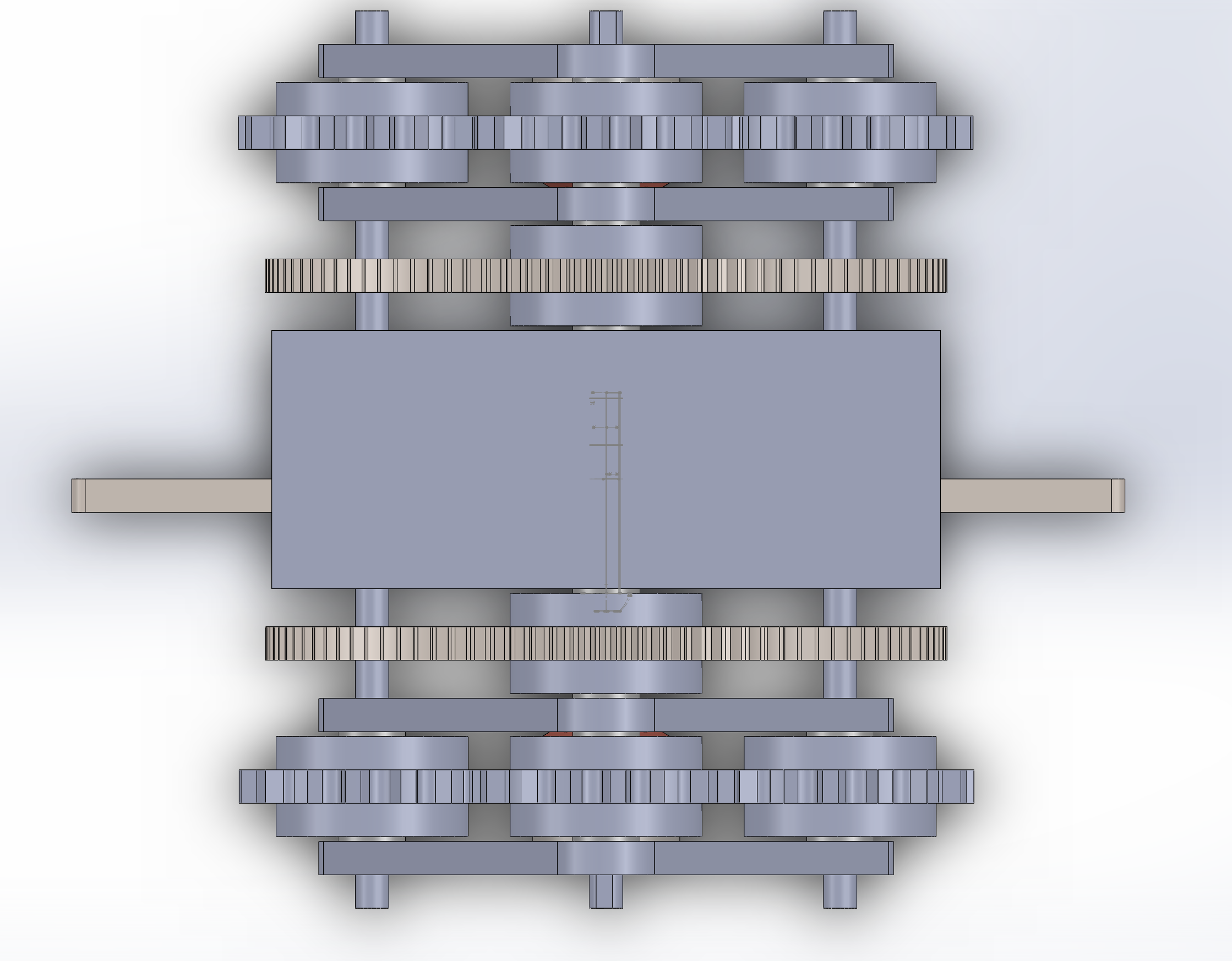

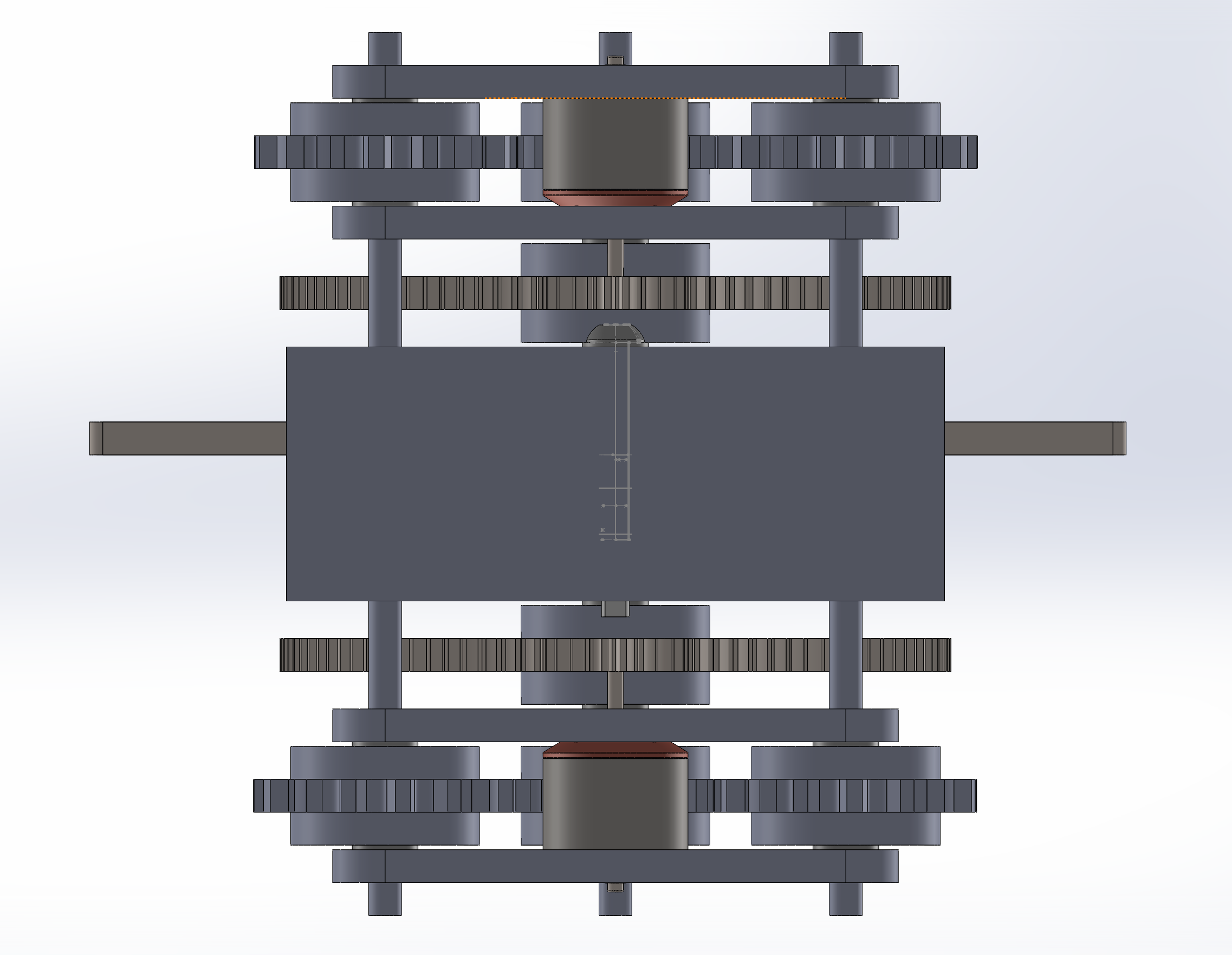

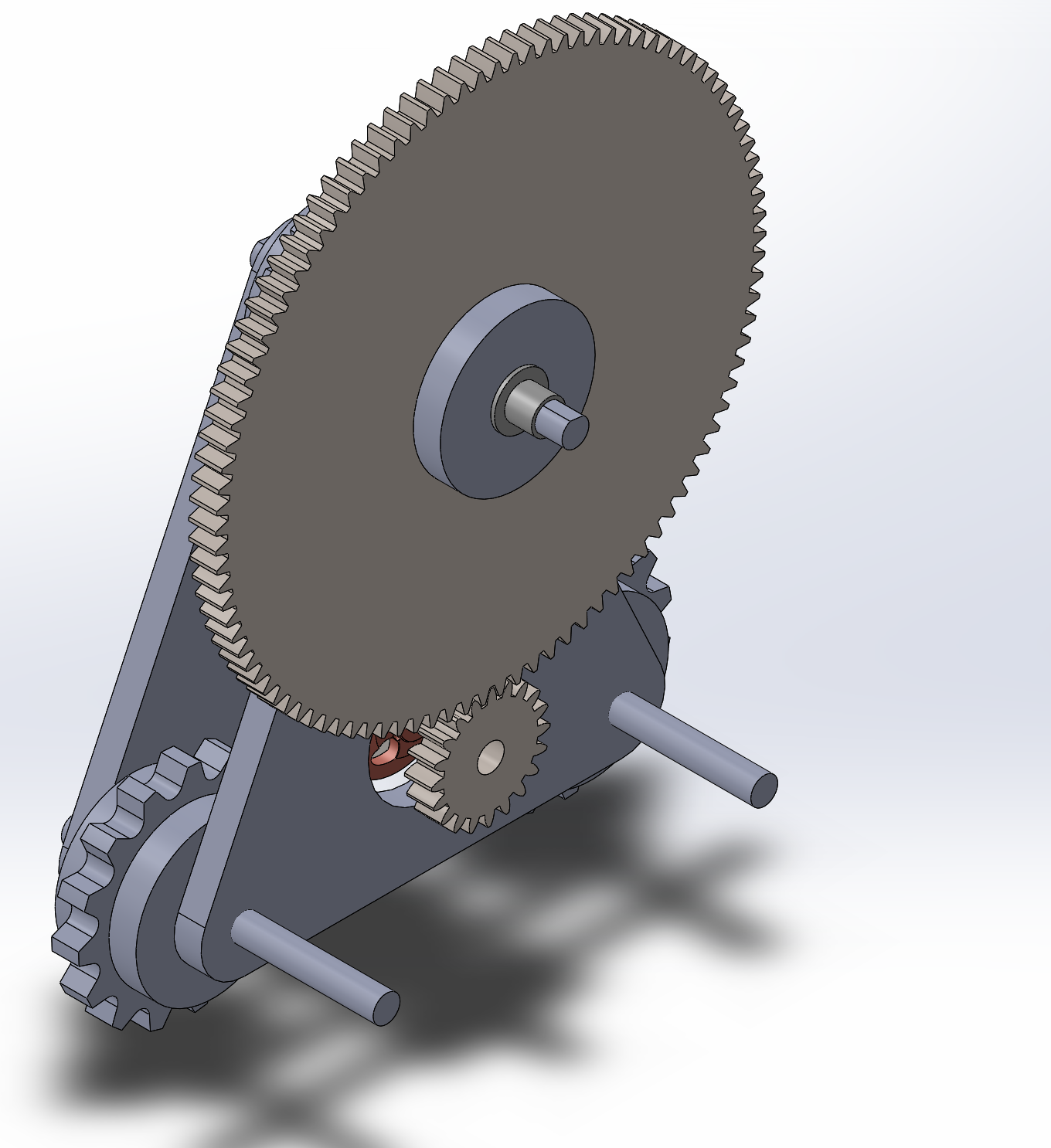

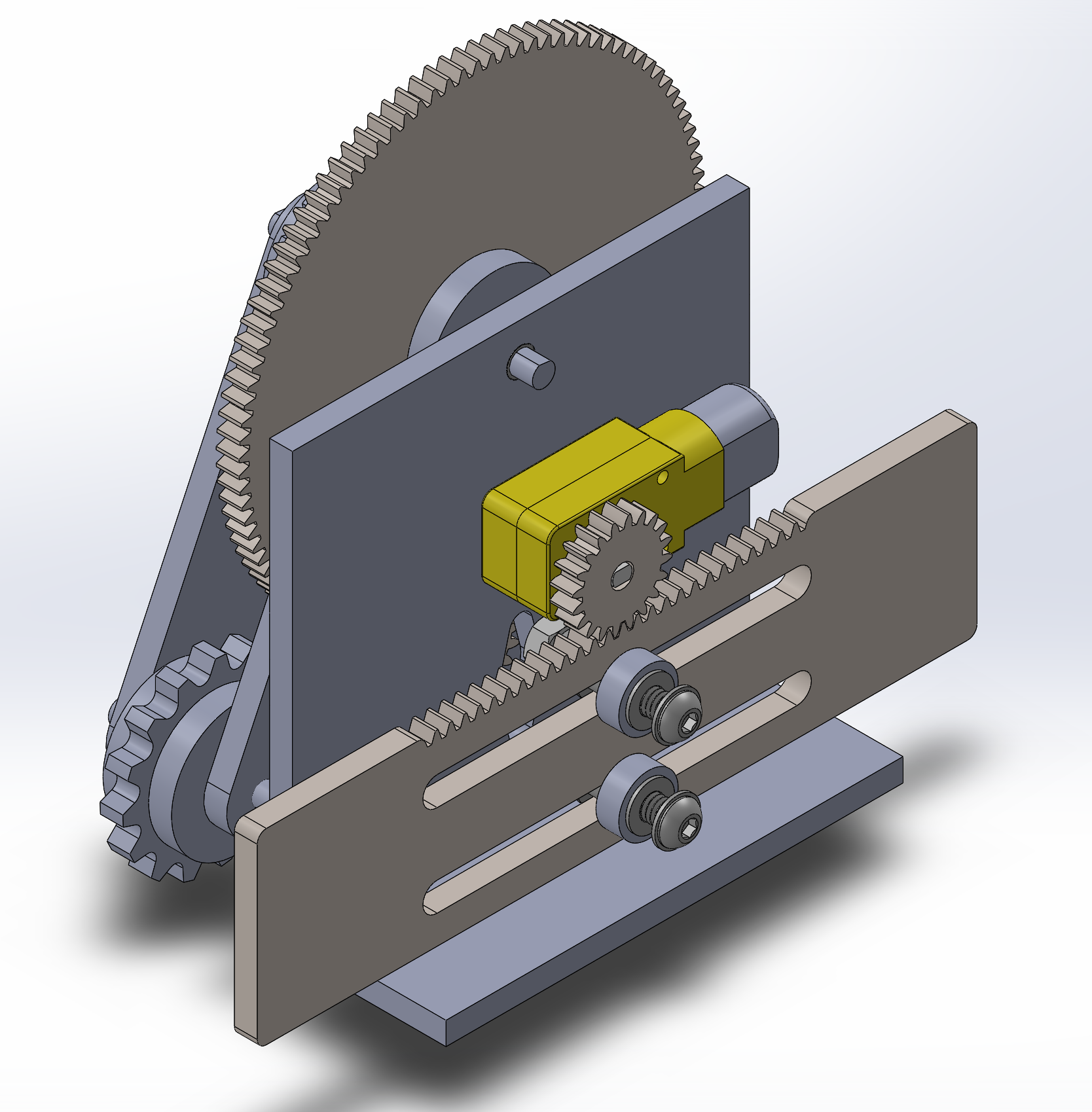

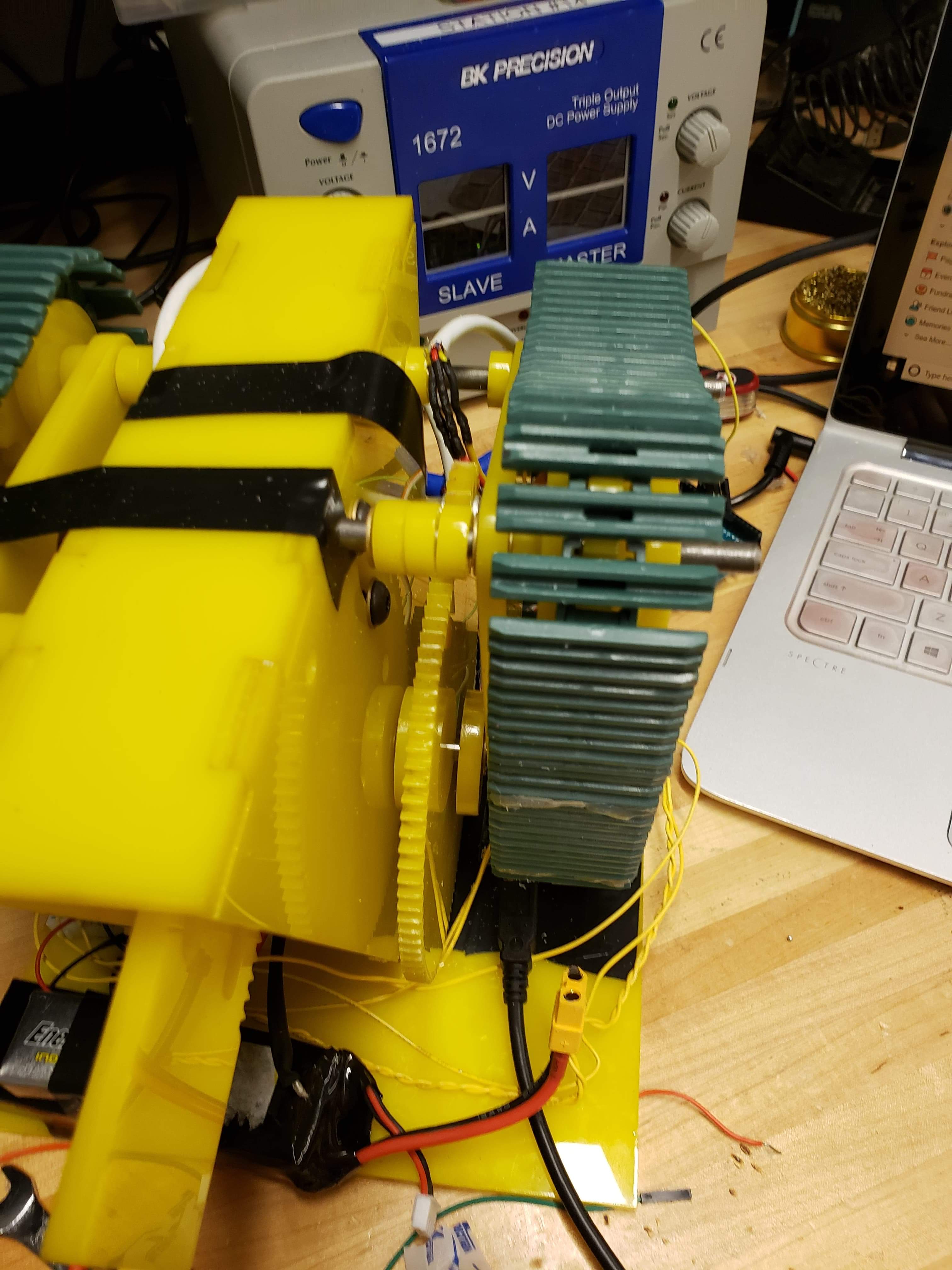

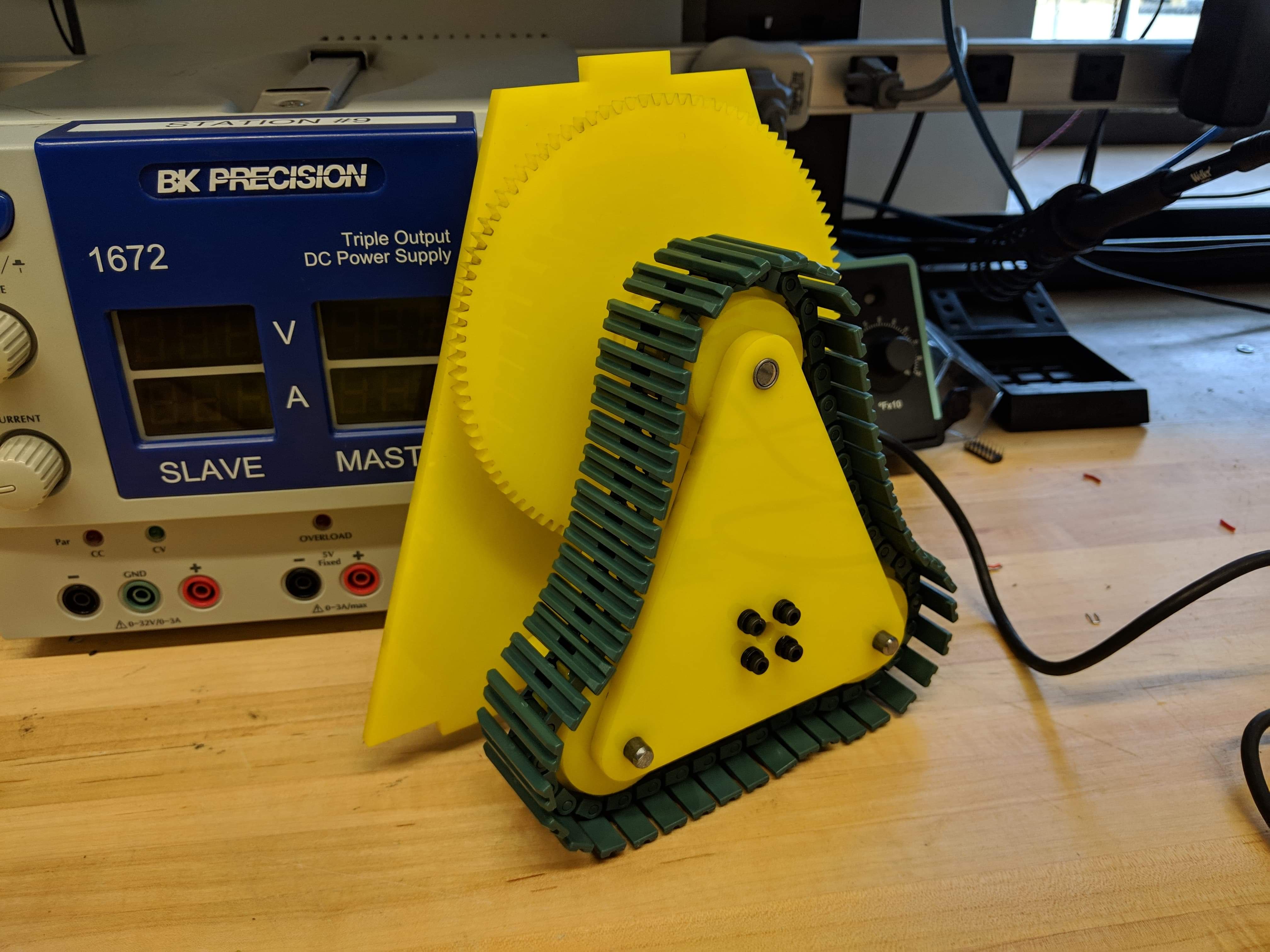

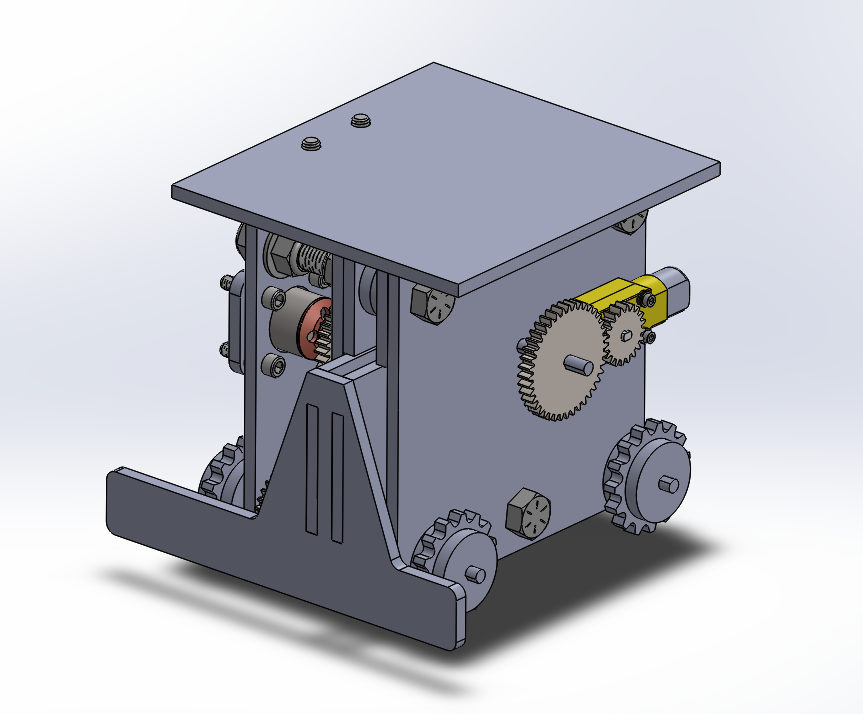

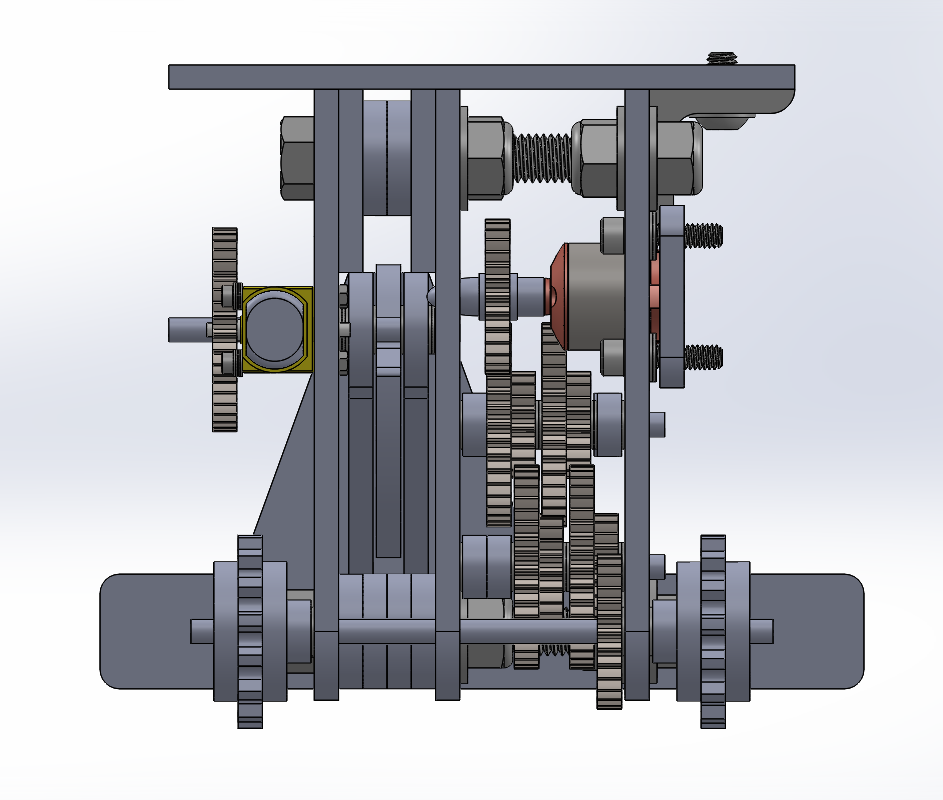

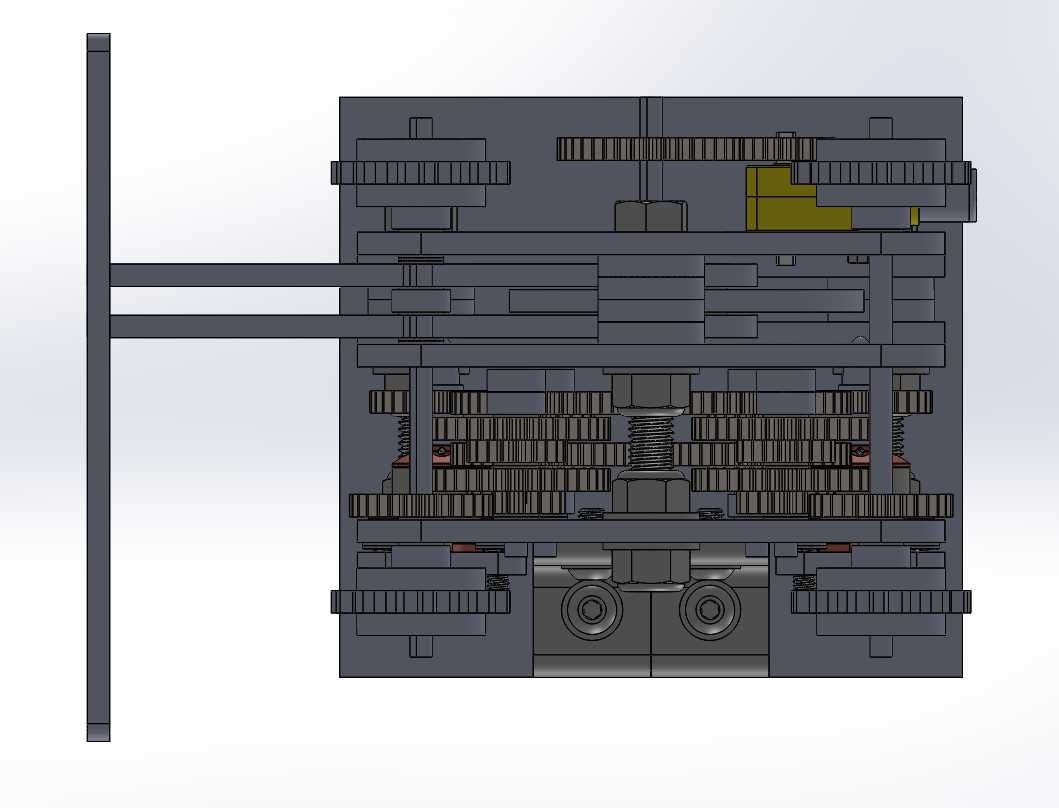

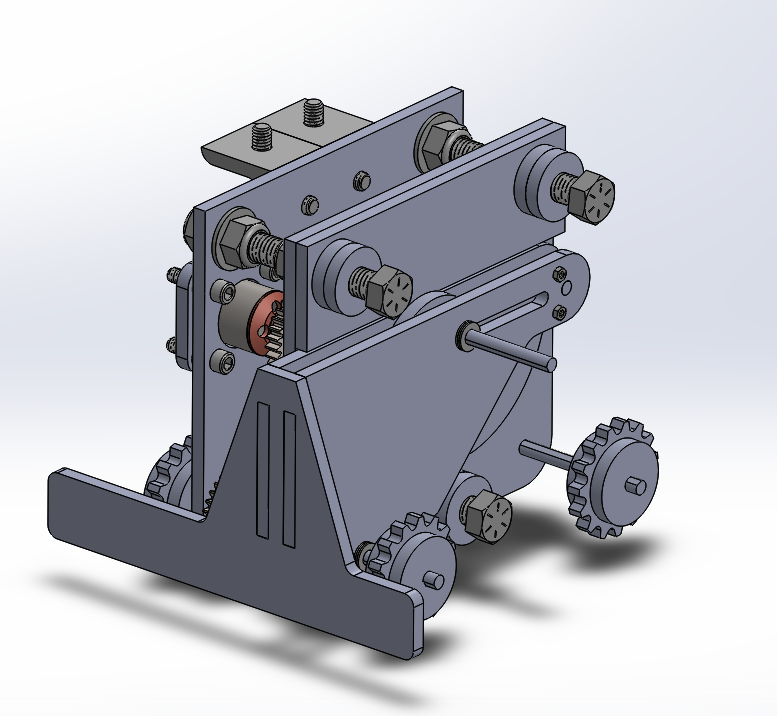

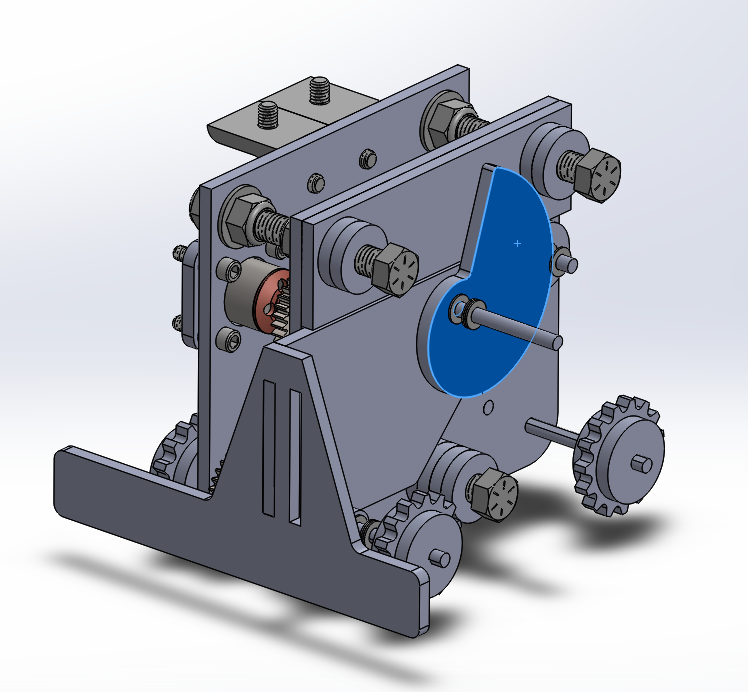

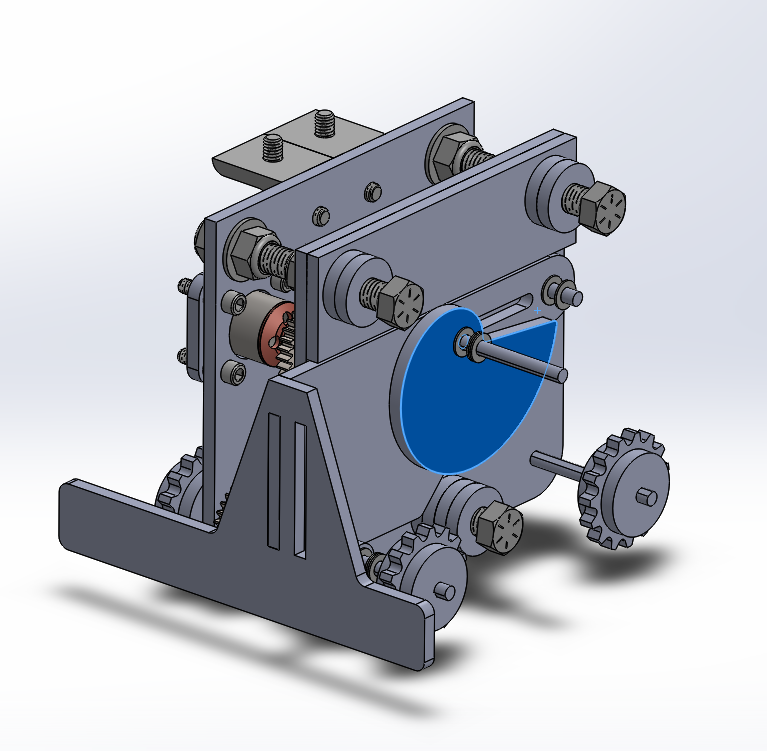

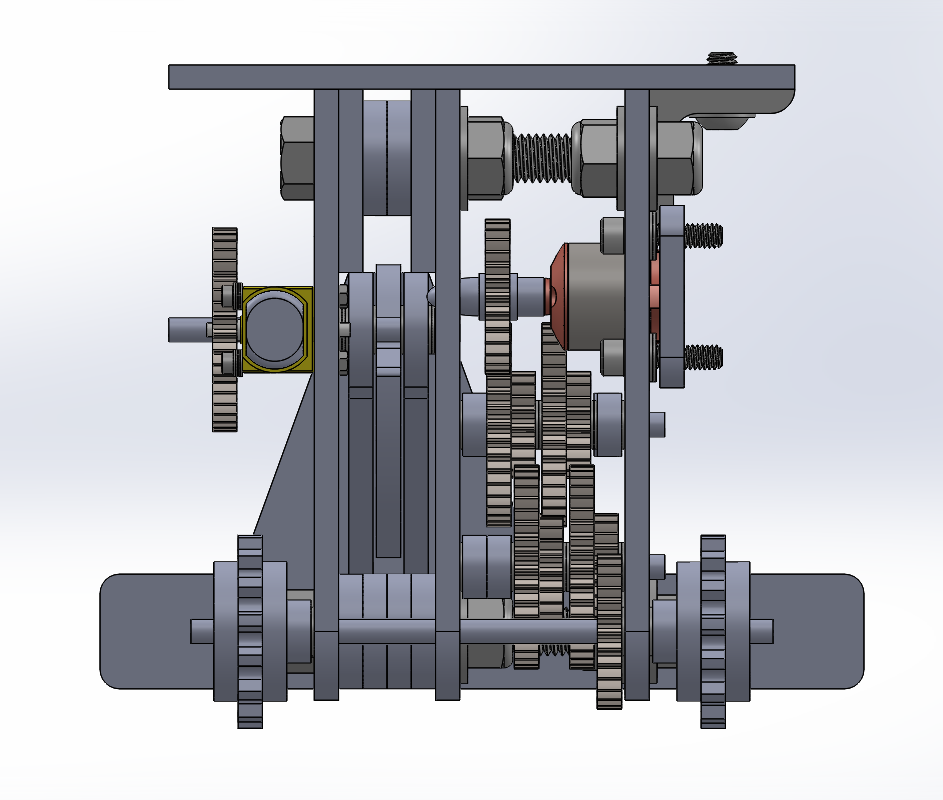

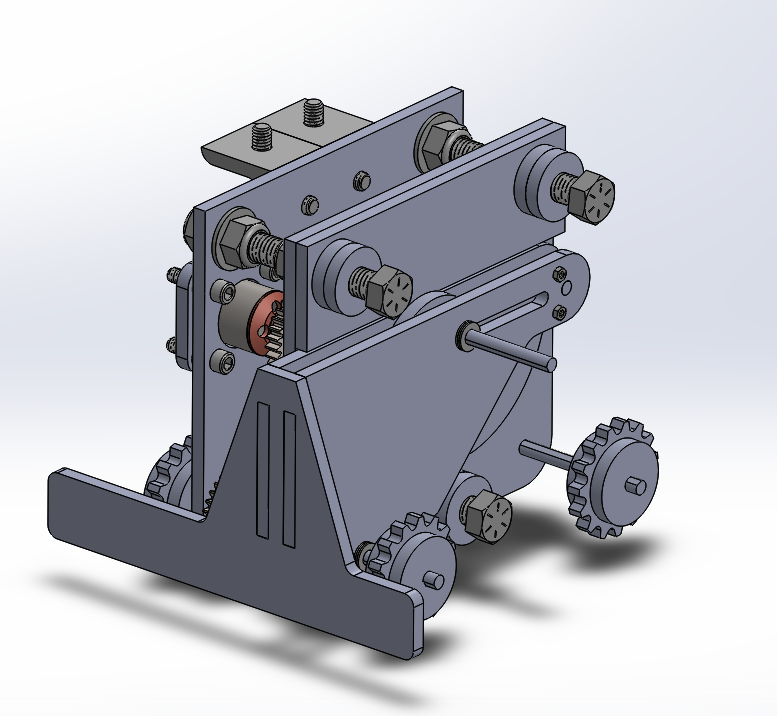

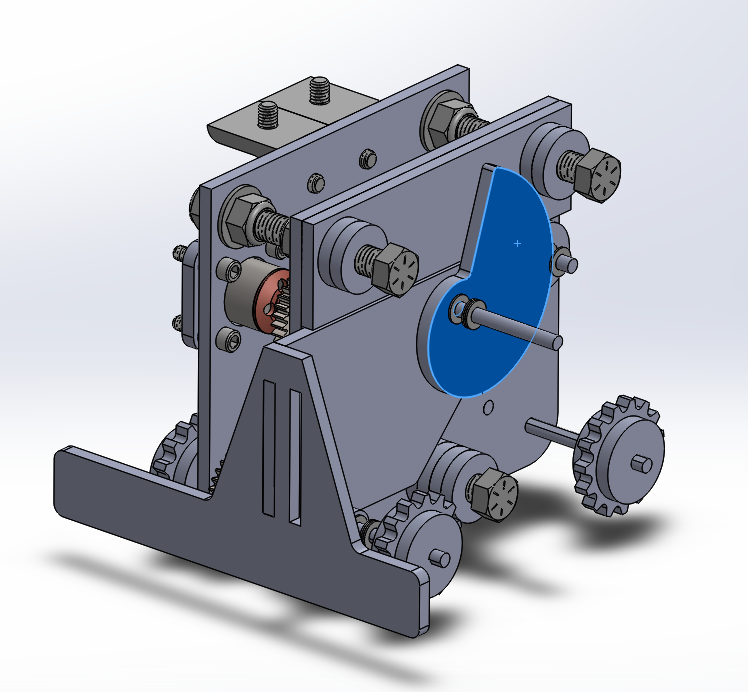

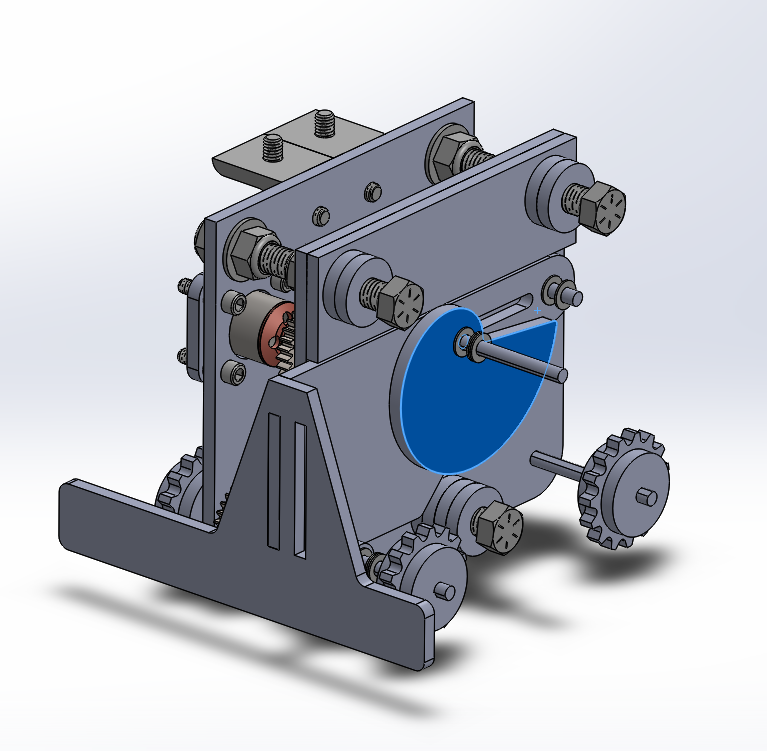

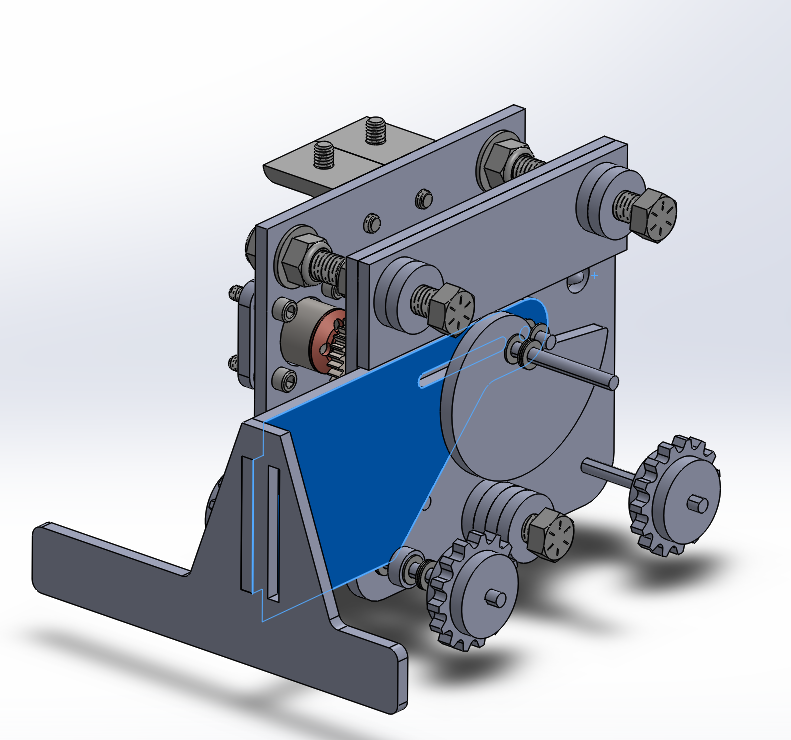

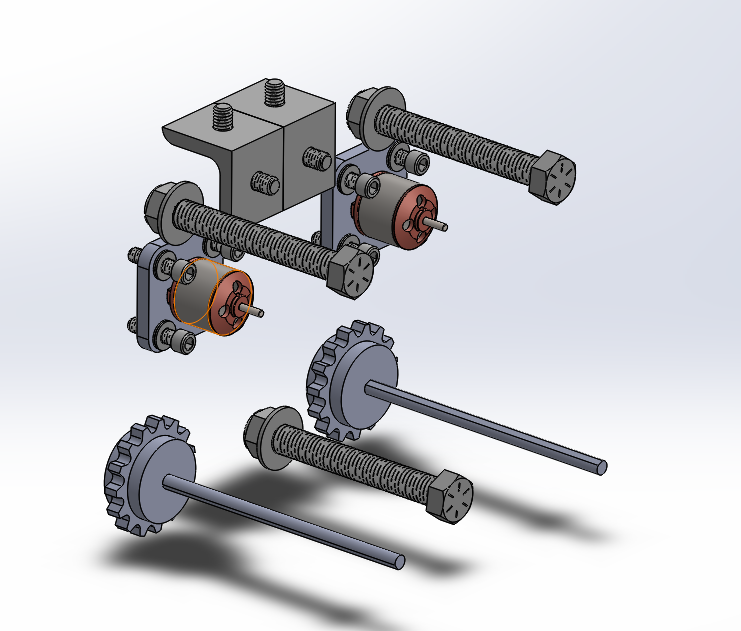

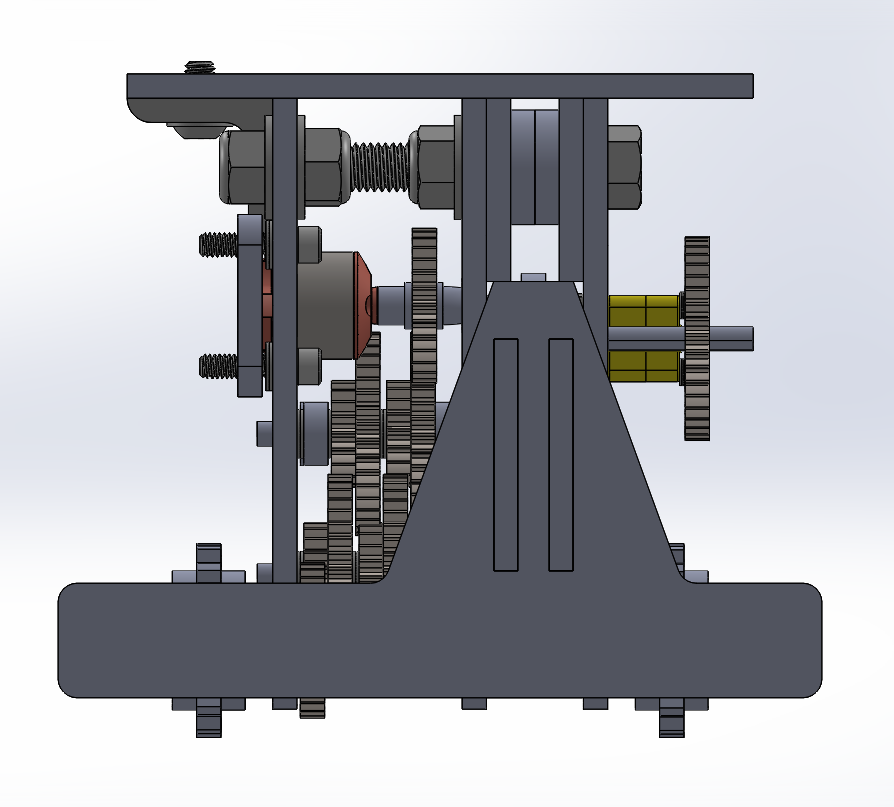

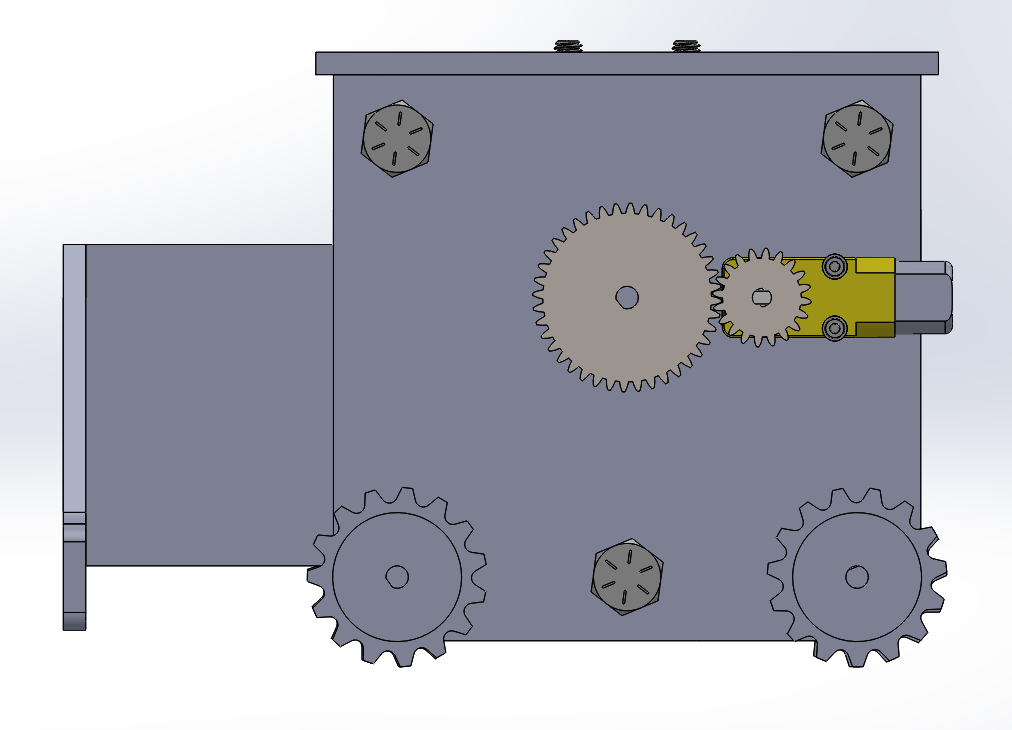

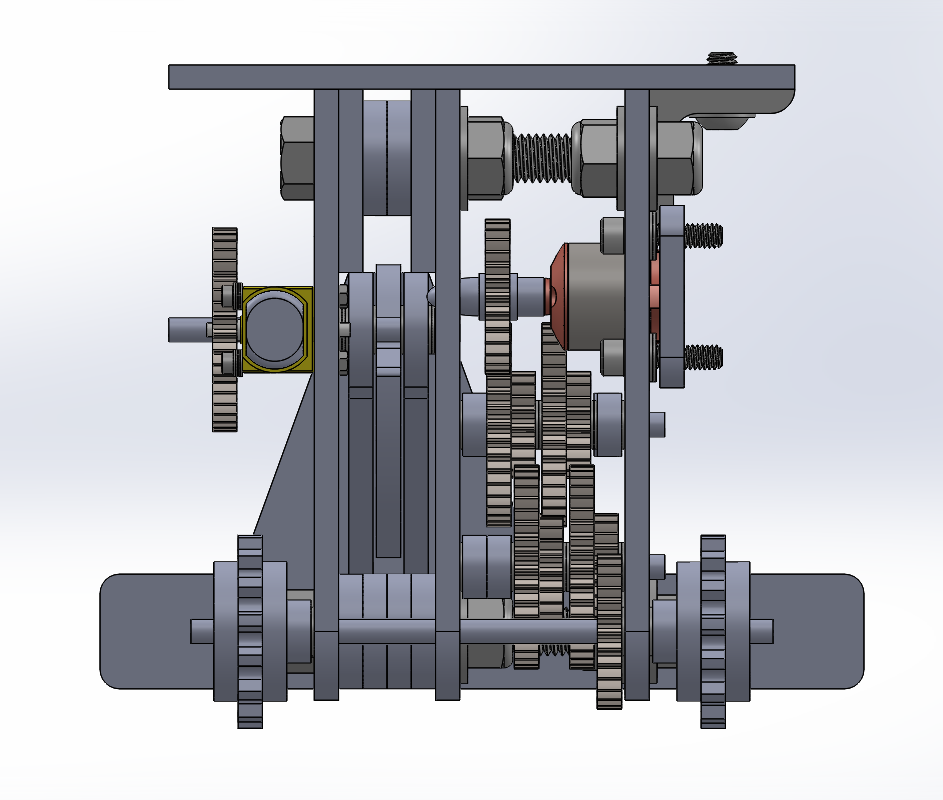

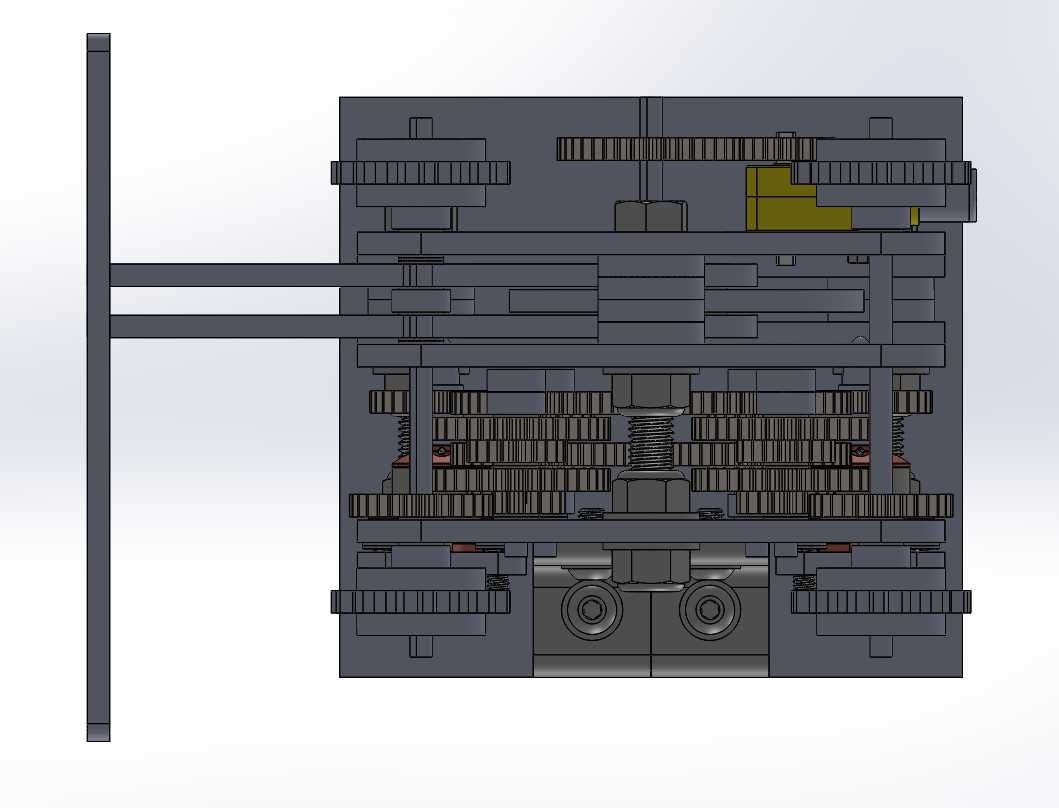

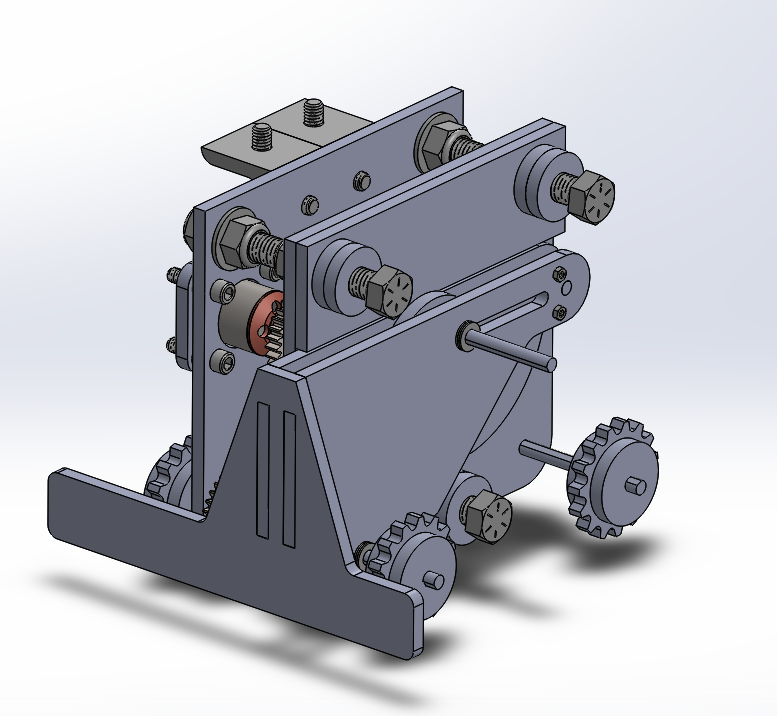

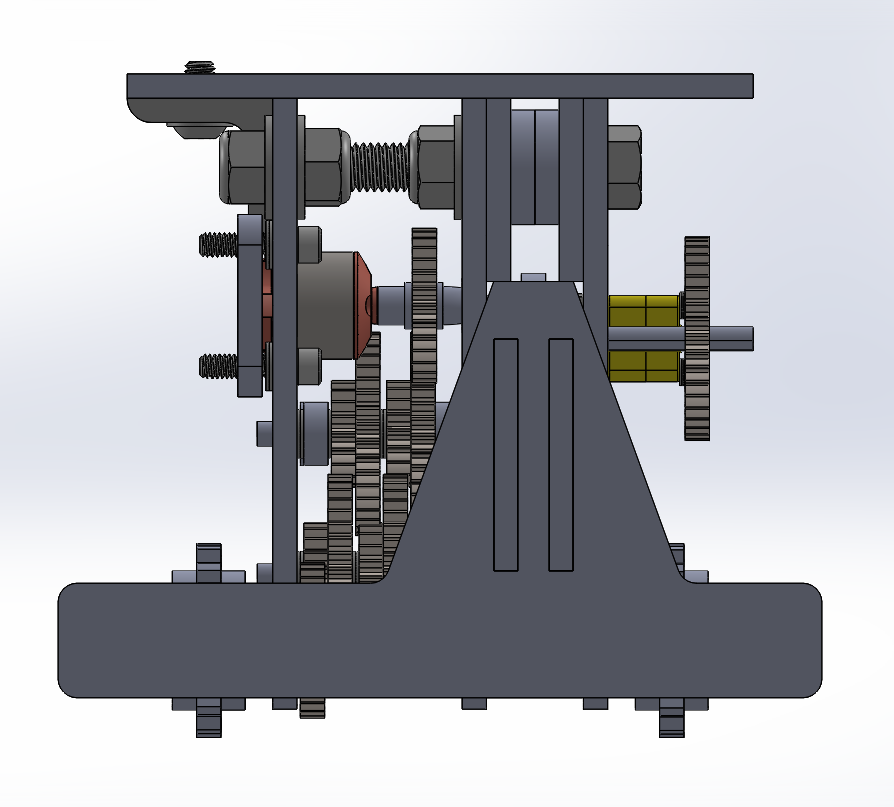

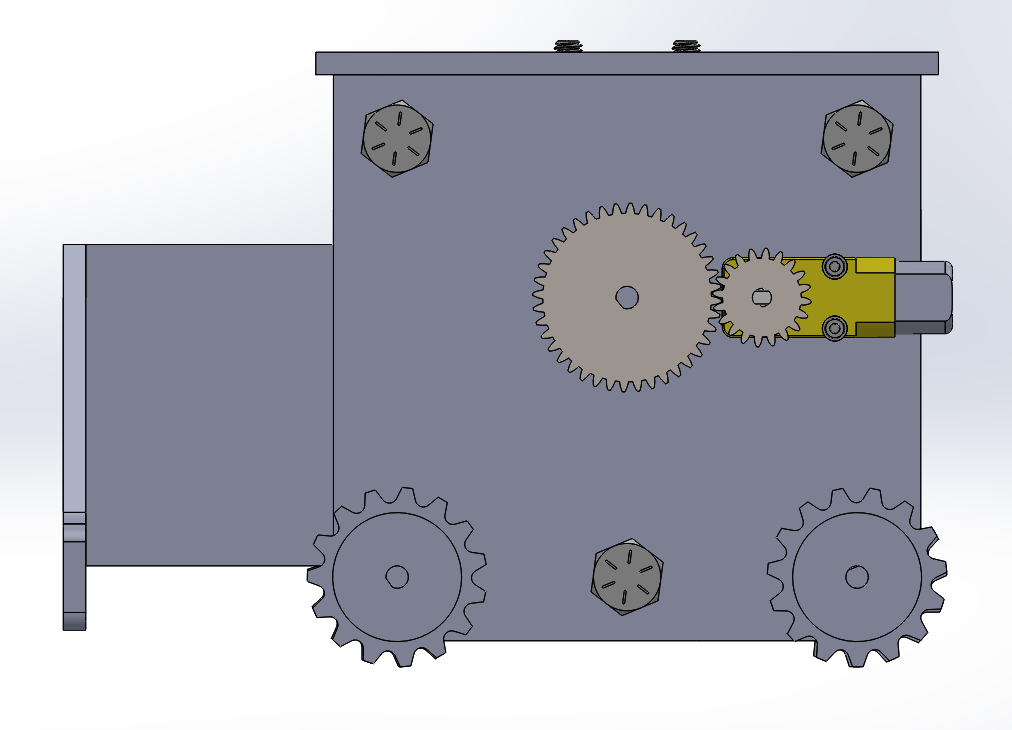

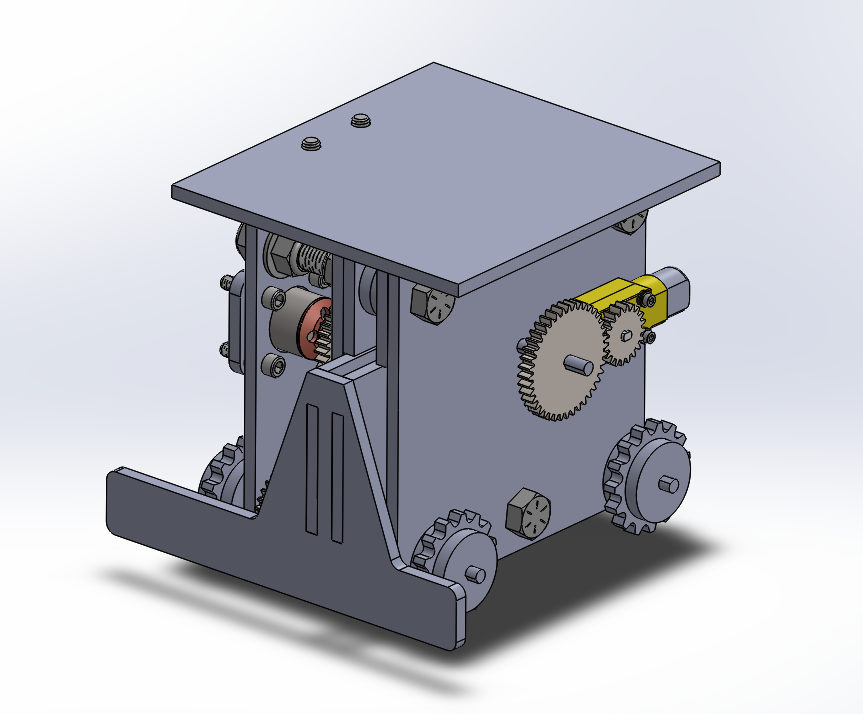

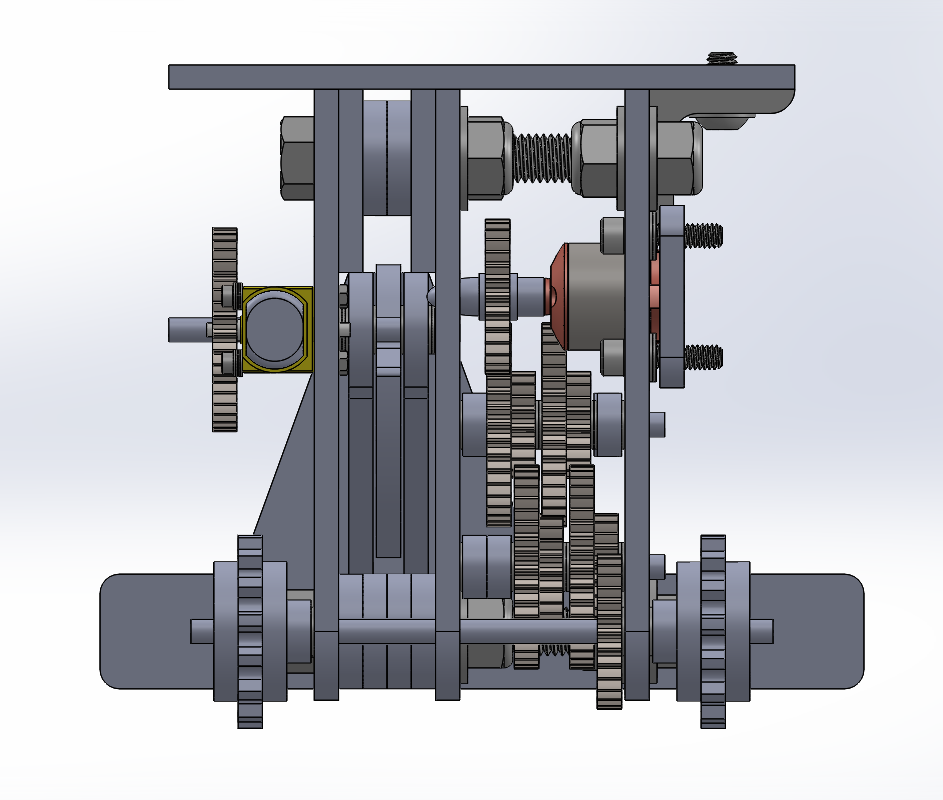

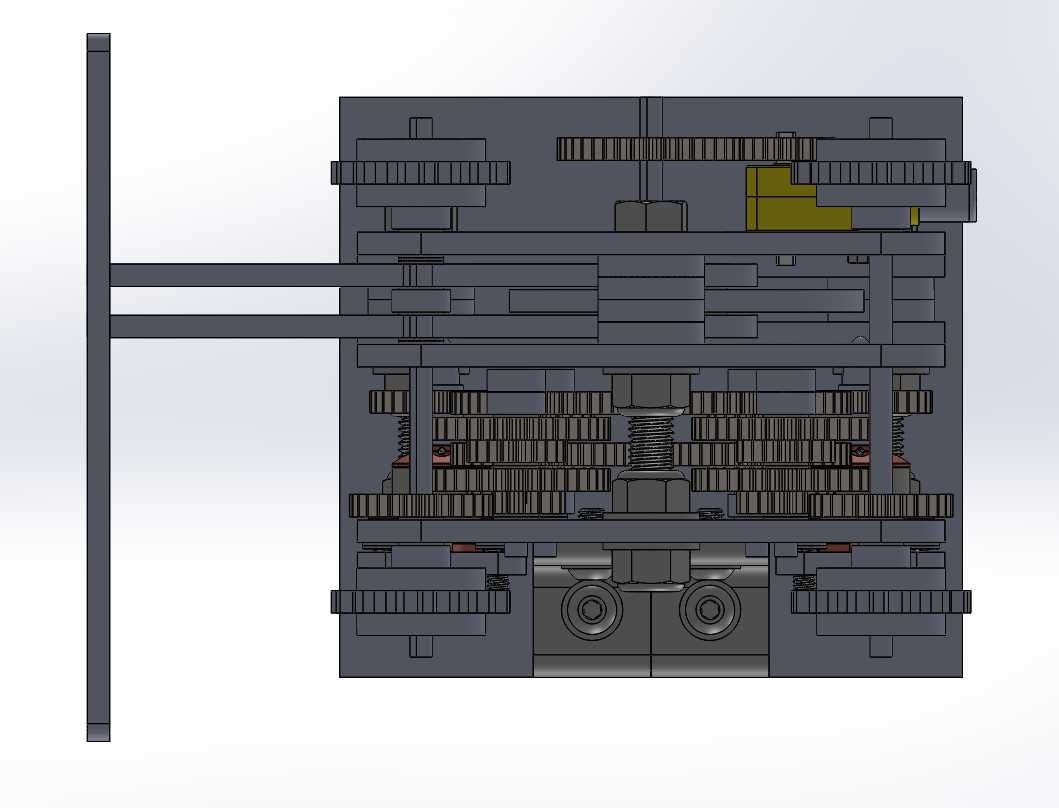

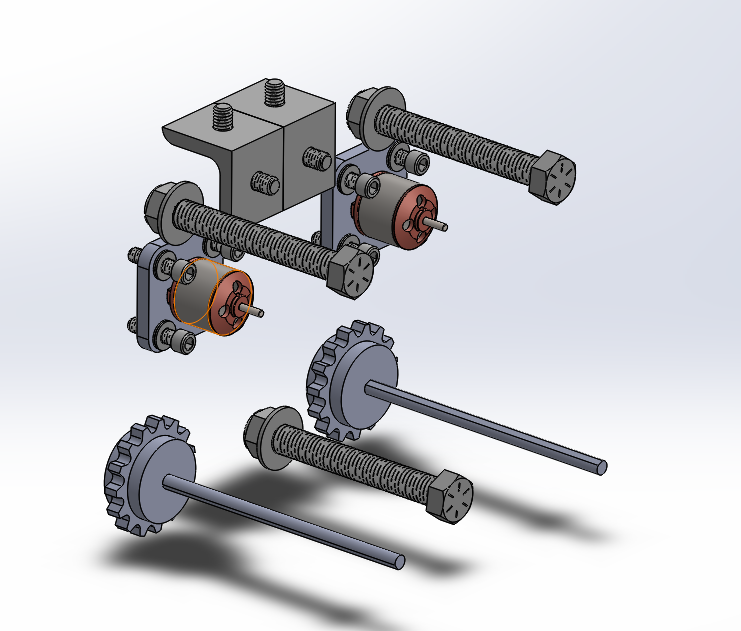

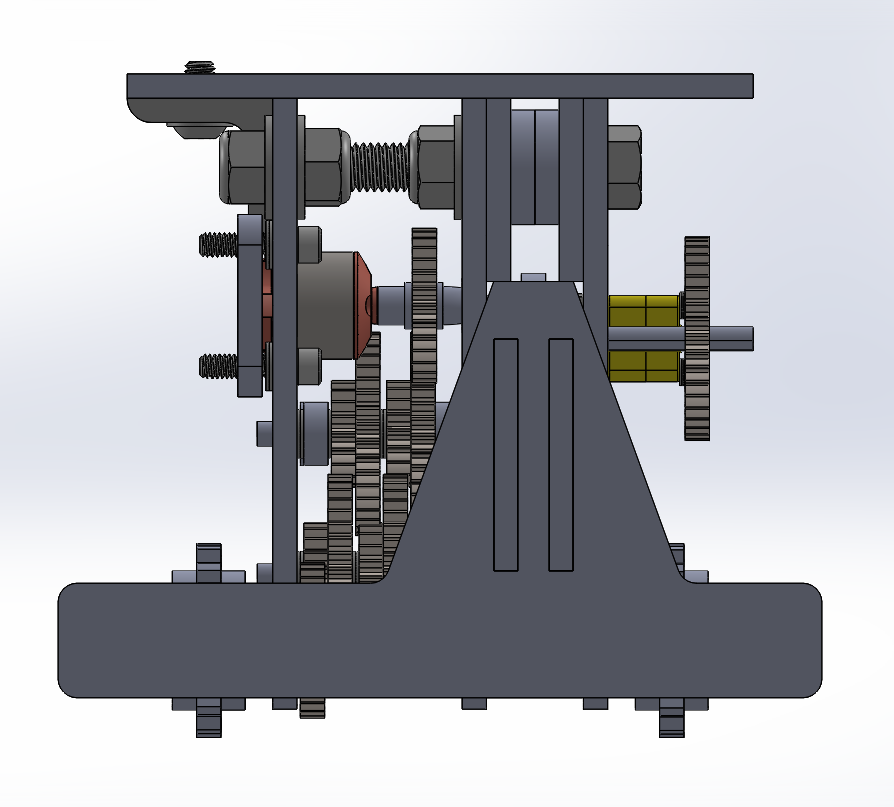

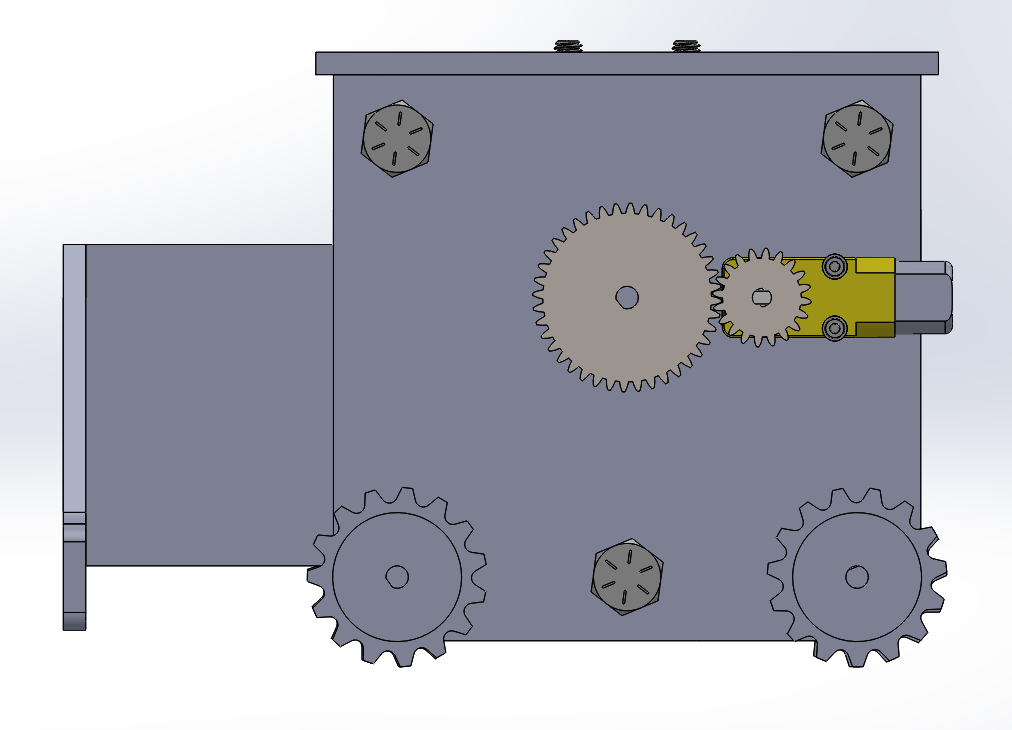

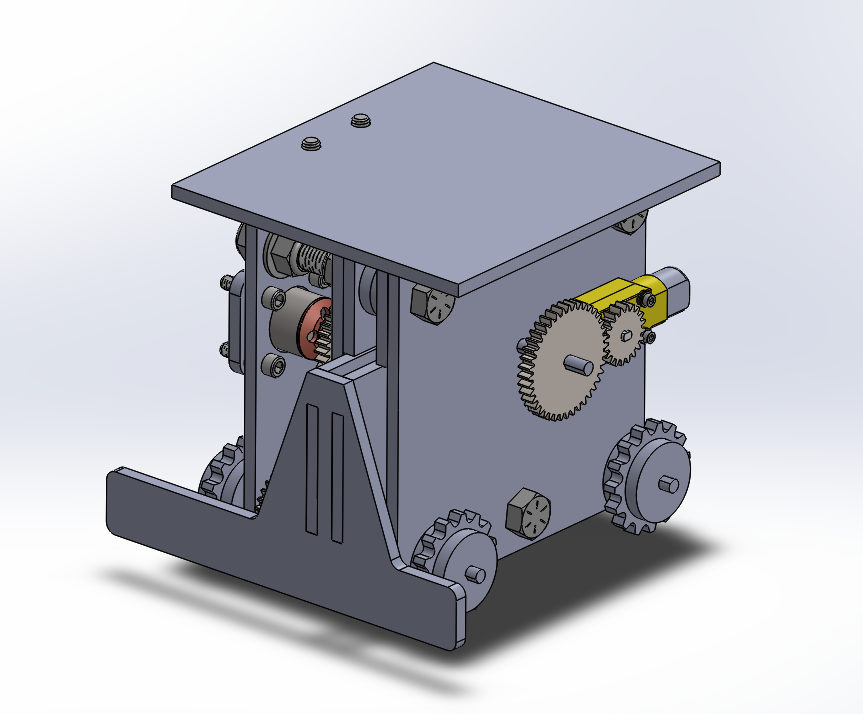

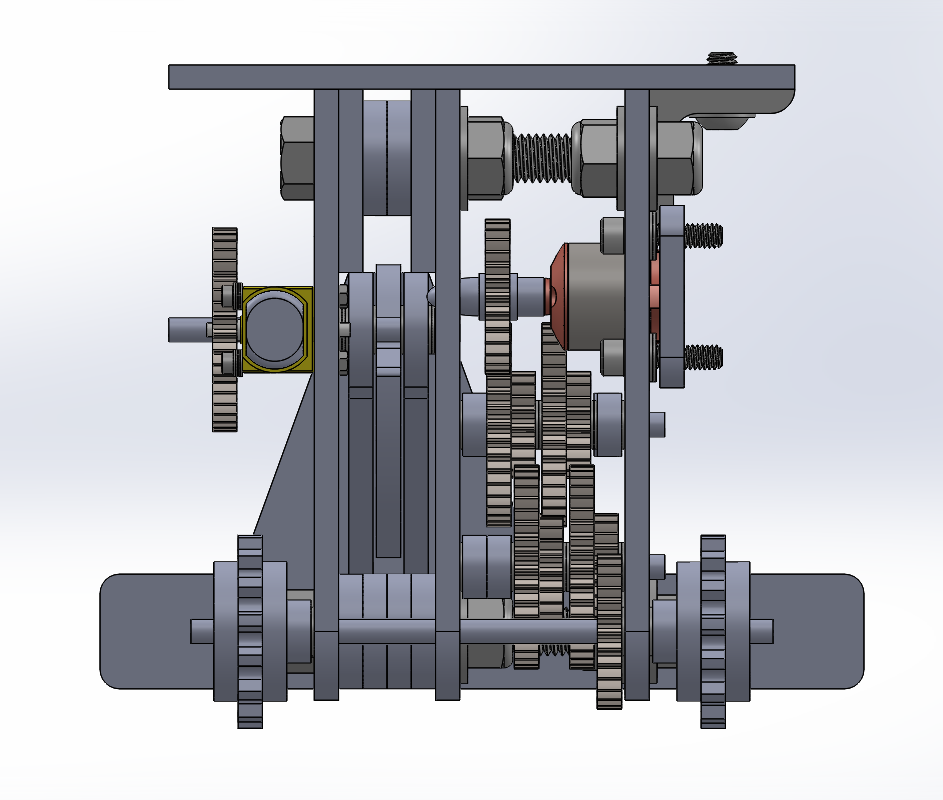

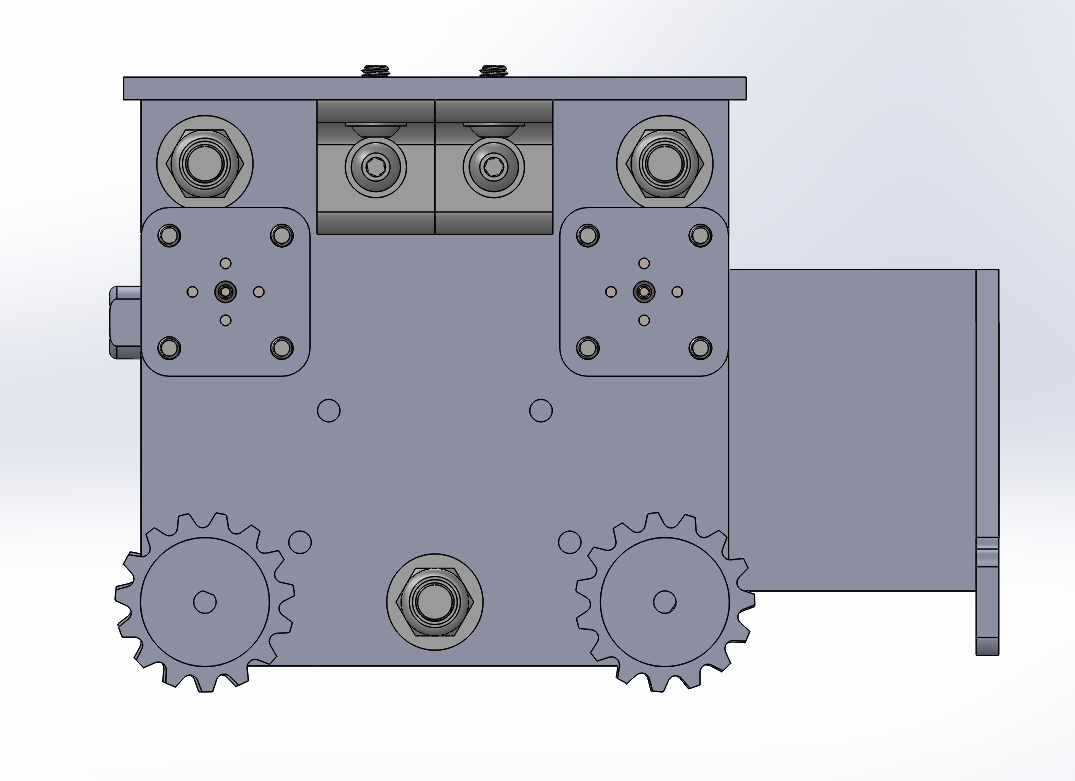

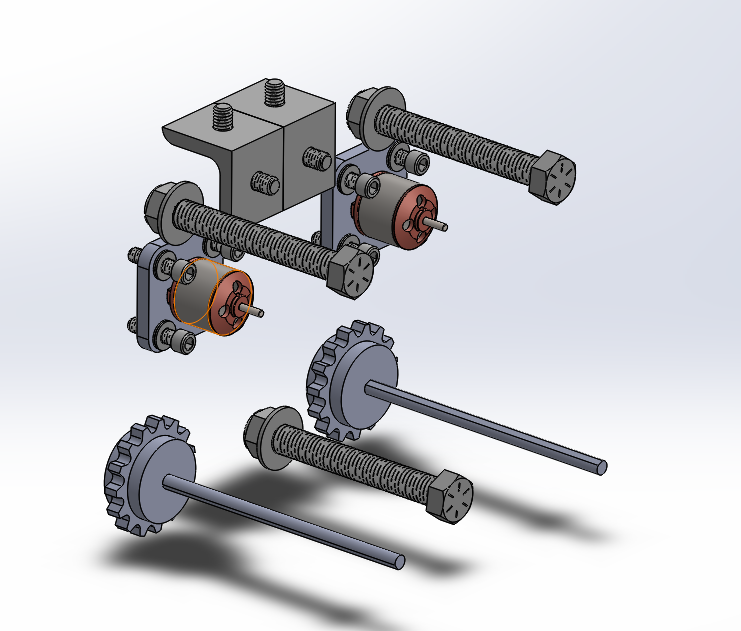

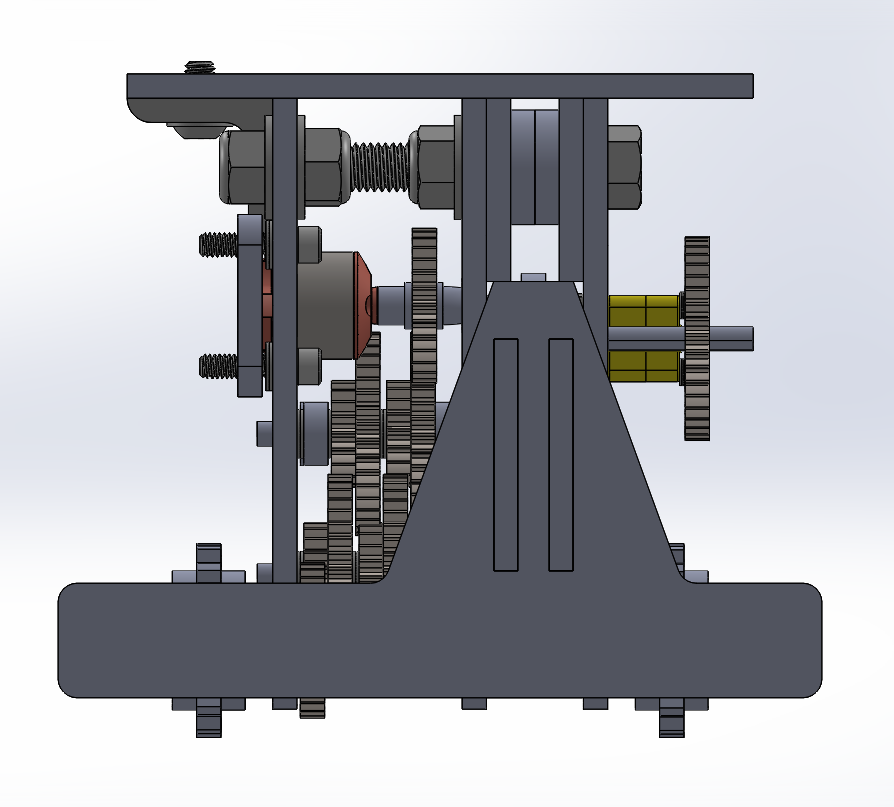

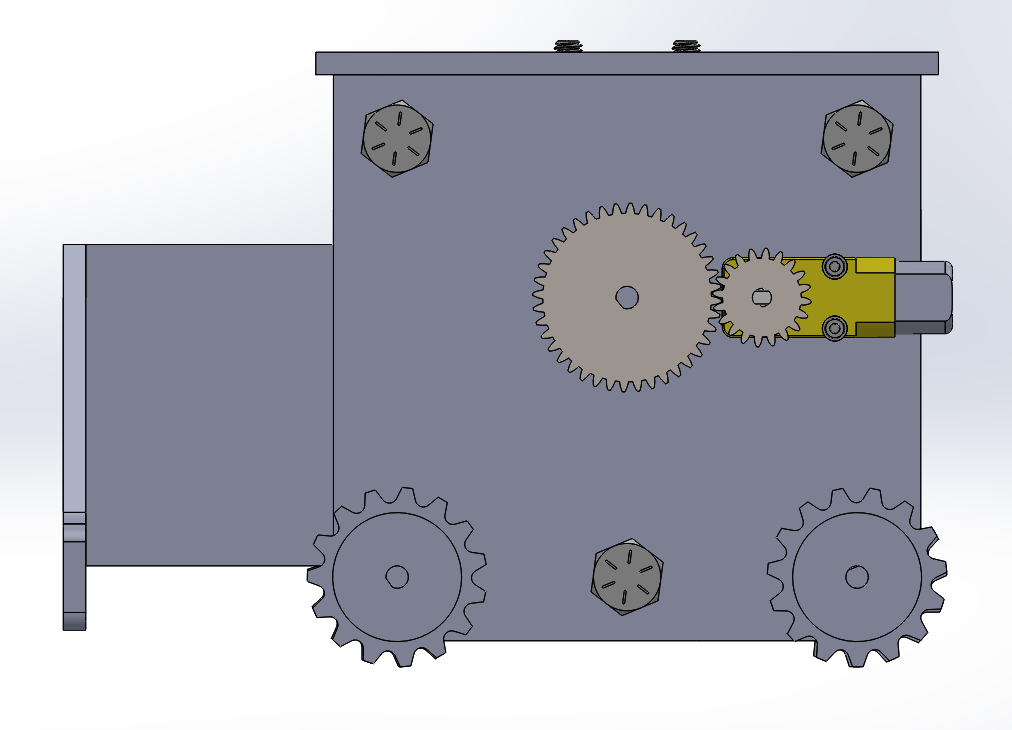

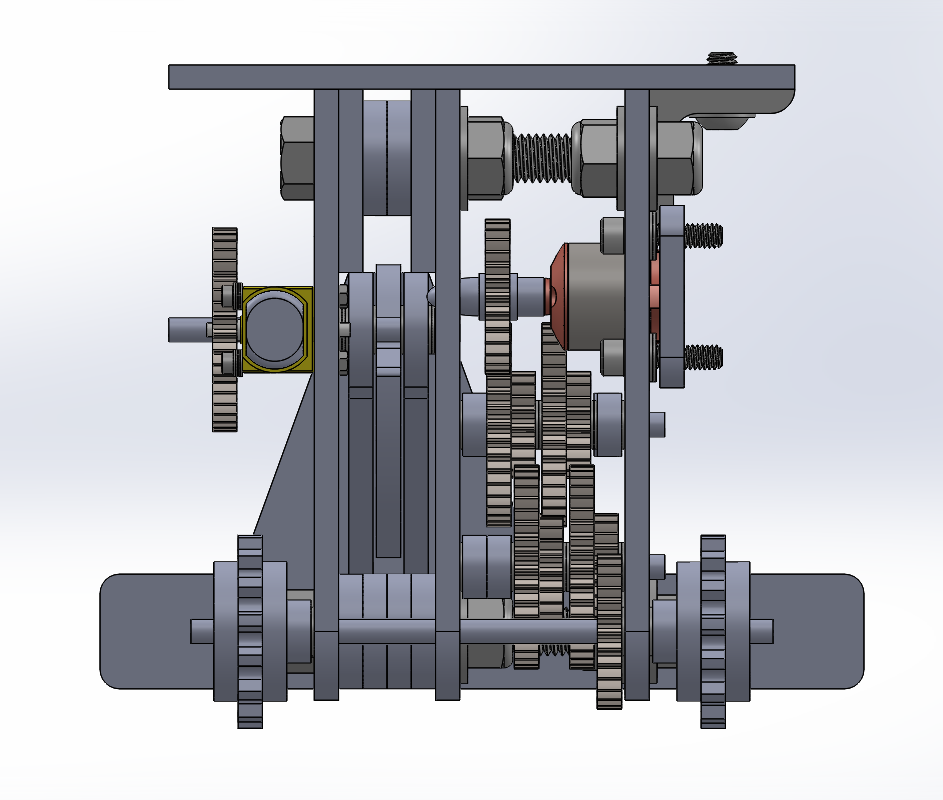

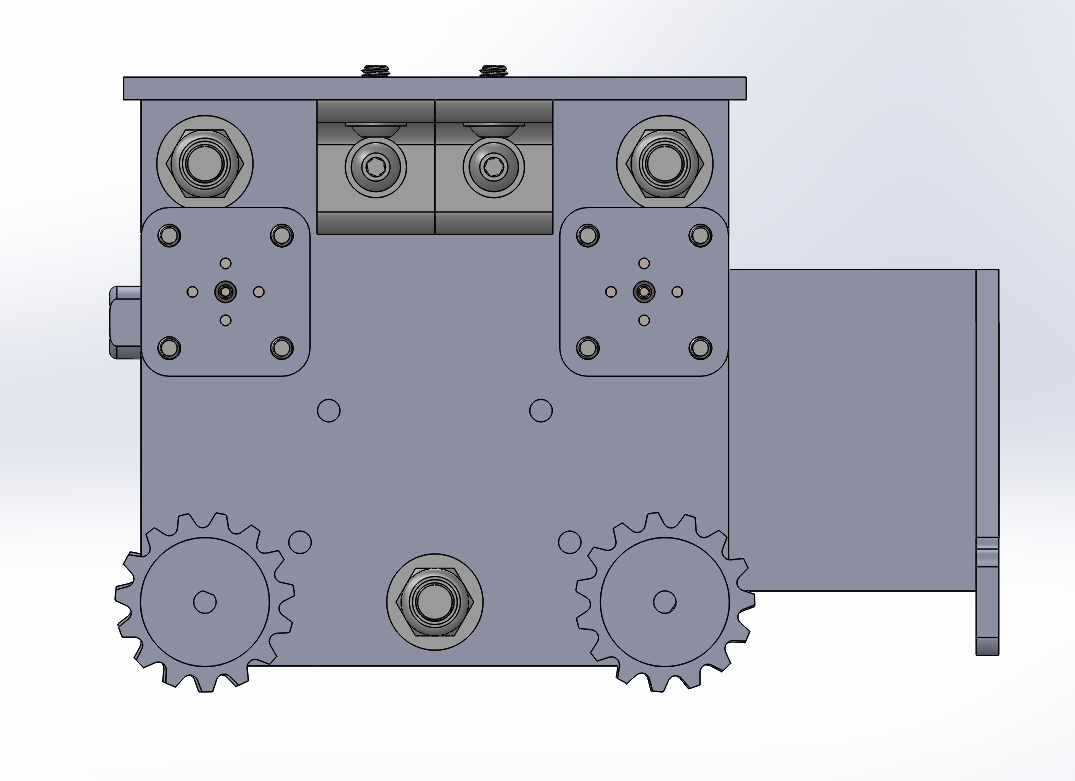

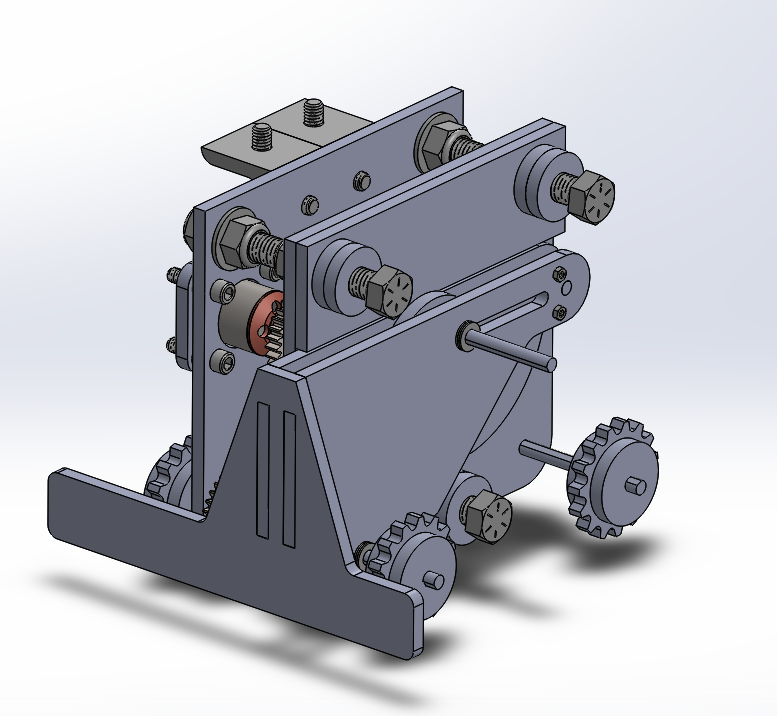

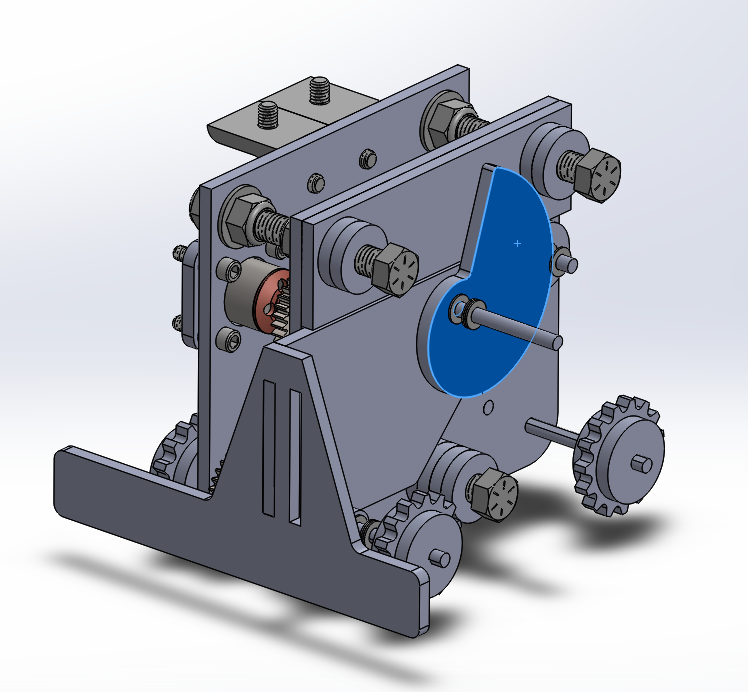

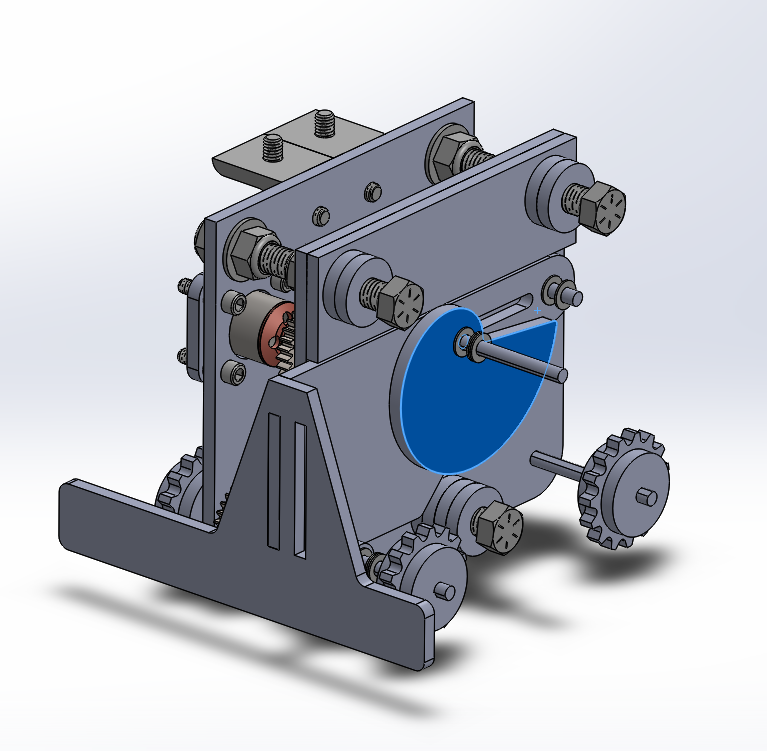

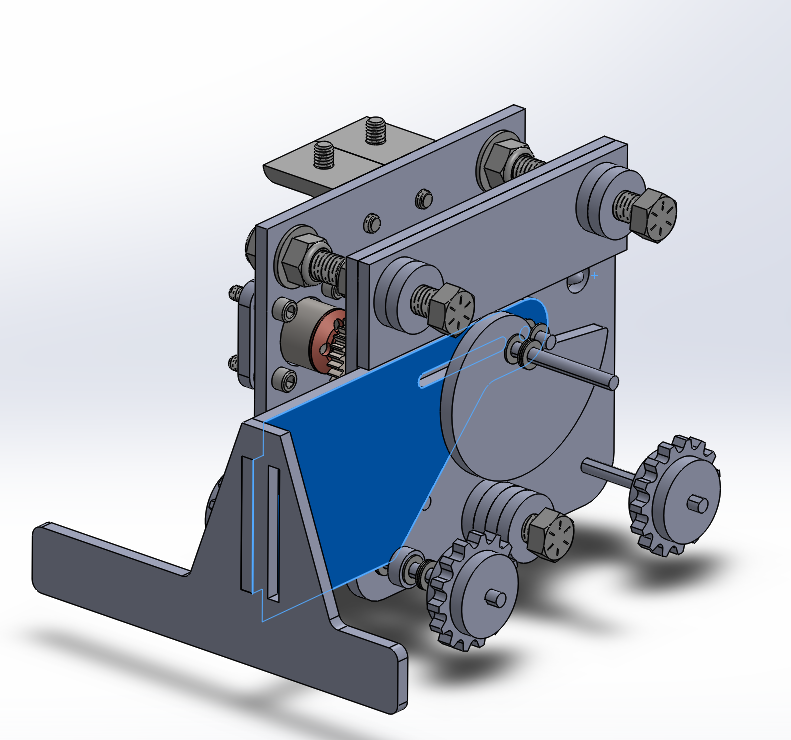

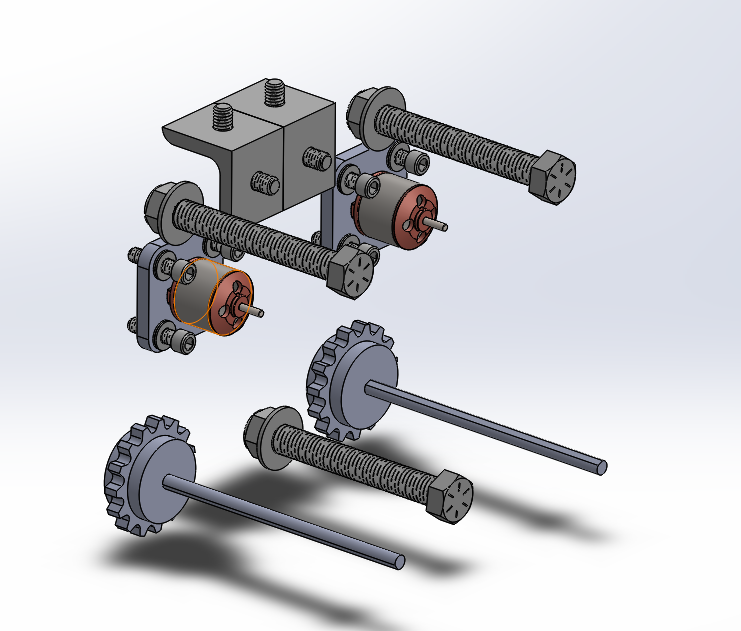

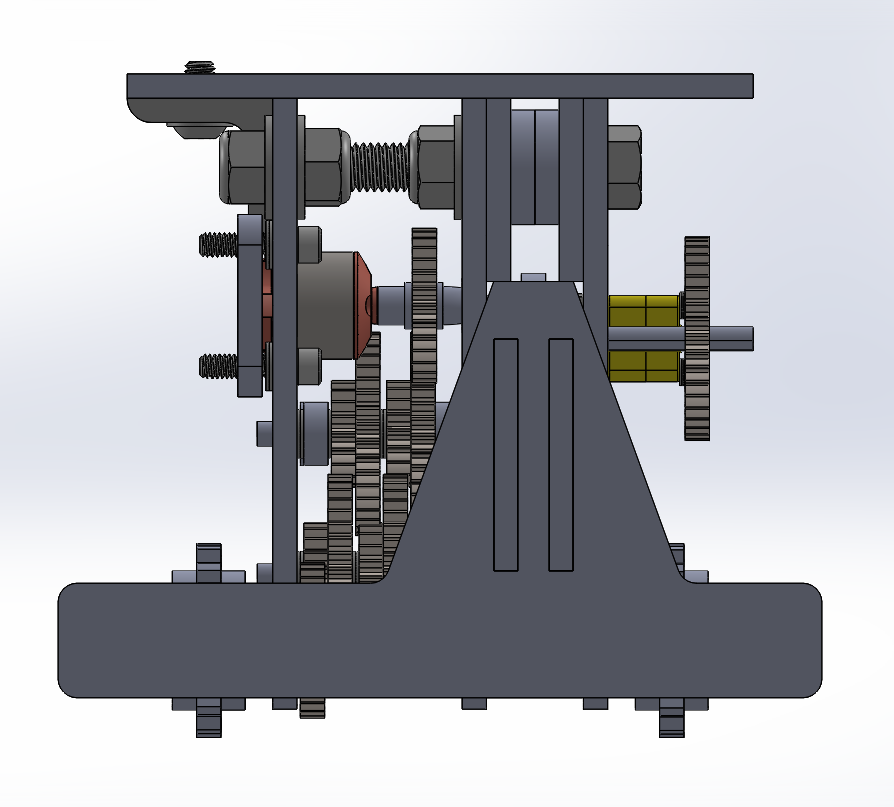

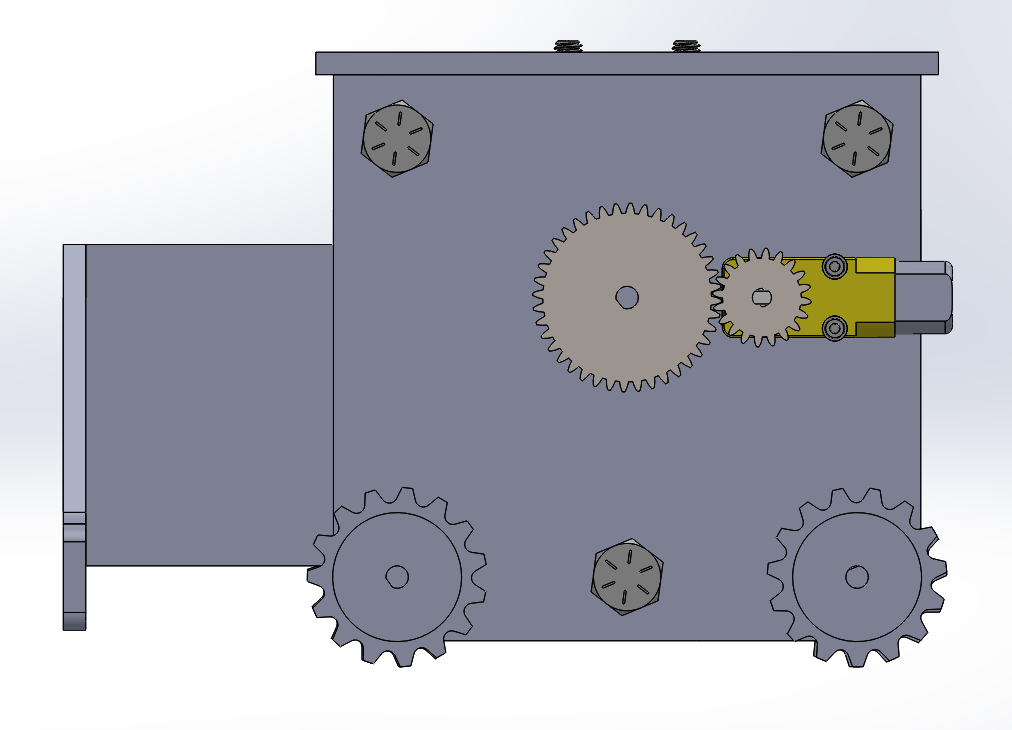

The striker was built with considerations for several mistakes that cropped up while building the goalie robot. While more complicated than the goalie's drive train, the striker used a five-stage gear reduction. This allowed it to fit entirely inside the body, while also providing much more precise control over the speeds available to the robot. The striker also has a quite simple shooting mechanism. A spring loaded pusher plate is stretched back via an archimedes spiral. A limit switch detects when the plate is fully retracted, and then the spiral is rotated just a few more degrees to release the pusher plate. To shoot again, the spiral just needs to continue rotating in the same direction.

Simple clip of the goalie robot driving (via remote control) while powered by a bench power supply

Demonstration of the striker shooting mechanism. Uses an archimedes spiral to wind up the shooter

Demonstration of the striker robot driving (via remote control) while powered by a bench power supply